Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

1,103 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by kbrandsma

-

-

I also have a January 1997 that has never leaked from the rear main seal. It seems to be a hit or miss. Some newer cars leak and replacement motors also leak. I think there is something wrong with the M96 design. One day your crank is concentric to the seal and months later after the replacement seal has been installed and it leaks, it is not. Something is moving and until PCNA or PAG lets a mechanic take a motor apart rather ship it back on a pallet....

Peter split the cases on a Boxster and I will try to get his pictures. The new seal installer tool sets the seal farther into the crankcase housing vs. the old tool that set it flush. Time will tell if that is the fix. When I asked Peter why some replacement motors were also leaking he gave a reason, you do not know when the replacement motor was put together. The new seal started production in Feb 2000 but the new tools came out around March 2003.

To answer your question. If it has not leaked for 6 years then you are ok since it would have shown up by now. Any seal will eventually fail from normal wear however.

Peter with his new toys.

Tool Pants,

The screws on the tool look like they can be used to adjust the depth. How does that work? The inside looks like they are rounded off. Does the tool turn and ensure the RMS is positioned equally all-around?

Has anyone successfully created their own tool or found a place to purchase? Good thread, thanks for doing it.

K.Brandsma

'98 Porsche

Everett, WA

-

I'm replacing my oil filler tube and was wondering about connection in the trunk? Or is the connection that leads to the trunk at the engine side of the firewall?

Thanks!

K. Brandsma

98 Boxster

-

I got a 4inch PVC connector and endcap for a couple of bucks. I'll smoot it a little and I can even drill holes in it to use the flywheel bolts to slowly and evenly bring it down. Along with the sleeve that came with seal, it looks like it will work. I will report back if I ever get that triple square bolt loose.

How did the 4" PVC connector and end cap work? Any pictures?

Thanks!

K. Brandsma

'98 Porsche

-

Fresh oil have to be in the engine not upon the engine certainly not at this area, so there must by a leak somewhere.

In case of leaking crankshaft seal the entire area is besmear with oil, not only one side.

This is my experience.

Could a loose bellows clamp have caused it?

-

Crankshaft seal - small amount of oil visible

Intermediate shaft seal - small amount of oil visible

Engine housing, flywheel area complete - very small amount of oil visible

Cyl. bank 2 - AOS area - bellows looks renewed

cyl. bloc - cyl. head and black crossbeam looks more oily than the rest

Cyl. bank 1 - OK

My opinion is, the major oil leak looks elsewhere.

Thanks for your observations.

Oil on Cyl bank 2 appears to be fresh oil. Checked service records from previous owner. He had replaced the bellows 4K miles ago. Retightened bellows as the screw clamps had worked their way loose. I hope that was it.

Anyone else have thoughts on this matter.

-

Password is:

guest

-

Drill a 4mm hole in the seal just where the points are, take a long philips screw and screw in half way, take pliers and pull the seal out. If you do it this way you cant destroy the crankshaft or the crankcase. You need special tools to install the new design seal, the seal sits deeper than the old one. There are 7 bolts to change, 3 x intermediate shaft ( do it one by one after you have drained the engine oil ) one above the crankshaft, one below the crankshaft and two on the bottom of the crankcase ( the dirty ones ) all M6. The new bolts have torx heads and are treated with product.

You got also oil leaks in the AOS area i think.

Tell me more about what you see with the AOS. Link to more photos

http://s267.photobucket.com/albums/ii302/k...mview=slideshow

password:

guest

Thanks!

-

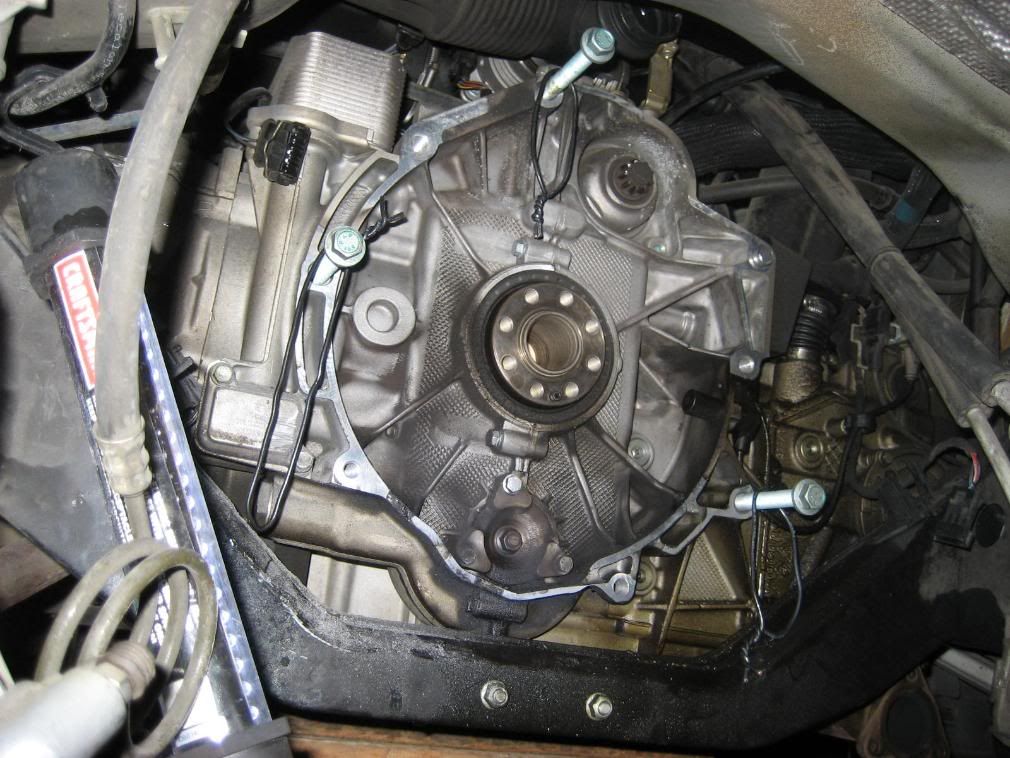

I am replacing my RMS and I stripped the last bolt which was the 10 mm triple square (bottom one on driver's side). What a bear. I drilled one side off, then ended up using my Dremmel and cut of the nut as close as possible then I grinded the rest of the nut off. RMS photos below:

Going to also replace the clutch, change tranny and engine oil and also O2 sensors while I am at it. Have 52K on the clock and figured I would take care of a few things while I have it up and taken apart.

What is the best way to remove the old RMS seal?

K. Brandsma

Everett, Washington

98 Boxster

-

Can you give additional information on how you bracketed the dash speakers with plastic melt? I am upgrading my front speakers. Thanks!

K. Brandsma

'98 Boxster

-

I recently ordered the brown speaker plug from Continental Imports. It should arrive in the next several days. I'm not sure of the grills but would be ineterested if you locate them.

Thanks!

K. Brandsma

Everett, WA

98 Boxster

Throttle Body & Loose Vacuum Hose

in 986 Series (Boxster, Boxster S)

Posted

I'm replacing my oil filler tube that leads from the trunk all the way to the engine block. The tube is actually two tubes and they connect right below the throttle body on passenger side. To get to the oil filler tube piece that mounts to the engine block, I had to remove the trottle body and the the round intake tube connected to the throttle body. I loosen the large four screw clamps and two bolts and disconnected the large intake tube from both manifolds and set them with the throttle body still attached aside.

While I was working on removing the screws that holds the oil filler tube to the block I noticed what appears to be a thin vacuum hose of some typye that was free and disconnected. The thin hose is a bit mangled and most likely will need to be replaced. I need help with two questions:

1. Anyone know the name of this tube?

and

2. Where does it connect to?

Thanks in advance.

K. Brandsma

98 Porsche