Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

506 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by bigbuzuki

-

-

Was there a specific time or event that made the temperature sit higher than normal?

What temperature did it display when you originally bought the car?

-

Run the test as per the attachment.

-

-

Carry out a fuel pressure test for piece of mind.

-

-

-

www.sonnenporscheoemparts.com

-

If you do have power at both terminals of fuse 56 and no power at the plug as measured from red/yellow and chassis, you must have a broken red/yellow wire from the fuse 56 to the plug.

-

The red yellow wire takes power from fuse 56 to the blower plug. Is there power at the plug now?

-

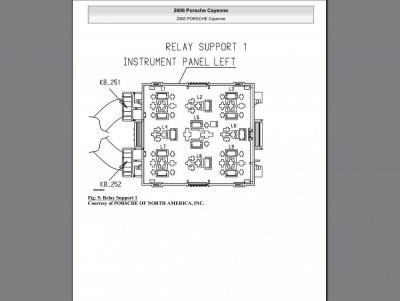

You should have power to fuse 56.

Fuse 56 is for the front blower.

Fuse 57 is for the rear blower if fitted.

-

The red/yellow wire at the blower should always have 12 volts on it.

The black wire on the blower goes to ground through the regulator.

Try measuring from the red/yellow wire to a chassis ground and see If you get any voltage.

You can also put a fused jumper wire from the black motor wire to a chassis ground and see if the motor works. This will bypass the regulator and give you a clue if it's regulator or motor issues.

-

-

-

-

That is correct.

Even when you change the mounts, the idle still dips as witnessed by your tachometer, but you just don't feel it anymore.

-

Change the engine mounts and the transmission mount whilst your there.

-

I never had the start issue you stated in your first post, just the idle dip when vehicle coming to a stop with resulting shudder through the chassis.

Along with the engine mounts, I had the transmission mount, all four O2 sensors, water pump, coolant thermostat, spark plugs replaced as well for preventative maintenence. Cleaned the Maf sensors and throttle body as well.

Car runs well and smooth, however the idle dip is still there, but not felt anymore.

-

I had my motor mounts replaced 1 month ago as I was getting vibrations through the chassis especially when the idle dipped briefly coming to a stop.

Am happy to report that although the idle dip is still observed on the tacho, no vibration can be felt through the chassis anymore.

It is smooth as silk.

Changing the mounts will mask the vibration, but not cure it.

Still worth doing for vibe free performance.

-

Agree 100% with Pkscheldt.

Changing the valve body and then doing regular fluid changes will return and maintain your transmission shifting smoothly.

My 2003 turbo had the same issues which have since disappeared after the valve body replacement. That was 30k miles ago.

Being an early model, I also had to have the transmission control unit replaced as part of a TSB requirement.

-

Sounds like you have 2 seperate defects.

-

It is a 95557215002, 95557215003, 95557215005, 95557215006, 95557215007 depending on your VIN.

-

You could try replacing the screen yourself.

Here is a link from someone who has done it.

http://www.renntech.org/forums/topic/30230-porsche-pcm-21-screen-replacement-tutorial-video-pics/

-

This is not a normal condition.Normally for some reason when I'm on longer highway drivers, the PSM light always comes on and stays on for a couple days then goes away....

As dan87951 states, you need to read the codes.

-

New water pump, still hot engine

in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Posted

Good to hear that it is fixed.

Strange though, as I have heard it said that this cooling system was supposed to be self bleeding.