Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

416 -

Joined

-

Days Won

1

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by tholyoak

-

-

Putting a 3.6 or 3.8 into an early 996 has the same issues as into an early Boxster. Look at my posts on that issue on the board. It really has nothing to do with egas, but the difficulties of integrating the 7.8 DME into the earlier car. That said I have done this with my car, the solution I am currently running is not OBDII compliant, and no system using an aftermarket controller to run the Variocam plus on the 3.6 or 3.8 will be, especially in California. I am currently working out the final details on the integration of the 7.8 into the earlier chassis, and I hopefully will have a solution to this soon. This would be OBDII compliant. Unfortunately my real job keeps getting in the way. Personally, if I were going to go to the expense of a new motor, I would buy the biggest one I could :) Putting the 3.8 in is no different in complexity than the 3.6. Todd

where have you bought the aftermarket controller to run the Variocam plus on

and what with vario lift what have you done

starts well enough but about 100 hp

I used a Perfect Power SMT6. I still have one with a new harness and the software etc that I would let go pretty cheap if you want to go this route. I also have maps and wiring for the setup. The lift is an all or none function while the valve timing is variable and controlled by a pulse width signal on the factory DME.

Regards,

Todd

-

I'm pretty sure I have a 996 throttle cable that I would part with for far less than that list price. I also have a couple of non-egas pedal assemblies from cars that were converted to egas to run 996/997 engines.

Todd

-

Paul,

It will functionally work but you need the proper connector to interface with it. Also the profile of the pedal assembly itself is different, so when installed there will be a large gap in front of the pedal between it and the carpet.

-Todd

-

1

1

-

-

It would have an 'S' stamped after the M96/03. So, no, not an X51

-Todd

-

The cam deviation is an adaptation value representing the deviation in the base timing from ideal. The actual cam angle can be used to determine if the variocam system is working or not. Actual cam angle will be ~0 or ~25 degrees depending on whether the variocam is activated or not. The adapted cam deviation should be +/- 6 degrees if the cams were installed properly.

-Todd

-

You are confusing two issues. If you monitor cam deviation while running the car, when the variocam kicks in, it will show up to 25 degrees from baseline. This is the variocam adavance, if you don't get this advance you have a problem with the variocam actuation. This is what your section is referring to. The maximal amount of cam advance available from baseliine. This is different than the amount of deviation that is acceptable without variocam actuation used for diagnosis of a static cam timing problem which is +/- 6 degrees at idle at operating temp with accessories turned off. The DME setpoints can be found in the factory diagnostic manual page 24-D8 to 24-D9.

-

25 degrees is the amount of cam advance available in the early variocam system. +/-6 degrees is the allowed deviation from ideal. This value is right from the factory service manual

-

The reason a piggy back or rpm switch coupled the 5.2.2 or 7.2 DME to control the variocam on a 3.6 or 3.8 motor is a bad idea has to do with drive-ability. The early variocam was all or none as stated above. This is fine with 25 degrees of advance and no variable valve lift with that system. The later system with the 7.8 dme uses a rotor and stator and is infinitely adjustable from 0-40 degrees via a pulse width modulation of the solenoid. This fine control depending on rpm and load is necessary for the greater valve timing change of 40 degrees. Couple this with variable valve lift and using an on or off type control results in poor drive-ability on the street where part throttle dominates and load and rpm fluctuate wildly. If the car is a track car operating at high load and throttle for most of the time, the piggyback approach can work fine.

The incorporation of the 7.8 DME into a 5.2.2 or 7.2 car is not difficulty once you figure out how to do it. The problem is it is not cost effective if you are paying someone else to do it, especially if you are paying them to learn how to do it at the same time. Simply, you will need a new 7.8 DME, a new ABS controller, new HVAC controller and new instrument cluster in addition to an egas pedal sensor setup if the car originally was cable operated. That is the easy part. Getting the wiring sorted out is the time consuming aspect if you have to figure it out from scratch.

Based upon the rising costs of the 3.4 motors from Porsche relative to the costs of the 3.6 and 3.8 engines, installing the later motors becomes more attractive. However, I would suggest the best solution for the 3.4 cars is to use LN engineering's parts, or if you aren't a DIY type, a rebuild from Jake Raby. This approach addresses the weak points of the M96 design and allows you to increase displacement without needing to update the electronics, all for about the cost of a Porsche 3.4 crate motor.

-Todd

-

Possible, yes. Reasonable, honestly, no. With a 996 the reasonable solution is to buy a newer car with the larger motor.

-Todd

-

Thanks for the correction Loren. I was looking at the wrong part number.

-Todd

-

The later cluster will work on all cars C2/C4/ convertible coupe, they are just encoded differently via the PST2/PIWIS. This is in contrast to the early cars where the C2 and C4 had a different cluster. The part you list is correct for a 2002-on C2/C4/C4S in GB with a tiptronic trans. If your Boxster has a tiptronic, this will work for you with recoding, regardless of the car it was originally installed in.

-Todd

-

If the built in error in the displayed speed bothers you, there are several simple electronic devices you can install for <$100 to calibrate the signal received by the cluster so that the actual speed displayed in the speedo matches the actual speed of the vehicle as displayed in the DME.

-Todd

-

I have a brand new one with 0 miles that I can provide fully programmed. Send me a message or email if you are interested.

-Todd

-

In the '80s, when the standardized 17 digit VIN was first implemented, the chassis were built before the destination of the car was known and a generic VIN was stamped on the chassis for its identification using filler codes (ZZZ) in positions 4-6. If the car didn't come to North America, after the car was completed, the actual VIN placed on the windshield post/door jam sticker would match that on the chassis and contain the ZZZ filler characters. On cars destined for North America the VIN had to meet US standards and thus the ZZZ codes were filled in on the windshield post number/door jam sticker(the actual VIN).

-Todd

-

M97 engines not the 9A1 direct injection motors. Logistics are the same as doing a M96 3.6 conversion.

-Todd

-

Yes, I've done two.

-Todd

-

Steve,

Sorry to hear about the troubles. The issue you have really has nothing to do with the conversion it has to do with the poor quality of the NHP fabrication. The resulting issue being that the NHP parts fit like crap. If you don't want to spend a lot of money, your best solution is to go to a custom exhaust place and get some mid pipes bent up that properly fit the NHP muffler inputs. The U-tubes provided with the NHP setup you purchased simply are not the correct size piping to fit properly into their own muffler. Many companies make proper fitting exhaust parts that fit just fine on the Boxster chassis (supersprint, fabspeed etc). Unfortunately, many of the cheaper solutions fit like crap. Fitting the factory Cayman setup is not too hard but will require some fabrication mounting the muffler, as well as mods to the shock body and the plastic fender well liners.

-Todd

-

1

1

-

-

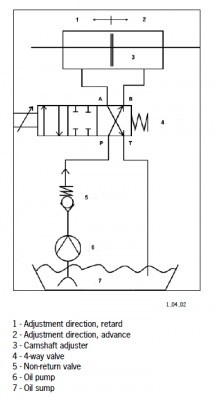

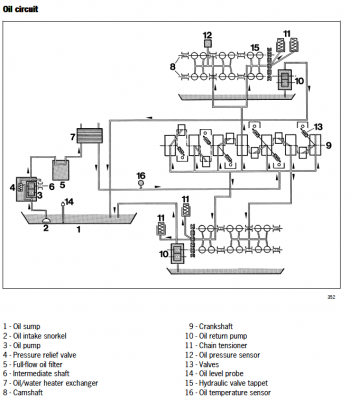

Here are some diagrams of the oil circuit and the oil supply from the 4 way solenoid valve to the vane adjuster on the camshaft. Essentially the solenoid valve is a 4-way proportioning valve that connects one of the control lines ( A or B ) with pressurized oil from the feed line P and open up the other line to allow oil to flow to the crankcase. If the A line is pressurized the vane adjuster is turned to advance, if B is pressurized it retards. In the center position both lines are closed and the cam maintains its current position. Intermediate positions between A fully connected or B fully connected to P are also available allowing for slower but finer changes in cam timing. Therfore the valve controls both the speed and amount of cam timing changes in contrast to the on or off cam timing on the earlier cars. The non-return nature of the valve allows for proper cam timing changes under low oil pressure conditions such as low engine speed and/or high temperatures.

Hopefully, these diagrams don't violate copyright issues on the site as they are taken from Porsche technical publications. If they do I apologize to Loren and feel free to remove them.

-Todd

-

According to the engine number you provide, the engine type is an M96/23. This is a 2003, 2.7L Boxster motor. Sounds like someone pulled a fast one on you. The fact that this motor runs off of a 7.8DME is the least of your worries.

-Todd

-

1

1

-

-

If the pressure regulator has failed and isn't allowing return it will result in too high of pressure in the rail. If this is true, the high pressure in the rail can result in the injectors drawing excessive current and the DME will not fire any of the injectors. To test for this, disconnect one injector and try and start the car. Disconnecting one injector will reduce the current enough for the DME to fire the injectors. The car wil run rough but it will run. If this happens then your FPR is bad. If it doesn't help you can look elsewhere.

This procedure worked on the older Porsches with DME injection so I think it should work with the newer system as well.

-Todd

-

Go to actual values, hit F5 (filter) this will bring up a number of predefined actual value subsets including all possible actual value data. If you select engine, the camshaft deviations will be there. You can also create your own filter subsets containing the values you want to look at together as a group. The deviation values are the same for the later motors as the early motors, the total advance is simply greater

and not actuated in an all or none fashion but via a pulse width modulation of the solenoids making them infinitely adjustable. Seeing you used the factory tools and the fact that the tabs for the hall sensors on the cams are easily tweaked they are likely the source of your deviation values being high rather than the actual cams being out of time.

-Todd

-

1

1

-

-

I'm curious why you say the pst doesn't allow viewing it. You certainly can. See this post for an explanation of cam deviation.

-

I'm pretty sure I have several of these off of new 3.6 and 3.8 crate motors that were put in boxster chassis. If your interested in one or a set I'll let them go for 1/2 of list price.

-Todd

-

Your procedure as written is wrong,

The old codes are the codes currently programmed into the dme, the new codes are the codes you want the dme to have after programming.

-Todd

3.4L to 3.6L Conversion NIGHTMARE

in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Posted

In general, if you want a factory-type situation and maintain all functions and diagnostics etc, you need to replace the DME with the 7.8 DME. In my experience, no other solution will make you happy for a street car. To integrate the 7.8 DME, you need to change out the ABS controller, the instrument cluster, the HVAC controller and the DME. Depending on what ABS system your car currently has, you may need to change out the ABS wheel sensors as well. The integration of all components will require rewiring for all controllers as well as likely new connectors for the cluster and likely the ABS controller (again, this depends on the ABS/TC system you have). The CAN bus then needs to be run between the new controllers. The instrument cluster acts as the CAN bus hub so a twisted pair of wires needs to be run from the DME to the cluster, cluster to ABS and cluster to HVAC. I think a 2000 already has egas, so you don't need to worry about swapping the pedal assembly and running the wires from the pedal to the DME.

The hardest part, once you figure out what needs to be done, is staring at the corresponding wiring diagrams for your current car and a car that came with the 7.8DME and figuring out how/where to swap all of the wires.

Good luck,

Todd