Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Johnny-5

-

Posts

215 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by Johnny-5

-

-

On 5/18/2021 at 10:47 AM, JFP in PA said:

Porsche part # 000-043-305-49 is a manual transmission lubricant, and should not be used in the Tiptronic.

Tip fluid should be part #000-043-304-01

Thanks JFP!

-

I have a few dealers locally who are confusing the hell out of me. Some of them are stating that the part# 00004330549 works for both the 996 Tips and 986 Manual. Others are stating no they are different but could not provide me part#'s for the 996. Most of them all validated the part# above is for the 986 just seems to be confusion on the 996.

Appreciate the feedback

-

On 4/20/2021 at 10:29 AM, JFP in PA said:

I like to use billet aluminum replacement tubes from a company called Rauch and Spiegel:

The primary mode of the OEM tube failures happen because the molded plastic tubes are not actually round, have molding flash lines, and that they harden and crack over time. These billet tubes suffer from none of those short comings, use the factory O-rings, and simply just work.

As for plug anti seize, I prefer the Nickle based high temp anti seize on plugs; never had any issues with it. Correct torque spec is 22 ft. lbs.

Interesting tubes. Thank you for the recommendation and additional info. Will look into those tubes and will get the nickel based high temp anti-seize you are suggesting. I believe Permatex sales them which I have but don't believe i have the nickel based so will pick some up.

-

7 minutes ago, JFP in PA said:

Use the Loctite 5900 sparingly; excess sealant is usually found clogging the oil pickup. Cover bolts torqued to 7.5 ft. lbs. ( I would use an inch pound wrench set to 90 inch pounds, which is much more accurate at low torque values).

Ok will pick some of that up. Also curious when I put this back on and torque to spec Im assuming Ill be doing a Criss-Cross style tightening sequence right

-

Oh and by the way off topic question. I did notice some oil leak on the valve covers and is probably due to the spark plug tubes. Does it mater what brand? I found a few places who sale a brand called German. Pelican sales it and its like $5 with seals. Or is it better to stay OEM? Im also going to try out the Denso Iridium's for the plug. So Im going to use dielectric grease for the plugs, a little bit of oil for the seals, and for the plugs i know alot of stating to use sparingly some anti seize and was curious if anyones used Liqui Moly LM508 Anti-Seize or if I should just stay with the permatex silver type? And is the torque spec 18.5 or 22? Im seeing alot of mixed specs. Also any recommendations on good pads? I was thinking of just going with regular pagid pads?

Thanks again

-

On 4/18/2021 at 7:16 PM, JFP in PA said:

The sump cover is a flat plate with an attached baffle system used to reduce oil slosh. What you would be looking for is an accumulation of material similar to what was on the drain plug, or any other accumulated material that should not be in there. When you get it down, take pictures to post here so we can see what you find.. The sump cover is sealed to the engine with a sealant material, there is no gasket. Reinstallation requires thoroughly cleaning the mating surfaces, applying a thin bead of sealant to the cover, pushing it into place and properly torqueing the bolts. You cannot see the IMS bearing from below as it sits below the crankshaft, which is housed in its own carrier assembly.

Thanks for the info. I may try to get to this by this weekend and will post pictures. Couple of questions...

What type of sealant would you recommend for the plate when reinstalling?

Whats the torque spec?

On 4/18/2021 at 7:49 PM, Silver_TT said:Yes, I recently spent time looking at Blackstone vs SpeeDiagnostix and think the later is the stronger product. Blackstone makes you pay extra to see the TBN (arguably the most important thing you want to see in the analysis) and even then doesn't show the breakdown just gives you a single number. To me this is akin to going to the doctor to get a blood test for a critical illness only to have the doctor tell you that if you want them to properly test your blood then you need to pay an extra fee -- seems like they should be doing it in the first place if they are a good doctor. Anyway, I am actually expecting my oil analysis from SpeeDiagnostix back this week but you can go to their website and see what the report looks like.

I think pulling the sump will tell you what you need to know on its own.... but the oil analysis is still something to consider regardless (cheap insurance).

Thank you will look into speediagnostix. The way you explained it was great makes total sense!

-

14 hours ago, Silver_TT said:

This was the first time you put in the magnetic plug, is that right? First time is probably the worst time. Not sure about the one you are using but some of them like the LN product are very strong magnets. I agree with JFP maybe it's a little more than you would like to see but not grossly so IMHO. An oil analysis from SpeeDiagnostix is probably a good investment of $60.

The IMS went out on your Boxster and cracked the engine block?

This is the first time installing an LN magnetic plug. I was thinking of using blackstone I believe is the company. Is Speediagnostix better?

10 hours ago, JFP in PA said:Ferrous debris can come from multiple sources such as the crankshaft, valve springs, cams, and of course the IMS bearing. Problem is that having ferrous debris running around in the oil is much like having sand in there, it will abrade all the bearing surfaces.

The correct move at this juncture is to drop the sump cover; if there is even more inside there, your options are limited, as is the life expectancy of the engine. You cannot simple try to flush this stuff out, there are far too many places it can collect inside the engine, and it will start to move around over time, slowly tearing things up. The oil passages in these engines are infamous for being difficult to clean out, even once the engine is disassembled, requiring the use of an ultra sonic engine block bath system to shake it loose.

A long time ago, LN set a protocol for inspection prior to doing an IMS retrofit in order to prevent people from throwing good money at a bad situation that is most likely to kill a brand new and expensive IMS bearing; that protocol starts with looking for the presence of metal in the oil, and particularly in the sump before starting the retrofit. What you saw on the drain plug would be enough to require pulling the sump cover for inspection. More metal there would disqualify the engine for an update.

Removing the sump doesn't appear to be that hard just afraid of it leaking if I don't seal it right? Whats the proper way to reinstall it? Probably would be a good idea anyways to clean it up.

10 hours ago, Silver_TT said:Curious your thoughts compared to this thread where Jake says "Turn off the hypersensitivity. You'll always find this on the plug". There's more debris on the plug of the poster in this thread but I would point out that not shockingly so.

Metal particles on magnetic drain plug - Rennlist - Porsche Discussion Forums

RENNLIST.COM

Metal particles on magnetic drain plug - Rennlist - Porsche Discussion Forums

RENNLIST.COM

996 Forum - Metal particles on magnetic drain plug - Hi everyone, I did my oil change today and found some metal particles on the drain plug. Nothing in the filter, it was clean with no particles of any sort. I had my IMS changed 3000kms ago. Should I stop using the engine or this...Thats sort of what Im going through as well. I didn't find anything in the filter just on the drain plug itself. I haven't changed the IMS yet and wild was recycled already unfortunately.

10 hours ago, JFP in PA said:There will always be some ferrous material on a magnetic drain plug, or inside the filter housing when using a Filter Mag; the question is how much is too much. It is not uncommon for people to panic the first time they change oil after installing a magnetic plug, or in particular the Filter Mag, as the first change will show what has been collecting for the entire life span of the engine before the magnetic field was introduced. Because the drain plug see way less of the volume of oil that the Filter Mag does, large amounts there are very concerning, which is why I would drop the sump cover next to see what we are dealing with. Pulling the sump cover is not difficult or expensive, but it will answer the question about what to do next with certainty.

JFP when its removed what am I looking for? Is there a way to check the bearing while Im at it? Or is it just to clean it and reseal?

10 hours ago, Silver_TT said:Well said. Yes I was also thinking it costs nothing to drop the sump as you are saying so I definitely agree.

9 hours ago, judgejon said:Agreed here as well. If I still owned my C4$ that’s just what I would do.

Thank you both for your opinion as well.

-

2 hours ago, judgejon said:

Yes, and no telling what else is screwed up. Sorry that you’re in this predicament. No good answers.

Im trying to be optimistic here!

1 hour ago, Silver_TT said:JFP saw these cars every day as a shop owner so I would never question experience......but is that really very much accumulation? It doesn't seem that bad to me from the picture. If that were my car I would do an oil analysis though. Second I would take a picture, like you did, each oil change and monitor it over time. If you notice an uptick from one oil change to the next that would be cause for alarm.

I know JFP is very well known here and knows what he's doing. But hell at this point I think everyone on here knows more then me on these cars and is why I keep coming back for more knowledge on these cars! Im just hoping its just the IMS bearing on its way out as Im sure this is the original bearing. Im tempted to get that changed and see where it goes from there. I know that the bearings can have some where and will have some metal in there as well. Unfortunately I recycled the oil and had oil in there previously so thats not an option. I may just drive it a bit and do another drain on a clean pan and send it out. Hopefully that will give me more info if it is the IMS

53 minutes ago, judgejon said:Doesn’t that approach risk catastrophic engine failure? Would it be better to just replace engine?

I'd rather not replace or rebuild it if I don't have too and trying to keep from having a catastrophic failure if it is the IMS. Im still trying to figure out the boxster which had a IMS bearing go out and crack the block on which direction to go with that at the moment so the timing really sucks!

-

2 hours ago, JFP in PA said:

Fine iron filings typically look black in oil. If you still have any, try magnet on it.

Ok so I ended up taking the oil in for recycling but I did have the paper towel from yesterday and put a magnetic to it and sure it enough its magnetic. So now my question is Im assuming its the IMS bearing am I correct?

-

13 minutes ago, JFP in PA said:

That has nothing to do with the amount of metal filings on the plug, accumulated metal (particularly ferrous metal) is a bad sign.

So that’s metal on that? I cleaned it and didn’t see anything shiny on the white paper towel?

-

3 hours ago, JFP in PA said:

That looks like a little more than I would expect to see. If the car was in my shop, I would drop the sump cover and have a good look; if you find a lot more of the same thing, the engine is definitely beyond the point of even thinking about an IMS retrofit. That kind of grit running around in the oil will kill a replacement IMS bearing that is open to allow oil into it.

Cars been sitting for about a year and I haven't done an oil change for a while on it as it wasn't really driven. So I figured that was the case?

-

3 hours ago, judgejon said:

If you are concerned re IMS issue, get the LN solution installed and forget about it. Good luck..,

Thats the plan just trying to save up for it. Had a rough last year so trying to get back on my feet. Just trying to keep it running in the meantime. Heres a picture of the plug.

-

If I was having issues with metal I would be seeing shiny things at the end right? The plug was black That shouldn’t be an issue would it?

ill try to upload a picture of the plug later today

-

On 12/23/2020 at 10:45 AM, JFP in PA said:

Simple: Replace them all.

Works for me! Thank you

On 12/23/2020 at 11:10 AM, Carlvs said:Unfortunately JFP in PA is correct, at the minimum cylinder head, rod and main bearing bolts. I would also replace timing chains the timing chain rails and possibly the tensioner depending on mileage. Good time to deal with the IMS bearing and water pump. @ $299.00 Raby’s manual will save you many hours of grief and possibly thousand of dollars and lots of heart a he.

I was hoping to reuse some of them but guess it makes sense if Im going to tear this down and rebuild it. Chains rails, etc everything inside Ill replace for sure. IMS is a must and figured I do the pumps, thermostat, etc....

On 12/23/2020 at 11:15 AM, Carlvs said:A link to my parts used and prices for the 99 996 engine rebuild. Still running after 5,000 miles. Fingers crossed every time I go out 🙂

https://www.ez-bizwebs.com/3.4/images/Spreadsheet/Porsche996_EngineRebuild2.pdf

Thank you for that break down list. That should help me order what I need and is pretty good way to do a total break down on costs at the end! Might even look at the same places you purchased your stuff at as well. 🙂

-

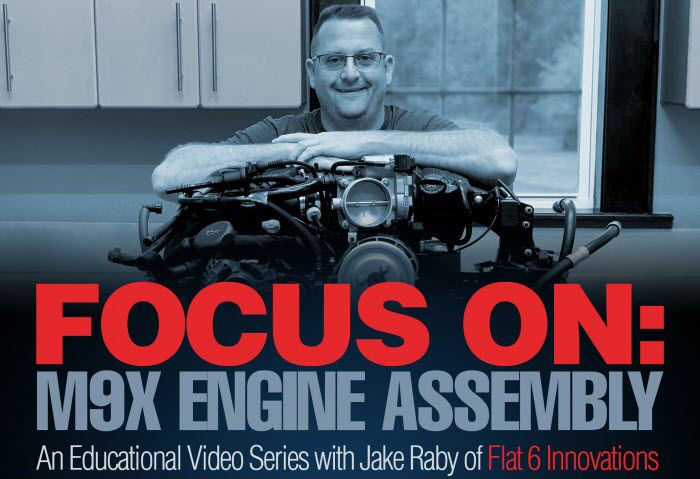

On 12/18/2020 at 8:40 AM, Loren said:

I think you mean Jake Raby of LN Engineering. The DVD is on sale right now for $299.

Jake Raby's Porsche M96/M97 Engine Rebuild DVD

LNENGINEERING.COM

Jake Raby's Porsche M96/M97 Engine Rebuild DVD

LNENGINEERING.COM

Rennvision’s Focus on: M9X Engine Assembly by Jake Raby goes step by step on how to correctly rebuild a Porsche M96 or M97 engine in this 5 disc DVD set.Thank you for the info. Will have to look into that.

On 12/18/2020 at 9:22 AM, JFP in PA said:Jake's company is Flat Six Innovations, and has done all of the development work for M96/97 component's for LN Engineering , which is owned by Charles Navarro. Jake does complete engine rebuilds, from mild to wild, and only sells educational materials such as the DVD mentioned, as well as the only existing complete engine torque spec manuals in print, but Flat Six no longer sells any hardware, only complete engines. LN manufactures and sells all the hardware (Nickies cylinder liners, IMS retrofits, piston sets, etc.), and also sells Jakes torque manuals which are excellent reference sources. LN will also provide machine shop services such as installing all new Nickies cylinder liners.

I ordered the torque manual so Im sure that will give me a break down on specs but was just looking for additional info on what to experience when I get the motor torn down. Thank you for the info.

On 12/18/2020 at 2:04 AM, Carlvs said:About a year ago I rebuilt the engine in my 996 and information was extremely difficult to come by. Lots of books will show you how to remove the cylinder heads but it stops there. I was able to piece things together by watching YouTube videos and a copy of the factory manual that I found on the Internet. Jake Ruby of Flat Six Innovations has a CD available that is supposed to be excellent.

Good luck.

Figured that was the case but had to ask! Thank you for the clarifications and experience.

Last question does anyone have a break down of what bolts needs to be replaced? Or can I get away with reusing the bolts? Example bearing cage bolts? Cylinder head bolts, valve cover, etc..... That would at least let me know which needs to be ordered and what I can still reuse.

Thank you again!

-

Does anyone have the Porsche Project 101 book? If so does it give any details on engine tear down? I heard the bentley book is pretty useless. If anyone knows a good manual to assist with tear downs would greatly be appreciated.

-

29 minutes ago, JFP in PA said:

You are in the correct forum.

Before putting an engine that has been used in class for years, I would be prone to pull it apart to make sure everything is there and no one has dropped a screw or nut into the internals. An engine that has been dormant that long may also have corrosion built up on the crank journals from sitting.

I was afraid that was the answer I was going to get. Dont think they dropped anything into the engine and all the bolts seem to be on and not seeing anything removing the valve covers or anything but you never know. I dont have the full knowledge on rebuilding from the bottom up and if Im going to be getting down into the journals at that point its better off just getting rebuilt from the ground up. Was trying to keep it minimal if possible but doesnt seem like that may be the case. Any other suggestions other then tearing it completely down?

And thank you for confirming this is the right spot to post JFP

-

I didnt realize I posted in the wrong place. Could someone help me move this to the correct forum. Sorry.

-

So I recently purchased a boxster with a blown motor most likely due to the IMS bearing and picked up a used 2.5L engine to throw in. I have no history on this engine other then its been sitting at a automotive class for years as a donation for them to learn more about the flat 6 engine. They no longer needed it and is why they sold it. So my question is what should I do before dropping this motor into the car? Ill probably do a leak down on the cylinders and scope it and see how the cylinder walls are but should I do anything with the timing chains, guides, etc? Or do you think a visual would be efficient enough? IMS is going to be done for sure just want to see what else I should do before dropping this in? Dont want to tear the heads off but that was something thats been crossing my mind if I should. Any feedback would be greatly appreciated.

-

On 3/11/2020 at 10:37 AM, DBJoe996 said:

Bentley Manual by far....

On 3/11/2020 at 10:47 AM, JFP in PA said:Problem is that Porsche stopped publishing service information around 2005, switching to an online subscription system; and has never conceded that the IMS bearing on engines up until 2005 could change the bearing without splitting the cases. By far, the best compilation of torque specs is found in the two book set titled "Fastening Specifications" that Jake Raby published, as he has provided data the Porsche never published. LN Engineering published the best set of instructions for IMS retrofits. There are some internet sources for PDF's of Porsche's service data, but be careful and some are woefully out of date.

Thank you for the posts. Ill get the Bentley for more general info and will look into the Jake Raby book. I believe you are right about LN Engineering but i believe I can find the info online through DIY and other searches so Ill focus on both the Bentley and Jake books first. Thank you again and hopefully I can get this boxster up and running soon! 🙂

-

Im looking for a book to help me with torque specs, break down, IMS bearing, things like that. I know theirs a 101 Project book but is that good enough? Or is the Bentley Manuals better? Just curious. Im looking for one specific to the 996 CAB and 986. Thanks in advance

-

Current motor is shot and was thinking of putting in a 01 Boxster S engine into it but wanted to know what issues may I run into doing this? If I recall correctly I should be using the 996.1 throttle body and 996.1 DME or update my existing DME. Also I have to add an additional wire but other than that I believe Ill be using my existing engine harness, gauge cluster, etc... Would I be able to use my existing 2.5L DME for a bit or does it have to be updated / replaced right away? If I do decide to drop in a 996.1 DME wouldn't I need the transponders, keys, etc as well? If I do opt to just update my DME which would make more sense who does this and about how much does it cost? Also curious would the car pass smog or is this something I would have to take to a smog ref? I live in California. Ive pondered on just putting in a 2.7L which I could just use my DME as is and just add another wire to the secondary air tube and be done with it.

Thanks in advance.

-

8 hours ago, JFP in PA said:

An automatic engine will not have a pilot bearing in the back of the crank as the torque converter does not need it, but one can easily be added for use with a manual trans.

Yea figured that was the case. I just heard somewhere the cranks were completely different either in length or something like that so wanted to confirm. Still doing a lot of research on what options I have so Im sure Ill post more questions periodically. Thanks again

-

6 hours ago, JFP in PA said:

Not really.

Ok good I remember someone saying the cranks were different so I just wanted to confirm. Thank you

Variocam guide replacements how to questions

in 986 Series (Boxster, Boxster S)

Posted

Does anyone know a good guide to replace these? Been looking online and can seem to find a good diy torque specs etc...

thanks in advance