Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Johnny-5

-

Posts

215 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by Johnny-5

-

-

I believe 99 was the last cable drive throttle body. Ive looked but would like to get more insight from anyone on here who has done it or know of it?

-

I picked up a 99 Boxster from a friend who doesn't have the time to work on this so I sort of took this on. I was thinking of putting back another 2.5L but seems like it would be a waste from reading up on things. Im looking for the best easiest solution to get this up and running and not looking to spend a fortune on it either. Is there any directions on routes of engine? Are the Boxster S be a better solution then the 911 engines? Could I just swap some of the parts over to make it easier for the engine to work? Any insight would be great just want to see what I got myself into with this.

Thanks in advance

-

16 hours ago, JFP in PA said:

Probably your best bet is the Bentley manual for the 996, which is in book form only. You can also look around for a set of the factory 996 manuals, but they are expensive and harder to find as they have been out of print for many years now. Be cautious about pdf files, they tend to be woefully incomplete and/or out of date (there were many updates to the originals over the years), plus as most are illegal copies of Porsche copyrighted intellectual properties, and subject to legal action. This website does not condone trading in such materials.

Thanks JFP for the info and heads up. Wheres the best place to pick up the book for reasonable?

-

Is there a place to get a Repair PDF Version or would people recommend the book? Im thinking of tackling the IMS and wouldn't mind having something like this on hand. Trying to figure out if I should go with PDF or actual book. Also where would be the best place to get either.

Thanks in advance.

-

On 8/10/2018 at 5:48 AM, b3freak said:

I have no dog in this fight. I'm not going to risk my $20K+ motor on a roller or ball bearing design, IMHO. Everything I've read over the years shows risks from radial load on roller bearings which potentially could lead to failure, but I guess the cylindrical roller bearing is their "solution"? Problems associated with ball bearings is why we're in the this mess in the first place. I believe the IMS solution by LN with it's oil fed plain bearing design is the best technology out there. Why do you think the Mezger engines are so valuable to racing?... one of the reasons is because of it's durability on the track. Those Mezger engines use a plain bearing design on their shafts.

Sorry for the delay. Thank you for the feedback and valid point.

-

22 hours ago, ttocs said:

I've done a lot of work on cars way back when, and I do most of the work on my 986, but I had the IMS done by an independent shop. The labor was about 2-1/2 to 3 times the amount of what the tools would've cost. For this operation having a warranty was a major deciding factor, especially when weighed against the possible savings available.

The "might as wells" included the AOS, RMS, and Trans Fluid/Filter.

Also, when a LN Engineering approved shop does the work, they check first to see if the engine is "qualified" for a Retrofit bearing, thus securing the warranty.

Lastly, the bearing choices from LN at the time I had mine done were the Single Row Retrofit or the IMS Solution, and I went with the Retrofit since it was about $1,000 less. Anything other than a plain bearing is a maintenance part - it'll need to be done again in the future. Knowing what I know now, I would've gone with the Solution.

Thank you for the recommendations. I'm tempted to try this myself but like you I may just go with a shop.

11 hours ago, b3freak said:So I got a question before LN Engineering was the way to go but there seems to be another company I heard nothing but good things on which is EPS which utilizes a cylindrical bearing design which also claims the life of the engine. Anyone tried that company?

-

So I'm currently debating if I want to do this myself or if I should get a shop to do this. I'm mechanically inclined to a certain degree but something about Porsche's scare me. Possible how cramped the engine compartment is??? Who knows! I've read here and there how painful the process is and wanted to get some feed back on the process. I'm sure if I take it in I'm going to get reamed on price that's for sure. Any feedback would be greatly appreciated.

Now my other question I had...While were at it is there anything else that should be done? Is it easier getting to the AOS with the transmission removed? I dont have any current issues with it but you never know and while were at it I figured I get that over and done with as well.

Thanks in advance!

-

Is there a place that can rebuild rear quarter window regulators for our cabs? Or if its even something a diy could do? Any info would be great.

Thanks in advance.

-

Ive been using recommended 0W-40 Mobile 1 but thinking of trying another type and weight and wanted to see what everyones running.

-

I recommend Sunset Porsche and ECS tuning.

Thank you for the recommendation. Ill check out Sunset and ECS. If I remember right ECS Tuning pricing is pretty high but Ill double check. Just to confirm Sunset Porsche in Oregon right?

Agree ---- Sunset

:thumbup:

There is a guy in Brooklyn who used to rebuild these. His website is no longer up and I cannot attest to the quality of his work. The phone number at last listing was 718-851-0100. I agree with the previous posters though (+1 Sunset). These regulators are such a PIA to access for repair that it's best to put in new if you can afford it.

I think I remember seeing that site not sure where he was located but yea he used to rebuild these but cant seem to find his website anymore. Sucks that these things have gone up so much in just a few years from last time I bought the passenger side! :censored:

-

I just had the drivers rear quarter window regulator go out on me recently and the pricing has jumped massively since a few years back when I replaced the passenger rear! Anyone know where I can get a new or rebuilt rear window regulator? The motor on these are fine its just the dumb cable that seems to be an issue on these cars!

Thanks in advance!

-

http://www.renntech.org/forums/topic/33970-strange-whistling-sound/?hl=%2Bwhistling+%2Bnoise#entry183929 http://www.renntech.org/forums/topic/15730-whats-the-vent-inside-our-gas-filler-door/?hl=%2Bwhistling+%2Bnoise#entry78365 http://www.renntech.org/forums/topic/20768-noise-from-inside-of-left-fender/?hl=%2Bwhistling+%2Bnoise Read this it might help.

Thanks RFM. Ill take a look at those sites. Got to also track down correct part#'s for the parts too.

-

-

-

Could be as simple as a vacuum system leak - have you checked for that?

Hi Loren,

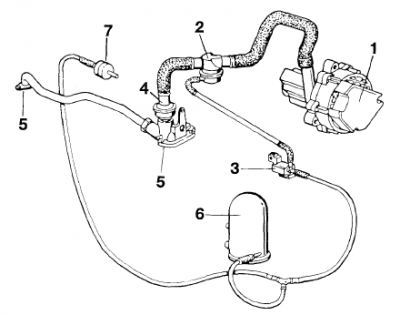

I checked all the hoses that I was able to see without taking anything apart for the secondary air injection codes with nothing out of place broken, etc.... I was using the diagram Ive attached. Now since this is a 2000 996 the Change-Over Valve is different (I learned the hardway). Part# 2 and 4 are combined now. Pump kicks on just fine.

Now going back to the second issue with the fuel system. Its making the wooing sound and when filling up the tank it clicks as its full and its not. So in that case for sure it would be the Fuel Vent Valve right?

-

-

Ive got two errors P0410 and P1411 which are the secondary air injection. I visually checked the pump, hoses, etc and they all seem to be intact with no issues. Now since this is a 2000 it uses a different Change-Over valve...haven't gotten around to replacing that yet. But anyways Im also getting that gas tank buzzing sound at idle (traffic, slow moving, etc) and I believe its either the gas tank cap, fuel purge or something inside the engine bay. I believe that started first and that's about when I started getting check engine errors. Would it be possible that the fuel purge or breather could also be triggering those codes? It probably wouldn't but figured I ask. Also when the buzzing occurs Ive removed the gas cap and its still on. Eventually it will stop but will come back. Also noticed that when filling up the car it would stop as its a full tank but when I get into it its like a quarter below full. So I don't think its a gas cap issue but either the fuel breather or that other valve in the engine bay. Can anyone confirm this. Thanks.

Gee's if its not one thing its another!!!

-

Yes, it's that bolt. Will make sense when you get there.

(click to enlarge)

Thanks Ahsai and Loren....

It doesn't look so bad! :eek: Its been raining massively here so haven't tried to hit this out yet. Will report back once I try to hit this out.

-

Unfortunately due to so many vacuum tubes and valves working together hidden behind the alternator, I don't think there's any shortcut hence the long thread I quoted before.

Btw, it may not even be one of the valves. A broken or leaking vacuum line is all it takes to effectively disable the SAI system and trip that code.

Yea you may have a good point. I just hate doing projects and not able to finish it due to a part or something Im needing. Especially when I hear the alternator is a pita. Any pointers from experience you can throw out with that bolt?

I hear you . Who doesn't.

Alternator removal here with tips http://www.renntech.org/forums/tutorials/article/198-removing-and-replacing-the-alternator/

Steps 7 and 8 are the secret of less pain.

7. Undo right fastening screw (with deflection roller) by three turns. A gentle tap on the fastening screw loosens the threaded bushing in the generator arm (use aluminum mandrel). Unscrew fastening screw and remove with deflection roller.

8. The generator must be turned clockwise so that the swivel arm is near the crankcase and the holding arm projects beyond the fastening eye.

Yea I seen this but Im so confused on what its needing me to do? Which bolt is it in the diagram? Is it the one on the far right with the roller for the serpentine belt?

-

Unfortunately due to so many vacuum tubes and valves working together hidden behind the alternator, I don't think there's any shortcut hence the long thread I quoted before.

Btw, it may not even be one of the valves. A broken or leaking vacuum line is all it takes to effectively disable the SAI system and trip that code.

Yea you may have a good point. I just hate doing projects and not able to finish it due to a part or something Im needing. Especially when I hear the alternator is a pita. Any pointers from experience you can throw out with that bolt?

-

I finally got to get the code off the car and Im getting a P0410. Any suggestions on what this could be? What I should do first? Can I check the hoses with the alternator on or would it have to come off? Just don't want to end up taking everything apart to find out that I need to replace one of the valves and have to order it and wait. Any suggestions and help would be grateful.

Thanks

-

Both valves live pretty deep in the engine behind the alternator so you definitely need to remove the alternator.

I would test the function of each valve and also check if the system holds vacuum. Could be one of the vacuum hoses is knocked loose/leaking. See details here http://www.renntech.org/forums/topic/10184-cel-p0410-p1411/

Funny I was just looking at that a few days ago but didn't get to finish reading it. Thanks Ahsai Ill see what I can find out on the hoses. Ill also read that thread and see what info I can get to it. As stated my main concern is the alternator as Ive heard its a pain

No problem. The alternator is not that bad as long as you know the trick to tap the long mounting bolt (with a hammer) to loosen the bushing on the alternator that's used to "lock" the alternator on to the engine. Check the altnerator relpacement in the DIY section for details.

Tried doing a search and found two one for a GT2 and another one but didn't get much from it. Is there a DIY on how to replace the cut-off valve and electronic valve? Im going to try to tackle this project this weekend.

-

Both valves live pretty deep in the engine behind the alternator so you definitely need to remove the alternator.

I would test the function of each valve and also check if the system holds vacuum. Could be one of the vacuum hoses is knocked loose/leaking. See details here http://www.renntech.org/forums/topic/10184-cel-p0410-p1411/

Funny I was just looking at that a few days ago but didn't get to finish reading it. Thanks Ahsai Ill see what I can find out on the hoses. Ill also read that thread and see what info I can get to it. As stated my main concern is the alternator as Ive heard its a pain.

-

The check engine light usually comes on when its cold start or when the air pump kicks on or a few seconds after it turns off or a after driving it off the drive way and down the street a bit. I believe the codes are: CEL : P0410 + P1411 But I have to double check. From reading here and there it sounds like its either the change-over valve or the air cut-off valve is usually the two culprits! I just want to know which one is more likely to replace and or if I should just replace both while Im at it. And if so is there anything else that I should replace while Im in there?

1999 Porsche Boxster blown motor questions...

in 986 Boxster Convertible Top Issues and Solutions

Posted

Is there any differences in the short block between the automatic and manual engines?