Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

89 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by JasonStern

-

My convertible top knowledge came from owning an early Boxster, so this might not be exactly the same as a later 996, but... If the microswitch is the JFP mentioned is the culprit, then you should be able to use a metal screwdriver to jump/depress the microswitch to determine whether or not that part is the part that is failing. If that does not work, there should be a several terminal relay by the fuse box. Unfortunately, I cannot seem to find a copy of the pinout, but hopefully someone else can provide it. If they do, use a multimeter to ensure that the switch is functioning. If the microswitch is not the problem, the next simple thing to check would be to make sure that the window repair guys didn't impact the convertible top switch. If both of those switches are working, verify the parking brake switch is working. If all of the switches are working, then in my experience it was the relay itself. However, I never opened the top manually so I have no experience or knowledge about the ECU getting out of sync.

-

Sorry for the delay, but I finally got a day off. With the car stationary, the fuel pressure read 3.7 BAR, which is within the 3.8 +/- 0.2 BAR factory specs. With the car at idle, the fuel pressure read 3.3 BAR, which is within the 3.3 +/- 0.2 BAR factory specs. With the car at idle, the vacuum applied at the fuel pressure regulator was 0.9 BAR. This is well above the 0.4-0.6 BAR factor specs. So: 1. The fuel pump appears to be functioning properly. 2. The engine was cold when the vacuum reading was taken. The PDF Ahsai linked to did not specify whether the engine should be warm or cold. Would this affect the vacuum applied to the fuel pressure regulator? 3. If engine operating temperature is not a factor, a low vacuum reading would indicate either a vacuum or intake leak. What would excessive vacuum pressure indicate? Thank you!

-

Thank you. This definitely seems relevant: My fuel pressure gauge and vacuum gauge arrived. Now I am just waiting on the fuel pressure adapter from Actron, which should arrive on Wednesday or Thursday. The original readings were done either at idle or 2,500 RPM. Those did not have the refresh rate in Durametric maxed out. The readings in the zip file were done at 2,000 RPM with the Durametric refresh rate set to the max. Regarding the freeze frame data, Durametric got back to me: So that is a bit disappointing.

-

New member please be gentle.

JasonStern replied to valfam's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

what kind of oil should he run? seriously, though, the Porsche forums - this one in particular - are amazing. my girl has a Mercedes SL500, and I go to their forums asking something that should be easy to find - the torque specs for the oil drain plug, and the most helpful response I got was "if your mechanic doesn't know that, you should get a new mechanic." :huh: -

What exactly happened? Did the insurance company reimburse you for the car and then offer you a chance to buy the totaled vehicle? If so, at what price? Odds are good that you could make more parting out the non-damaged pieces than the price of buying the salvaged car back from the insurance company. But that presumes you are capable and willing to keep a wrecked shell and sell the pieces on demand. Regarding keeping the engine, your guess is as good as mine. What condition was the motor in? Have you done preventative maintenance likes IMS bearing replacement? Are you going to swap the motor yourself, or have a shop do it? A shop swap is likely going to run at least $3k in labor plus whatever preventative maintenance you elect to do while the motor is easily accessible. And if you can't find a 996 core, the 3.4L motor can be swapped into a 97-99 Boxster if you want a deceptively fast convertible: http://www.pelicanparts.com/techarticles/Boxster_Tech/11-ENGINE-911_Engine_Swap/11-ENGINE-911_Engine_Swap.htm

-

IMS advice needed

JasonStern replied to dgjks6's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

The 996s are new enough that you can get a salvage low-to-medium mileage motor for $5-7k. If you aren't planning on keeping the car for 40-50 years hoping it appreciates, then instead of rebuilding your core, I'd look into picking up a motor with good leak down (or at least good compression) numbers, and then doing preventative maintenance (IMS bearing replacement, gasket replacement, etc.). It would probably save you $4k+. And while you run the risk of abuse from the prior owner, that risk is also mitigated by the fact that you are running a factory motor instead of one rebuilt by a low-volume shop. Or, if you have the cash, there is always http://www.flat6innovations.com/# - but that is only cost effective if you plan on keeping the car long-term. -

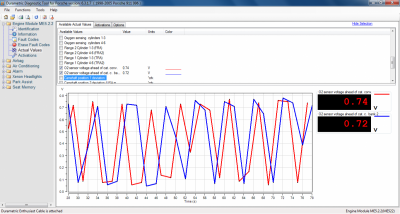

As far as I have been able to figure out, Durametric 6.3.1.7 can only read the "O2 sensor voltage ahead of cat. conv." and "O2 sensor voltage ahead of cat. c. bank 2" on Bosch ME5.3.2 equipped cars. There doesn't appear to be pre-cat/post-cat and cylinders 1-3/cylinders 4-6 options, of which values were requested. :( Regarding that TSB binger posted, while the information isn't relevant yet, if further diagnosis indicates an O2 sensor failing, that information is very good to know. Thanks for that.

-

IMS Lawsuit is in motion..

JasonStern replied to Jvc300's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Million dollar airplanes break too. I've seen cars of all makes and models have engines blow up. All parts are eligible to fail. I've watched a friends Harley fail right before my eyes. Piston rod failed on the rear cylinder. 2011 MB E class engine blew. Why would anyone think the Porsche would be bullet proof. I love my 2004 and it's sold as a rock. I'm sorry for those that have suffered the failure, but I don't lose sleep at night over it. QFT. Although if Porsche knew about the design problems, which they likely did given multiple revisions, then it speaks a lot about the company regarding their willingness or unwillingness to provide good faith repairs to their loyal customers when it comes to fundamental design flaws. -

Detailing and maintenance.

JasonStern replied to valfam's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

I highly recommend you check out Drive Clean on YouTube: http://www.youtube.com/playlist?list=PL96D52AF54166C886 If you have specific detailing questions, the guy tends to be helpful. Or, if you'd rather be distracted/entertained than educated, blonddrive.tv: http://www.youtube.com/watch?v=iXkL-8RvdBA ;) But seriously, listen to Drive Clean. -

How to remove stripped drain plug?

JasonStern replied to LVDell's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

If you buy an LN Engineering magnetic drain plug, the torque specs are 19 ft-lbs. Very important to remember or you will be rewarded with your "following the Porsche torque specs" diligence with the privilege of starting your own "how to remove stripped drain plug?" thread. :blink: Wrong! Read the Porsche Service Manual. The torque specs on the oil filer is 19 ft-lb. The torque on the oil drain plug is 37 ft-lb. For a factory oil drain plug, 37 ft-lbs is the correct torque specs. However, if you replace the factory oil plug with an LN Engineering magnetic drain plug: http://www.lnengineering.com/drainplug.html ...the torque specs are only 19 ft-lbs. Forgetting this fact and torquing the aftermarket oil plug to nearly twice its recommended torque specs has a high probability of shearing the drain plug, hence my evangelist reminders in oil changing threads to prevent others from encountering the same problem. No disrespect is intended to LN Engineering or their products - they clearly state their torque specs - it's just one of those things that you know when you first buy it, but then after a couple of oil changes, especially if the car sits a bit, you tend to forget. The magnetic drain plug is cheap insurance against metal flaking in the motor, although cutting the oil filter after every oil change probably has the same effectiveness and is free. So, if you're like me and concerned about IMS bearing issues but would prefer to do due diligence during routine maintenance instead of spending thousands replacing a part that did not fail enough to warrant a recall, make sure to also cut your oil filters in half and comb them with a magnet to ensure that there is no metallic debris accumulating. If the IMS bearing does deteriorate rapidly, then this is likely a waste of time. But, it helps me sleep at night. :) -

First off, no need to thank me. You are the one taking the time to help me out, and I appreciate that. Regarding no idle issues, there are none that I know of. The car keeps a consistent idle at around 700 RPM. There is only minor deviance when running at idle or when shifting from load into neutral. But there definitely has not been any surges or stalls. Regarding performance issues, there are none that I am aware of. The car is used as a daily driver when both I choose not to ride my motorcycles and when the roads permit, so as a result I usually shift at around 3,000 RPM. And in that non-track, speed limit enforced, public road setting, I have noticed nothing out of the ordinary. This makes me think that something is beginning to fail as opposed to something that has already failed. Regarding running rich, it probably is. Probably not consistently, but when certain criteria - high ambient temperatures, car fully warmed up, engine at idle - I would presume so. I see no other reason as to why the CEL would trigger otherwise. From just a nearly baseless "sniff test", the car runs really rich when it starts, but once the O2 sensors heat up, it tends to lean itself out. Regarding the O2 upstream sensors looking worse, alright. I'll donate to read the link you provided. :) Regarding changing the downstream O2 sensors from ohms to volts, the Durametric does not appear to have the ability to do so. Remember - I only have access to a $287 aftermarket tool and not factory diagnostic tools.

-

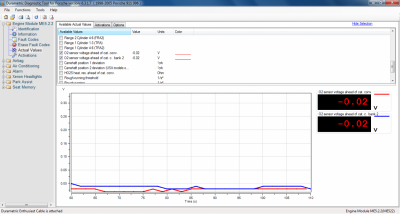

The MIL came on again with the same P1123 code. I was driving home in ~100'F weather. I drove about 15 miles on the freeway, and then the light came on after roughly 30 seconds idling stopped at a traffic light from the freeway off-ramp. So the problem is recurring. I cannot seem to figure out how to get the freeze frame data from the Durametric tool. I e-mailed their technical support, so hopefully they can explain how, presuming Motronic 5.2.2 is supported - they worded it rather vaguely in the manual. Attached are logs from almost all of the meters that the Durametric tool will let me log. Unless stated "cold", the readings were taken with the motor running at approximately 2,000 RPM. Do note that there is no TPS voltage reading. However, there is a throttle plate angle metric that varies between 0' with no throttle applied and 67' when the throttle is depressed. The IAT sensor measured accurate cold. However, I didn't do any additional testing beyond that. The Durametric does not have the ability to measure the individual O2 sensors, but the values that could be read are provided. I am still waiting on the vacuum and fuel pressure gauges in the mail and will post the results once they arrive and I have time to measure the respective values. Regarding those PDFs: Rate of Occurrence: 120 miles Time of day: Evening Engine temperature: Normal Outside temperature: Hot Driving conditions: Idle Gas Pedal: Released Gear: Neutral Occurs after: Driving Road Conditions: Dry Fuel: 91 octane with 10% ethanol :( MIL: On No Starting Faults No idle issues No performance issues Same gas mileage No pinging No smells No smoke Above 80'F Ambient Temperature No recent repairs No modifications other than a 997 shifter Thank you! durametric.zip

-

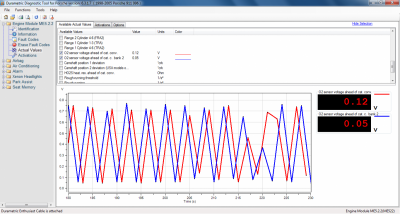

Again, a thank you to all providing your invaluable information. The coolant was warm when I took the screen shot as I had just driven home. However, the car was off for a few minutes prior to the reading in order to grab my laptop and Durametric, so if there is some sort of temperature gauge on or near the catalytic converter, then I have no idea what the temperature was at the time of the reading. It is almost the weekend, so I will try to read up more on the Durametric and provide more information then. While the fuel pressure gauge and vacuum gauge seem like they will only verify whether or not the problem is either the fuel pump, fuel pressure regulator, or a vacuum leak, it would still be nice to rule those out. Unfortunately, I had to order those online so it will be a few days before I can check them. I will definitely consider taking it to a shop if the code re-triggers. However, so far I have just over 75 miles without the code re-triggering, and the car is showing no symptoms of any problems, so I'm cautiously optimistic the CEL occurring was just a hiccup due to the low octane, ethanol laced mixture they call gasoline in the western U.S. Not that such a thing would stop me from doing some simple checks to try to ensure a potential failure is not about to occur. That might be due to the Durametric has a time value in which it polls for updates, and I left it at the default value. I will try to read up more on it this weekend and hopefully provide additional information. Attached are the cold reading values. As you said, at first nearly no voltage was read, but after about a minute, the values started oscillating. For clarification, I did see 0.4V-0.78V the first time (without a screenshot) and 0.05V to 0.75V the second time. See the screenshot in my previous post for the graph the Durametric tool generated.

-

First off, thank you for that PDF. After clearing the fault code but not disconnecting the battery to make the ECU re-learn the fuel curves, I have driven 35 miles without the fault re-triggering. The O2 sensor readings were for both pre- and post-catalytic converter. Attached is a screenshot of the O2 sensor readings from Durametric when warm. The low values seem to be lower today than yesterday. Getting cold numbers is a bit more difficult due to working in the morning, but I will try to provide those when I can. Unless you mean "Oxygen sensing cylinders 1-3" and "Oxygen sensing cylinders 4-6", I am not seeing how to measure the O2 sensor voltage of a specific bank. And the oxygen sensing reading for cylinders 1-3 is 1.01 to 1.05 and for cylinders 4-6 s 0.99 to 1.02, which seems out of the sweet spot if that value does reflect an O2 sensor - unless maybe the value is scaled so that 1.0 is 14.7:1...? Sorry about that. My car is a 1999 Carrera C2. It does have a fuel pressure regulator on the fuel injector rail. Looks like I need to order a fuel pressure and vacuum gauge. Regarding the MAF, darn. I didn't think so. It's never the relatively cheap part that is easy to access... So if it does turn out to be fuel injector related, what are the odds that sending the injectors to be professionally cleaned would fix them versus having to replace one or more injectors? Thank you!

-

How to remove stripped drain plug?

JasonStern replied to LVDell's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

If you buy an LN Engineering magnetic drain plug, the torque specs are 19 ft-lbs. Very important to remember or you will be rewarded with your "following the Porsche torque specs" diligence with the privilege of starting your own "how to remove stripped drain plug?" thread. :blink: -

Drove home and CEL came on. Attached my Durametric. Error code is P1123. No other error codes. Car is stock with 20k miles. No recent known problems. I did have a non-start problem before: http://www.renntech.org/forums/topic/43615-changed-oil-installed-997-shifter-now-car-wont-start/ ...but after replacing the fuel filter, I haven't seen any symptoms in five months. Idle is at 680 RPM. Air Mass reading is 15-16 kg/h at idle and 50 kg/h at 2500RPM with no load. Oxygen sensing reading for cylinders 1-3 is 1.01 to 1.05 and for cylinders 4-6 s 0.99 to 1.02. O2 sensors read between 0.4V (lean) to 0.78v at idle and 2500RPM with no load. Due to wife and nagging woman problems, I won't have time to dig into the car until this weekend. Checking the EVAP canister purge valve is on the top of my "to do" list. So I do apologize for posting without doing as much due diligence as possible, but, again, time concerns. Some guidance up front could easily prevent me from unnecessarily replacing moderately expensive parts. Due to the lack of other CEL codes, the fact the car is running rich and I don't plan on driving it hard, and the code being a non-serious error, I cleared the error code and will drive it the rest of the week to see if the error retriggers. So, my initial questions for the masterminds here: In Durametric, what is "oxygen sensing reading"? My best guess is that it is the flow rate injector compensation, but if that is the case, the value was changing constantly. Does that 0 to 0.03 discrepancy noticed between cylinder banks provide any useful information to further diagnose the cause? The MAF sensor readings look within spec, and since the MAF affects both cylinder banks, it seems unlikely to be the culprit. But, the sensor is 14 years old, countered by it only having 20k miles. From what I have read, the MAF sensor seems to take the blame for a lot of P1123 issues. But that could be misdiagnosed, especially if the issue is not easily reproducible. The O2 sensor values seem right, but I'm basing that on other vehicles, and the car wasn't under load. Do those values tip off any red flags? Are there any other metrics I can pull from the Durametric that might reduce the number of potential areas to investigate? Thank you!

-

Ebrake Adjustment

JasonStern replied to Wausau 911's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

As long as you are not adjusting the cable engagement to mask rear brake pads needing to be replaced, and as long as you aren't adjusting the cable engagement too far out of spec (causing either a constant partial engagement or excessive force applied when the e-brake is engaged), you're fine. Do remember that you will need to readjust the cable when you eventually replace the rear pads. That said, this video does a great job highlighting exactly where the adjustment screw is: -

Interesting, though surprising. But I guess the bigger question then becomes the variance in battery life expectancy. I just had a ~22 month old Walmart Everlast battery go out on my ZRX last Friday leaving me stranded. And the battery was never deeply discharged throughout its lifetime as I'd rather ride my bikes weekly/bi-weekly in ~30 degree weather than winterize them (which may be related to the failure rate). I imagine that this discrepancy has to come down to quality control. Another replacement Everlast battery would have been $50, but the better warranty battery I ended up purchasing to replace the dead battery cost $90. I know Walmart has purchasing power, but to get the price point down that low, it would seem that some corners had to be cut. Not saying that every Everlast battery is a dud, but if all batteries start from a common recycled basis, and from personal experience, the Everlast batteries don't last as long as other manufacturers in my same cars and motorcycles with similar usage habits, then cutting back on quality control to increase profit margins sounds plausible. From your personal experience, does this sound right? Or did I just spend an extra $40 I didn't need to?

-

Again, all I can speak for from personal experience are the motorcycle batteries from Walmart. And those require manually filling the battery acid and, at least a while back, used to be made from recycled cores. I have no problem if the core is recycled so long as the lead-acid cells are replaced. I mostly fear that when a battery manufacturer engages in a business contract with a corporation like Walmart, they do so while working towards agreeing to a certain price point. Likewise, retail outlets like Walmart have an increased potential for people to try out a battery and then return it if a battery replacement fails to alleviate the problem. This leads to reduced lifetimes of batteries that were ran hard during automobile diagnosis, as well as a higher potential for returned batteries to make their way back onto consumer shelves. As far as personal experience goes, I run Bosch batteries in my 996, and did in my 986 and Miata, While I didn't keep my 986 or Miata outside the extended warranty period, I also never had any problems with the replacement Bosch batteries. They were also price comparable to other budget battery brands. I honestly wouldn't be surprised if other battery vendors offer better value with respect to both the longevity and performance of their products. Just be glad you do not own a modern Mercedes. Their ECUs keep track of the lifetime of the battery, so if you replace it yourself without using proprietary Mercedes software to update the ECU of the replacement, it will affect how the battery is recharged, thus inadvertently reducing the battery's lifetime.

-

Footwell Lighting Install ?

JasonStern replied to Wausau 911's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

No worries. There are several types of relays. A relay's main purpose is to isolate electrical systems. Since you wouldn't want something going wrong with your footwell lighting to affect you headlights, it makes sense to isolate them. What you want is one of the most basic relays: http://en.wikipedia.org/wiki/Relay#Pole_and_throw Notice the SPST diagram. The squiggly line to the left represents the coil terminals. In a normally open relay, the switch closes as electricity is ran through the coil. So by splicing the headlight wire across the coil terminals, you are running electricity through the coil which effectively acts as closing that switch, which would turn on your footwell lighting. -

Spacers - Porsche 996 C2 1998

JasonStern replied to jorgenkarls's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

If the main point is aesthetics and not safety/reliability/performance, then the answer is fairly subjective. From a safety point, you're probably fine as long as you live in a speed regulated area and obey posted speed limits. From a reliability standpoint, you have altered the suspension geometry. So, yes, best case there is an increased potential for tire wear. But more likely all of the suspension components are no longer balanced, so you can expect a reduced life. The rate at which the components fail does heavily depend on your driving habits, though. As there are quite a few people who track their 996s on these forums, the emphasis on performance and safety tends to be prioritized. From a performance standpoint, spacers neither increase traction for cornering ability nor reduce role resistance for straight line speed. If anything, you have increased wind resistance. So, no wins there. -

Oil and Transmission Fluid change

JasonStern replied to hi8ha's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Actually, you have that backwards.The LNE bigfoot drain plug is "machined" out of a billet piece of high strength hard anodized aluminum. It is MUCH harder than the standard OE stock drain plug. If you've ever held the two in your hands you can feel the difference.If you apply more torque to the higher strength metal plug against the sump, it is going to have a tendancy to damage threads in the plate or plug. if you apply less torque to the lower strength OE plug, it might not seal as well. Not trying to spread false information, so I apologize if I am incorrect. Judging by the metal not deteriorating around where the hex socket enters the drain plug, the metal itself likely is stronger than the OEM plug, However, judging by the drain plug splitting in half, I am inclined to believe that the density of the casting is not as uniform, which may actually be intentional. I'm not trying to badmouth LN Engineering here. They stated the torque specs, and I simply forgot that their product required different torque specs and did what most people would do in that situation - ensure the factory torque specs were used. If I managed to get myself in this position and unable to remove the sump plug, I think I would simply remove the sump plate and take it to my local machine shop. And luckily for me that wasn't the case. The oil drain plug simply cracked in half and I was able to get the half that did not break off out with the hex socket. The state of panic was momentary, and mostly stated for the sake of story telling. Had I repeatedly read that the torque specs were different, something likely would have resonated in my head and I would have lessened the torque I applied, hence why I took the time to make a post reiterating that. I think I would replace it with another LNE drain plug, however in the case you mentioned above, I would more likely be replacing my sump plate. The sump plate is fine. This actually happened on my 986 and not my 996, which I might add still runs an LN Engineering magnetic drain plug. LN likely engineered the plug to fail this way to avoid the negative reputation of having to potentially replace an expensive Porsche sump plate to protect a relatively inexpensive oil plug bolt, in which case, thank you.