Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

mdreef

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Posts posted by mdreef

-

-

14 hours ago, DBJoe996 said:

I have a feeling the vacuum leak would keep the system from creating a vacuum in the reservoir, which is required for the change over valve and shutoff valve to work. I went ahead and ordered a new upper tube and will post an update if this takes care of it.

-

The plastic debris in your filter does look like guide rail material because of the color, but if it's soft, then JFP might be right about it possibly being sealant. The color, however, doesn't look like sealant.

Last year I replaced the guide rails and know what it took to get it done. I can't believe that anyone would be able to perform this major job with the engine in the car, although I did read that it's possible. I'm surprised that your cam deviation didn't set-off a CEL. Mine came on with a 6 degree deviation.

I had a quote from a shop in Houston and they wanted over $2,500 because it's a pretty big job.

Good luck!

-

-

On 10/30/2011 at 1:04 PM, thom4782 said:

The car has been to the shop multiple times. First, they checked for vacuum leaks and found some, These were fixed. Codes reappeared. Then the various secondary air valves were replaced. I took the view that labor costs were the biggest part of the bill so replacing parts when things were easily accessible was the less risky approach. The codes reappeared. Then the air pump was replaced. The code reappeared agan. Then the MAF was replaced. Still the codes reappeared. It always the same story. Clear the codes; drive at leaset 50 miles; the light and the codes come back on at a subsequent cold start. Now with nothing left to fix in the secondary air system, it's on to the O2 sensors. They're paid for and in hand so it's cheap to actually put them in given the car's high mileage. So I've done everything I can think of. The two independent shops - unless they are both incompetent - have gone through all the diagnostics and have nothing else to recommend. The local dealer wants to start back at square one and charge big bucks before they will either escalate my question to Porsche or recommend what else to do. A smog test two months ago showed the cats are working great and the car is running very clean. So if all else fails. I might just set the car to ROW and have the secondary air system ignored by the diagnostics because I just don't know what to do next.

Hello thom4782 - you probably no longer own your 986, but I'm hopeful you might share what the problem ended up being and how you resolved it, as I'm experiencing the same issues. I've replaced every single component of my SAI system but my CEL continues to come on with the same P0410 and P1411

Thanks in advance!

-

3 hours ago, MagnusO said:

For clarification, they're not entirely clogged up, just enough to have the airflow differ from one side to the other. It is that difference that triggers the CEL. I have given the indy permission to proceed with a cleaning and will report back on whether it worked or not.

Thanks for the clarification - I hope your investment pays off for you - which for me sounds like I might be in for another big project if it fixes your problem. Thanks again!

-

I have a 2001 996 Cabriolet with 140,000 miles and I continue to love my weekend driver. However, I've been fighting CEL P0410 and P1411 for months! In fact, my state inspection is due soon and I'd like to get this resolved once and for all.

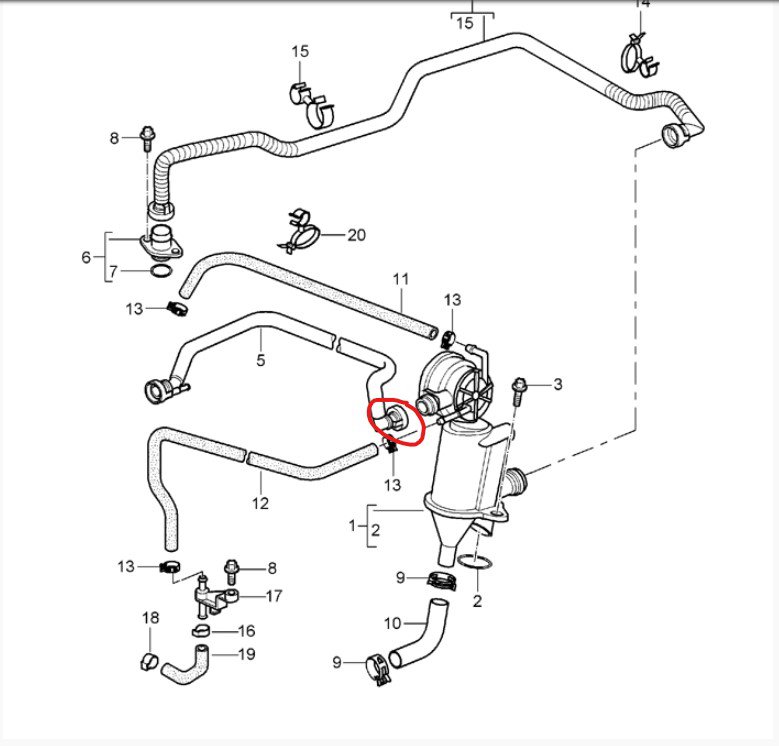

With the exception of the SAI pump, which is still operational, I have gradually replaced every component associated with the Secondary Air Injection System. I thought I was in the clear after driving over 800 miles without the CEL, which I achieved by finally replacing the vacuum reservoir, which was leaking. I replaced all vacuum lines, rubber elbows, Y connectors, electronic change over valves, check valves, shutoff valve, EVERYTHING! As part of other CEL crisis situations I also replaced the AOS, the camshaft position sensors, timing chain guide rails, catalytic converters, o2 sensors, and a number of other sensors while I was in there.

The past couple of days I noticed that during a cold start the engine would start normally, except it would immediately rev down once to almost stall and then stabilize to normal warm-up RPMs. I didn't think anything of it until my friends CEL P0410 and P1411 came back! I cleared them and then the next cold start the CEL came back immediately. Usually the CEL registers after driving over 60 miles, which causes me to wonder why it was immediate this time.

I sure hope that I don't need to pull the engine again to perform the recommended "cleaning" by MagnusO's mechanical team. Does anyone agree with their recommended solution? I'm a bit suspicious of it because the openings through which air is supposed to flow are pretty big, and it would take a great deal of carbon build-up to clog them up - am I wrong? That's just my thought, but if it is indeed the cause, then I supposed that's the only thing left for me to do. I will pray for someone to reply with a better solution (PLEASE!)

I've thought about the SAI delete option recommended by DBjoe996 but I'd like to keep my car as stock as possible.

Thank you for your guidance everyone!

-

I read about people not completely engaging the coil connections, so I was very careful about that. I think Schnell's scenario is the most likely. I'll try to switch them and report back.

The new coils are actually a tiny bit larger so I had to add spacers so the heat shields didn't hit them.

Thanks for your support. Without your help I would not have done this job!

-

worked all weekend to get the engine back in the car and it started beautifully after letting it crank for oil circulation.

I let it idle for a bit and shut it off to continue assembly of axles and body parts. I was thrilled it started and sounded so well. Then came the test drive and upon going into gear I got a blinking CEL P0300, P0301, P0304.

Part of this project was to replace my coil packs, which I did with BERU 997-602-107-02 coils. The first thing I noticed was that part numbers were for 997 models, which caused me to worry and do some research. It looks like they were upgraded at some point - but could this possibly the source of the multiple missfires?

Is there any way to mix-up and install the wiring harnesses incorrectly? It doesn't look like it to me, as they clearly have different relationships. I also thought that maybe O2 sensors got mixed up, but that's not possible either.

I cleared the codes and now am only getting P0302 (cyl.2). any ideas?

On another note, I screwed something up with shift linkage because I can no longer get reverse. That's anoying!

Thank for your guidance along the way!

-

So I replaced the actuator chain pads (both banks). I used the timing tool and aligned each cam as indicated and able to turn the crankshaft clockwise 6 times (each bank). Does that confirm that timing is correct?

Now... is there a way to check for oil leaks from cam covers before I put the engine back in the car?

-

Yeah, good idea, thanks!

-

Just pulled out spark plugs and found a significant amount of carbon deposits on piston #1. Before I started this job (actuator pad replacement) the car ran perfectly except for cam deviation fault. Again 135,000 miles so maybe to be expected. There was no ticking/clicking, etc...

So....the question then is, should I go deeper by going into the head?

-

Perfect timing, as I'll be doing this project today.

Does anyone know/have torque settings for actuator bolts, oil pumps, and ignition coils?

I found conflicting information of 10Nm or 14Nm for the cam covers - has anyone been able to confirm?

Thank you!

-

On 5/22/2018 at 1:08 PM, dporto said:

They are M8 x1.5 (I think - double check). There's a thread around here or Rennlist that tells how to make the compression tool out of a bicycle skewer. This is what I did and it worked perfectly. The threads on mine were right handed. Some people have found that theirs had left handed threads. You may be able to find the exact specs for the tool in this thread https://rennlist.com/forums/996-forum/983191-cel-came-back-finally-got-around-to-getting-a-durametric-11.html it's a thread I started last year when I did the chain tensioner pads on my motor. It's long and there's a bunch of unrelated stuff in there, but I cant find the exact info... Good luck

Thanks dporto, I'll give this a shot!

-

On 5/20/2018 at 5:50 PM, mdreef said:

Noted - thank you! Now that the engine is out I feel like I should do as much as possible.

Thank you all for your guidance!

Good advice - thank you!

Now...I have read in several posts about using reverse thread bolts to release tension from the variocam actuators. Does anyone know what size and thread pattern the bolts should be? Also, where on earth do you find a reverse thread bolt? Are these common?

-

Super helpful - thank you, this is exactly what I needed!

-

Currently have the engine of my 2001 996 Cabriolet w/ manual transmission and 135,000 miles out for chain actuator service. I would like to take this opportunity to replace all coolant hoses in the engine compartment (will replace front hoses in the near future). Does anyone have a comprehensive parts list for the numerous coolant hoses for a 996 with manual tranny? Also, does anyone know how much coolant I will need to put back in? I used pentosin hf the last time I flushed the system but can't remember how much I needed.

Thank you!

-

On 5/18/2018 at 10:18 PM, Schnell Gelb said:

Suggest you inspect/test/upgrade the entire SAI system. It is prone to multiple failure points that are cheap and easy to deal with now but awful later. Jake sometimes suggested Knock sensors for the same reason.

Noted - thank you! Now that the engine is out I feel like I should do as much as possible.

Thank you all for your guidance!

-

On 5/16/2018 at 10:11 PM, Ahsai said:

For your 5-chain engine, you need this set. You need the tool on the lower left to time the cams. Turn the crank at least 4 to 6 times after timing to verify timing, then you can reseal the cam cover.

Thank you for the link. I ordered it right away and it's supposed to get here on Wednesday. I just dropped the engine and will pull it out completely tomorrow, so there's no going back now!

I now feel like I should change all sorts of other things while the engine is out. I recently replaced the following:

1. AOS

2. Bank 1 camshaft position sensor

3. Starter

4. Alternator

5. All vacuum lines

6. coolant line to oil cooler

7. IMS

8. RMS

9. Clutch

10. Coolant expansion tank

11. Water pump and thermostat

12. Engine and tranny mounts

Spark plugs and oil tubes have 15,000 miles on them so not sure I need to change them again.

In addition to replacing the actuator tensioner guide rails, I'm thinking about replacing the following:

1. Oil pressure sending unit

2. Coolant temperature sensor

Can you think of anything else I should replace while I'm in there? The car is running great except for cam deviation CEL.

Thanks!

-

23 hours ago, Schnell Gelb said:

I found it helpful to use M6 s/s studs +washer+nut to hold down the 'bridges'. I was paranoid about causing any avoidable wear on the aluminum threads with steel bolts. Yes. it is a chore to measure and source the correct size/length but imho ,worth it.

Interesting...would you happen to have taken a photo of what you're describing? I have a 3D printer and plan to print the cam support brackets and anything to help me would be greatly appreciated.

Thank you!

-

23 hours ago, Ahsai said:

Usually you want to time the cams when the cam covers are still off (seal the covers only after timing is verified). In that case, you need those cam bridges to support the cams while you rotate crankshaft to adjust/verify timing.

Thank you. The part that confuses me is that, if the crankshaft is at TDC for bank 1 and the intake and exhaust cams are locked with the cam lock tool (see attached image of cam lock similar to what came with my IMS tool kit where the ends of the cams must be in line for this cam lock to work), and the light metal chain links are aligned with dots in the cam sprockets, wouldn't that mean that bank 1 is properly timed at TDC?

I wasn't planning to rotate the crankshaft at all, in fact, I fear that if I rotate the crankshaft separately from the camshafts, I will be completely out of time and totally in trouble.

Am I using the wrong cam lock tool? what am I not considering?

-

-

On 7/15/2017 at 6:38 PM, Ahsai said:

I'll repeat here again in case you missed it. Please refer to the Pelican steps. If you use the cams hold down tools that John mentioned, they will work buy they don't index the cams so you need to make sure you're at the right TDC before opening the cam cover.

At the right TDC, the notch at the end of the intake cam of bank 2 above the scavenge pump should point TOWARD the crankshaft (should point away if you were working on bank 1). This is critical because the cams will have the least stress on them (from the valve springs) only in this position.

-

Question for you experts:

I have a 2001 996 Cabriolet with 135,000 miles and chain rattle at startup with CEL P1341. Replaced the Bank 1 camshaft position sensor but that didn't fix it. Durametric revealed variocam deviation of 8 deg. so It's time I pull the engine.

I'm trying to get "all my ducks in a row" before I proceed with actuator pad replacement (the ones between the camshafts). I recently replaced the IMS and have the camshaft locking tool that came with the IMS tool kit so I think I'm good there. I've been doing lots of research including reading all your great posts - thank you - and now getting ready to pull the engine out of the car this weekend.

I'm trying to understand the need to support the camshafts once the cam cover is removed. Since I have to remove the cams to access the actuator assembly and both chain pads, If I'm careful to keep the relationship between cams correct by aligning the lighter chain links with the "dots", why is it important to support the cams? As Ahsai mentioned, there's the least amount of stress from valve springs at TDC.

I'm just trying to understand. I completely get it if I was only planning to replace the solenoid without affecting timing.

Thanks in advance!

-

Hi dporto,

I'm preparing for this job on my 2001 cabriolet as well and would like to know how your project went - especially what you did to lock your cams. Did you buy the special tool?

Any lessons learned/advice other than what's been mentioned in the previous posts?

Thanks!

1999 996 Carrera Cabriolet, no fuel preasure

in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Posted · Edited by mdreef

Hello Jack and everyone else,

I'm in the same exact position with my 2001 996 Cabriolet and I'm getting desperate. The problem started when I got a CEL indicating no voltage at Bank 1 post cat o2 sensor. I replaced it, and since then, I haven't been able to get the car to fire. It started for about 2 seconds and died. It all seems too coincidental.

I thought I might as well replace parts, as I have 150k miles on the clock. I have replaced the following:

The MAF has about 30k miles on it. I disconnected it to replace the o2 sensor and I thought maybe the harness got damaged, but I read that unplugging the MAF would put the DME in a default program, so I don't believe that's it.

The fuses are all good. I tested for spark and confirmed spark. I can hear the fuel pump running when I jump the relay. The car cranks well but no fire.

I have an Autel 2-way computer, and when I ran an active test of the fuel pump relay, I got a message stating "no voltage" so the test failed. That leads me to believe that something is keeping the pump from coming on, confirmed by the fact that I don't hear the pump running when I try to start the car.

What could be causing a no voltage situation at the fuel pump relay when there's voltage when jumped?

Jack, did you ever figure out your problem? Has anyone else run into this situation and/or have any advice?

Thanks in advance!