Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

121 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by Domiac

-

-

- Is there a tensioner for the crank-to-IMS chain? I couldn't find one.

IMS to crank chain tensioner is quite obvious, see the links in this msg. But you already split your cases so you are probably talking of something else?

Navigate to

https://www.dropbox.com/s/rkr4wuilr1o9slx/996-3_chain.png?dl=0 https://www.dropbox.com/s/52v4fgt1igarbzd/996_IMS_upgrade_tensioner_removal.jpg?dl=0

PS. How the heck I nowadays add new images to Renntech? "Link" gets garbled into renntech.org based and "Image" just hangs when pointing to external website.

-

I'm a bit dismayed by how complex the "auxiliary" systems attached to the engine are. It will be hours and hours before I can so much as take the valve covers off due to the sheer number of hoses, wires, nuts and bolts are attached to the engine. Getting everything back in its original position will be very difficult.

Once you put it back together, many parts fall in place naturally. Nevertheless, I recommend one to use e.g. zip ties and use permanent marker to write matching numbers between parts or something similar, that is quick to do and idiot safe. Take also bunch of pictures with your digi camera from different angles just to be on the safe side.

Before you start wrenching plastic intake manifold back in place, attach all parts together first loosely, then check for alignments between the parts and adjust tube positions (push deeper together or pull shallower). You'll notice how this will affect getting a perfect fit between the plastic and aluminum parts by adjusting angle of the whole manifold.

BTW Do you plan to do some kind of vacuum test for your engine? Now would be the perfect time to do it and see where it leaks, it's a perfect moment to change some lines or oil checkup tube etc.

-

I'll take it to my local shop for just a leak down test in the new year, unless it is easy to get the engine to TDC.

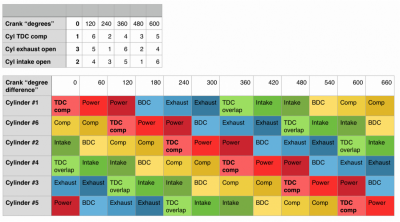

If you perform leak down test by yourself, have a look at http://www.renntech.org/forums/uploads/monthly_04_2014/post-93239-0-35664900-1397384617.png which helps you to find out TDC compression cycle for each cylinder.

Here are the steps

1. Turn crank into TDC Zyl #1 mark, now test Cyl #4

2. Turn crank 120 degrees, now test Cyl #3

3. Turn crank 120 degrees, now test Cyl #5

4. Turn crank 120 degrees, now test Cyl #1

5. Turn crank 120 degrees, now test Cyl #6

6. Turn crank 120 degrees, now test Cyl #2

A few tips about this test:

- on 996's turn crank only clockwise

- Zyl #1 mark on crank means TDC overlap for cylinder #1 and TDC compression for cylinder #4

- a proper tool to find out the exact TDC point helps big time

- let someone (or you) hold crank in place while pressurizing, otherwise engine might turn if you are off from TDC

Please post your or the shops findings here.

-

Kon5t, go back and reread my posting that you seem concerned about. Notice I said the experience wasn't mine. Note also the understated language I used compared to the original and the comment at the end about the sample size.

Threads were on pedro's and 986forum. I stripped out the sensationalism and product loyalty.

Judge for yourself the meanings of that mechanic's experience.

(When I see a posting that is of interest and/or is contrary to the PR, I bring it to the attention of folks so it may be examined. I don't make up things, nor do I ever intentionally post BS. If personal attacks cause us to learn less about experiences that contradict our opinions, we have all lost.)

Yeah you are probably right, looks like my internet balls were a bit fierce last night, now how do I delete those posts?

I am really just trying to understand whether it was a dodgy install, the product or another factor that just happened to be solved. If it was the camshaft timing that was off, it would suggest to me that someone did not install the product properly, allowing for some play with the IMS. It is of course very difficult to confirm any conclusions without being there and working on the actual car yourself.

Actually, the VarioCam is oil pressure operated, so depriving it of either volume or pressure can make it bounce around wildly, so the bearing could have been still running true. Low oil delivery to one head would also cause all kinds of lifter related noise. But before anything could be determined, animosity and defense mechanism's set in and shop doing the remedial work got pissed off and clammed up and stopped posting, so any opportunity to learn something was completely lost.

If you look at the "edit" related buttons under your post, there is a "delete" button.

For what it is worth, I have noticed that I get some misfires on highest RPMs if my oil level is somewhat low, still acceptable, but low. Once oil level is ideal, misfires are totally gone. I have actually tested this two times with Durametric. I do not know why but I assume it has to do with volume or pressure change.

-

Make sure that all of the broken impeller blades are accounted for, because they can get lodged in the coolant passageways and create cracked heads if you're not careful

Not entirely sure, but shouldn't one flush the entire cooling system by two different directions just to maximize the chances that all foreign parts come out from those small cooling channels? This is actually quite easy to do as the big coolant tubes are easily accessible underneath the car.

Would hate to see myself that much later some cyl is running a lot hotter than the others.

Perhaps more experienced persons should comment to this.

-

Yeah - Not in the budget.

If you use jack stands, please make absolutely sure they are safe even if something rocks the car (even a small earthquake on California). I made rock solid jack stands the cheap way, see my posting here http://www.renntech.org/forums/topic/46241-create-rock-solid-jack-stands-for-your-porsche/

Also, my garage is less than 19' long and I've managed to pull my 996 engine + transmission twice. However I fabricated two trolleys from 2x4 and strong castors and I could steer the whole package out in two axis.

-

-

I am playing with fire but what the heck, have a look at http://www.bobistheoilguy.com/motor-oil-101/ also :beer:

-

Hello,

Please have a look at this video:

https://www.youtube.com/watch?v=4WD1b8naXgo

On my car it only lasts for a couple seconds. This occurs perhaps 1 per 20 startups and I have a strong feeling that only after cold nights or during cold mornings (defining cold here as 40-50F). I drive this car on a daily basis.

Would you consider this normal behaviour?

Many are posting similar questions like mine but without a video it is hard to judge if it is fine and occurs because some oil flows past rings to combustion chamber due to Boxster engine layout. Also some are talking of white, some grayish and some blue smoke :-)

My car is 996, 2004, 3.6L, around 90k miles. AOS, plugs, coils are brand new. Both exhaust and cats look like brand new when borescoping. Leak down test >96/100PSI each cylinder, does not consume oil or coolant. Oil level is very close to maximum level, perhaps a tad lower than maximum. Using Motul X-Cess 8100 5w40.

Thank you!

-

Interesting thread. So this means that I need to find overlap TDC #1 for the IMS procedure on my 5-chain motor? The LN tool should only lock in this one way, correct?

1) Crank clockwise until overlap TDC #1 is seen

- cyl #1 exhaust has just closed, cyl #1 intake is just about to open

- cyl #6 exhaust open, cyl #5 intake open

- bank 1 smaller circular cutouts are pointing away from the engine (or when looking at bank 1 and intake camshaft is above and exhaust camshaft is below, then smaller circular cutouts are on the left side, larger cutouts on the right side)

2) Lock bank 1

That should be correct. You should only be able to put your locking tool for bank 1 when engine is on overlap TDC for cylinder #1. It can require a bit finesse to get the tool in as the tolerances are quite tight. Take your time and if it does not fit the first time, turn another 359 degrees (always clock-wise only) and the soonest you approach 360 degrees try fitting your locking tool again. I had to gently "tap" my crank back and forth (within less than a degree) in order to get the locking tool secured.

As you can see the "half moons" are alternating their position per every 360 degrees, one is overlap TDC #1 and another compression TDC #1.

Please follow LN's instructions to the letter if you have LN's bearing.

Have fun and good luck!

-

Thanks guys for the replies. Any other opinions on flywheel bolts? I think I might at least use the gun to get the bolts off, and then torque by hand when reinstalling.

Regarding TDC this is the quote I was referring to on another forum (search for "not another ims thread"). It was good to re-read it.

>> This is where experience from other engines isn't beneficial.. If you attend my engine rebuild school you'll learn that at TDC EVERY VALVE in the M96 is "off lobe".

>> The engine was designed in this manner and all camshafts are relaxed at this point.

Domiac I see what you're saying, but either way I'll pin my crank, lock my cams, pull my tensioners and hopefully the job will go well.

All I am saying is that when you pin your crank Zyl #1, you have either bank 1 or bank 2 relaxed, never both. Observe the exhaust cam locking "moons" from this thread: http://www.renntech.org/forums/topic/46354-tdc-cyl-1-for-a-3-chain-996-2004-36l/?hl=domiac#entry252752

It can very well be that at some other point (but not on Zyl #1 mark ever), one can get into such position where there is no tension in any banks.

-

-

1) I found posts from Jack Raby saying locking the crank at TDC OR TDC Overlap is OK--either position will unload the IMS as all cam lobes are off the valves. But maybe the cam lock tool will only go in properly when I am truly on TDC?

To my understanding this cannot be true, there's always load in either bank 1 or 2 when you put locking pin to crank pulley (TDC Zyl #1) you are either

1) TDC compression #1 meaning

- Cyl #1 TDC compression, has no valves open

- Cyl #6 compression stage, all valves closed

- Cyl #2 intake stage, has intake valves open (STRESS on bank 1)

- Cyl #4 TDC overlap, no valves open (under overlap)

- Cyl #3 exhaust stage, has exhaust valves open (STRESS on bank 1)

- Cyl #5 power stage, all valves closed

or

2) TDC overlap for Cyl #1 meaning

- Cyl #1 TDC overlap, no valves open (under overlap)

- Cyl #6 exhaust stage, has exhaust valves open (STRESS on bank 2)

- Cyl #2 power stage, all valves closed

- Cyl #4 TDC compression, has no valves open

- Cyl #3 compression stage, all valves closed

- Cyl #5 intake stage, has intake valves open (STRESS on bank 2)

I have personally turned crank multiple times and observed how valves move on each cylinder.

-

I've spoken to a few Bay Area Porsche mechanics who say they never lock the camshafts, but of course the full instructions from LNE says to lock. I will err on the side of caution (lock), but would like to skip the step if it's truly not required. My 99 should be a 5 chain motor, which I understand is even less likely to skip a tooth during the operation....

If you can, have your Bay Area Porsche mechanics answer to the following question: "Have you ever replaced IMSB?" If you asked this from Porsche dealership mechanics, they are even not allowed to do such retrofits.

Both LN and Pelican insists that IMS needs to be secured before replacing the bearing.

-

Hope you found your issue and are able to fix it with reasonable budget! Please send pics!

-

Any news on this? Patman, pictures would be much appreciated.

Hopefully some others may provide more information to your questions.

-

Also, if you suspect your engine is fine, could the ATF heat exchanger cause such symptoms in your case?

See the cooling diagram on this message.

-

A couple of things I noticed: the machined surface where the cam carrier mounts is very rough, like it was milled with a dull tool. I know this isn't a sealing surface, but I am wondering if this is typical or does this indicate that someone has worked on the heads in the past? I did find some little bits of rag in the heads, so either Porsche is more sloppy than I thought or someone has been in here before.

The head gaskets seemed not to be in great shape: the rubber surface was very gummy, not sure if this is normal. No obvious leak paths were visible though.

This caught my eye "Head gaskets not in great shape, rubber surface was very gummy". Head gaskets on these cars are extremely strong, material is multi-layered steel, can't believe that someone has DIY'ed this gasket from some other material? Please post a picture of your gasket and while at it, also cam carrier mounts.

-

AWDGuy,

I was able to correct the problem which was worn belt tensioner pads on the camshaft drive chains. however, when I put it all back together, my timing was off. I was 20 degrees off TDC. As a result, when I went to start it, I cracked cylinder #1 and exhaust valves on cyl #1. I ended up purchasing and upgrading my engine to a 2002 3.6.

Bummer, sorry to hear about that. May I ask why did you end 20 degrees off and what you did wrong or forgot to do before starting your engine? Also, did you by any chance turn your crank multiple times over by hand before starting your engine?

In any case, enjoy your new 3.6L :thumbup:

-

Noticed today that my front left fender is almost 10mm / 1cm higher than front right. Back fenders are at identical height. Took measurement multiple times on different locations, car was level. Definitely something is off on front suspension.

-

One more thing. When you install your hardtop, diligently check that it does not grind against your car and mess up with your paint. Some people have had a nasty surprise the next summer when they remove their hardtop.

-

There exists (at least) two different connection mechanisms for 996 / 997 hardtop. The older and possibly noisier version is a bayonet kind of mechanism, the newer and quieter is a screw based mechanism. Please have a look at the PDF on this message.

In case your car has the older connection mechanism and you are suffering of noises, you can consider upgrading all four connection pieces in your car and hardtop to the newer version.

One option for the upgrade is here: http://www.suncoastparts.com/product/PK997HTM.html . The price currently is sky high, I think I paid something like $300 a year ago.

PS. I have an extra pair with new locking mechanism for a hardtop.

-

No,those are the exhaust ports of the coolant fans. Um, actually it does look like something is missing....not sure.

I think something is missing as there are three horizontally rectangle holes there. Thanks for the link (next msg), I'll inspect it tomorrow!

-

No need to start a new thread on my account.

I assume that your stands were under the chassis letting the suspension hang?

Yes. Multiple times I had a thought that I probably should raise suspension a bit too to relieve stress but I never got into it :-(

To my understanding I have jacked the car always from proper places. I have removed my engine & transmission twice and the car has been on jack stands for around 3 months or so in total.

Just picked up a non-running 996; where to begin?

in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Posted

I can warmly recommend Andonstar 2.0MP that has "HD" CMOS, the image quality is truly amazing and the price is around $60. With this you can even inspect individual pixels in Apple's retina screen. I bet you could inspect cracks and such with it. However it is bulky and has manual focus. It just fits through spark plug hole with self fabricated mirror setup but requires you to play a role of an surgeon. For tougher angles and much smaller space you can purchase a general auto focus endoscope but the image quality is totally different even if they claim 2.0MP. Both these are USB which is handy for doing recordings to your laptop. From amazon you will get both under $100.