Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

-

Posts

926 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Posts posted by lewisweller

-

-

5 hours ago, Doug_B_928 said:

Thanks, Lewis. I'll look into the M1 Engine Flush. But I should clarify that the only code that is occurring is the 1355 (the others in my first post in this thread have not come back since changing the battery). Not sure if that affects your thoughts on the cause but I just thought I should make that clear given that you implicate the O2 sensor voltage code in leaning toward the sticking valve lifter.

Yes your probably right the code would be bank 1 system lean or exceeds limits or something, being as it was low voltage it's the sensor power supply side or one of these ghost codes that bad batteries produce to totally mislead you.

-

49 minutes ago, Doug_B_928 said:

Update: So I sprayed carb cleaner to hunt for vacuum leaks and did not find any (doesn't mean there aren't any as I was a bit nervous about the fire hazard and so may not have been as thorough as I could have). I checked the engine stabilizer bar and the rubber looks fine. I also switched coils between cylinders 3 and 7, cleared the fault, and after a bit of driving the fault came back on cylinder 3. There is another thread on this list (something like 'Cayenne S Rough Idle Resolved') where the problem turned out to be the variable valve lift hydraulic valve. His codes were not the same as mine (he had an overall code and a similar code on two cylinders on the same bank), so I can't be sure that's the problem here. I looked at actual values in my Durametric. There are some values for the variable valve lift. I forget the nomenclature, but there appears to be a setpoint beyond which the value for a given cylinder is rough. I watched this value for all of the cylinders at idle and it looked like 3 was often at/near the setpoint and sometimes a bit above it. So, based on Lewis' input above I guess it could be a sticking lifter on cylinder 3. I think, unless anyone out there has a better idea of what this trouble code means, that I'll soon have to take the car to the stealership so that they can at least diagnose it.

Well I reckon the inlet valve lifter on cylinder 3 is getting stuck hence the low o2 voltage code, remember an o2 sensor can only see oxygen or lack of it and it can't see the unburnt fuel that is likely being dumped and not fully combusting due to lack of air. Your engine year has variocam plus which is inlet cam advance of 25 degrees and valve lift height adjustment from 3mm at idle to 10mm at higher rpm I think roughly. Which sequence is not functioning properly I don't know. But its all pressure oil flow controlled.

For me two options

1. take to garage and brace yourself for some possibly wallet bashing news.

Or

2. Take a really long shot chance and engine flush it with mobile 1 engine flush fluid and hope that it can flush out the sticking or stuck valve lifter component. It may be waste of money gamble but if it works may save you 1,000's dollar in engine tear down repair.

This procedure is drain very hot oil and fill with 8-9 litres of mobile flushing fluid (don't use a flush additive because it's cheaper its not as effective) start and let idle for 8mins (check this duration according the spec) and then drain fully, replace filter (check old oil and the filter for debris which may indicate internal issues) and add new 0w/40 mobile 1 fully synthetic oil 9 litres odd.

Follow mobile 1 flush instructions and do this at your own risk some people swear engine flush is bad news, personally I think that is crap, maybe on a total old and sludgy POS engine a flush will dislodge gunge that may get trap somewhere unwanted and also make gaskets that where caked and plugged start leaking etc.

I have flushed my golf R 2.0t at 10,000km intervals with mobile 1 and refilled with mobile 1 0w/40 for 3 yrs running 21psi boost 350bhp and the new owner still has it purring like a kitten at 150,000km, he brought it to my warehouse just the other day in fact to adjust the APR tune selection back to 98ron setting via the cruise control stalk which he managed to fumble into valet mode lol. Did a quick vagcom scan for him and everything was spot on.

Good luck and keep us posted how you get on.

-

5 minutes ago, Brainz006 said:

What's your resting battery voltage? I could swear my CTT runs better when the battery is fully charged. I do a lot of short trips (work is only 3 miles away), so my battery tends to lose power over time. I know it's time to charge the battery when I get the CD changer error. On my 997, a low battery causes a Check 3rd Brake light error. I use a CTEK charger, and it seems to do a good job bringing the charge back.

Sent from my Nexus 6 using Tapatalk

Normally around 12.6volts. I do alot of long journeys and sometimes the whole day im driving, so really in theory it shouldnt need a maintainer although i do have one which i used a few times to experiment with no real differences. Since the new hitachi alternator and 3rd new battery under warranty everything starting and charging wise has been fine knock on wood.

-

1

1

-

-

After some more research on fuel pressure and pumps I started to investigate the likely hood that I had a power or ground fault to one or both pumps possibly.

I was passing my favourite porsche parts guy Hussain and couldnt resist nipping in and buying two new 15amp fuses and 2 new relays 404 for both pumps. I fitted them in a parking spot nearby and reset the DTC codes so as to clear the fuel trims and get a fair Base line if it made any difference.

Well guess what the idle Dip is gone! And the acceleration seems smoother, the stutter at 2700-3200 rpm has not disappeared but it almost like it trying to behave. I may have stumbled on something here. And I fully intend to dive in to this further and do some amp testing and voltage test and ground volt drop tests to see the extent of the problem.

I will bench tested the old relays as well and if I found some anomalies I will cut them open to investigate.

And would you believe it, I ran the journey home with AC on high which felt and blew cooler than its been for a while (34oC outside today) and the "rear check tail light fault" warning I couldn't get to pop up on dash with all lights on and front fogs and music pumping to try and draw some extra power as it voltage related I'm sure.

I don't know, it's all to good to be true at the moment and I've been here before thinking all was good and bang it didn't last long. I've got less than 1/4 so also I'm suspicious of this (hence the title of the post) and will fill up tomorrow and see if the problem return or not.

I need to see some clear wiring diagrams of the power and grounds for the fuel system and the rear comfort control module to see if any common power or grounds are there. And the spec for running amps current of the fuel pumps would be good to know.

Loren if you could be so kind as to PM me anything you have relative to this I would be most great full thank you.

-

1

1

-

-

1 hour ago, tdatk said:

UPDATE,

I got a Durametric pro to see if anything was not showing up on my generic code reader.....yep....knock sensor bank 1. I am not getting any knock at all so I replaced it, same result. I got the wireing diagram and found out which wires go to each sensor to the DME. Knock voltages to the DME are whichcraft so I didn't bother to try and measure anything, I figured I'd try feeding both sensor inputs from the bank 2 knock sensor using a jumper. Worked perfectly, everything related to low boost was gone, boost and performance went through the roof compared to before and fuel mileage increased by 4 mpg highway to 18.5 mpg !!!! I will eventually replace the signal wire to the bank 1 sensor but at 185,000 miles, i'm not too worried. Thanks for your help.

Result thanks for sharing.

I wish I had a code to follow, the misery continues.

-

3 minutes ago, Ddavidoff said:

That sounds pretty accurate, but mine is very subtle right now. Trying to deal with it before it's a major borp. Right now it just feels like a misfire.

Sent from my iPhone using TapatalkI Watched more closely today the issue starts at rpm is 2700 to around 3300-3500 and then clears. At that point the boost has kicked in already.

So I though that maybe it's the boost blowing out the spark for some reason or ignition related misfire stutter due to boost combustion conditions.

So I disconnected the MAP sensor which cuts off all boost and you run on motor alone. The stutter is still there but not as pronounced. So it is not the boost! But is worse with boost!

So what do I take from this? Not forgetting it runs ok when cold.

In left with these possibles :

1. Crankshaft sensor air gap issue flywheel expands when hot air gap reduces? Spacer experiment is planned next week.

2. The variocam Switch over is not smooth? struggling to find any tangible info about exactly when and how many degrees the intake cam is supposed to advance at that rpm. Could it be oil getting thinner and causing this? Maybe a thicker oil would improve this? It's a long shot. I'm using 10/40 semi synthetic. Could a thicker oil work better for the variocam?

3. Fuel / ignition problem only showing when warm? Everything is new so find it hard to believe.

4. Dme getting warm, the eprom for the fueling and ignition map is faulty when warm or someone been playing around and flashed it with some sh*t software tune. Like the "Bluefin" I bought for my 2013 Golf R which made it pink and detonate at light throttle in the midday heat. I quickly removed it and took the Ecu to APR head quarters in uk and had Keith (software Tuning developer and the number 2 man of APR) bench flash my Ecu from his laptop (whilst I picked his brain for 2 hrs) for a killer special tune which had me whipping *** in dubai with any and all takers for 18months and never missed a beat.

-

6 hours ago, Ddavidoff said:

Mine has a very slight hesitation at low RPM's. I have replaced the ignition coils as well as spark plugs air filter's and have fixed the T vacuum connector at the back of the intake manifold as well as fixed the vacuum line for the brake booster. Also found some air leaks in the intake tube's which I was able to tighten the connectors on to seal up any leaks. Still similar issues, hesitation as well as low idle, it will also hunt for gears. Doesn't matter how much fuel is in it it has done it with low fuel as well as a full tank. Might pull one of the fuses next to try and isolate it to a fuel pump but thinking that might not be the issue. Took apart the AOS recently to make sure that it was functioning properly and no torn membrane so I put it back together.

Sent from my iPhone using TapatalkWould you say the low rpm hesitation sensation is increasingly worse when the boost is coming on strong as well?

Example 2 gear come of roundabout ......

Accelerated maybe 1/2 to 3/4 throttle

The stutter stutter stutter bop borp borp borp increases as rpm climb

Then boost kicks in around 2500-3000rpm and it's worse, heavier stutter more abrupt.

After 4000rpm it clears and sings pretty well clean to the redline to change gear and if your at 3/4 to wot the next gear pull is above 4000rpm so it doesn't happen.

How does yours compare to this?

-

11 hours ago, Ddavidoff said:

Same here similar problems. I'm hoping you find something soon.

Sent from my iPhone using TapatalkWould you care to elaborated pls?

-

On 21/03/2010 at 2:53 AM, Reborn996 said:

Funny you should mention that Loren... just so happens the same folks I bought the EVO diverter valves from are the same ones who flashed my ECU. Since I installed the diverters myself the boost leak issue is probably due to my poor installation but I will be having the shop fix that and can ask them to recheck the DME for me. :)

Will let you know what I find out. Thanks!

Old thread but seeing im the 1314 code in the transkission module only on my 06 ctt and having running issues of hot engine having stuttering acceleration, idle Dip when coming to a stop and poor low rpm when crawling de-accelerating.. I've changed and check almost everything and have no other dme codes.

Interesting to read maybe a dme flash could be the issue or create the code. I have no idea if this dme is flashed. It came with the e81 power kit 500bhp from factory as an option so an Ecu flash would seem unnecessary but that's not a definitive answer for me.

-

Took of the manifold today looking for leaks and found nothing. Tested all the check valves and pipes even replaced the DV pipe from changeover valve just in case it was a bit squashed. I even added a smear of gasket sealer before reinstalling the manifold of course with green gaskets which are still like new from a 8 months ago. Looking inside the valves all look OK no real gunk or build up, can't see any chips or cracked valves from back side . Looked at injector nozzles each one has four little holes and all looked cleaned, each injector tested for 12.5 ohms resistance.

That rigid metal turbo vent lines which are obviously leaking some oily yuk is so difficult to fix, I thought about cutting it out but would need to straddle the engine and I'm not exactly a small guy. So I rechecked the jubilee clamps were tight and cleaned off the muck. When I blow or suck the vent pipe no air passes so it must just be a bit of oily vapors escaping over time and I'm sure it not going to make the car turn into a kangaroo when warm.

I also removed both camshaft potion sensors for a look. Can't see anything obvious, looked inside at the camshaft pick up tab(s) luckily one was in view and both in exactly the same spot on each bank which testifies to the cam timing being pretty much spot on I guess. The tabs are not bent at all either.

Put it all back and it started first time. Check for codes nothing in the engine module but see code 1314 ( Engine control module fault) in the transmission module! Seen this a few times before and cleared it without it coming back for months and months.

Is this really a fault? A ghost? Is this the transmission module's subtle way of saying all the issues are the dme but it's not going to tell you about it itself?

I got one small pipe connection from intercooler to plastic pipe before intake Y which I can see is leaking a bit although I tighten it some weeks ago I will change the oring as a matter of course. All the while No boost loss or noises runs fine when cold so really doesn't seem this is the issue, a very small leak.

The crank position sensor spacer I will try for the hell of it but I'm seriously doubting it will have any positive effect more likely negative effects.

Anyone ever had a cayenne dme failure??

-

1

1

-

-

6 hours ago, Zakowsky said:

Just to add an end note to my saga; drove 7250 km through winter conditions and the windows stayed up snug and functioned when needed! Good thing it went out just before I left. I will do a proper cable replacement now. And for people that like drama, after towing a 5,000 lb. trailer admirably back across the country (3500 km), after unloading it and on the way to U-Haul to drop it off, the cardan shaft support bearing gave out. Had that happened in the middle of the Prairies I would have been so totally boned. Since my bearing wasn’t exactly perfect I cleaned it, repacked it and did the Jimi fix with 5/8” fuel line and zip ties for now. Seems more solid than the OEM system, and no problems so far.

That's a legendary road side Fix Mike.

-

Transfer case fluid changed from Toyota type iv to redline D4, as of yet not seen the four wheel drive faulty warning but I'm sure it will appear sometime soon as it not related to the fluid by all accounts it the software on 06 models and the stepper motor actuator and software on older cayenne.

The bank 2 precat new lambda sensor also fitted (much more trick than the passenger side accessed from underneath and squeezed my cut and bruised arm passed the pipes and stuff in the way) had to heat up and bend the 22mm spanner about 15degrees I reckon.

Battery disconnected for about 2 hours total. Did a throttle reset and let idle for 10 mins. Driving no real changes stutter is still prevalent. If I was being generous I would say it is marginally smoother around the other rpm's but definitely not the cure to this saga.

Next job except the front differential oil swap which I wait until oil change is due, will be to experiment with crankshaft position sensor spacers!

Also I may take the manifold off and fix the vent pipe at the rear and recheck for other vac leaks etc. Running out of ideas.

-

1

1

-

-

Busy day planned today.

First will be changing the bank 2 precat sensor and front differential oil for redline heavy shock to try and quiet down that noisy bearing at some speeds I can hear and hopefully extend its life for many more 1,000's km as I don't want it to break one day.

Then will have a test to see if the bank 2 sensor replacement has any positive results.

Following that I also have redline D4 atf fluid for the transfer case. The reason I'm going to change this again three reasons:

1. The current fluid is Toyota type iv which may or may not be exactly as per the transfer case spec it's highly debatable, but the D4 is the same spec as the esso 71... fluid spec Porsche recommends.

2. Noticed the transfer case leaks are worse and maybe could be caused by the fluid change or type can't be sure.

3. The transfer case on the cayenne and other vehicles ie BMW x3 has been reported for problems related to hesitation or drive related issues so going back to the spec'd fluid is the baseline idea. The random "faulty four wheel drive" warning also showed itself for the first time shortly after all fluids was replaced following head gaskets work but this also was the same time the temperature here increased considerably. So unsure if related or not to fluid type.

Another line of thought is some Porsche and other brands suffer with crankshaft position sensor proximity to the crank Wheel and the Fix was to use a small spacer to give a little extra air gap and thus "clean up" the wave signal and make the dme a lot more happy with the info received and processed for all critical engine functions.

As the cps is so easy to access and takes 5 mins to put a thin card spacer in, its something I may as well experiment with.

The last thing on my radar is this exhaustive thread ( below) for VARIOCAM "bump" non smooth transition of the cam phasing which is plaguing other Porsche models and the symptoms they have are nearly exactly like what I have. This thread is so long I haven't got to the end yet!

And yes the newer model have "variocam plus" valve lift adjustment and inlet cam adjustment) but they still feature the use of inlet cam advancement just like the cayenne.

So even though I did test the variocam confirming it is working so to speak, it may not be Switching smoothly or at the correct time to produce a smooth power transition and thus the stutter hesitation and also the feeling of roughness when deaccelerating down to lower speeds and rpm just like the engines in the post experience. Idle dip may or may not be associated I'm not sure.

Some people think it could be software related as they have nearly brand new cars but on the cayenne it's more likely a oil/mechanical or electrical / mechanical issue like blockages for oil flow/pressure through small orifices in actuator, oil viscosity vs older engine, cam actuator getting hot and malfunctioning, the cam phasing/timing chain stretched/worn.

Many questions and not so many answers ..........

Has anybody had or found any issue with the variocam on their cayenne?

http://www.6speedonline.com/forums/991/300360-engine-stumble-hesitation-around-2500-rpm-8.html

-

1

1

-

-

Bank 2 precat lambda sensor arrived today will be fitting tomorrow but not getting my hopes up this is the final cure.

I'm also going back to basic of the cayenne engine and looking for leaks again.

Inlet manifold will be coming off and will cut out those leaking rigid pipes at the back the turbo vent. I know they don't leak a physical amount of measurable air on the grand scheme of things so the chances of it being the cause of hesitation is remotely slim.

Maybe I find a crack in the manifold or something drastic! What ever it is, it affects both banks and makes it run lean when warm / hot engine temps is all I know for sure. I did a propane test and can see both sensors show rich, then rev and both go lean. If not this, im back to dme or fuel delivery issues which is baffling me.

Not to mention fuel trim numbers which look to goo to be true maybe? Stft 2.9 0.8 ltft 0.8 1. I think this is because at idle and cruise I have good mixture lambda 1 is showing on both banks but during acceleration or load with Fix throttle position ie going up slope is when you will fell it shudder stutter and hesitation.

No codes ............... : (

-

1

1

-

-

1 hour ago, TJrob2000 said:

I need some help. I started replacing the starter (intermittent no/weak cranking) and have everything apart, but cannot see a way to get the starter out past the coolant pipes (they are the metal upgrade). I'd really prefer not to open the system since there are currently no leaks and I don't want to induce any leaks or have problems with air in the system.

Ah this is a little gem to get out but yes it's possible With out actually removing any pipes or doing anything to the cooling system like draining it.

I have a 2006 turbo but I think its all the same under there.

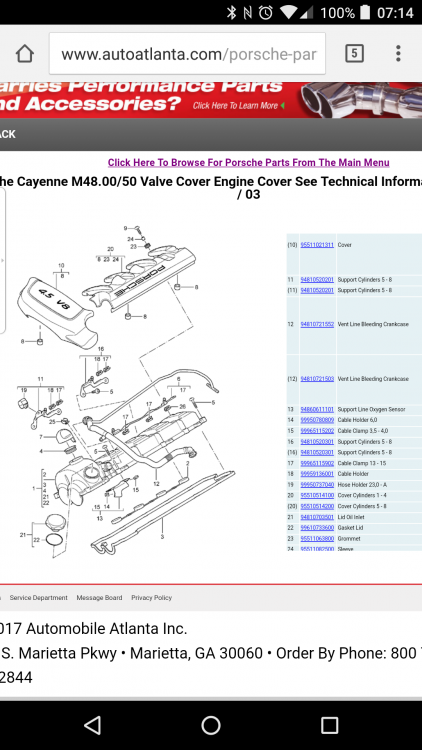

So assuming you had the socket and extensions to get the bolts undone and the electrical connection are removed. Then the starter has to come towards you rotate and lift up at a funny angle. It took me maybe 15 mins of jiggling to work out how to do it. Just remember the spot and angle you take it out so putting it back is easy. I also slackened off the number 19 bolts in the diagram

for the black plastic looking bracket across the back which allowed me to slightly lever up the pipes that gets in the way of the starter coming out easily.

for the black plastic looking bracket across the back which allowed me to slightly lever up the pipes that gets in the way of the starter coming out easily.

Good luck. And if you want to see picture of the starter motor stripped check my thread on alternator/generator fault, I also stripped and cleaned my starter looking for a no start cause which turned out to be a seized newly installed reconditioned alternator. (Never buy recon parts... never again)

-

16 hours ago, ekstroemtj said:

I fixed the wiring with some special glue but i would prefer to replace this entire connection. Can find it in a parts diagram. Maybe somebody can help please.

Hi Thomas

Saw your email.

I think this is the whole Wiring Loom and not a single part you can buy new. See picture either its the Green circle or less likely the red circle hard to tell really from this no descript diagram.

I would try to find the connector with some cable and solder to the existing wires and heat shrink wrap it. Will cost only a few Euro and good as new as long as you solder it well and heat shrink it properly.

This Bosch diesel injector connector looks similar to it? Some searching I bet you can find one.

-

2 hours ago, Doug_B_928 said:

Thanks, Don, for taking the time to look at the info and respond. No loss of interest, just a combination of lack of time and trying to be penny-wise. I visually inspected everything for cracks and put my mityvac on the tester port by the vacuum pump. Figured I'd need a smoker to test better but your carb cleaner idea is an interesting one. If I attempt that I'll wait until it's nice enough outside and will have my wife watching with fire extinguisher in hand :) . Good to know hot film MAFs can actually be cleaned. Air filters in it have always been factory or OEM. I'm aware that coils tend to go at the same time, but inspect them frequently enough that I figured I'd try to save the $ and replace as each one goes out, but it has been in the back of my mind that one or more other coils could still be causing this. The engine strut mount looked good when I did the coils, but I'll inspect it more closely. Haven't checked the motor mounts as I have to wait to get it up in the air. I did the throttle body adaptation re-learn a few times, with no improvement. The 1355 code doesn't provide any additional information. From what I can tell, all I can do is clear it and see if it comes back (which is what happened). The CEL does not appear with this code, at least not yet.

If I remember correctly the possibles for this for other people's fixes was:

1. Coil (swap the new coil from 7 to cylinder 3 and clear codes, its free and a quick check you need to drive a while to be sure though not just around the block, maybe a day or two with a few starts at least 300km).

2. Vacuum leak for sure can somehow cause cylinder 3 to also be the magical problem cylinder on the v8. Don't ask me why but it is.

3. One member had this code and turned out to be the hydraulic valve lifter (inlet or exhaust not sure) was getting stuck. He had all his lifters replaced as a matter of course and problem solved. I don't know who or how it was diagnosed. I don't see how the dme can tell individual cylinder has the issue that accurately, it must be combination of knock and crankshaft sensing as it fires plus lambda signal for that precise time and it cleverly combines the data to work out what the issue is and where.

I don't see the harm in removing the sensor(s) cleaning checking swapping unless when you remove they break, then not so penny wise. Lol.

What i would do for a trouble code ........

-

17 hours ago, PCarMa said:

Glad you got this sorted lewisweller! Those pipes are very tough to get positioned when it is largely a blind fit. I second the notion that I will not miss getting inside the fuel tanks after 2x in...

Ha ha .....have to laugh. Day after car stank of fuel in the morning, so bad I got a headache on short drive to meeting.

Opened the left side cover and see the fuel filter is having a puddle of fuel in it. I'm thinking how the f*ck the fuel got in there and the filter isn't cracked or leaking.

Opened the filter and see the rubber gasket is partly hanging inside the tank and partly around the tank neck hole. I'm amazed how the fuel managed to to get up and around the lip into the cupped filter and didn't go anywhere else! Ta Da, Magical Porsche this one.

Fannied around with it and got it to stay in place, f * king pos , it seem these rubber gaskets even new are too big to nicely fit the aperture.

Anyhow no more leaks and no more smells. Smiley face with rolling eyes.

-

16 minutes ago, Brainz006 said:

That 02 sure does look suspicious and makes perfect sense for your symptoms (only hot and mid throttle, precisely when the O2s are supposed to be doing their job). Fingers crossed you found the issue.

And Yes. The Scanner Danner YouTube vids are highly educational. Completely recommended for learning how to troubleshoot with a scanner. I successfully used that on diagnosing my 997's issues (which as I noted earlier in the thread, I did see a meaningful improvement with new O2s despite low mileage - - I think they got fouled).

I'm really hoping this is it. Good luck

Sent from my Nexus 6 using Tapatalk

What still has my head scratching is why when the sensor doesn't show a peak rich condition the dme identify that as a problem and do something? Seems a basic red flag for performance Mr Bosch, err hello I'm full throttle but sensor says I'm not rich wtf something is wrong Mr dme. And if not showing rich the dme should add fuel short term and long term to compensate!

This is why I'm going to do the propane test because if I didn't learn anything from the last year working on this b * tch car it is that despite finding some real issues they are not proving to be the actual cause of the mother f**k*** "STUTTER" .

-

On 23/02/2017 at 8:39 AM, Brainz006 said:

Diagram 1:

Jet pump: Yes, I believe it's molded into #4, and is back by the firewall at the back of the manifold -- not sure whether the cylinder is the jet pump or the checkvalve after the jet pump, but same area. One thought: #4 has those weird squeeze fittings on both ends. Make sure both ends of #4 are firmly seated on the respective nipples -- it's easy to not get them fully seated.

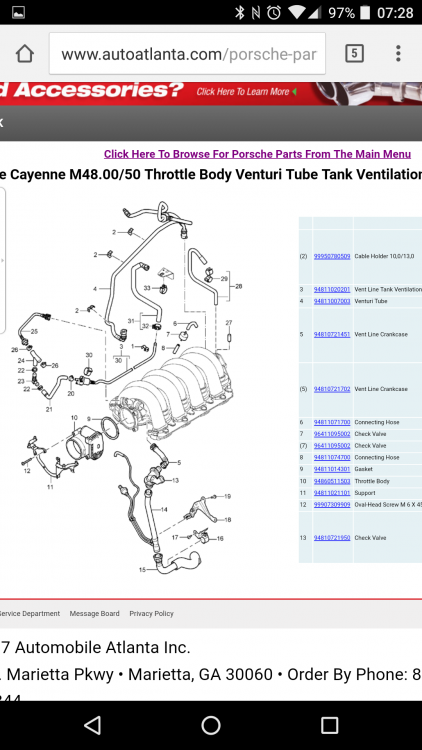

Good that Pipe 12 is new. Can cross that off the list for now. See Diagram 3, Pipe 5 below.

Diagram 2:

Yes Tee 25 is notorious for cracking/crumbling. If you've not replaced that, definitely start by replacing it with a brass or aluminum tee. There are two crimped fittings each on the turbo vent lines 18 and 20 at the back of the manifold -- are those the fittings you suspect of leaking? I remember some modest play in mine, but I don't remember thinking they might leak. I have no idea the exact function of 18 and 20, although I suppose they allow the turbo oil catch tank to breathe which keeps the oil flowing freely to the sump. Strange that you cant blow/suck through them, although I suppose maybe you're trying to blow/suck the oil in the drain line too, which could be difficult.

Another thought: With the engine running, if you place your palm (or a sheet of paper) over the uncovered oil fill hole on the valve cover, is there good vacuum?

Diagram 3:

The other corrugated pipe I was thinking of was #5: As best I can tell, it's the main crankcase vacuum line. If you don't have crankcase vacuum per the test above, that line or the AOS would be suspect. That's big vacuum line. Also check the "turbo check valves" that it attaches to -- it's the "3-leg L fitting" that connects to the AOS spigot. I just had another thought: I believe it's possible to install the turbo check valve a couple ways (but there's only one right way -- the leg you can blow into goes to the AOS spigot on the valve cover). I suppose if you rotated the check valve clockwise one position, the valve would accidentally function as a giant intake leak. It's worth confirming that's not the case.

Lastly, all the little hoses and connectors from #25 to the purge valve are suspect until proven otherwise. It's those hoses that can rub on the belt pulley under the Y pipe. I suppose a quick test of that plumbing (and the purge valve) would be to temporarily plug #25 at the manifold and see what happens -- similar to the purge valve test.

Best wishes.

Sent from my iPad using TapatalkBrainz006

Most of the above is either checked or replaced.

Today I did some interesting graphs of the bank 1 and 2 precat lambda sensors. Scannerdanner is the bomb at diagnosing using data. Helps to have a scope. Big Props to him.

Note: snap throttle test of bank 2 sensor compared against bank 1 sensor shows its not showing a peak rich condition and also produces a steady but lower than normal amperage. Unless fuel is the issue on just one bank then this points at the lambda sensor I believe. If extra air (vacuum leak, pretty hard on a shared manifold to only affect one bank) was the issue then fuel would be added and the lambda sensor would show that.

Driving the car shows something is wrong with bank 2 (old sensor) whereas bank 1 (new sensor) looks to be working great as you would expect.

The first and second screen shot shows me driving at full throttle, bank 2 sensor doesn't go peak rich, it's goes up some but not enough, bank 1 is pinned peak rich high until the gear change which is the Dip then peaks again. So initial conclusion would say this old sensor is just knackered but does enough to not set off a code.

The 3rd and 4th screen shot is the short term fuel trims of bank 1 Green and bank 2 blue immediately after I reset the DTC codes which clears the fuel trims and start the dme learning process. Look how the green line bank 1 starts at rich and then lean adjusting to find the fuel trim setting required. Bank 2 blue line is flat lining doing nothing. So unless I have a fuel/air issue which I'm thinking how this could be on one bank and make the sensor behave like this it can only be the sensor?

This also explain why when driving with the bank 2 sensor disconnected it's makes no difference to the running.

Due to this sensor I'm running lean on bank 2 at mid to full throttle and hence the hesitation!!

Sensor ordered already from AutoHaus 80dollars.

Tomorrow will do propane test to make sure it's not a lack of fuel! Both sensors if working properly will spike a peak rich regardless of any fuel injection or vacuum leak if I'm pumping propane in via the MAP sensor hole briefly lift it up to add.

If this doesn't Fix It I may torch it.

-

1

1

-

-

6 hours ago, Mr.Flip said:

Thank you guys! I tried to lock it with the button on the door to no avail. Locked it with the key and tried to unlock with the handle, same thing. I'll be checking the fuses when I have time and in the meantime I'll just be locking it normally.

It will be the mosfets inside the module are failed or at least one is. I changed both of mine but actually only one was faulty and 3 MELT resistors which correspond to that mosfet. It's not actually a difficult job. Before you tackle this get the dummy key from eBay or amazon or a dealer and see if the internal antenna is working. Read the fault codes for sure something is there. Mouser.com for all the components. But take my advise remove the module open it and check the parts and part numbers first as not all mosfet is the same type. I bought the ones suggested and opened mine up to find different type and needed to reorder, your car will be totally unusable when embed of course so have a second car and assume a week without it I would.

-

1 hour ago, Pkcayenne said:

Can someone check if there vacuum pump ticks ?

Pulsing sort of noise yes but should not run all the time which means leaking pipe, connections or the brake booster is leaking internally itself. You get psm failure light as well?

Looking back through my service history or previous owner Porsche replaced the pipes and brake booster and master cylinder after psm light came on according to the workshop report.

Have you tried to suck and blow the pipe 19 when you pull the hose off the vacuum pump? Check valve in the line should mean you shouldnt get anything either way with just your mouth. If you can blow or suck air then remove the whole pipe and test it off the car maybe split or maybe check valve is stuck. If no leaks then its the brake booster.

-

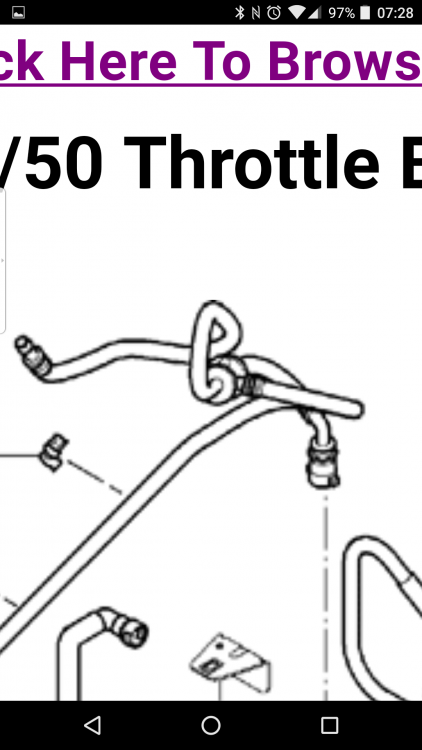

The jet pump is where because I only see a little cyclinder diagram 3 part number 4 (venturi tube), blow up in picture 4 which must be it? Your referring to pipe 12 in the first diagram and yes it new when head gaskets were done. I also leak checked t a few months ago when I had the manifold off and starter motor out. The small Tee 25 labelled in second diagram at the back is the connection to the turbo vent rigid metal lines which leaks. This is the leak I intend to cut all out and replace with a hose and two jubilee clips.

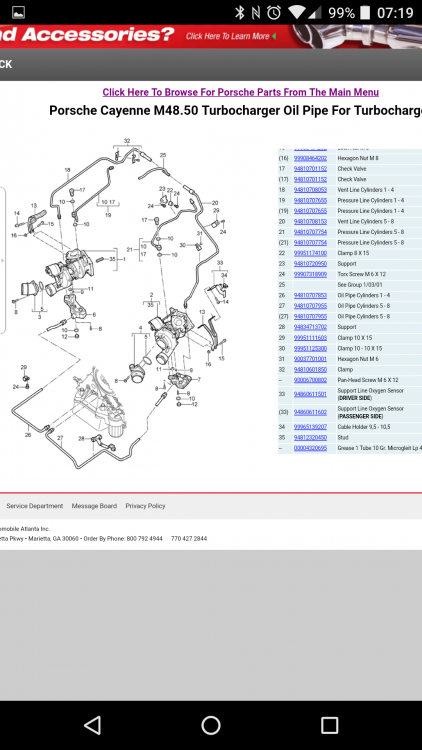

When I tried to blow or suck those rigid turbo vent lines 18 and 20 I couldnt get anything in or out which was strange for a "vent line" ! That oil collection block 6 and 7 must be having a non return check valve or something inside and looks more complicated than it might first seem possibly internally?

-

3 hours ago, Brainz006 said:

Transfer case has a chain in it that reportedly gets stretched over time, but it doesn't make sense that would be your issue. There's also the hi/lo motor that reportedly gets frozen, but from reading, that gives an error light but no drive ability issues.

Here's the piping diagram. Let me know if this diagram doesn't come through in high resolution and I'll PM you.

Your symptoms sound most like the time my line that goes from the Y pipe to the brake jet pump didn't get fully seated under the Y pipe. That particular line also connects on the back of the manifold, but seems like if you had a crack on the manifold side of the jet pump that you'd get a brake booster error. So seems like from the jet pump to Y pipe would be most suspect.

Good luck.

Sent from my Nexus 6 using Tapatalk

Thanks for the diagram.

What is the "jet pump"?

Do you think the manifold has some internal chamber at the rear where all those pipes connect? I did wondered this before but after changing the pipes and checking the check valves everything looked good to go. Am I right in saying the manifold itself has nothing else moving or adjustable inside (like some have variable track length etc)

The more I rack my brain and the more I drive and listen to when its doing the stumbling there is a noise constant with it, this rules out really a drive train type problem for me. It really does sound like a missing pop pop pop but really fast with the rpm. Like the ruler hanging from the table edge and you ping it down then it starts to move up and down and then slide the ruler to make it shorter and the frequency increases.

.png.7a20687b4417f9b7fcb21b70d3bfcc2a.png)

.thumb.png.3cb47557a902cd42da1f452fd3ac6aed.png)

.thumb.png.a5897bc72b89efca9d4ac85b243a5bbd.png)

.thumb.png.065412c31ee6dccdb8fdef1087176b30.png)

.thumb.png.a1179a23d3cf743b9cbda5478241028f.png)

HP Fuel Adaptation Value

in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Posted

You said you checked the fuel system, I'm assuming this included the low pressure delivery and flow as well? Has the fuel filter been replaced at all?