Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

-

Posts

926 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by lewisweller

-

-

On 30/01/2018 at 8:00 PM, cfiiman said:

Hey guys,

So my compressor wouldn't kick on the other day and after trying everything I new to do and scanning with Durametrics and finding nothing I took it to my trusted Indy. He found no faults either and said his hunch was the compressor is plugged b/c of debris and that I needed a new one. He put his gauges on the system and when revving the car the high pressure side didn't move hardly at all and he said it should go way down and that as many as he has replaced he is sure. I trust him implicitly, he is a friend as well. With that said he is moving in a few weeks across the country and is backed up solid, he said he "might" be able to get me in but not to get my hopes up. He said I shouldn't hesitate to do the job and then just bring it to him to pull the vacuum and recharge the system. I always do all the work to all my cars, only the Cayenne has ever gone to him and it is only because I don't have the coding abilities so I am mechanically inclined. He said the AC system is straight forward to remove, but he wants the compressor, dryer/condenser, etc. all replaced because of the crud that shot out of the system through his gauges. He said once it is all out I would need to flush the lines with an assload of brake cleaner. I have a lift in my garage so I'm thinking I'm going to tackle this, not really because I want to but because I feel like there is a definite possibility he will not be able to get me in before he leaves and I don't trust the other hack shops I know of around here. My thought is, if nothing else I can do most of the job so he has time to help if needed, but if I wait that window closes as he is shutting down his shop and plans to be gone by March unfortuantely. Has anyone tackled this job that can give some advice/pointers? I'm trying to get my hands on a service manual now but all I can find is from ebay sellers, if someone else has, or could send me the pages pertaining to this it would be greatly appreciated. I plan on filming the whole thing so it can be a diy for anyone in the future, but any guidance before I start would really help put me more in a favorable mindset. I'm already a little ticked I just bought the car and have this **** problem to deal with :( Thanks for any help!

I had issues with my AC sounds the same as yours, low pressure looks normal but high pressure doesn't move and ultimately the compressor control valve was all that needed to be replaced and worked brilliant after even in hot middle east. No need for 1,000's dollar of parts and labour.

I bought the CCV and had local garage discharge system, swap CCV, vaccum for 20mins then, add 5ml of oil, regas to 1150grams(if 4 zone) or 750grams (if 2 zone).

You can check my post, I think I wrote a decent amount of info and pictures.

CCV is held in with a Circlip and is accessible from underneath without removing anything except the undertray.

Found it after I wrote above.........

-

-

2 hours ago, DAVIDS04 said:

Hey guys,

I just got a 2004 Cayenne S V8. Does anybody know how do I reset the parking brake light? It just came on this morning.

Thank you,

David,

Erm I think you mean the parking brake is saying it's on after released? If so the strut which hold the foot brake lever in place after release is weak and needs replacing. It's a 2 min job if that is what it is.

Easy way to confirm is lift the parking brake pedal up and if the light goes off then it's the strut issue.

Or I'm totally miss understanding what you mean.

-

On 21/01/2018 at 7:42 PM, Mark06111 said:

OK, I changed the crankshaft position sensor and the fault code related to that hasn't returned. It's been about 2 weeks. And the problem of stalling occasionally also seems fixed as it hasn't stalled since replacing that. Since then the hard starting when warm continues, however it's not once been so bad whereas power is reduced after starting. So now although it starts hard, it runs fine once started. Fault code 1023 did return however.

Now I have a full tank of fuel and start further testing. I hooked up the durametric, erased the fault code and then set up to watch the fuel pump signals. Upon start, both activate. After about 5 seconds, fuel pump 2 signal drops to zero as expected. Truck continues to run and no additional faults. Pull fuse 14 (I believe this to be fuel pump 2) and it continues to run no issues. Since that pump isn't active anyway, I would expect that. I replace the fuse then pull fuse 13. Takes about 10 seconds and the truck dies. Watching the 2 fuel pump signals, it seems as it dies fuel pump 2 is activated but the truck still dies. So I leave fuse 13 out, restart. Both pumps get the signal to activate but since fuse 13 is still out it's obviously not running. The truck starts and as seems typical, the signal for pump 2 drops leaving pump 1 signal active. Again the truck dies after about 10 seconds and again pump 2 signal goes active but too late. When the motor stalls both signals are dropped.

Looking at faults, now I have 1632 "Fuel pump "B" control circuit/open - No signal/communication". Also have a 0230, "Fuel pump primary circuit - No signal/communication". So I clear these.

Now both fuse's in, restart. No faults. Pull fuse 14, no faults. Turn off the motor, restart and fault 0230 returns. Since fuse 13 is still in place the truck contuse to run. I put in fuse 14, then pull 13. After 10 seconds the truck dies and registers fault 2632. Code 1023 hasn't returned yet.

So it seems both pumps are active on starting, then pump 2 shuts off after about 5 seconds. This appears to be normal behavior. I would have thought though that pulling fuse 13 and killing pump one that at some point pump 2 would kick in and keep the truck running. It almost seems like that's how it should and want's to work but it kicks in too late - or perhaps that 2nd pump is the problem.

Any insight on this one from anyone?

I suppose the next logical test would be to check the fuel pressure. I don't have the kit yet and don't know yet where to plug in either. I believe I've seen this somewhere either on this forum or on rennlist. I know deilenberger ran into a similar situation and it ended up being the check valve that's part of the in tank fuel filter. Sure seems like a potential candidate, but - would or could that contribute to a fault 1023? I'm assuming possibly yes but am not sure. From what he was saying the check valve should maintain 4 bar for 10 minutes or so. How quickly it should or could fall after that is unknown. I know that if I restart within minutes after shutting down it will typically be a hard start. Same if it's been 30 minutes to an hour.

Jury is still out...

Does anyone know what the failure mode is on the HPFP? What fails only when warm?

https://rennlist.com/forums/porsche-cayenne-forum/986829-2008-cs-with-p1023-error-code.html

This sounds like the same issue. Check valve built inside. Whole hpfp needs to be changed. Watch out for the cheap ones, infact even Porsche had some go bad after only a few 1,000 km.

Some guys are on there 2nd or 3rd hpfp for similar symptons. Expense item so make sure it's that before you shell out.

-

On 18/01/2018 at 1:24 PM, Renzo511 said:

Thank tounJFP . Its 8 degrees here today so i will be waiting a couple days for it to warm up

Just a note. I had an alternator seize up and stall my engine on a roundabout, would not start with jumpers or substitute battery.

A lot of head scratching later I remove the serpentine belt and the car fired right up. Checked all the pulleys and alternator was jammed.

The fact yours ran for 15 seconds is suspicious of something seizing up......or the starter didn't disengage, normally you would hear that though.

-

38 minutes ago, andrewjt19 said:

I don't know would that be a part of that job typically? It was warranty work.

Sent from my Pixel 2 XL using Tapatalk

Well to get to the rear main seal they have to split the engine and transmission and remove the flywheel thus exposing the crankshaft main oil seal.

The torque convertor seal is right there so it's a no brainer one would have thought and only a 40 dollar part.

Maybe they did it without you knowing but I would ask so you know. If in the future you get red transmission fluid leaking out the bell housing holes that's the torque convertor seal leaking and the whole process needs to be repeated.

I had it done on mine before selling it. What a pita.

-

1

1

-

-

On 10/01/2018 at 5:31 PM, andrewjt19 said:

So I recently had the RMS replaced on my 04 CTT at a local indie. I ended up having to pay nearly a thousand extra for additional work that I do not believe should have been completed. The mechanic said I needed a new drive belt, coolant hose, breather hose, valve cover gaskets and spark plug cover gaskets. After cost of parts and labor it was $950 or so. My question (which I think I know already) is why would he be messing around with those items if he was changing the RMS? To do so doesn't require any to end work, right? If I'm wrong please let me know and if anyone has a guide on how to change the RMS on a turbo Cayenne is love to read it over. Thanks.

Sent from my Google Pixel XL 2 using Tapatalk

I hope they changed your torque convertor seal as well or you might be in for a nasty surprise one day.

-

On 01/01/2018 at 6:17 AM, ekstroemtj said:

thank you very much guys. Have found the harness connection behind the air pump. Should be easy to access. It needs a lift I guess to reach the sensor in the bell housing.

HAPPY NEW YEAR FOR EVERYBODY!!!

Set suspension to max height and switch off regulation and there is enough room to go under just, but to be comfortable jack it up a bit as well and use jack stand for safety.

Happy new year

-

Check the flex disc and Propshaft centre bearing for movement.

-

On 30/12/2017 at 5:11 AM, Mark06111 said:

Hi Ekstroemtj. Check this DIY. https://rennlist.com/forums/porsche-cayenne-forum/944275-cayenne-s-957-v8-crankshaft-position-sensor-replacement-diy.html. Take your time, expect some bleeding but yea, it's doable. The smaller your hands the better too. The upper harness I ended up breaking otherwise it was a reasonable job. I'm still not sure if my problem is resolved yet though. Might take a few weeks before I know.

Thomas ours is easier to do as there is no hpfp or harness in the way of the sensor plug harness on the 03-06 ctt. The locations are the same as the diy posted and it helps to have a friend in my case the wife work from the top and you work from underneath, disconnect from top and bottom and pull old one out from bottom. Fit new sensor by dropping it from the top down with you waiting at the bottom to grab it and fit. Piece of cake really compared to other nightmare repairs ie alternator.......

-

1 hour ago, sunlion said:

A cayenne without and engine is not worth anything......perhaps parting it out......?????

Thick Oil additive Lucas for example and auction it.

That's what some independent garages do as well but sell to private buyers offering no warranty. Scandalous I know.

At least in auction buyers tend to be in the trade and know the risks the price reflects this.

Not the most upstanding course of action but let's face it every car at an auction is there for a reason.

-

21 hours ago, Dawdoo said:

all spark plugs and coils are new and problem still again

Check for vacuum leaks. Lots of helpful stuff here.

https://www.pelicanparts.com/techarticles/Porsche_Cayenne_Tech.htm

-

On 23/12/2017 at 2:31 AM, sunlion said:

Yep. Its risky. I'm saving on labor doing some myself and have the help of a mechanic friend and a shop. I looked into used motors but as another mechanic friend said, I already have a used motor. If I walk away, its a huge loss. Another used vehicle is still a used vehicle and comes with risks. With a new vehicle, one essentially commits to spending x amount of dollars over a 2-4 year period. I've got a '15 escape right now and my wife hates it. There is lots of piece of mind getting a new vehicle with a warranty and maintenance included - occupies less brain space for sure.

Either way its pay now or pay later.

I haven't made a decision but I wouldn't go the rebuild route if the labor part wasn't cheap. And I have help with future breakdowns.

Seeing around 5k for that block and pistons plus another 2-3k at least for the work and consumables, head bolts, maybe new valves costing a fortune, gaskets, oring seals vac pipes surely brittle and break, fluids I'm screaming noooooooo. It will cost more than you expect I did double head gasket and spent 6k! The part list just keep growing.

Having bought a 2006 ctt and then having to spend the best part of 7,000 on repairs over 14months I would say don't do it. Your still left with a car of no additional value and your be wishing you sold it and moved on long ago when the next big expensive repair is required.

For example: front diff, transfer case, rear diff, steering column failure and control module, steering rack seals, alternator, AC compressor, DME failure, water leaks Turbo T, pipes under intake manifold, any combo of pumps, sensors etc failure and diagnostics to fix. This is excluding normal servicing, brakes, Tyres etc All costing 1,000's to fix.

Stick it in an auction and spend your hard earned dollar on a less deep money pit.

-

10 hours ago, wizard said:

Happy for you .... but disappointed that my valiant attempt at diagnosis (octane (doh)) fell so flat on its face at the first hurdle :-).

I'll get my coat in future!

Enjoy your Christmas.

Wizard its only been 15 miles you could still be on to something with the Octane ......lol.

I've been so wrong many times .......it's all good.

Merry Christmas guys all the best.

-

16 hours ago, Mark06111 said:

Update: Using my Durametric I've been getting 0335 & 1023 codes. 0335 is crank sensor and 1023 is high pressure too low. The CEL wasn't lit and hasn't been lit. After clearing the codes earlier today and starting up when warm, 0335 kicked in right away as well as the CEL. It took about 10 seconds to start and once started had no power to speak of. The 1023 didn't return yet but I'm sure it will without doing anything else. After starting I turned it off, restarted and where previously (days earlier) it started right up and acted normal, this time it started but was still crappy. I had to drive it and it was just lethargic, no throttle response, max maybe 3500 rpm and after about 4 miles showed 9 gallons per mile. I've never seen it that bad. After turning it off and getting out, seemed to be very hot from underneath with some metallic popping like the CAT's were seriously overworked. After researching the 0335 and 1023's, then checking the rail's fuel pressure set point and actuals, I'm thinking it could be the crank sensor. Driving it today was so bad that I decided to pull that trigger and picked up the Bosch unit from Pelican for just under $70 with delivery by the end of the week. I'll put it in Saturday and report back on the result. Hopefully that's it. For the $70, and with nothing else to go by it's worth a shot before going further.

I think the crank code is triggered as a result of the bad running.

My bet is the hpfp is the real issue here. It's expensive I know, so understand your hoping its the crank sensor at 70 bucks instead. I hope I'm wrong and your right for your wallets sake.

Good luck.

-

On 06/12/2017 at 6:18 AM, Mark06111 said:

For a while now, when warm my 08 Cayenne S cranks fine but takes a while to fire up. Cold is fine, warm is not. And recently after starting power is significantly reduced. Floor it and it takes a while to get to 4K RPM, and that's about it. I'm leaning towards the HPFP but... the last 2 days I smell an electrical sort of smell which could be the started overheating, not sure. But I can't reconcile the starter being the issue when it cranks for 10 seconds then fires and no matter what, RPM's are slow to increase to a max of 4K. HPFP? I'd naturally go there but read too that a fuel filter fixed some issues. Any codes I should be seeing? I'm not.

Lost in CT - I don't want to be lost on the road when it gets below 32F !!

Classic hpfp symptoms, software will show the pressures which identify the specified and actual, this will tell the story more accurately.

Fuel filter can be blocked but less likely.

Low pressure fuel pressure regulator and low pressure fuel pump (left primary) can also cause long cranking and struggling to rev up.

Don't waste money on parts until you confirm the fault.

-

The SAI pumps themselves are prone to impellor damage and sooting up with dirty exhaust Gases that can leak past the check valve.

Could be worth getting a t40 screwdriver and whipping off the SAI and opening them up to check inside and give them a good clean. There is a foam filter also which could be clogged too. Easy diy job will take you an hour remove clean and refit both.

-

On 04/12/2017 at 8:30 PM, Alibenson420 said:

N one more thing... I observed the gears are not shifting n speed o meter guage s not working... This all happened after replacing battery... I checked all fuses n supplies if any person went through same problem kindly guide... I am really pissed

Go see Chad at Motor MEC in Al Quoz and get him to recode the steering angle sensor with his PIWIS tester. Seems the 2004 model year is a pain in the *** for disconnecting battery issue after.

I disconnected my battery on 2006ctt about 30times in a year and only had to drive forward a few meters and all dash lights went off. No fault codes remained.

-

32 minutes ago, Corvetteboy6988 said:

Thanks lewisweller, I have seen some of your posts. Fortunately the dealer gives me a loaner car, but still it's not fun to keep going through this.

I keep rinsing with hot water from my garage house the top of the motor till i see it run out the bellhousing the 2 times now that out leaked. It sounds like its when the coolant sits in there, keeps running down and building up, heats and dries forming crusties that destroys the torque pump seal, I hope.

What happened with the head gaskets on yours, what symptoms did you have, and what caused it? I thought head gaskets failing on these was rare?

So where should i put the rtv? I was gonna use "the right stuff" but ill compare to your suggestion, still wasnt sure where to put, cause i did see you don't want it on the orings.

Yeah bit tricky to get a nice bead around the pipes to block orifice recess area. I think on the pipe only put small amount of Vaseline on the oring so it slides in easy and a wide bead of smeared RTV silicon behind the oring on the pipe itself. Slide the pipe in all the way and then pack the RTV into the gap between pipe and orifice. This maybe be more difficult than it seems access wise.

I did think maybe the flat face inside the orifice could be smeared with RTV before inserting the pipe but not sure it that will work well or not.

I remember on mine under the manifold one of the pipes had a hard resin type sealer on it, which worked but wasn't the oem type approach and would never come apart again I doubt.

Head gaskets symptoms loss of coolant and overheating at idle, if you rev the engine it will cool down to normal and the cycle repeats.

Was blown between cyclinder 2-3.

Torque seal, yes exactly how it happens dry crusty then seal is deteriorated and leaks.

Good luck.

-

On 01/12/2017 at 5:17 PM, dyazdani said:

I recently had a CEL pop up with the following:

P2187: System Too Lean, Bank 1

P2187: System Too Lean, Bank 2

P0507: Idle Air Control RPM Higher Than Expected

P0302: Cylinder 2 Misfire Detected

Symptoms while driving:

Rough idle

Rough Acceleration

"Cruising" (i.e. no acceleration) is normal

Fuel consumption is poor (relative to the norm)

I just had a number of items worked on including air filter, cabin filter replacements, and spark plug replacements.

For both banks and idle codes, I'm thinking there could be a leak in the intake somewhere. I doubt both MAF's could be the issue. Also not ruling out the need for new coil packs, as I can't say that mine have been replaced.

Any help or ideas would be appreciated.

Intake air leak for sure.

Check the Y pipe and it's fitting underneath pipe 4, check the connecting pipes jubilee clamps are tight, check the smaller pipes connected to the throttle assembly are all connect properly. The pipes are prone to splitting also.

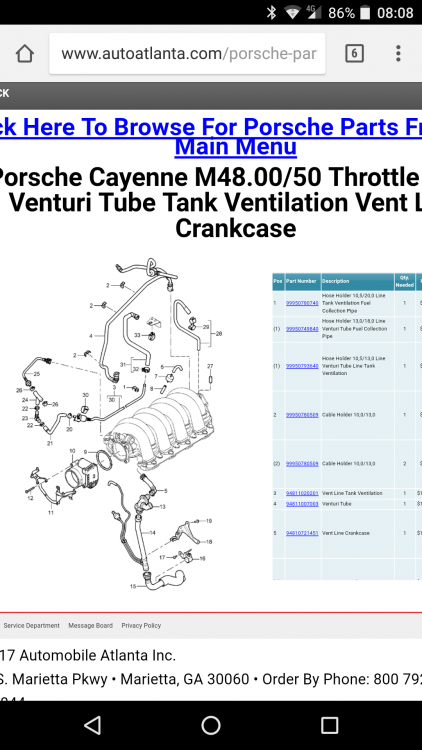

Check 25, 14, 13, 5, 4 oring 9 can leak but don't make sense that it would assuming they didn't remove it, check 24 directly under the throttle assembly is not rubbing against your water pump pulley.

If your still stuck smoke test your intake. Search my posts about that. Simple home made smoker.

-

10 hours ago, Corvetteboy6988 said:

Hello all, I purchased my first Porsche, a 2005 Cayenne Turbo in Sep. has 44000 miles and mechanically is in great shape, no issues. With the help of this forum I budgeted to replace the coolant pipes with the upgraded alumn ones after purchase. I called around for pricing, went to a local ex porsche dealer who still has their master tech, and got them replaced.

This was done proactively as the original plastic pipes were not leaking.

About 500 miles later, lost a good chunk of coolant, out the bellhousing weep holes, the very thing i was trying to avoid.

Dealer said pressure tested and leaking where main coolant pipe enters the block. The after market pipes orings appeared flat instead of round after removal, I sent the pipe back to the manufacturer, and they indicated the orings where softer than they should have been. So, plan was to replace with OE porsche pipe and orings so did that. All other pipes where fine, even the main couple at back distribution bank.

500 or so miles later, small drip or 2 out the bellhousing, andc the smell of coolant. Back at the dealer currently, and leaking again at the main pipe and the double orings where it enters the block, not as bad this time.

The tech cleaned the mating surface in the thermostat housing good, but he mentioned it was a bit rough and pitted from corrosion and thinks that's the cause for the leak.

Any ideas, what else can we try, is there something we might be doing wrong. Everyone is saying this is the first tune this had happened. Ive read other posts of pine hole leaks due to bad castings, or loose clamps, etc. But not this.

Should we use rtv or an anerobic gasket maker on the mating surface?

The current plan is to fine polish the mating surface in the housing to eliminate the pits, I just don't want to remove too much material so using very fine grit wet sandpaper like 2000 or 3000, then we are gonna try the Hamburg Technic pipe from ECS tunning. I got the Porsche lube as well to use sparingly. That will happen this Monday.

Also, why would it pass the pressure test once the job is done, then last for a while, then leak?

Ive attached some pics.

Looks like they damaged the right top side of the opening a bit by prying to remove the old pipes, but its way outside the oring area.

I love this truck, but ive hardly even been able to enjoy it, and regretting being proactive but know in my heart it was the right thing to do.

Sorry for the long post, but need done help.

Btw, the dealer suggested possibly needing to replace the top of the block to correct this, wow.

Wow bad luck my friend.

Without trying to be too negative one of the problems if coolant leaks and drains via the bell housing is the torque convertor seal will started to leak transmission fluid. An engine out job is the Fix. Ask me how I know and ask me how many 1000,s I spent on my 06 ctt before giving up and selling it on before I had even more repairs. (The major ones ....Head gaskets, alternator, battery x3, power steering rack end seal leaked all fluid whilst cornering, kessy module, torque convertor seal all in one year). Read all my posts if you want to get depressed.

Unless you have a lot of money and a spare car to use whilst this is in the garage frequently, I would get this coolant pipe fixed and sell it on.

If the surfaces are pitted the oring won't seal. If you remove material you will need thicker orings possibly.

Use this RTV silicon to seal the gap between aluminum parts but don't get it on the oring.

Suggest you remove and reinstall all those new pipes and orings whilst it is all apart again.

-

4 hours ago, ekstroemtj said:

Thank you Lewis. The Hitachi is fitting without correction of the water cooling lines?

Hitachi should be what's already fitted and yes doesn't required any modifications and is small enough to fit though the tight space you will have to turn and drop it though.

Top tip:- the way you take it out remember the angle and position so when you put in the new one it goes in easy.

The other brand Delphi is a total b * tch to install or remove as it's bigger!

Never again .............

-

4 hours ago, ekstroemtj said:

@Lewis how long did it take for you to replace?

i remember you was very disappointed

The second time was much quicker and having the Hitachi brand which is the right size to fit through the small space.

It takes about 3-4 hrs to get it out if your not familiar, once you know, it can be removed in 1.5 hrs I reckon.

Either way it's a whole days work to remove and refit new.

-

6 hours ago, Zakowsky said:

It's late here and just returned from a test drive and so a quick update. You were correct Lewis, looks like I should have just replaced the N80 to start with. And thanks for the tip Thomas - those were the kind I was going to get. Anyways I really needed the car tomorrow and was looking at the $150 one sitting in the garage and just said ok Porsche wins this round. Installing it was a lot easier than taking the old one out; fired it up and cleared the codes, drove for 30 minutes and no codes came back and actually didn't smell any oil anymore. No bumps or hard braking, will test that out tomorrow, at least fool myself it is fixed for one night! But the idle is noticeably smoother and it even the "Evaporative Emissions" readiness check was green, something it hasn't been in a long time. Will see how the next few days go but looking OK. And btw I was wrong about the mechanical air pump; on the turbo with the electric ones there is no mechanical one that runs off the back of the camshaft.

We have a winner.....hopefully.

Good luck tomorrow, cross your fingers on the humps .......lol

Cayanne S 2004

in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Posted

https://www.pelicanparts.com/techarticles/Porsche-Cayenne/17-BRAKES-Parking_Brake_Strut_Replacement/17-BRAKES-Parking_Brake_Strut_Replacement.htm

Item 23 mate