Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

hankster66

Contributing Members-

Posts

29 -

Joined

-

Last visited

About hankster66

Profile Fields

-

From

Mountain View, CA, USA

-

Porsche Club

PCA (Porsche Club of America)

-

Present cars

2000 911 C2

-

Former cars

2000 BMW 540i

2006 BMW 330i

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

hankster66's Achievements

Member (1/1)

2

Reputation

-

Hi JFP, Project Update... good news, bad news. First, I just want to thank you for all your advice along the way. I did end up sending the heads to Len Hoffman; unfortunately, not until after doing some DIY trial and error that could have been saved if I just sent it to him to begin with... but better late than never. Good news: Got the car up and running. Felt great completing the project, and getting the car on the road with nothing "blowing up"! Bad news: durametric telling me a slightly different story about my results. Throwing o2 sensor fault codes ahead of cat P0150 (bank 2) and P0130 (bank 1). More concerning is my timing being off: Bank 1 -4.97, while Bank 2 is 0.00. I had taken the car for a few short drives to ensure fluid levels, oil pressure, etc. I put the durametric on it after a 30-minute drive at idle. On background, I changed all the IMSB/RMS, tensioners, chain guides, cam-to-cam chains, lifters, springs. Before the work my deviations were Bank 1 (-10.44) and bank 2 (-5.64). Don't know if it's coincidence or means something that the difference between the two banks is roughly the same before/after, and bank 1 continues to be the only/bigger problem. I find it interesting that I could even get bank 2 to perfect 0.00. Some have suggested that the long chain may be at issue, but since I'm in spec to just leave it alone (for now). Bank 1 seems to be on the outer end of the spec, so I wonder how long it will be before it's out of spec again. Curious if you have any thoughts or suggestions.

-

Working on a 996.1 C2 head refresh... replacing springs, lifters, etc. and doing the valve job. I can't seem to find a micrometer that fits the spring base, regardless of the height range. Tried the ProForm 66902 and 66903 valve micrometers, which appear to be licensed under other vendor names, but base are too wide. I know I can do the measurement with a standard micrometer, but wanted to do it with something that has less variability. Anyone ever do this or have an idea?

-

Thanks for looking it over. I had pulled the sump early on as part of the LN checklist, including borescoping, etc. Found some particulate in filter (normal levels) but the sump was clean, except for some plastic from chain guides and a quarter-sized non ferrous piece of metal that everyone confirmed was a leftover from the manufacturing process. That's what drove me to go into the lifters to eliminate possible issues there. Like here, I had sent pics to LN to verify everything was ok before proceeding. As I tore down the engine, I did not find any particulates elsewhere in the engine... nothing in the heads, cylinder walls, on the chains, and never saw anything in the oil draining in the collection pan under the engine as I rotated it on the stand to do work. Everyone was speculating that I had the dual row, which is not always the case in these 2000s from what I've learned. Fortunately it was the more robust one that kept this engine going this long (90k). I guess I was lucky to have the clutch go out so soon after purchasing the car as it forced me to do this work probably much earlier than I would have otherwise.

-

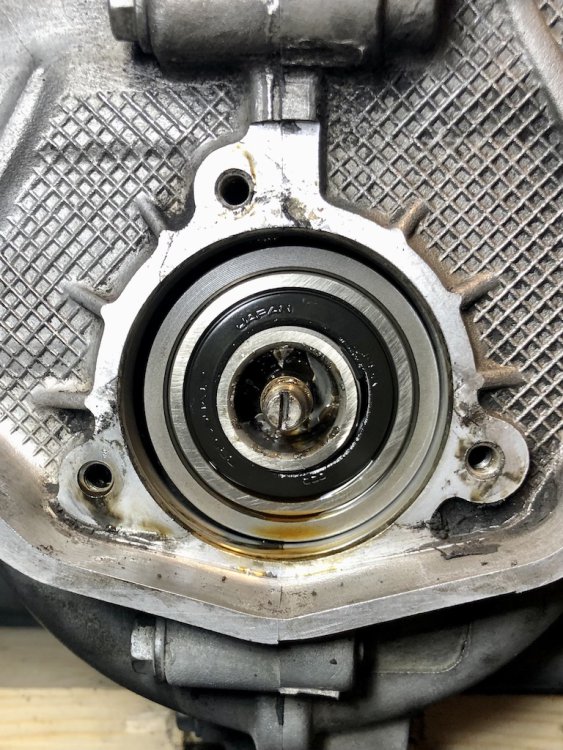

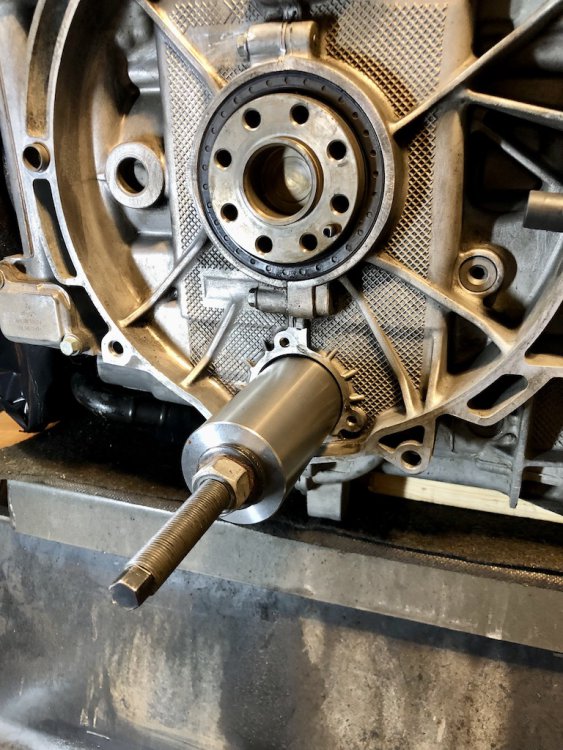

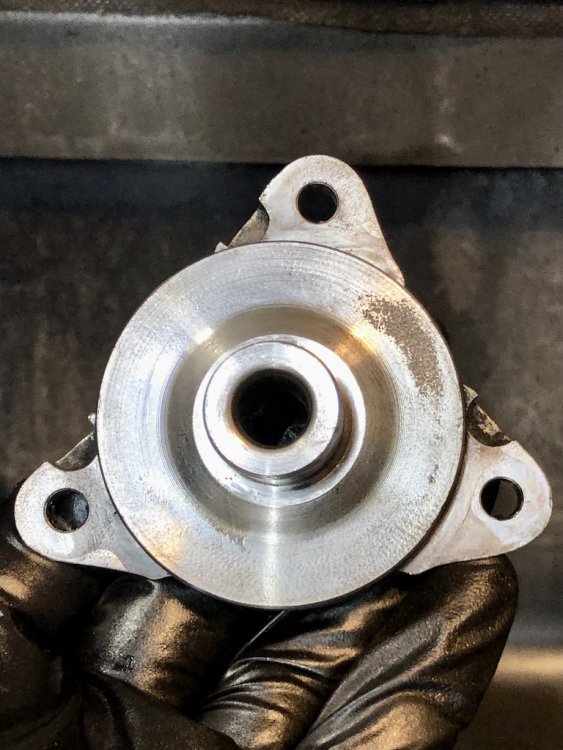

Pulled out IMSB, pics below. Everything looks like the bearing did not fail. Bearing spins, but not freely or necessarily as smoothly as it probably should. Some movement fore and aft, less so laterally. All bearings seems to be in tact, but some of the balls have loss of material, which likely explains the particulate I found inside the shaft. Curious what you think about the pitting on the inside of the flange and the black scuff marks on the out race of the bearing and inside of shaft end. It seemed to clean up nicely. Is the particulate I found normal or an indication of the bearing due for replacement?

-

Thanks JFP on recommendation. Having an exchange with Len and obvious after a few exchanges why you are recommending him. I was wondering before I keep going, if ok to do the IMS work now, my reasoning being if I discover issues with IMS, I may have to rethink what I'm doing with this engine. LN instructions call for locking cams presumably because most scenarios assume heads are in place. Do you see any issue with pulling and replacing IMS bearing with heads off if engine has been locked at TDC and chains are secured against the guides... or do I need to wait to have heads back on w/ cams, etc.

-

I attempted to spot check variation, and there appears to be some, but very difficult to confirm with springs in. Essentially, after thinking it through, I agree with you that I have to remove the heads. Even with the cams out, I'm getting air out of the exhaust, so have to resolve that. In addition to my question above regarding timing, questions below about head job... - Would you recommend I take the head to machine shop for resurfacing? - Is there anything I should do with the head before taking it to the shop? - Unless I find any obvious defects with guides, stems and springs, plan to reuse? Is there anything here that you would replace regardless? - I was thinking of lapping valves myself and checking that they properly seat and measuring for installed height, etc. Seems straightforward, but your thoughts? - Saw one of your old articles commenting on replacing head bolts. I see mixed comments and references to later 3.4 (mine is a 2000 C2) not needing to replace head bolts, especially as they don't seem to be a failure issue. I will likely be in this engine again (hopefully not to soon) to refresh the heads/rings and just wondering what I can get away with for now.

-

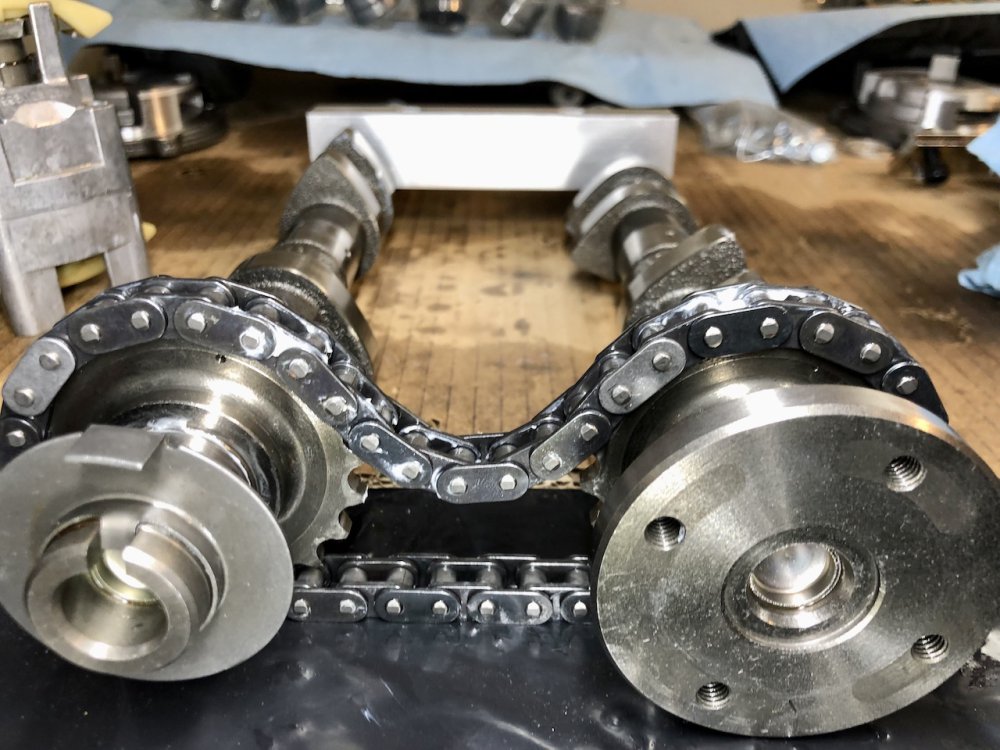

When installing... - confirmed correct cam allocation - lined up link to cam marks - assembled vario cam / cams, and checked link and mark aligned before/after install - put cam tools in place - torqued down variocam and caps - set long chain to sprocket to exhaust cam - released variocam compression tool - installed tensioner (pumped with oil) - torqued down sprocket bolts - confirmed timing marks - rotated engine 360 at TDC - confirmed cam timing with timing tool (but can't recall if I checked links / marks) Below are pictures of cams with chain in time and then after I rotate two times until cam notch is facing up (out). Again, outside of engine, confirmed cam allocation and even double checked that the new chains were exactly same as original, and that there were six links between marking links. Is it that the cams have to rotate x times before they return to the original alignment?

-

So I disassembled both banks to measure valve install height and I noticed that on both banks I was out of time (chain link to cam mark) on both banks. I assumed that they always lined up as the cams rotated back to TDC. When I took both cams out and removed the variocam to orient the chains to the cams again, I rotated by hand to see what happened and they don't line up after multiple rotations... had not read that anywhere. On the outside, both sets of cams remained in time (cam tool slotted in perfectly). Can you confirm what the behavior should be on the chains?

-

Thanks for taking a look. So I guess my next move is checking installed height. - I saw that the way to do this is with spring removed, but wouldn't measuring them in be similar or is the issue measuring from the space covered by the spring? - As I understand I'm looking for deviations from cylinder to cylinder, but is there also standard spec or range for installed height in these engines? - If by chance I see no deviations, I may still have to go in to resolve, but is there anything else I could have done in the assembly that might explain this?

-

Isn't it odd though that multiple cylinders are leaking when there were no issues prior to disassembly. Assuming they're not burnt, I can see how something in the assembly process has hung them open, but again odd (although this is new to me) that multiple cylinders would be experiencing the same problem that was not pre-existing. If issue is hung open, is the only remedy taking the heads off?

-

As a follow-up. I replaced all the lifters, set both banks timing as instructed. Confirmed respective cam notches and lobes are pointing appropriately at TDC... Everything looks good. My main concern now is if there is a simple way for me to validate that everything is operating properly. I tried to do a leak-down test (as that's what I have) but seem to get considerable air coming out of exhaust. I knew I would get more air escaping than when I did the test before disassembly because of lack of oil, etc. but not as much as I'm noticing. The only thing I can think of is that lifters may have leaked and will not "set" completely until engine is running. I just want to eliminate any potential mistakes I may have made.