Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Zakowsky

Members-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by Zakowsky

-

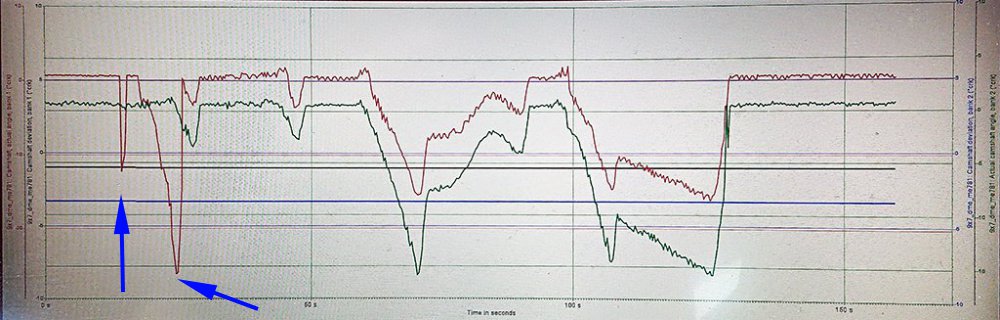

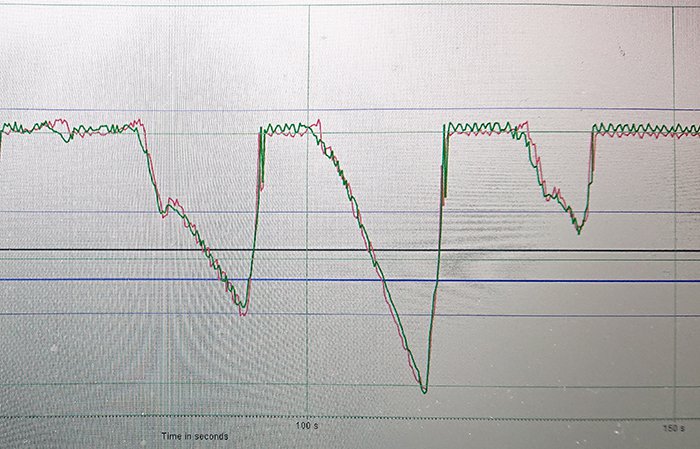

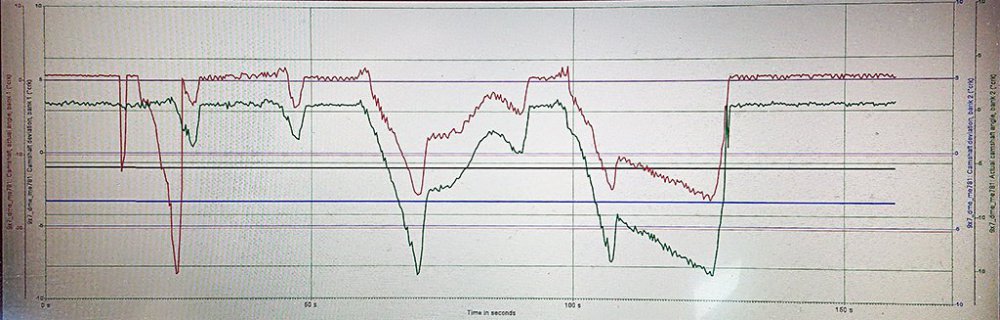

Interesting, thanks Loren. I believe the 996TT uses a slightly different mounting system than the 997TT, but the idea that this could play a role is something for me to check. I feel pretty dumb, but I figured out the shift - I had no idea the PIWIS auto scaled each trace separately - duh. So they are in fact not shifted. But unfortunately I still get the P0021 coming right back. I think the problem is that although it tracks most of the time, there are times that Bank 2 just doesn't respond at all like Bank 1 - so in that graph like at the arrows. Looks like the variocam is sticking sometimes. Is there any oil "flush" that is safe and useful for this engine? I used SeaFoam on my Jeep, but not on the Mezger...thanks.

-

Thanks Loren, I have read through all the documentation on this, and scoured the online resources. Just wondering if anyone has seen these kinds of logs before - I believe the variocam works by the oil pressure from the holes in the camshaft sleeve shifting the helical gear in the adjuster one way, and the oil from the solenoid pushing it back the other. So since the timing shifts both ways fine, it seems these circuits are OK. So the only way this could be the variocam is if maybe the bolt that holds it on the cam shaft is loose maybe? And that causes the offset to come and go? That would mean it would be bad to even run the engine, I would think. But you would think there is a pin or something to hold the variocam to the camshaft...thanks.

-

Hi all, I used to contribute a lot here regarding the Cayenne TT, but I haven't posted in years - my Cayenne Turbo went the way of all things and now I have a 997.1 TT to fill my time. I am really at an impasse now, and as I saw some threads regarding the P0021 situation here I was hoping Loren or JFP or anyone might have some experience with something like this. I had a P0021 with the Signal Implausible clause (read from a PIWIS 2) after a 3-4 shift at WOT with a puff of black smoke out the back. Sure enough Bank 2 did not respond any more to throttle blips. I replace both actuator solenoids, and the solenoids and actuators seem to be working now. But after driving for a while I would see the offset between the 2 banks jump all of a sudden, and bank 2 occasionally not track bank 1 If I stop logging and reset the PIWIS they start moving in sync again! Which I thought might be the PIWIS, but the P0021 comes right back when this happens, so it seems real. So I was previously worried obviously about spun cam sleeves, but if the solenoids and the actuators are working, then that seems less likely. I am at a loss for what to try next, the only things I can think of are 1) Camshaft position sensor is faulty - but that should generate a different error code, shouldn't it (like P0343 for bank 1)? 2) The camshaft has jumped a tooth - but then wouldn't the offset always be the same? 3) Something is sticking inside the Bank 2 actuator. To note, when I replace the solenoids, I found that the Bank 2 solenoid had not been installed properly, so it is possible it had had compromised function for some time. So maybe the bank 2 actuator works to adjust, but the base offset gets stuck? I am not sure how the actuator is designed. Any ideas would be appreciated, before I resign myself to tearing this all apart. Thanks, Mike

-

Your best bet is to buy the CANBUS decoder from the manufacturer of your HU, assuming the additional harness is for the adaptor. The CANBUS decoder will be specific for decoding your model vehicle, and communication with the HU specific to the HU manufacturer. Just so you know, it might not work perfectly, as the Porsche CANBUS is a bit different than most it seems. But if you don't have a CANBUS now, I don't know what would be causing the clicking...I'd sort that out first and make sure it isn't a current draw, especially if it happens when the car is off and the key is out. ACC switched taps in the fuse box are not easy to find - where did you connect it too? If you just connect the HU ACC line to the power line, does the clicking go away? If so maybe your tap point isn't ideal...

-

If your new HU has a supplied CANBUS adaptor, they can use different protocols to keep the bus alive when the vehicle is off but the key is still in the ignition. The first adaptor I tried did the same thing, kept clicking a relay in the dash. But the company sent me a new one which worked by a different method I guess and it doesn't click. The fact the SWC don't work also suggests the CANBUS unit is jacked. But the clicking never seemed to be anything but annoying, and you can use mtcdtools or the equivalent for your unit for the buttons if WheelKey doesn't work.

-

There is a bit of a trick to it - if you feel around back of the mount, there is a small spring loaded lever that drops into the slot on the roof rail when it is in the correct spot. On mine, if you push this down a bit further so it is firmly in the slot, the side closes easier. If you have to force them, the locking lever might not be exactly lined up in the track. I practice, I just push the back lever down and shake the rack back and forth a bit until it feels exactly settled correctly, then the sides snap closed easily.

-

I'm going through this as well - bought some non-Osram D1S bulbs (wanted 8000K...) and they seem to have toasted one of my ballasts. Live and learn... The pictures you posted are of the calibration procedure your new Valeo units need, however although VCDS will perform a lot of functions on the Cayenne, I can not get it to communicate with modules 55, 29 or 39. Plus I don't think Durametric communicates with them either, so this has to be done at the dealer. The only way around this are supposedly to buy used LAD5G ballasts/control units. I would imaging this works (if it does in fact work) by virtue of a "calibrated" bit being set in the control unit. Although I am surprised the main ECU doesn't also check for a known, calibrate serial number on the ballast. If you run a ballast from another car without calibrating it, I suppose the vehicle it came from should be the same in terms of having air suspension or not etc., so the lights come out at the correct level. If you are still working on this I can post how it goes with an older replacement unit.

-

Just realized we are having the same conversation on Rennlist! Here is the link to the pdf, which has a link to the site, for people here. http://trioma.ru/products/most/pdf/most-amp3.0_eng.pdf If anyone has experience ordering from these guys it would be great to hear about it. Apparently there is a new version 4.0 with is improved. About $160 US.

-

If you are replacing the amp, consider not putting a Bose back in - get free of the MOST system while you have the chance! With a nice (and expensive) HU like the AVIC just run RCA lines to the back and put in something like a JBL XD600/6. With the MOST adaptor you do not have front/back fade control, and in my CTT anyway it really needs the sound shifted to the rear speakers. Plus the sub performance is questionable. This is what I am getting around to doing with mine. Lots of threads online of people who have done this.

-

Just to finish this for people searching for oil smells and such...the new Porsche N80 valve solved the errors and the engine is running smoother than ever. The oil smell blowing out the vents when I went over a bump, or slammed on the brakes, was just as strong right after the fix, but over the past week has faded to almost (but not quite) nothing. So I suppose the oil vapors that blew by the valve when they were not supposed to condensed and collected somewhere, and were splashed loose when bumped. That reservoir of crap just took time to slowly clear out. So engine is quite good now. But don't worry, still things wrong - driver side door open/closed micro switch is not working, which doesn't seem that big a deal but things like the fuel pump not turning on early can lead to misdiagnosis, plus it is really easy to lock your keys in the car because it re-locks the doors thinking you didn't get in! Should be time consuming to get to the door latch. Plus a replaced cable for the passenger window sounds like it broke again so all that has to come apart. Would be nice to be worrying about what kind of wax to use for a change!

-

Quick note - codes are still gone but it didn't help the blast of oil smell unfortunately. I hope the codes don't come back too. Looks like they were maybe unrelated after all. Still have the Secondary Air Pump not ready warning that has always come and gone. Maybe the oil is something to do with that. Edit: Over the course of the day the smell is getting less and less. Perhaps wherever the oil pooled is slowly getting cleared out. So still hope. And it is definitely running better.

-

It's late here and just returned from a test drive and so a quick update. You were correct Lewis, looks like I should have just replaced the N80 to start with. And thanks for the tip Thomas - those were the kind I was going to get. Anyways I really needed the car tomorrow and was looking at the $150 one sitting in the garage and just said ok Porsche wins this round. Installing it was a lot easier than taking the old one out; fired it up and cleared the codes, drove for 30 minutes and no codes came back and actually didn't smell any oil anymore. No bumps or hard braking, will test that out tomorrow, at least fool myself it is fixed for one night! But the idle is noticeably smoother and it even the "Evaporative Emissions" readiness check was green, something it hasn't been in a long time. Will see how the next few days go but looking OK. And btw I was wrong about the mechanical air pump; on the turbo with the electric ones there is no mechanical one that runs off the back of the camshaft.

-

You're right Thomas - but I just went and bought the new part, and when I got home and looked at it, it says Bosch on it but it is Made in China! Plus it has the white paint on it like a remanufactured part. If Porsche themselves are selling non-OEM parts what are you supposed to do any more. I can still return it, and maybe order it from Germany or something?

-

An update - inspecting the EVAP stuff in the rear wheel showed no sign of problems, couldn't find any leaks or broken wires, so I removed the N80 plus the hose from the engine. It was a PITA as there a lot of plastic there I didn't want to break. Anyway once removed it I tested it again and found that sure enough, when I hit it on one side it would open, then when you hit it on the other it would seal closed. Explains why it would throw codes after going over bumps. Tried to clean it out but no luck, and I can't crack the casing open without destroying it. Has anyone tried using a VW or Audi N80 instead? The Bosch part number of the Cayenne valve is 0280142398, which only matches up to the Porsche version. Touareg's use one that looks identical but the Bosch number has a different last 3 digits. Reason being is you can get the Touareg one for like $20 online, and here in Canada the Porsche N80 is $148. Either way this should fix the problem and I can finally get this back on the road.

-

Well this is great. After no errors or smells for 2 days I was feeling more positive about this – until it started stinking constantly today and the CEL was for a new version of the code, P0455 - 001 - Large Leak Detected. But what I’m wondering now is maybe the two are unrelated functionally, so like if a bump causes the oil smell, it also jars something else that causes the EVAP problems. And now two problems are stuck open. So I just picked up my #4 gaskets ($50 in Canada for basically 2 o-rings btw) and will seal off the valve cover leak tonight. Then if I still get the smell and error, it’s something else up front so replace the N80 valve; if no smell but error code then it must be at the back in the EVAP canister (as the gas cap is fine). It would be great if the gasket oil leak is also causing the EVAP leak, but I probably won’t be that lucky. Would be nice though; we can’t use the car until this is fixed. Edit: Installed the new seals, valve covers are clean now but on a trip out for gas there was one more blast of oil smell when stopping at a light. No error codes...will have to run it for a few days and see what happens. Maybe residual leak. But I did find an interesting thread where someone had similar problems with the codes and after replacing the usual items for this it turned out to be the mechanical air pump. Didn't even know this had a mechanical air pump. And its right at the back passenger side where there is that pipe that has a bit of oil on it always. I took the electric pump off and still couldn't see it even with a mirror, don't know how you would work on it, but even Pelican says it can leak oil externally and into the air supply.

-

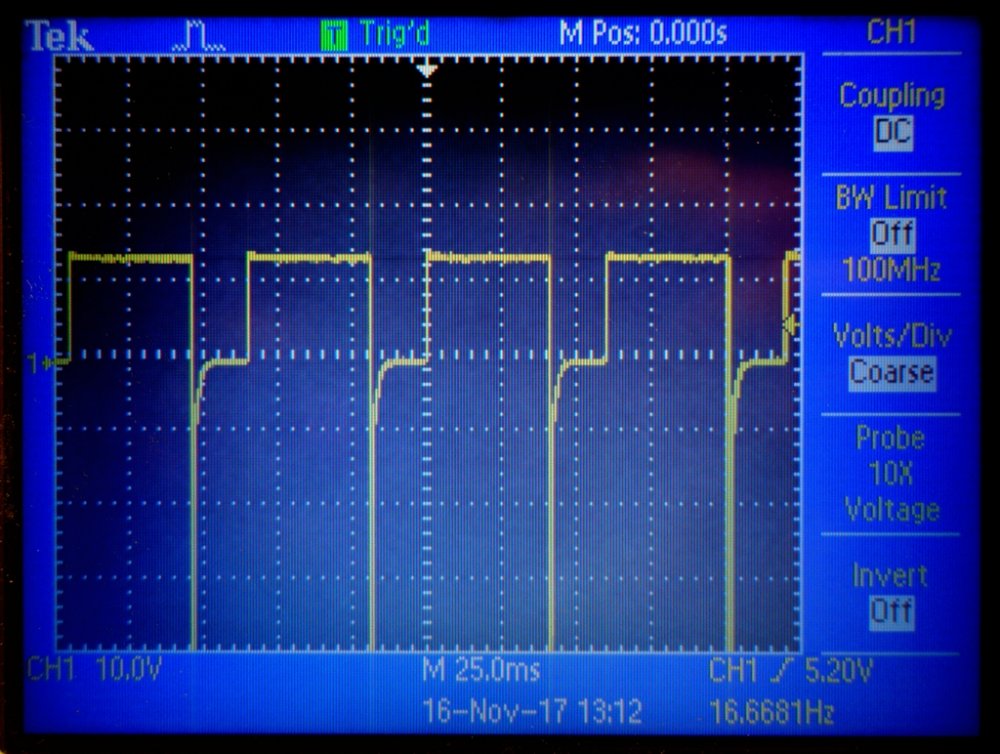

It's hard to see, but the scale is on the bottom left, 10.0V per major division - CH1 / 5.2V is just the trigger voltage for the scope (the small arrow). I still don't like digital oscilloscopes… Interesting link - I wondered about this about the N75 as well, thanks. Hah! True enough. So I did clean it and made sure everything was tight and lines were in their proper place with no stress on them, and the errors have gone away for several hours of driving now. Even the Readiness is back to normal. There is still a much fainter (but still present) smell of oil every now and then, so I'm thinking I just improved things enough not to trigger a code, but there is still some leak problem. So I might go ahead and get the valve and see if that helps things. The only other candidates I have left is the AOS diaphragm not functioning correctly, but I have already broke two of the tabs on the cover and I've tried but can't get it off without stressing the remaining tabs so much I am sure they are going to break. A heat gun would help, but I don't want to melt the membrane and then have to wait for another one from Russia. But if you miss working endlessly on your Cayenne, I also have to take the passenger door apart again because the replacement window cables ate themselves and now it needs to be fixed again. And I just realized that my drivers door open/closed micro switch sensor needs fixing. I never cared that the light didn't come on when I opened the door, but now I am realizing that the key weirdness's I've always had could be due to it thinking the driver's door hasn't been opened. Plus there is the fuel pump that doesn't turn on when I open it and slow starting…its all so connected. Speaking of which did your VAGCOM ever access the door electrics controller? I can't make a CAN connection to it for some reason. Was that a controller you had access to?

-

Not positive, but I think the valve is supposed to work like this, turning on and off rapidly to mediate the flow, much like the N75 solenoid. I can't hear ticking when the engine is running, only if I listen carefully when the engine is off and I apply external battery power. The odd thing is after putting everything back together last night, it stopped throwing error codes again. The smell is still there, and under "Readiness" there is still a fault with "Evaporative Emissions", but no codes. So maybe this is something at the front rather than the back after all. Curious about those negative spikes though. Will see how it goes over the next few days.

-

Thanks Thomas - I checked the wires and they are fine. Maybe it’s the cold and hostile wasteland of Canada, but the wiring on this vehicle is in really mint shape. Anyway to be certain of all this I patched in the oscilloscope into the circuit and monitored while running: So a good 13.7 volts are getting to it; when I hook it up to a current source it clicks and opens and closes smoothly and without fail, and when I accidentally disconnected it while the engine was running I got a P0444 - EVAP Purge Control Valve (N80): Circuit Open error, which I have never seen before. So the only chance that it is the N80 valve is if at 16 Hz it somehow fails. Anyone who has monitored solenoids like this before, is that big negative spike normal? I am figuring it is just an artifact of the probe, or does it indicate that the N80 is drawing too much current when closing? I can't hear the valve when the engine is running, but its right next to all the lifter noise. Btw I checked my fix of the one-way valve 4 times - took the Y-pipe off and disconnected the T hose, so not disturbing the one-way valve, and it was working perfectly each time. So if everything is OK up front, I guess I have to go look at the EVAP canister itself? Is it in the rear wheel tub or something? ****.

-

Thanks Lewis; it seems the vacuum pump is working fine, pumping the brakes caused it to turn on as described...I also tested the white one-way valve at the back and it seems to work. And it makes sense that #4 is open to the manifold. But now seems I've screwed something up blowing air maybe through the system, as the error code instantly returns now, even though the valve at the front is working fine. When I clear the code the engine changes its sound quite a bit, not in speed but it sounds like the flow of air changes. And once the vac pump came on when I cleared the code, so it seems I have even more to figure out now. Edit: took the morning to test the n80 purge valve and it works perfect. Other one listed is a N115 valve, but I don't think the Cayenne even has one. Tonight I guess I'll look for the EVAP canister itself.

-

So do you still get the oil smell Thomas? Because the more I look into this the more I think it is an EVAP system problem not a leak. I fixed the check valve - if anyone is interested they do come apart if you pry at them: You can see the center of the diaphragm was ripped out - some glue and a small piece of latex glove backing and it sorks like new again. But the problem isn't fully solved. Drove all day and didn't get any error codes, and didn't smell oil. But I went over a hard bump, smelt the oil and then pulled over and check for codes and sure enough the P0441 came back. So I'm thinking the oil smell must be some venting of the crankcase. The check valve seems like it was part of it, but there is still something else going on. Lewis, do you remember the air flow through hose #4 on your diagram, the one from the bottom of the Y pipe to the back? It splits into one line that goes to the air pump, and the other into an elbow into the manifold, and another that goes off to the drivers side somewhere. When I suck/blow into it there is some air flow in both directions - I get the feeling there should be a check valve on this line because it goes right into the intake, and you would be always bleeding off boost pressure, unless there was positive pressure in it all the time. You have to blow pretty hard into it to get air to flow, but it does.

-

Checking the two valve for flow by sucking on them, the one on the right was perfect, the other even if I can get it to close wasn't fully sealed. Yeah right, $70 for a $3 check valve - so I soaked it WD40 o/n, then hammered on it until I got it working reasonably well. Just started it up and no error code in about 10 minutes of running, whereas before it would take about 30 seconds, so we'll see. One thing to note, my P044 code indicates a flow problem, and so it would make sense that it is a check valve rather than the N80 itself. But time will tell.

-

Interesting that yours does it too Thomas. Once a day mine would trigger the workshop warning, too much to let slide. I thought of all these codes and a low battery, but going ahead and recalibrating the suspension seems to have stopped the suspension one for a day anyway. Btw coding the suspension was a nail biter, but it turned out fine. I didn't think you had to hit save after doing each wheel, and it wouldn't let me confirm the changes on channel 5, it just denied access to the channel. Then when I exited it said calibration was incomplete and disabled the air suspension, like permanently! Freaked out for a while but by following the instructions exactly, channel 5 appeared, confirmed, and now the vehicle is closer to level and no errors (yet). But the EVAP error is getting much worse, CEL sometimes on and the error quickly reappears after clearing. Quick question - so the electronic valve itself seems OK, but one of the check valves is strange. We all know these lines well, but in the picture, there are the two one way valves that goes into the T (red and green arrows), that then goes into the valve (blue line). The green one, the one that then goes up and into the AOS line, it works as a one way valve if pointed down, but if you lay it flat or tip the T end upward, it won't close. This is not normal, correct? I'm just wondering if my N80 valve is fine and it is this check valve that is causing the error. Another thing I was thinking Thomas is the oil smell we are getting occasionally, maybe it is not dripping oil (which I really can't see on mine), but if the EVAP system is malfunctioning, maybe crankcase vent fumes are occasionally being barfed out somewhere because of a pressure build up due to a malfunction. Btw - is there a part number for these check valves? On the fiche it looks like it is part of the breather hose, 94811014800, but when you look at the part online it doesn't appear to have the valve, just the hose. Thanks.

-

Must be nice to be just putting on your winter tires now, here in Canada they have been on for weeks! Those don't look too bad, comparatively. I'm running my ice tires now on 20" rims, and I have bought a set of 18" rims but I can't decide on tires, been reading way too much and stuck between getting BFG KO2's or Cooper ATW's. Want to do some off-roading in the summer, but still make it through the deep snow and ice we get here. Will probably get the KO2's. But with all the tire swapping (or possibly the cold snowy weather) I now have a bunch of error codes to worry about. Daily I get: 01772 - Signal from Level Control Pressure Sensor (G291) 008 - Implausible Signal - Intermittent So RossTech says either a wiring, sensor or air leak problem. But since I've been changing wheels so frequently these days, I'm hoping calibrating the suspension will help. At Normal level my absolute offsets are: 123.0 Left Front (G78) Absolute Height 134.0 Right Front (G289) Absolute Height 124.0 Left Rear (G76) Absolute Height 124.0 Right Rear (G77) Absolute Height The right front is way off, and the error appears mainly when I go to higher levels, so once I get the nerve to enter the security codes and figure out how to recalibrate it I'll see if that helps. But many people online say this could mean the compressor needs a rebuild kit, although it sounds fine and runs the same as it always did. And as far as leaks, it the suspension doesn't sink or anything, or the compressor turn on when you don't expect it. Other code is: 16825 - EVAP Emission Control Sys P0441 - 002 - Incorrect Flow - MIL ON So it sounds like my N80 valve is going to need attention. And I still get 16405 - Bank 2: Camshaft A (Intake) P0021 - 008 - Retard Setpoint not Reached (Over-Advanced) - Intermittent once in a while. Have to look at the wiring of that one too. Hope these aren't too serious...