Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Zakowsky

Members-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by Zakowsky

-

Not sure here, but I would think if the turbo vent line was blocked (rather than leaking) you would get an over boost situation. There is that one way valve there, or perhaps it is just filled with oil? You did have all those oil problems before. It would be hard to blow through to test, as there are multiple exit points, but might be something to consider.

-

So the main one that was leaking on mine was the one you undo to drain the oil out from. It was easy to tell that it was leaking because there was oil sprayed around that area. I sealed that up with Teflon tape and the car ran better. I have since ordered the proper replacement gasket so no more tape. I was worried about where they meet the Y-pipe as well, and did my Teflon tape test there as well. But that didn't make any difference so I took it out. I think the steel clamps around rubber onto plastic holds well enough.

-

I was thinking of posting this in your over-boost thread Thomas, but it is a pretty specific question for boost issues in general. I happened to meet someone with a lot of experience with such problems on the Cayenne yesterday; he checked out how mine ran and strongly suggested new diverter valves. I know this was the suggestion from Lewis way back at the start of all this, and it really makes sense now. My rapid loss of boost and the weird sound from the wastegates opening a bit too early just says the springs in the diverters are shot. And in your case maybe they aren’t opening fast enough (?). Any I was wondering which diverters people here were using? Many people seem to say just get the stock ones rather than aftermarket, which sometimes need to be oiled and offer no real gain. The stock Porsche part is 95511071001, but that seems to just be a Bosch 710P, which some people use, or some people use a 710N which has a stiffer spring. Is there a VW or Audi part number that can substitute? I don’t know if I can get a Bosch number here in town. Thanks.

-

Sounds like you’re close to ending the saga though. Hope you come and visit occasionally once it is sold!

- 22 replies

-

- ac

- expansion valve

-

(and 2 more)

Tagged with:

-

To give a post-op wrap up, the new pump is in, checked the torque on the bolts 5 times, no leaks as of yet and seems fine. Didn’t do the vacuum re-fill of coolant; when I drained it I siphoned out the expansion tank, and then just unbolted the pump and caught the coolant in a pan as it spilled out. Just refilled through the expansion tank, ran it for a while then added another liter. It’s holding at full and engine temp is steady where it should be. There was so much coolant everywhere up front I lightly pressure washed the front of the engine. Figured the water might damage the pulley bearings, but it is better than coolant drying there. Engine squealed once when I started it right after, but hasn’t since. Finally had the nerve to clean the throttle body, very careful not to move the plate, but got most of the gunk off. Putting a new throttle body to intake gasket was a waste of money, mine was perfectly fine. But for me the throttle body to Y-pipe o-ring was the “exciting” part, the new one made the Y-pipe much more snug fitting. Virtually no dip in speed when coming to idle. Drove for an hour or so, engine is as smooth as I could want. Didn’t wind it out yet because I haven’t got a torque wrench on the pulley bolts, no room with the one I have, just did it by feel. But my mileage seems better after the cleaning, 10l/100km at 100 kph, and 9l/100 kph at 90 kph on a run I usually test it on, where I used to get 11l/100km at 100 kph. Not that anyone can drive that slow for an extended period of time. I tried to free up that sticking one way valve but was only partially successful. It needs to be angled down to close properly when it should. Still need to look into that. So thanks for all the help, so far this has worked out well. Now to get that **** rear wiper arm off!

-

It’s because I live in Canada! People often think it’s the same as the US, but its not. There are Canadian models of electronics (lacking a few features), Home Depot Canada carries way less than the US site shows, and the Canadian dollar is weak compared to the US, and many things cost more because they are shipped up from warehouses in the US. There is no Porsche warehouse here, everything comes from California. So the pump is 270$ from Pelican in the States, converted to CAN$ is 340$, plus $50 for shipping and it works out about the same, plus if it gets held up at the border you can wait weeks. So I’m just going to install the new one, one less thing to worry about. And I did head the warming Lewis and I bought a new pulley as well. Took the day off work to get this done, so might as well go do it!

-

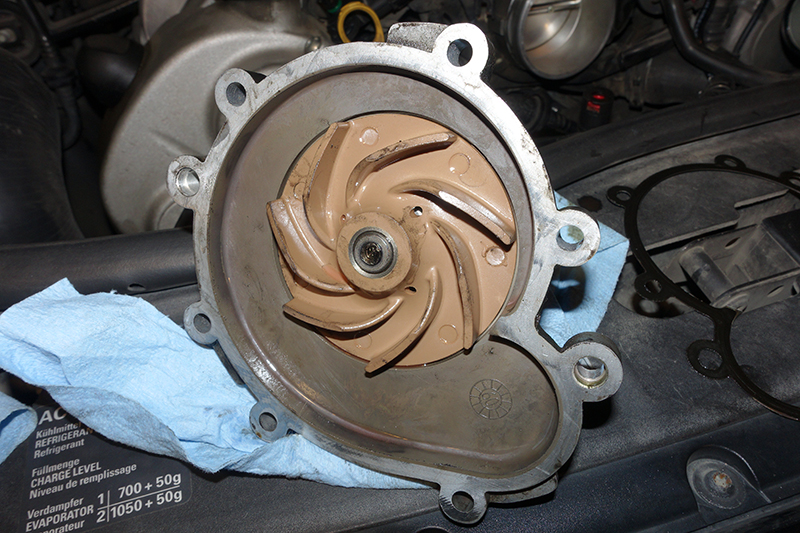

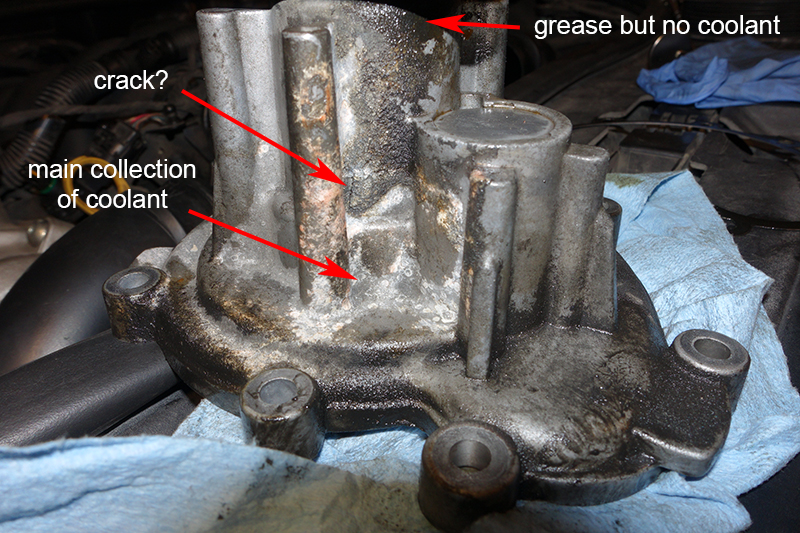

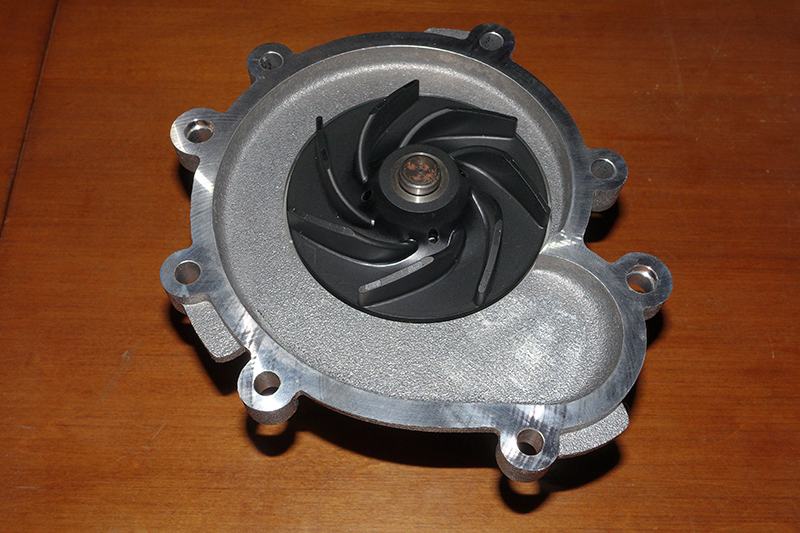

Thanks Thomas and Lewis. I can’t see any other hoses there it could be spraying from, and that was not a crack on the pump, just a mark in the dirt. When I released the pressure to the system it started dripping from the bottom of the pump. If you look at the picture on the very top of this page it comes of the lower edge of the pump and collects on the flat part below it, then sprays due to fan wind I guess. This is a close up, pointing to a drip. So I am thinking it must be a gasket leak too. If it was from that flat metal disk, that means the bearing chamber is filled with coolant, which would destroy the bearings, but they seem fine. I have always thought I smelt a bit of coolant with this engine, so maybe it has been leaking from the gasket slightly since I got it, and now it is worse. But could this really be just from one bolt loose? So I also learned that now I do have a new pump in there, but it is made by Laso, and it looks better made than the Porsche part. The Porsche pump is known to fail, so is the Laso actually better? I really don’t know what to do. I have to decide today if I should keep the Porsche pump or send it back for a 20% restocking fee. I guess I should trust the Porsche part and rule that out, as you say Lewis.

-

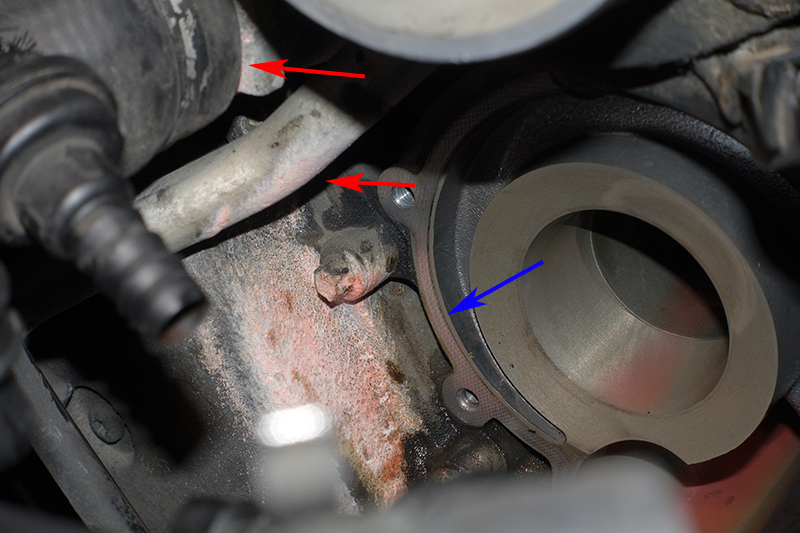

OK, now I am really not sure it is the pump. This is the spray pattern...could it be a leaking gasket (blue arrow)? The gasket looks fine but there is faint pink on it that you wouldn't expect. Two of the bolts were not tight. Or a leaking tube or the upper rad hose (red)? The bolt has more spray on the bottom than on the top, so probably it is going up rather than down. Pump looks fine on this side: This side looks fine: And on this side it is hard to tell: Has anyone seen a pump looking like this before? Could it be spraying from the gasket, hitting the engine at that big patch in the first shot, and then splashing back on the pump? Thanks.

-

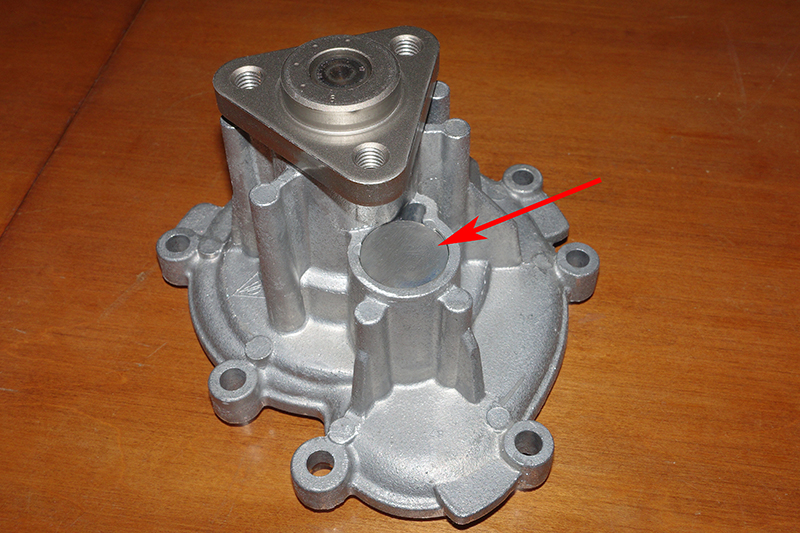

Yes, took a break for the night, but back at it now. Can't figure out what that steel looking insert is in the body of the pump. Haven't taken the pump itself off yet, but most things are cleared away. Posted some new pictures, maybe they got pushed to a new page.... Why do you ask? Do you think the new pump looks bad?

-

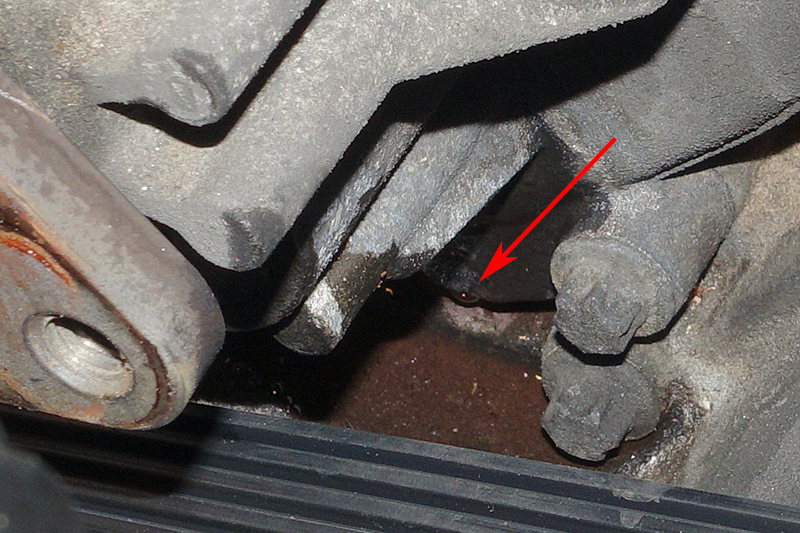

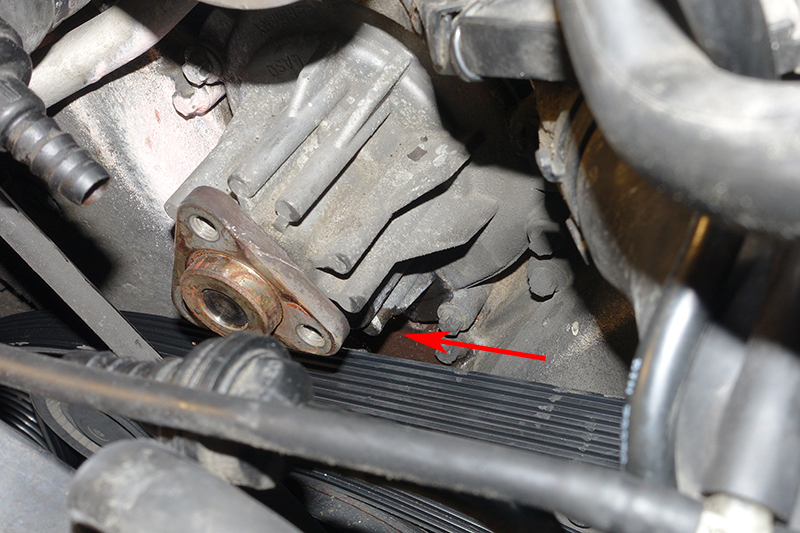

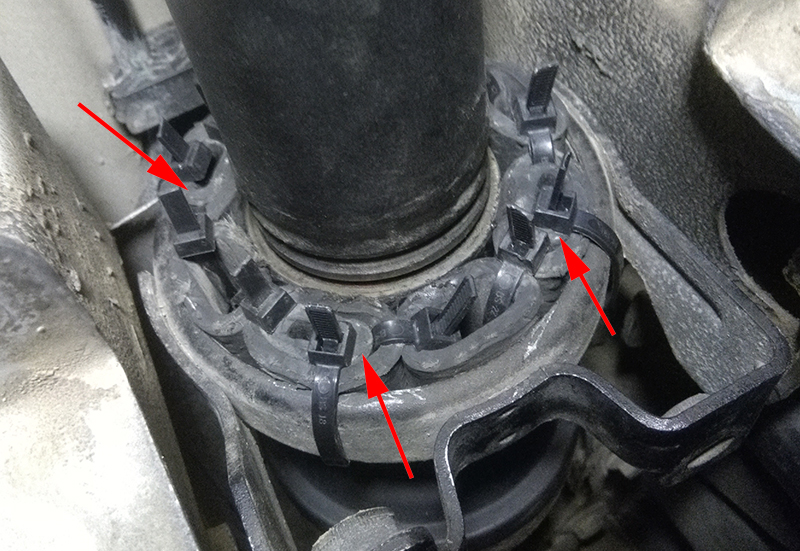

OK now this is strange - the pump is not leaking from the bearing at all, and it is tight with no play. But it is leaking badly out the pump body (now that I’ve relieved pressure on the system). Hard to see but arrow shows where it is coming out, about 2 big drips per second. It's dry under the bearing and pulley mount. Looking at the new pump, it seems like it is coming from here: What is this metal cap disc thing? Is it fixable? If my bearings are fine I’d much rather save the $400! Just to mention, more for the boost problem threads, but I do in fact have a faulty one way valve, the one on the left in the T junction for the oil separator lines: Under hard pressure it will work a bit but flutter; low pressure it flows both ways. If the water pump bolts come out and are not seized this is going to be an easier job than I thought. Famous last words or what!

-

You said yours went back to 500 - so that is your normal idle speed Lewis? That seems low, mine is at 580 which is I believe normal. Anyway, mine has kicked up the idle only a few times but it has. It was “hot” out (in Canadian terms, so above 30C!) and the air conditioner was on max, at idle and using a lot of accessories. It jumped up to around 1100 and stayed there no matter what I did. Seemed like a normal response to increased load so never thought about it.

-

Thanks Thomas. I’ve never taken off the manifold, or even the throttle body. The main reason being I’ve read some stories saying if you move the throttle plate during this process your car won’t start and has to be taken to Porsche to have the throttle matched up with the engine again, and Durametrics can’t help you. But I did buy a throttle body to intake gasket, so I am going to have to try this time. There is an intake manifold gasket in stock in town, so if the pump goes OK I will give the throttle and intake a try. What are the chances of re-using the 100$ intake gasket? I would like to replace that line too, and would have to take it off to get to it. I considered doing the thermostat, but mine has always been rock solid in the middle so I figured don’t mess with it. My parts came in early so starting tonight. Has anyone ever ordered an OEM Porsche pump? Mine looks kind of junky in my opinion. Is it normal to have scoring on the gasket face surface like this on a $400 pump? It doesn’t look like it was ground down and polished very well. Or is this to grip the gasket? OK, time to drain the coolant and get started.

-

My pump comes in on Wednesday; I'll take some pictures of the install. In the mean time I have been struggling with my rear wiper arm for 3 days! Trying to remove it to replace the switch, but don’t want to shatter the plastic arm. Have a puller on it and soaking it in WD40 but it won’t budge. Nothing is easy on this car. But the driveshaft is vibration free with the new mount design, guess that was it after all.

-

The only thing I can add is check the gasket between the Y-pipe and the throttle. Mine looked OK-ish, but when I put a thin wrap of Teflon tape around the throttle side before putting it together the engine ran better (smoother idle, less dip when coming back to idle) and then ran worse when I took it off. Ordered a new gasket that will come in with my water pump. Also that plastic fitting at the bottom of the Y-pipe right under the MAP is prone to leaking on mine.

-

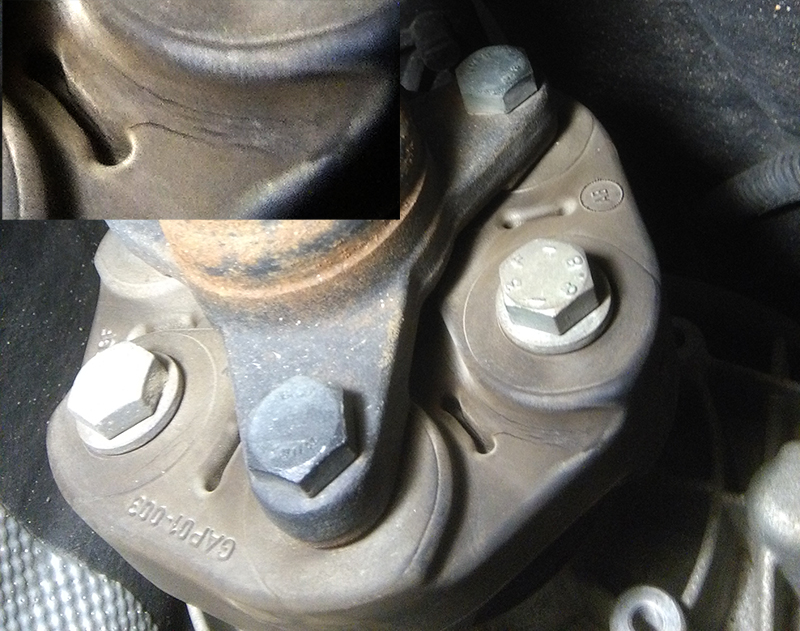

Hah! I was getting ready to upload a picture of the flex disc to show that it wasn't cracked, and then looking closely at the picture - I saw cracks! So you were correct Thomas, they can be hard to see. I shot this with just a cell phone; I will take more with my real camera later. I still think it is not the cause of the vibrations, but for sure I will replace it before it is! Why I say that is I replaced the hose/zip tie support system, and now the vibration is gone, on the test drive anyway. Couple of things to note. When I took the hose sections out they were definitely softer than when they went in. But rather than just replacing them and have the same thing happen down the road, I modified the design a bit. I reused the old large hose sections (5/8") and inserted smaller hose sections inside 4 of the 8. This makes a very solid brace for the shaft bearing, but is still compressible enough to get it in there. Another but - while doing this I also checked the bearing itself again, and it does now seem to be wearing, there is a bit of play in it. Repacked it with grease, although that usually just quiets them, and won't actually help with the wear. So where was the vibration from - the bearing, the support, or the flex disc? Easy answer is to replace them all. But I am guessing the support; greasing the bearing should not make a difference with these kind of forces, and if it was the cracks in the flex disc, it wouldn't go away with the new mount. Anyway water pump should come in next week and I'll be back to the regularly scheduled thread.

-

Hi Thomas, I did re-read your thread on the disc and vibrations; actually I compared my disc to your pictures, which is why I think mine is OK! It’s bolted in right now so can’t get a meaningful picture right now. But I think I am making headway - interestingly the vibration went away for a while, and then came back. So figuring it had to be something changeable (temperature maybe) I looked very closely at my support bracket fix again. It seems the hose has got softer over time, and is a little more compressed on one side versus the other. Mounted it is several different positions and had different effects on the vibration. So could be just that, the obvious explanation, so I am just going to make a new one. Takes only 30 minutes, but I am out of zip ties, so can’t do it tonight. Want to get this fixed, or at least know what I have to do before my water pump comes in next Tuesday. New driveshaft here is $1500 from Porsche, and you still have the crappy support bearing; getting a rebuilt one from the US will take too long, and replacing the support bearing alone looks like hard work not to screw up your shaft in the process, and again you have the OEM support bearing problem. There are those half circle bearing support brackets, but they are the price of a rebuilt shaft, plus they use the old bearing and I hear they are too firm and cause problems because of that. So I kind of like the tubing fix, and if you have to put a new one in every 10,000 km that is not so bad. If that doesn’t fix it I will just buy a new flex disc and try that. But not from Porsche - they quoted me $160 for the disc, but said I had to buy the driveshaft as well, they wouldn’t sell it separately!

-

Thanks Thomas. I agree, the metal impellers are too much of a risk. I refused to buy the one he ordered for me and just ordered one this morning from the Porsche dealer here, $400, but I need it soon. I am assuming it has a composite impeller as it is OEM, but I will check when it gets here. With the vibration Lewis, I am still at a loss. Examined the flex plate and it is fine, no chunks out or cracks of any kind. I even mounted the support bearing bracket at an angle and drove it, to see if it would make it worse, but there was no change at all. Definitely comes and goes with speed, so that doesn't fit with the support bearing also. I could buy a whole new driveshaft, but I really don't think that will fix the problem, and I don't have much time before the trip. The air suspension seems fine so I won't mess with it. Will change the wheels tonight; I guess it is possible a rear wheel is out of balance and I don't feel it up front at all. I just had the wheels balanced a few weeks ago, maybe one of the weights flew off. But it is almost a roaring sound right from the midline of the car, sort of toward the back. Family refuses to go on a road trip in the 96 Jeep Grand Cherokee…while it did break down twice on our last trip to California, it has many new parts now because of that (:)), but they still don't buy that logic!

-

Well good the the A/C is working, that's a major selling issue solved. If it is not affecting how it drives maybe if you just inform a new buyer of the ball joint being ripped up. Probably need to fix the air bag though. But it's sounding close to sellable; and don't forget it looks great, so when people idle around in the nice cool leather seats someone might overlook the few more repairs that are needed. As soon as they sort the lug nuts out maybe run an ad and see how the market is.

- 22 replies

-

- 1

-

-

- ac

- expansion valve

-

(and 2 more)

Tagged with:

-

Thanks, and after looking it over I agree, should be relatively easy. I don't have the play in the pulley that others have but everything else says pump. But of course things never go easy. After picking up my E-Torx sockets I drove out to get my new pump; I had ordered a Porsche unit from a non-Porsche dealer here who is usually pretty good at getting OEM parts (cheaper than the dealer), but when I got there the pulley was right, but the pump was a GRAF with a steel impeller, priced at 370$ CAN. Other than the fact that it goes for 59$ on Pelican, this puts me back a week now waiting for one from Porsche here. But the great part is on the drive I noticed I now have a vibration in what seems like the driveshaft. Lewis, you just went through this I think? It is between 86 and 98 kph, and feels central. No shaking or anything odd with the wheels or steering when it is happening. Flex plate looks fine, and I know I have the “aftermarket” shaft support, but it is exactly as it was when installed, and the vibration feels nothing like when the OEM support bearing went, so I don’t want to jump to any conclusions. I thought I had been feeling an ever so slight vibration over the past few weeks at this speed, and the last time I drove it I took it down a dirt road (getting the coolant to leak so I could see it better). This is the first time I’ve driven it since then and it is much worse now. The only other thing I’ve noticed is there are occasionally small clunking sounds from the front end when backing out of parking spots with the 22”. It seems there are many different reasons for vibrations on the 955; I’ve checked the wheel bearing by torqueing on the wheel while raised and they seem OK. Tomorrow I was going to put my other wheels on and see if it is still there, but does anything else come to mind? Didn’t you calibrate your ride height and it helped?

-

OK, so using my trusty GoPro on a stick, I checked out the area. The pulley isn’t really that loose, and from above it looked fine, but looking between the water pump pulley and the main balancer pulley below it there was crusted coolant for sure. This is between the two: And I managed I think to get a shot behind the water pump pulley, these are the bolts holding it on? Some look OK but some have white stuff on them and you can see where it might be spray on the engine around it. So ordering a new water pump tomorrow - looks like a tight fit on everything (as usual) in there.

-

Great, thanks Lewis. Y-pipe is coming off tonight and I will check the pulley and look around. Have never had to do anything up front before so still getting oriented. But I was wondering about how much coolant would come out during the replacement, since it seems sensitive to how you refill, so good to know its only a couple of litres. In some ways glad this didn’t happen on our up coming trip, and this could also be that slight smell of coolant I’ve been getting for a while. Cheers.

-

So I found a thread where someone had a leak from this exact spot, and it turned out to be the water pump. His leak was intermittent, and now after setting it up in the garage for a tear down, I brought it up to temp and there was barely a drip. Looking more closely at the pulley Thomas I did in fact see the side closest to the engine had a white line around it like dried coolant, and if I watch the pulley carefully while it is running it looks like it could be moving a bit. So water pump rather than the heat exchanger lines, or alternator cooling lines probably? And if the pump is leaking a bit can I drive it if necessary in the meantime, or is total disaster immanent? Thanks.