Here’s a quick tutorial on how to fix a P0492 error code on a Boxster 986 / 987 / Carrera 996 / 997.

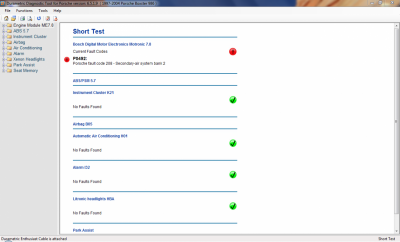

Error: P0492 – Porsche fault code 208 – Secondary-air system bank 2

Symptoms: no visible symptoms, except for the CEL (check-engine light) being triggered, particularly during cold engine startups with the SAI (Secondary Air Injection) pump running for the first 90 seconds.

Diagnostics: when troubleshooting the P0492 error code, I initially focused my attention on all SAI components located on top of the engine, such as the SAI pump, hoses, solenoids, vacuum hoses and reservoir, etc.

I found it easier to remove all vacuum components and work on a workbench and running individual tests, with the invaluable help of a handheld vacuum tool. I did find the vacuum reservoir had a leak, and one vacuum line was damaged (mostly brittle due to heat / time). Also tested both solenoids with a 12-V DC power supply and then replaced the damaged components with new ones. The CEL was off for a few days, but it came back on, throwing the same error code.

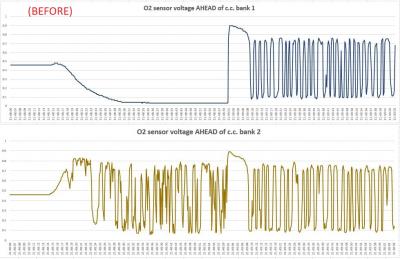

With great help of Ahsai on troubleshooting the O2 sensors readings during a cold startup cycle (thread here), it looked like the problem was an obstruction in one of the paths used by the SAI pump to blow cold air form the engine compartments into the catalytic converters. And because I didn’t wanted to work on my car during the cold season, I parked the project for the winter and lived with the CEL on for many months, certainly one of my joys in life ;)

Solution: When the first nice spring days finally arrived, I used the opportunity to do this and other maintenance jobs in my car, like deep cleaning after the winter season (It’s my all-year-round daily driver), two axle rebuild job, etc.

With regards to the exhaust manifolds removal procedure, where a broken bolt can quickly become a nightmare, I had already done some prep-work on all manifold bolts: driving the car until reaching running temperature, quickly jacking-up the car and loosen all exhaust bolts while still hot, thoroughly cleaned, anti-seize and remount. This method, while not everyone’s cup of tea, ended up being quite effective in my case.

And when I finally removed both exhaust manifolds, where I was originally expecting lots of carbon buildups, I instead found a soft clay-like product (oil?), which was quite easy to remove with a finger nail (through the gloves, of course ;).

I thoroughly pressure-washed all components, carefully avoiding to send the water jet directly into the exhaust valves / catalytic converters and the use of any degreasers. A 2,000 psi electric pressure-washer with a 10 degree spread nozzle can be extremely effective, particularly at short distances. Attached is a picture of the engine block after the pressure-washing job.

Finally, a grey Scotch-brite, well lubricated in oil, for mirror-like surface finishes (well, in most cases). It honestly looked amazing… too bad I forgot to take a picture… my apologies.

Finishing-up with another thorough cleanup of all exhaust bolts, a new thin layer of anti-seize and a complete car reassembly, and my P0492 error code is finally gone, hopefully for good!

Cheers,

Jones