Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

All Activity

- Past hour

-

Fuel4All joined the community

- Today

-

Gilles VAREON joined the community

- Yesterday

-

Convertible Top Life Span ?

jim_hoyland replied to jim_hoyland's topic in 987-1 Boxster Convertible Top Issues and Solutions

I went to get estimates on doing a replacement; seems like a legit upholstery shop wants 3K which includes the top, labor and taxes. Here’s a few pics of what my 19 year old top looks like. -

Joe Lyon joined the community

-

Denis G. joined the community

-

John Charette joined the community

-

SEAN D joined the community

-

Alan Murtagh started following Need Advice Squid Ring/ Clock Spring replacement

- Last week

-

Alexander DeMars joined the community

-

Hi everyone, I’ve spent the last 18 months bringing a 2004 Cayenne S (4.5L V8) back from the dead. It sat outside for 5+ years and had a laundry list of issues. I just finished a massive diagnostic session and wanted to document the specific failures and fixes, especially regarding the "0L" CAN bus error and a terrifying compression test result that turned out to be a false alarm. The Patient Vehicle: 2004 Porsche Cayenne S (non-Turbo). History: Sat for 5 years outside in PNW. Incorrect turbo injectors installed by previous owner. Crank no-start (clogged drains, soggy floors caused the common splices under the carpets to disintegrate) Initial State: Running Condition: The car would crank and start after fixing the splices, but ran incredibly rough and would not idle without holding the gas pedal. Communication: Impossible. The Durametric scanner showed "Link Error" or could not find modules. The OBD-II port showed "0L" (Open Loop) when testing resistance between CAN High/Low (Pins 6 & 14). Phase 1: The "Invisible" Electrical Break The Symptom: I couldn't scan the car to diagnose the rough running because the Gateway wasn't talking to the OBD port. Multimeter showed "0L" (infinite resistance) across Pins 6 & 14, where it should be ~60 Ohms. The "Aha!" Moment: On 2003/2004 models (specifically my VIN with the 10th digit "4"), the Gateway is inside the Instrument Cluster. It is not a separate box under the dash like later models. The Fault: I traced the wiring and found: Continuity between OBD Pin 6 and the Green Plug on the back of the Instrument Cluster. NO Continuity between the OBD port and the main CAN splice under the Passenger Seat floor. The Fix: I bypassed the broken section of the dashboard harness. Spliced into the CAN High and Low lines near the OBD-II port. Ran a twisted-pair jumper wire directly to the factory splice point under the passenger seat carpet. Result: Resistance returned to 60 Ohms. The scanner immediately connected, showing "No Codes Found" (initially), confirming the network was back online. Phase 2: The "Smoke & Misfire" Scare Symptoms: With the electronics fixed, I could finally see what was happening. Smoke: Massive cloud of White/Grey smoke smelling strongly of raw fuel. Codes: P0300, P0303 (Cyl 3), P0308 (Cyl 8). Scary Symptom: A loud "Ticking" noise from Bank 2 (Driver's side), which often signals the dreaded bore scoring. The "False" Diagnosis: I performed a dry compression test and got terrifying numbers: Cylinder 3: 60 PSI (Dead) Cylinder 8: 100 PSI (Very low) Spark Plugs: The plugs on Cyl 3 & 8 were "steam cleaned"—the ground straps were perfectly white/clean, while the center electrodes were black. The Real Diagnosis (Fuel Wash): I performed a "Wet Compression Test" (added a tablespoon of oil to the cylinders) to see if it was rings or valves. Cyl 3 jumped to 190 PSI. Cyl 8 jumped to 230 PSI. (!) Conclusion: The engine block is healthy! The low compression was caused by Bore Wash. The cylinders were so flooded with gasoline that it washed the oil film off the walls, preventing the rings from sealing. The "Ticking" was likely a dry lifter or piston noise from the lack of lubrication. Phase 3: The Injector Diagnosis I had installed "Remanufactured" Bosch injectors (Part # 0280156101) thinking I was doing the right thing. Wiring Test: I tested the injector harness voltage (Key ON, Engine OFF) to ensure the DME wasn't shorted and holding them open. Bad Cylinders read ~7-8V. Good Cylinders read ~7-8V. Result: Wiring is perfect. The DME is functioning correctly. The Verdict: The "Remanufactured" injectors were mechanically stuck open immediately upon installation (likely due to debris in the rail or just being bad "reman" units). They were dumping fuel, washing the cylinders, and killing compression. Summary of Fixes No Comm/Rough Run: Fixed by running a dedicated CAN-Bus jumper from OBD port to Passenger Seat splice. Low Compression: Disproved engine failure via Wet Compression test (Results: 190/230 PSI). Misfire/Smoke: Identified stuck-open "Reman" injectors. Current Status: Waiting on Brand New injectors. The fuel rail is getting a deep clean, and the gas-contaminated oil is being drained. The 230 PSI result on the "Ticking" cylinder confirms the engine is saved! Hopefully, this helps someone else who sees "0L" on their multimeter or "60 PSI" on their compression tester. Don't scrap the car—check the wiring and the fuel!

-

Happy new year everyone! I was wondering if anyone had experience with the bottom of the front doors not sitting flush with the car when closed? What could be the potential culprit, top door hinge, striker plate? Any ideas/info would be greatly appreciated. I have attached a picture from another forum as an example.

-

Laurent Carron joined the community

-

Paul Vizanko joined the community

-

Joseph Greco joined the community

-

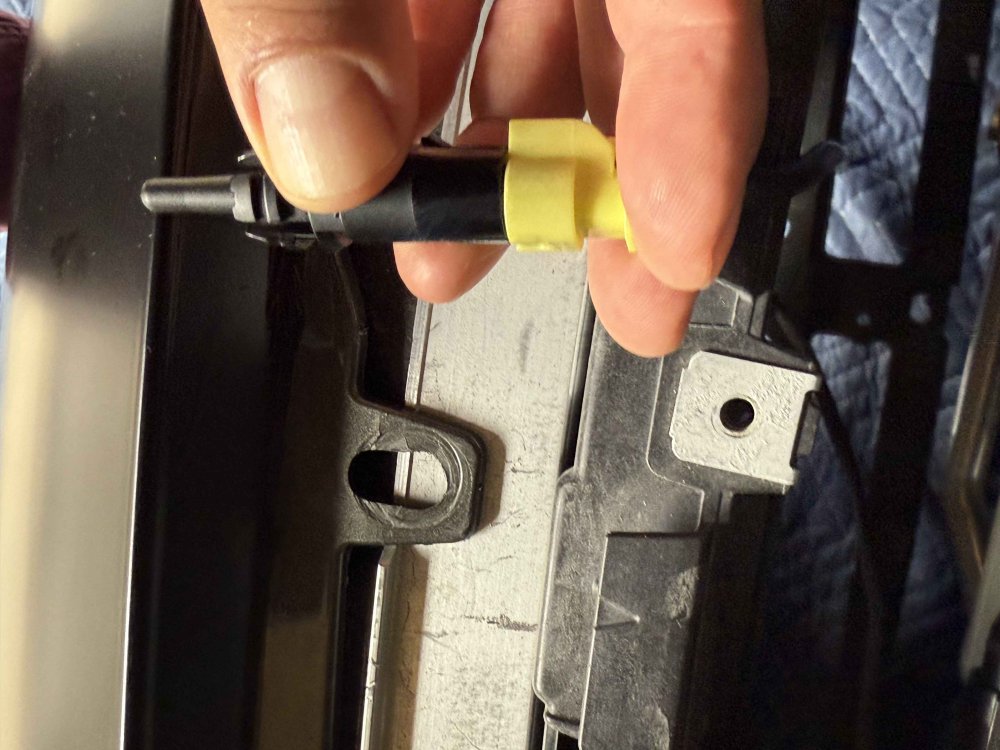

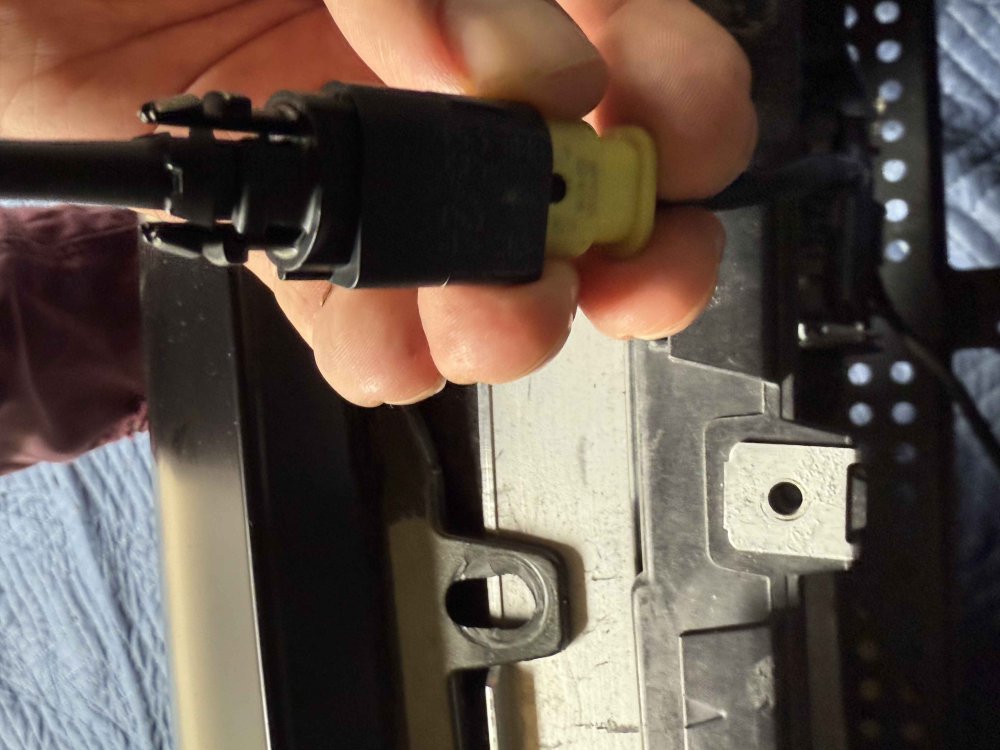

Does this help?

-

Headlight dial switch is stuck

yeeha68 replied to yeeha68's topic in 986 Series (Boxster, Boxster S)

Thanks for the reply Loren. However, the ignition switch is not the problem. Its the headlight switch. The problem is I cant remove the vent. There are three screws holding it in place. Two outside by the door rail, and one hidden behind the light dial. If the dial cant be removed, the vent cannot be removed. -k -

Alex Burkart changed their profile photo

-

yeeha68 started following Headlight dial switch is stuck

-

Hello All, Its been a while... My headlight switch is failing and I need to replace it. Not a big deal, it should be a 20 min. problem. But, part of the problem is that the dial refuses to pull out, so I cant remove it to get to the panel screw under it. I can think of no other way to remove it other then drilling a hole through the dial and then having to buy a new dial too. Anyone ever come across this problem and have a better solution? Thanks, -k 1998 986

-

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)

Ride height and M030 spring questions

Loren replied to Andrew Howell's topic in 986 Series (Boxster, Boxster S)

Chances are your 20 plus year springs have softened and are already sagging a bit. Springs, swaybars and struts are a matched set - I would not mix them as you could produce unstable handling. Especially if you track the car. RoW 030 is fine for street and most track driving - you just have to be careful of large speed bumps on the street. PSS-9 (adjustable) Coilovers can supply suspension tuning and even lower for track days - but you would definitely want to raise it up for street. -

Ride height and M030 spring questions

Andrew Howell replied to Andrew Howell's topic in 986 Series (Boxster, Boxster S)

Thank you for the reply, Loren. That makes sense but the low ride height was confusing me. I wonder why the car appears to be so low on the stock springs? Perhaps I'm making an error when measuring. I'll try and get a pic of my measuring points in the next few days just to confirm. I have a set of US M030 struts and the front US M030 sway bar that I was thinking/hoping to use. I was considering leaving the standard rear sway bar installed. The car is mostly used for autocross so I'm thinking a softer rear sway bar might help with some extra rear grip, which can be an issue on tight courses. Is it critical to get the US M030 springs to use with the US M030 struts or would it be okay to run these standard springs? Especially since the car seems to be so low already. I imagine the US M030 springs are a bit stiffer but I want to avoid lowering the car much more than it already is if I can. Would the stock springs be too soft for the US M030 struts? I don't want to make the car bottom out too much or cause excessive wear to the strut. Just trying to explore all my options. -

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)

Ride height and M030 spring questions

Loren replied to Andrew Howell's topic in 986 Series (Boxster, Boxster S)

Blue/white marking are stock springs. For factory Sport Suspension you will need new springs, stuts, and swaybars. RoW Sport Suspension Package for 3.2S 6 speed - Carnewal WWW.CARNEWAL.COM -

Ride height and M030 spring questions

Andrew Howell replied to Andrew Howell's topic in 986 Series (Boxster, Boxster S)

Hi Loren, I'm running the 18" turbo twist wheels. Yes, I'm measuring from the points listed in the factory workbook pages that I linked. -

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)

Ride height and M030 spring questions

Loren replied to Andrew Howell's topic in 986 Series (Boxster, Boxster S)

What size wheels are you running? Are you measuring from the chassis points as shown in the factory workbook pages that were posted? -

My 2001 Boxster S appears to have the standard suspension installed and I'd like to upgrade to some M030 parts but when I measure my ride height, my car seems much lower than I expected. I used the factory measuring points and specs listed here: http://986forum.com/forums/boxster-racing-forum/66183-ride-height.html The front of my car appears to be about 120mm from the ground and the rear is around 133mm and my car is on the 18" turbo twist wheels. According to the specs from the link above, the standard suspension should be closer to 150mm. I have confirmed that the struts are the standard (not sport) part numbers (986.343.041.20 for the front and 986.333.051.20 for the rear) but the front springs have a blue and white marking on them, which I'm having a hard time identifying. They appear to be this model from Pelican: https://www.pelicanparts.com/More_Info/98634353118504.htm?pn=986-343-531-18-504-OEM&SVSVSI=785&DID=6869 My questions are: -Why is my ride height so low compared to the factory specs? -What are the springs installed on my car? Are they the standard or sport springs? -Can I use these springs with the M030 US struts?

-

Ian Sloan changed their profile photo

- Earlier

-

alex222 started following Samtec HSX-ISO connector for OBD II

-

Andrius Klopotas changed their profile photo

-

Quick update... I ended up putting a little super glue on the broken edge, and with the combination of tweezers to locate the broken tab in the key fob cylinder and my index finger to press it into place, I was able to get the tab to stick in place long enough for me to insert the key fob and turn it. Needless to say, once the key fob was inserted into the key fob cylinder, I did not remove the key fob. I did not want to chance the tab falling out and being back at square one. Key learning is the tabs in the key fob cylinder are depressed when the key fob is inserted, which in turn releases a locking mechanism within the key fob cylinder so that the key fob will turn in the cylinder resulting in the car starting. I hope no one else has this experience!

-

Kit Weber changed their profile photo

-

hmmm ok before i check that (or have it checked seems like something that could turn into a big job if i mess something up lol) do you think this has to do with the muffler delete the shop did?as mentioned its never had any issues with the tip and always shifted smooth as butter, only issue its ever had like this was the prior issue with the crumbling abs harness i had talked about where it was doing the exact same thing its doing now until i had a new harness installed and the battery reset, then it started working perfectly again, til the muffler delete and i know theres a few ground wires and the transmission connector near the muffler so maybe something got tugged or damaged during the work?