Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Zakowsky

Members-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by Zakowsky

-

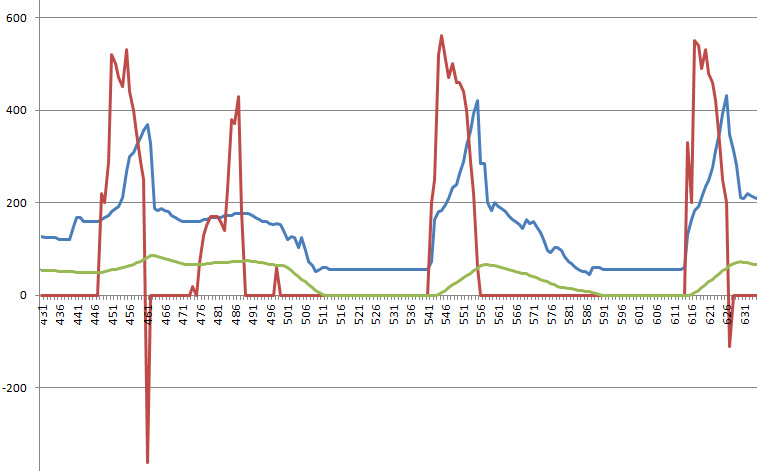

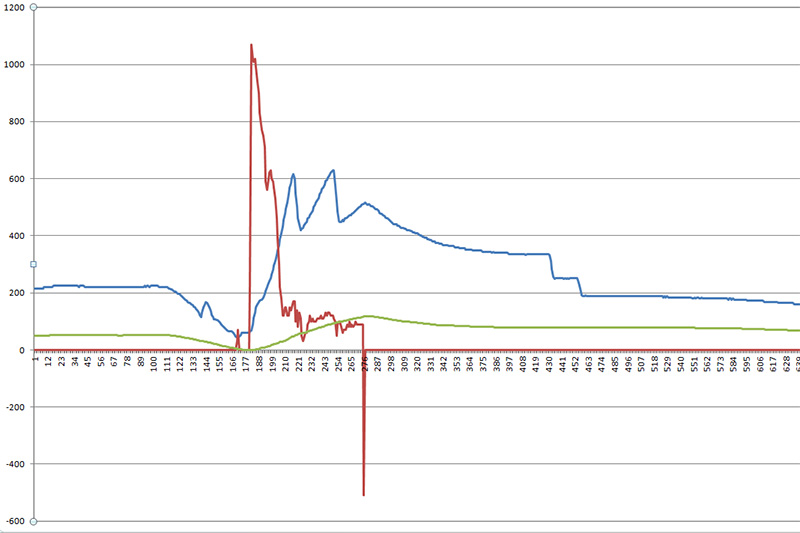

Well the diverter valve test was a great idea Lewis – I disconnected the line from the changeover valve at the T, hit record and went to the beer store. No difference in the negative pressure, wheezing sound when I let off the throttle, and no stumbling or anything else new. So it look like my diverters are actually doing nothing. Since they seem alright there is a good chance the valve is bad, or there is a vacuum leak to the valve. And for some reason disconnecting the diverters made the other problem, the quick turbo shutoff a little bit better. Red is boost, blue RPM/10 and green speed in kph. You can see the boost stays up a bit longer than before, although this was not winding it out in any way – I didn’t want to blow anything out with the diverters disconnected. Also the idle was smooth and it just ran really well. So I am ordering a changeover valve and an N75 valve and as I wait weeks for them to come in I will check for leaks at the back of the engine. That sucks about the fuel pump. I’ll keep logging my injector timing and maybe some logic will come from that. I am still getting Overruns all over the place.

-

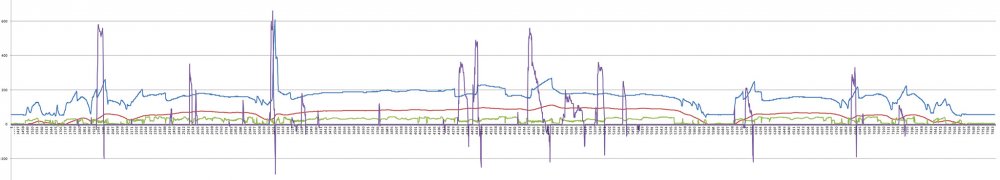

So it does seem my N75 valve is not normal, and as per your email Lewis, great idea to disconnect the T to the diverters and simulate a changeover valve failure. I'm starting work now but will try it tonight. I keep thinking there is something else going on here - this is a graph of just normal driving...is it normal for the turbo to only come on when accelerating a bit hard? You can see how mine only comes on 10-20% of the time; and sometimes for no real reason, although if I hit an incline it will, which wouldn't show on the graph. In this one purple is boost, blue is RPM/10 this time, red is speed in kph and green is advance BTDC. Good luck with the other fuel pump.

-

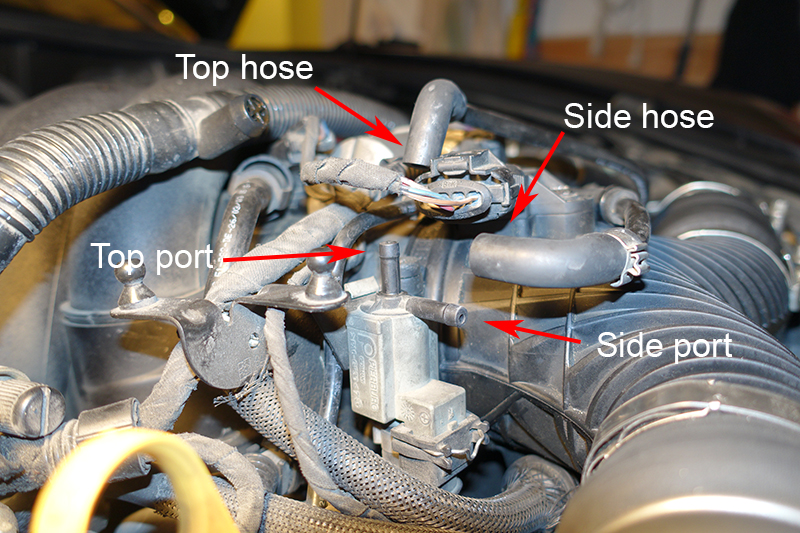

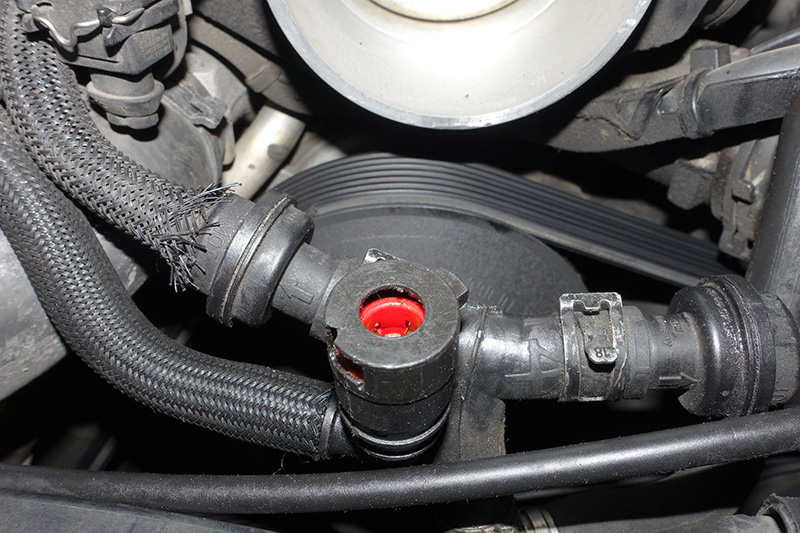

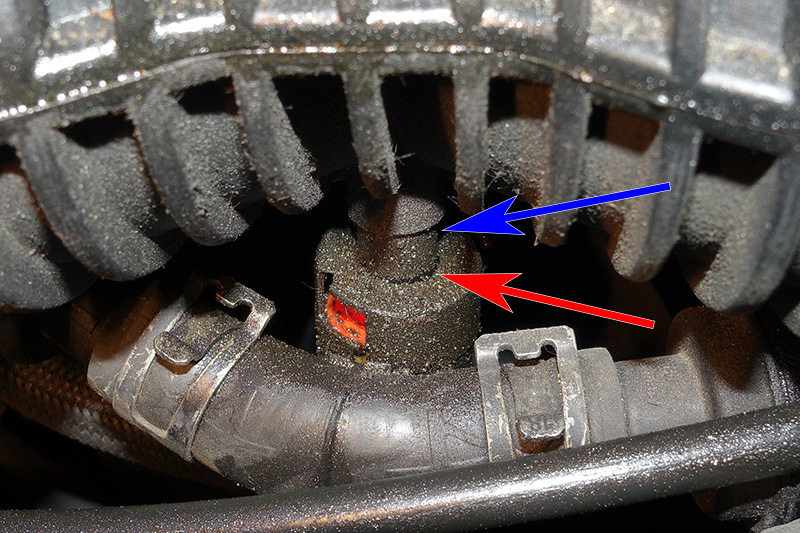

Thanks - hopefully this will be useful for others too. So an update; a big clue came from looking at the measuring block reading for Idle, Part Throttle etc...the car basically never shows Full throttle, it goes from Part Throttle right to Overrun! And when Overrun hits, the boost pressure drops like a stone. The only time I can avoid this is by not pressing the throttle all the way, during which time I can get the boost pressure to hold at around 0.7 - 0.8 bar. This would explain a lot in terms of the performance; it often seems stronger when I don’t put my foot all the way down. Now the hardware side of this; Lewis suggested the N75 value which makes sense in terms of its tie in to shutting down the boost when an overboost is detected. But I am not so sure it is the valve itself. I know its been talked about, but just to make sure, how should the air flow go when the vehicle is off? In this picture I have labeled the two input hoses (top and side) and the two ports they attach to. The one out the bottom is to the wastgates I assume. So when I blow into the side hose, there is no air flow (although it feels like you are blowing against a diaphragm). The top hose vents to atmosphere. This are normal I believe. The top port is shut (can’t blow air in), but when I blow in the side port I can hear air leaking out the passenger side down by the turbo. Is that normal? My first guess is that I have something wrong with the wastegate on that side. Anyway I think this is narrowing things down...

-

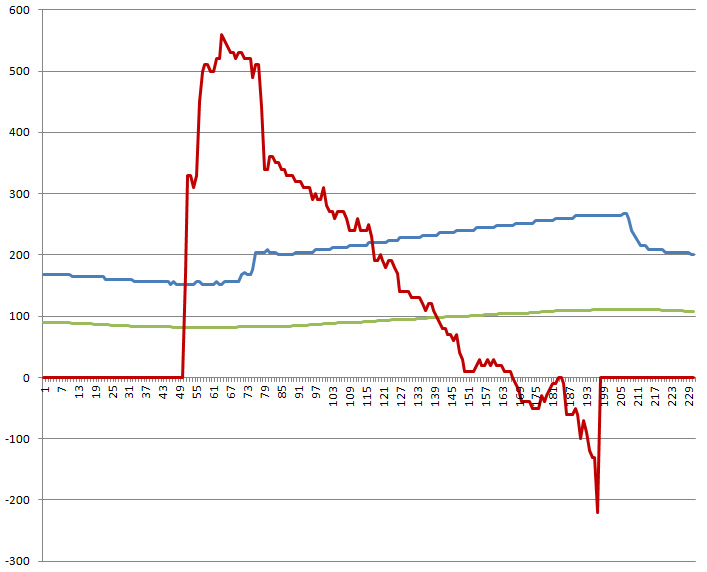

I have been doing some data analysis on the boost profile of my 2004 CTT which is having some performance issues (almost 8 second 0-60, yikes). Lewis has pointed out that I have a boost leak, but I thought I would start a thread in case this is useful for others, or if anyone can provide more feedback from experience. So when I first got the vehicle it was notably faster, then after a few weeks I started hearing a wheezing sound when I let off the throttle and the turbos slowed down. Logging the data during light acceleration looks like this: Green is speed in kph – so this is cruising at ~90 then slowly up to ~120 kph. The blue is RPM/10, so you can see it downshift then come up from 2000 to 2600. The red is boost in mbars, so it is climbing to about 550 fast, then tapers off, but when I let off the pedal it goes negative and that is when I hear the sound. In this case I am doing a 0-60 mph, so the green goes up to ~ 100 kph, and the engine is shifting at a little over 6000 RPM. It is remapped, so the boost goes to almost 1.1 bar, but rapidly shuts down, then when I let off, a really big negative spike. I don’t think the 1.1 bar is too high and triggering something as it will do this even when the initial spike is only 0.6 – 0.8 bar. So I am going to do a smoke test, but does this negative spike and quick loss of turbo pressure mean anything specific to anyone? I will post results as I work on it. Cheers.

-

That was the exact one I was looking at getting...its crazy you have to replace the entire cover. The glove has kept it silent and sealed so will just order the membrane. With your dipping throttle coming back to idle, mine does that as well. Now, I don’t believe it, nor do I trust the very expensive tuning shop that maintained my engine previously, but they insist that with this engine that is normal. They said it was related to the power kit – again, that never made sense to me but it is possible that it is normal behavior.

-

The rubber glove trick did the job - thanks! I was as careful as I could be but one of the tabs broke off when removing the cap...****. It still seems to hold fine, but I guess I should replace the whole thing. It doesn't seem you can buy just the diaphragm any more anyway – does anyone know a source that still sells the diaphragm alone? Otherwise I guess its PN 948-107-236-02-OEM, and I don’t have to worry about the broken tabs. Anyone know a trustworthy place selling these for less than Pelican’s $163? Thanks again Lewis. Edit - actually, looking closer at the part, pictures of that PN don't seem to be the same as my setup. The Pelican tutorial images look correct, and they say 948-107-236-52-OEM is the PN, but neither that or 948-107-236-02-OEM look correct...anyone know what is up with this? Mine is a 2004 CTT...

-

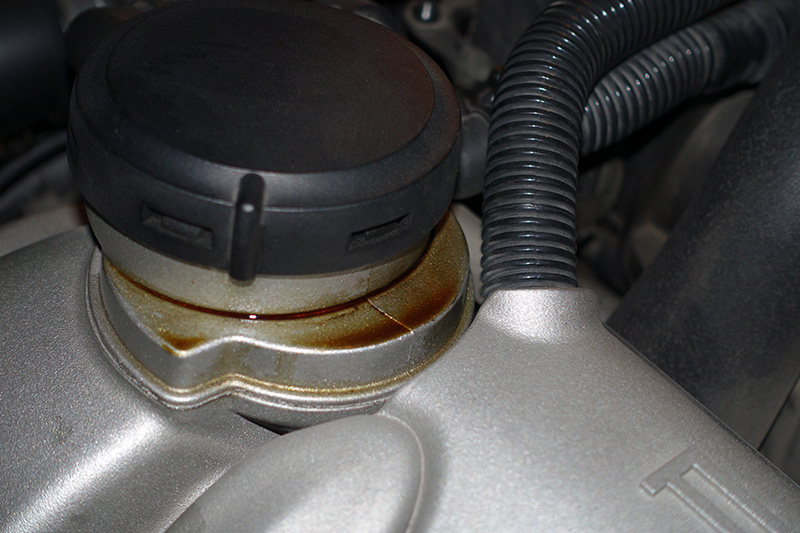

And Happy New Year - although my CTT didn't quite get me what I wanted for Xmas! We took our first real road trip with it, about 4000 km over the holidays. It ran great, and in fact it is running the best it ever has. No hard starting, smooth idle, turbo is strong. But on the last 500 km I stopped for gas and when I started it the engine light came on but the dash info screen showed no warnings. It ran home fine, and I figured it was a gas cap or dirty oil related problem. But when I parked it and opened the hood, looks like I am not so lucky. There is now a chirping sound coming from the top, front part of the engine, sort of near the oil filler cap. Also, when I turn the engine off there is a fairly loud hiss of a vacuum (or pressure) bleeding out from the driver side turbo area (maybe). And oil spray, but that looks like the valve covers. Looks like I have to order my cable with rush delivery, and I am sure the codes will tell me what is up, but it is kinda depressing right now. Does the chirping noise sound like a familiar problem? From what I’ve read it could be many different things; I just hope it is not something with the cam/valves.

-

OK, lame post, but where can you start to pry to get the headlights off of the Cayenne without breaking stuff? If I torque any harder on the release gear it is going to break. I am turning in the correct direction, I have anchored my GoPro suction cup mount on the lens and pulled super hard, even taken hardwood and tried to pry it forward while turning…in Canada things can get pretty seized up. Is there somewhere on the back of the casing that you can push/pry on to give forward force while turning to get it out? Reading other posts about this, do you have to take the wheel tub out to get to the back of the light housing? Thanks.

-

If the dash lights flicker as the starter is failing to turn, it is often a grounding strap. If they don't flicker (or don't go completely out) while the solenoid clicks then the problem is confined to the positive side of the power (starter/battery).

- 44 replies

-

- generator

- alternator

- (and 2 more)

-

There are some great pictures there - I think I will go ahead and take off the manifold; the coolant pipes were upgraded but I occasionally smell what might be coolant, so I should check them out. I am going to order in the o-rings (top and bottom I assume), intake and throttle body gaskets first, and if the battery and throttle body are going to come off, I really need to get the OBD online first as well. While I wait for those I am going to go over all the check valves I can get to this weekend.

-

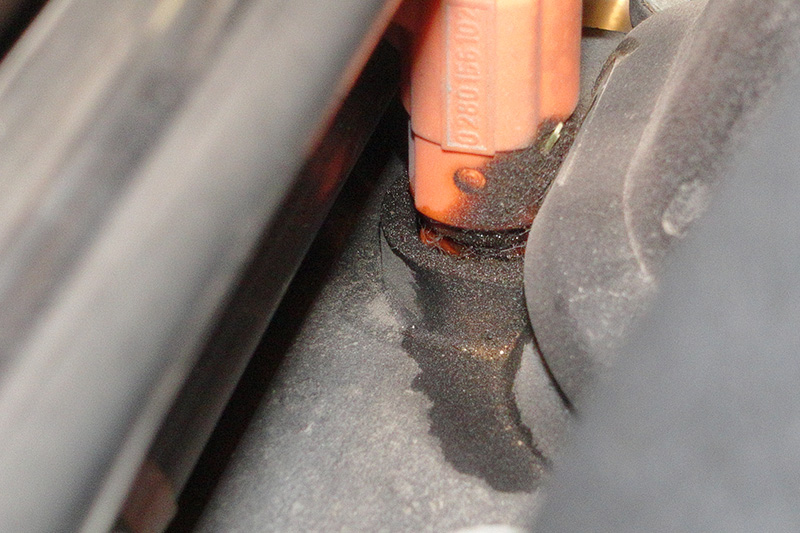

Thanks Lewis – my job for this weekend will be the check valves and to go over the vacuum lines, especially at the back where I haven’t really looked much yet. The boost is fine sometimes (0.8 – 0.7) but other times not, and there still is what I think is a minor surging sound when I lift off, after the wastgates open. I recorded it with the GoPro, just have to get it processed and posted. Pictures always! Here is the leak from the rear injector, the others are fine. I suppose I haven’t paid much attention to this because on my old Jeeps most of the injectors leak and they still run fine! - but then again, this isn’t a Jeep engine. I have also had engines where as soon as you pull the fuel rails off, all the o-rings start leaking, so I guess I try to avoid doing so. I am not sure how long this has been like this – I need to clean it off and see how it builds over time. But maybe this does contribute to the variable rough idle and maybe even the hard starting.

-

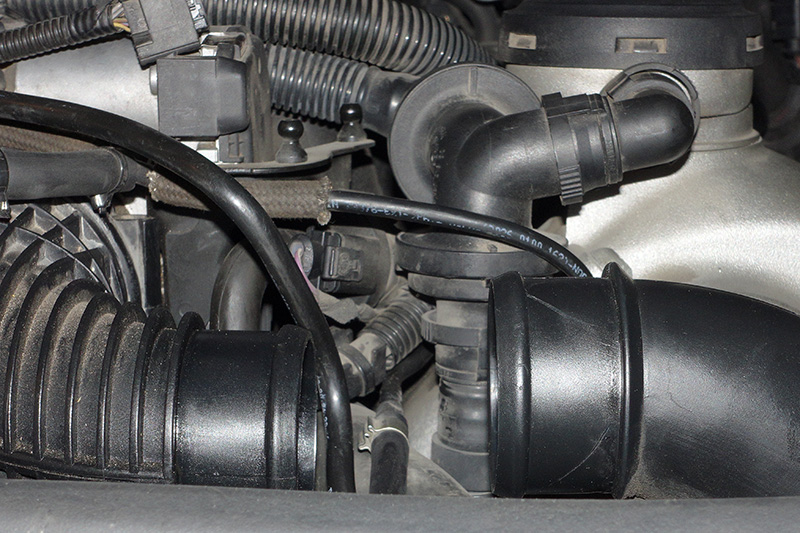

So I pulled everything apart and reassembled, here's how it went. The hose (it does have the 2 clamps) on the drivers side and Y pipe were a bit oily, but a lot better than before I drained the oil from the intercooler hose on the bottom. What did surprise me is that my Y pipe is starting to de-laminate inside. You can see the plastic cracking and coming loose at the arrow: I also seem to have a really big off set on the drivers side for some reason: I did the throttle adaptation and I was freaked out at first because the first time I drove it it wouldn't shift out of 2nd after accelerating(!) but after a few minutes of driving it was fine. I should have tested this when I had it all apart - I will probably take it apart again this week and will try blowing in it then. After taking out the Y pipe I noticed one of the clips on the venturi line is broken, which might contribute to it not attaching well. I moved it in front of the other hoses as Lewis suggested and it did fit better, although still not perfectly. I will have to look at where it is attached at the back next. After driving it all day, no more oil was seen around this fitting. As far as performance goes, I think I am indeed still looking for an air leak somewhere. Before I had a rough idle 50% of the time at lights, depending on if I had been driving it hard or not (hard driving = smooth idle). Now I still get this occasionally, but when it is smooth it is almost perfect, and the roughness is less. The two main issues left are a lack of power, sometimes...if I manually shift with PSM off it can go OK, with the boost pressure going to 8.0 then dropping to 0.7 as the revs get higher, as long as I shift by 6500. But in automatic the boost will fall as low as 0.5 in 3rd and 4th gear, PSM on or off. Even when shifting manually, 3rd doesn't pull as hard as I think it used to after 4500. And there is still is this sound after the wastegates open that doesn't seem right; not very loud but it is like a wheezing sound that again wasn't there when I got it. The other problem is when slowing to a stop it drops to 400 rpm and then recovers, and that is actually worse after all this. I did notice a very slight leak around one of the injectors; need to look at that as well. Anyway overall it is better, but I am still looking for leaks as well. I was thinking a smoke test should be next. I thought I would go green after looking at all the fire-based DIY smoke testers on YouTube. But I figured the pressure was a bit low and maybe all that water vapor woldn't be good for things...but good for a laugh anyway!

-

Reflecting on my workmanship comment, he we go again – on one side and in the Y pipe there are metal rings to take the force of the ring clamp, but on the passenger side it was missing! Consequently the pipe is crushed in a bit, and maybe not sealing like it should. This is why I work on my own vehicles!

-

OK, one quick paranoid question - it's ready to take off, but to get the pin out to remove the Y tube you have to disconnect the electrical connection to the throttle body. If the engine is off and the key is out, will I have to have reset any codes after doing this? There seems to be something wrong with my OBD2 connector...and I guess in general, can you disconnect electrical components on the engine when it is off without tripping a code? Or are there systems that are continuously monitored? Thanks!

-

So just to rattle on a bit here, first of all thanks ekstroemtj and lewisweller for taking the time to answer questions like this. Ekstroemtj, you commented a few posts back on how not many people are stepping up to do so, but you guys certainly are, and I think all the photos and info that is shared will help many people for years to come – already almost 2000 views on this thread alone. The irony here is with the Cayenne, Porsche tried to make a vehicle targeted at customers that would just take it into the dealer to service, which is somewhat in contrast to many of the other Porsches that have many more resources for enthusiasts to work on their own vehicles. The irony is that the Cayenne is developing a large set of online resources such as this and DIY guides to make up for it. And that is great, so thanks again guys. As for the venturi tube itself, wow, great catch Lewis! I never would have guessed this, as this is how I bought it. For my second comment, I bought this Cayenne from someone who had it extensively serviced at the dealer, or at a very expensive private tuning shop. Going over the bills they spent 22 thousand dollars over the past 3 years. But when I look at the quality of the work that has been done, I am really appalled. For example, when I replaced the hatch shocks, those white pieces of plastic were broken; clips were bent in the headliner and not attached properly, just a lack of careful workmanship. So it doesn’t surprise me this is on the wrong side. But again, I never would have guessed, so thanks, and I’m going to go work on it now!

-

You guys have a lot of experience with the hoses up top, and I was hoping you could help – this is where my venture tube attaches to the Y pipe. Is it supposed to be on more? So is where the red arrow is supposed to be all the way up at the blue arrow? Or is there supposed to be some space? There is obviously some oil leaking there, and it looks a bit crooked. Also, if you follow that tube back where it runs near the fuel rail it is rubbing on a bracket (at the arrow), which doesn’t look right either. Is yours like this? I can’t push it on any more without taking things apart, and I don’t want to break anything because it is really jammed in there. Thanks.

-

I think we have quite similar engines Lewis and we get similar mileage – combined city/highway is usually 14.5 l/100km range, best on the highway is around 11.0, drive it hard and it can be as bad as you want it to be! Also, I have the PCM 2.0, but it also has the option to change units.

- 10 replies

-

- ctt oil use

- oil consumption

-

(and 1 more)

Tagged with:

-

All I can add is mine is very sensitive to making running adaptations too; maybe try with and without PSM on? I found with it off it the adaptations are less, and it makes less “mistakes”. After idling for a while mine will definitely run poorly. Also agree that engine running condition has a significant effect on shifting.

-

Mine uses about 1 litre per 1500 miles; about a cup of that goes into the intercooler pipe.

- 10 replies

-

- ctt oil use

- oil consumption

-

(and 1 more)

Tagged with:

-

Even sadder story - I was just almost beaten by a 4 door KIA! A 2 lane getting on the highway contest, could barely keep a car length or two in front of him. Ready to sell it after that! But seriously, thanks for all the photos, I am now going to dig into mine and see if something is leaking, lowering my power output. Might relate to the transmission shifting problems too.

-

Yes; are you thinking a vacuum leak could do this? The work on the MAFs was somewhat successful – after draining the oil from the intercooler hose I cleaned the MAFs yet again, and this time it seems to be lasting longer. The idle gets rough much less often, and starting has been better overall. But I do suspect some airline problem, as it now does sink to 400 rpm then pick back up again to 580, which is often a sign of a vacuum issue. So I’m thinking since the transmission hard downshift is only after the throttle has been open a lot, the two could be related. Just not sure which lines might be the culprit. I guess a smoke test is in order.