Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

89 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by jchapura

-

2005 C2S 997.1 I just changed my fuel injectors and want to check for fuel leaks before starting the engine. Does the fuel pump activate with the key in the key on position? If so, does the pump stay on in that key on position, or does it time out if the engine doesn't start? I have a Durametric if that's needed to have the fuel pump stay on for 10-20 seconds without starting the engine.

-

If it's a dealer or a Porsche-focused independent shop then they will have the PIWIS. It might be as simple as a couple of connectors not making the best electrical contact. You could locate connectors along the light's electrical path and then undo them and spray in some Deoxit and then plug/unplug/plug them a few times.

-

My car's been in the shop a few days to try to diagnose the issue. I picked it up today. It was the air conditioner (high) pressure sensor switch - it failed in a way to indicate a high pressure and that caused the computer to command cooling the Freon with the condenser and radiator cooling fans on high. And the high pressure indication was in the presence of the system that had no Freon. The lack of Freon was odd because I remember the A/C cooling the car the last time I drove it in the Fall and despite the fact that the system held vacuum for 30 minutes (after the pressure sensor and drier were replaced) and a sniffer could not find a Freon leak after the system was recharged.

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

Well, John, I continue to be stumped... One last attempt to learn more before taking it to a shop, I took it out for a 30 minute drive. (FWIW, the climate control was in ECO mode.) As expected, thirty seconds after start-up, the radiator fans turned on high. About 1 minute later, the fans turned off as I was driving very slowly out of my property. (And the PSM Failure dash warning also turned off.) At various stop signs, no radiator fans could be heard. After pulling into the garage at the end of the drive, while idling, neither the radiator fans nor the engine compartment fan were on - on would have indicated continued abnormal operation of the fans (because it's cool outside). ...just stumped (about the original problem).

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

I cleaned the battery posts and cable ends. I refitted the battery into its position. I cleared all fault codes with the Durametric. I started the car (in total, I idled it about 10 minutes). Starter rotational speed and engine start-up time were all normal. The PSM error was displaying on the instrument panel. Within 30 seconds, both front radiator fans turned on high, and remained on during the 10 minutes. I cleared all the fault codes. Toggling the ECO switch on the climate control made no difference to the radiator fans being on. I left it in ECO mode. The engine compartment fan never turned on during the 10 minutes. I cleared all the fault codes. After the last "clearing" of the fault codes, these fault codes were seen: C141 8023 C140 C131 Thoughts? What can I check/do next? I'm perplexed.

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

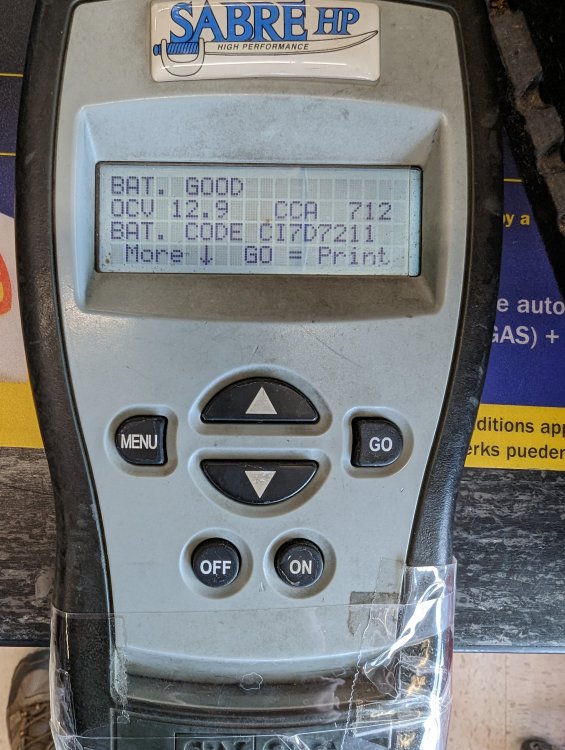

I took out the battery and I had it load tested at two places. The battery is a NAPA Legend that has 765CCA. Place 1: Tested good. Voltage sagged to 11.5v. Place 2: Tested good. Voltage sagged to 12.2v. Where to go from here to solve the "fans" problem?

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

Lost Radio Code - post your request here

jchapura replied to pennyporsche's topic in Lost Radio Codes

@Loren - I have a 2005 997.1 C2S with the Bose stereo. If I disconnect the battery for an extended period, will I need a radio security code to able to use the radio after I reconnect a new battery? -

@Loren Loren, I have the Bose system...would it need a radio code after changing out the battery (disconnected for a few hours).

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

What is your "throw away" voltage when on the load? Less than 9.6v?

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

Would you agree that the 2005 997.1 should not need a radio security code?

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

When the current battery dies, the battery I'm thinking about getting is an Optima Yellowtop.

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

I don't have a specific battery load testing tool. Nor a recording multi-meter to capture the voltage while cranking the starter. Is there any risk to taking the battery out of the car and taking the battery to an auto parts store to use their load tester? For example, will any computers/settings be (semi-permanently or permanently) lost that would then need a PIWIS to get going again? Or, should I buy a battery load testing tool? I see they range from $40 (no-name on Amazon) to $130 (Foxwell BT705)? Or, should I just buy a new battery?

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

My 2005 C2S 997.1 has been sitting for a few months. It has been on a CTEK battery maintainer. I took it out for a one hour drive today. Just after engine startup, at the end of the drive, and another engine startup after a two hour rest in the garage (water temp gage showing about 120degF), it exhibited symptoms I'd not seen before. Immediately at startup with a cold engine, the engine compartment fan came on and stayed on. About 30 seconds after engine startup, both cold engine and warm engine, both radiator fans came on and stayed on. I have a Durametric and captured the following fault codes while the engine was running (I traversed every menu item on the left of app window): C140 C141 C131 C152 (I think this is due to the inactivation and removal of the PASM module when I converted to coilovers) 8004 8028 8029 8042 FWIW, I was not in ECO mode so the air conditioner compressor was probably running. I was trying to recirculate the freon and oil. (I usually run in ECO mode.) FWIW, there's no CEL indicator showing on the instrument display. Engine water temp about 105degF. Started engine. Engine compartment fan is on. Within 30 seconds both radiator fans roaring (seemingly like they are on high). Using Durametric, went to Front/Activations and found 3 "Radiator fans" (not sure why there's 3). See pic below. First entry - clicked STOP. Nothing happened. Second entry - clicked STOP. Nothing happened. Third entry - clicked STOP. Nothing happened. First entry - clicked START. One of the front fans (or maybe both, it got quiet) slowly spun down and then 10 seconds later it went back to high. Second entry - clicked START. One of the front fans (or maybe both, it got quiet) slowly spun down and then 10 seconds later it went back to high. Third entry - clicked START. Nothing happened. Toggling the ECO button on the climate control didn't seem to make any difference. Gas has Stabil in it. Battery's installation date is July 2014. Yesterday, after the battery-maintained multi-month inactivity, the car acted OK - normal starter rotation speed and fire-up time. Today, battery's voltage after sitting all night, NOT on the battery maintainer, is 12.67v. Why might these fans be acting abnormally?

- 16 replies

-

- cooling fan

- radiator fan

-

(and 1 more)

Tagged with:

-

I would have asked for more info/evidence from the salesman. The service records. What pre-sales work was done on the car. Type of oil used at the oil changes. The AOS-related crankcase vacuum. The borescope video or pics. The spark plug pics. Type of climate in which the car has resided during its life. Based on new info, I then might have had it PPI-ed. All of this let's you negotiate from a better position. (I'm surprised the salesman left the exhausts oily. Oversight? Hint to the unsuspecting customer? Just not knowledgeable about oil in the exhaust? After the new info was collected, I would have then asked the salesman specifically about the oily exhaust. Part of your discovery is to try to learn their ethical standard.)

-

I don't have any specific experience resurrecting a car in this condition but I can offer general pointers. Did you smell plastic burning or melting when the over-voltage occurred? That would be a bad sign and wiring damage is likely. The resurrection becomes a lot harder if cables/bundles have to be assessed and replaced. It is possible the over-voltage caused fuses and relays to be damaged. I would hand check every fuse with a DMM/continuity test. I would bench test every relay. Or just replace each and every one. Check or replace - just depends on if you have more money or more time. After you've established that electricity can flow to downstream components, the next likely damaged component is/are the computers. I'm not sure if there's a business that can bench test them out of the car - if you find one - you may want to send them each module. When you find one dead - you'll have to replace it and then move on to the next module. An interim goal might be to get the module that directly connects/sends info to the OBDII connector (do they have that in the UK?). Then once that's working you can use other diagnostic tools (OBDII reader, Durametric) to get other modules assessed.

-

2007 997 C4S

jchapura replied to Russ B's topic in 997-1 Series (Carrera, Carrera 4, Carrera 2S, Carrera 4S)

For phone calls and listening to Amazon Music on my Android in my 2005 C2S, I use the iSimple Tranzit BLU FM Transmitter and Bluetooth Adapter. One has to tie it into power and the antenna but that wasn't too hard of a job, just tedious. I'm not sure it's still available but there are even more options available today (for "wireless" FM transmitters/Bluetooth connectivity). -

It is normal to see rubber bushings deteriorate with time and usage. The deterioration accelerates in high stress areas. Normally, bushing "separation" would lead to "clunking" sounds but even if those are absent, if it were me, I'd plan to replace the parts "next time I was in there" (perhaps when doing other maintenance items). I replaced a lot of the "harder to get to" parts even though they showed minimal issues, when I switched to Ohlins coilovers. Rubber/stressed things just don't last forever.

-

Smoking Exhaust

jchapura replied to PAULSPEED's topic in 997-1 Series (Carrera, Carrera 4, Carrera 2S, Carrera 4S)

As far as I know, the Primary AOS on the 997.1 3.8 is not serviceable by draining. Have you checked your crankcase vacuum? Either with a manometer or the oil filler cap removal resistance method? How old is the AOS? If not original, is it genuine Porsche? Any squealing, screeching noises? Do you park on an incline? Is the smoke persistent or only at start up? -

Water Pump Torque Number

jchapura replied to PAULSPEED's topic in 997-1 Series (Carrera, Carrera 4, Carrera 2S, Carrera 4S)

Well, at least not charging "flat rate" or "book rate". 😉 -

Water Pump Failure

jchapura replied to propchef's topic in 997-1 Series (Carrera, Carrera 4, Carrera 2S, Carrera 4S)

I'm not sure. I've heard it's best to stick with a Porsche branded pump (rather than even the OEM Pierburg). -

Water Pump Failure

jchapura replied to propchef's topic in 997-1 Series (Carrera, Carrera 4, Carrera 2S, Carrera 4S)

Thanks for sharing. That's quite a failure mode. Never heard of the prop shaft just snapping like that "out of the blue". You lucked out that the impeller didn't wobble into the block (and shed plastic) while it slowed down. I replaced mine about 4 years ago. The replacement period consensus I gathered was to replace at about 40000 miles. Definitely replace the thermostat at the same time. And other things, as you mention. Happy motoring.