Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

Contributing Members-

Posts

926 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by lewisweller

-

Rear park assist

lewisweller replied to angusc's topic in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Get a really quiet area and put car in reverse with ignition on engine off. Then jump in the boot, and pass your hand over each sensor, you will hear a faint click if the sensor is good. No click or very weak click normally indicates a dead or faulty sensor. -

Removing the top hose is not worth it, trust me. This might help you visualise what the maf is connected to. It is a tight fit even with the clamp loose, to get it out rock it side to side whilst hold the lower flexi pipe ribs. As long as you don't rip the lower pipe up, so holding it tight you can wiggle and curse the maf out of the housing. When you refit maybe a small wipe of silicon grease on the pipe inner contact point will serve you better for the next time.

-

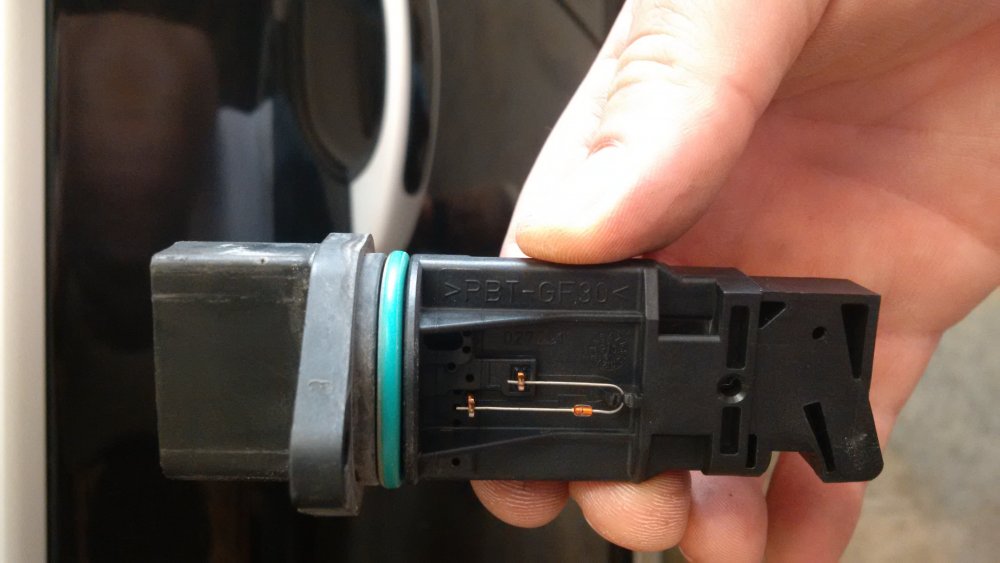

If you have the special tool bit you can unscrew the maf sensor alone and pull out spray clean and refit. Unplugging with ignition off will not set any new codes. The MAP sensor yes can be cleaned with carb cleaner. Remember do not rub wipe scrub any sensors, only spray then let evaporate and repeat. I used electrical contact solvent cleaner but the proper MAF cleaner is probably better. Try and let the spray run out and not ingress into the sensors housing and other areas which may not like it. Picture is what your going to see maf removed, just right of my thumb is the slot where the air passes the metal heated plate spray through there and it should be shiny and like mirror clean. The diode to the left of my thumb, also can spray clean no probs.

-

I'm at the point where if I sell this thing someone gets a bargain with a shed load of new parts and tlc for free and probably a great suv for a good few years more. That's why I made the decision now what ever happens I will persevere because I can never get back what I spent so have to take the enjoy instead. After driving the old man's ford Explora 2016 around with its pants 300bhp bag of nails sounding weak asthamtic engine I think screw spending 175k AED on that pos I'd rather spend 45k AED on a ctt with 500bhp and do some work and spend some money making it a great motor once again.

-

Sorry mislead you with saying transmission mount lol. Did you find anything yet? I got a bit of a steering wheel shake when I accelerate a bit hard and higher speeds. I don't know if wheel balance, engine mounts, or just old bushes in the lower arm, ball joint and or steering tie rods and rack mounts are showing their age now. Nothing oblivious is loose or broke. I changed the right side top arm some weeks ago, the ball joint was oval shape and loads of play, I have the left side arm ready to fit but I checked and it's solid still so wasn't rushed to change it. I think given its 10yr old I might as well crack on and strip the left side replace that top arm and have a good search and check for anything else worn out. Wheel balance and rotation doing on Friday, alignment done 4 weeks back and all good.

-

Its the AOS diaphragm is split I think, haha I thought it sounded like a balloon when you blow it up and stretch the neck and let the air escape slowly screeeeech, make sense the diaphragm is rubber. I will pop it out later to make sure, now need to buy another one from that BMW website and a air compressor seal and piston ring as well whilst i am at it. . VID_20161101_171405.mp4

-

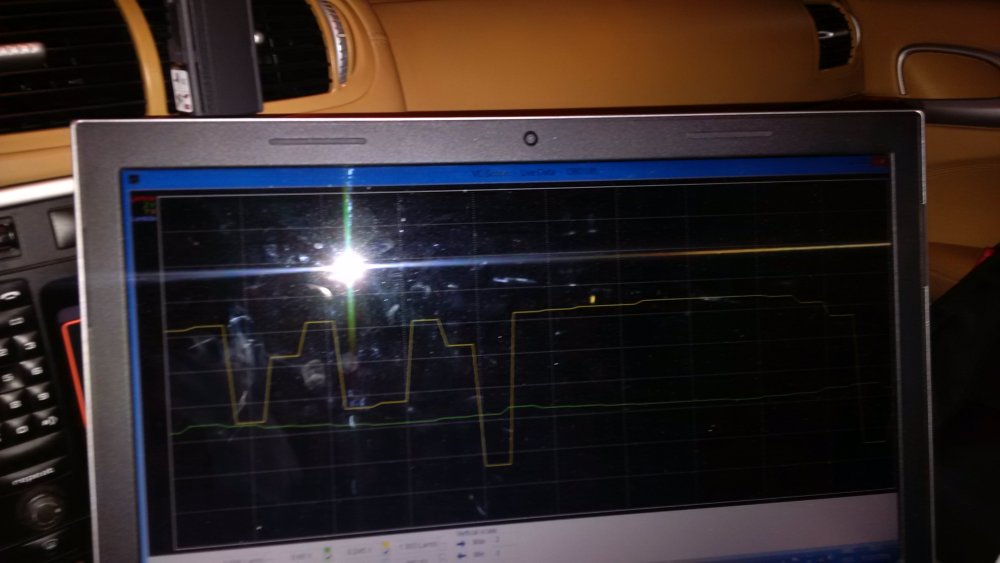

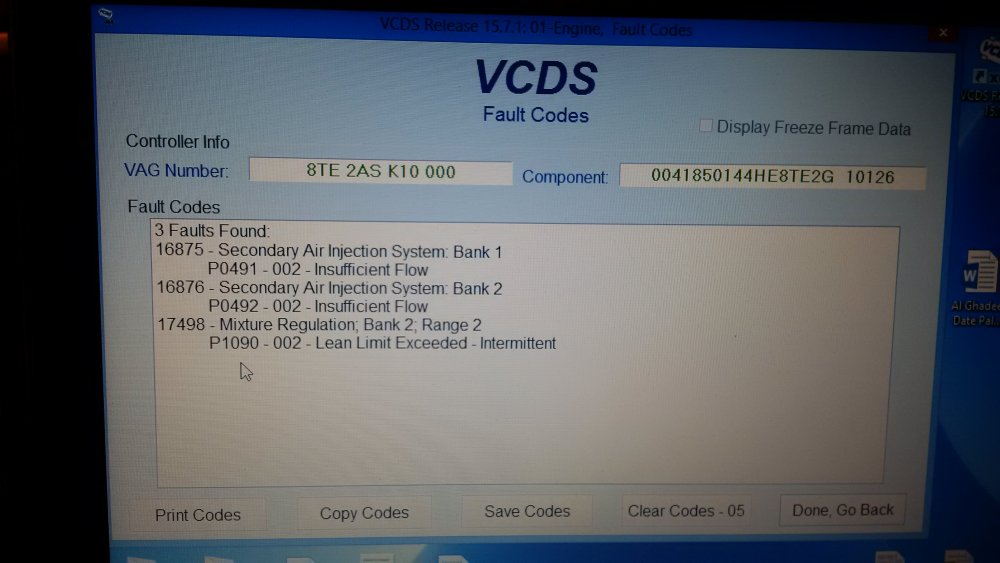

I got a code!! Driving today gave it some beans and here a weird noise something leaking I think, sounds like a fan belt screeching but it only on high boost not rpm related. I pulled P1090 code and looking at the O2 sensor on bank 2 it's all over the place jumping up and down. First pic is o2 sensors graph with snap open throttle, yellow line is bank 2. Second picture is at steady idle, look at yellow line of 02 sensor bank 2 going wild. Third pic the dtc codes the Vagcom scan shows, ignore the SAI code I disconnected them. The maf reading g/s is also low for the idle I noticed. Few possibles here, leaky pipe somewhere, dv valve fault, faulty maf or o2 sensor or combination of these hence the noise has to coming from somewhere. Haven't time to get dirty today but excited to fix and see if by magic the remaining running hesitation is gone. Anyone got experience of P1090 code and weird boost leak screech noise.

-

Driveshaft rebuild done today but was rushing my *** off so no pictures at all. Quiet as a mouse now on full locks forward and reverse. Tick box The test drive was great, first time since changing the wastegate to n75 valve flexi pipes that were leaking. Amazing difference in throttle response and pick up. Still is a bit clumsy from low rpm when the boost comes in strong but wow what a different car to drive without this small leak on the wastegate. I think the wastegates really play a critical role in how boost is delivered in the lower rpm especially and low early boost periods ie when boost is requested this is when the wastegate is most prevalent in how if it is malfunctioning you will feel it, at high rpm full boost acceleration it's less prevalent to the way the engine behaves. I need to find the correct groups on my vagcom to log boost requests vs actual and see if they are far apart. What's still mind boggling is in Park or neutral you rev the engine to 1k and just over 2k and it vibrates to hell, why I have no idea but if I fix this i out my life on it the surging and hesitant acceleration will also be gone.

-

First thing to visually check from underneath is the three mounts for the transmission, if they are cracked or split you get clunk when getting on throttle. Next is to check the engine mounts. Normally engine mounts will produce a vibration coming to a stop as the idle speed range is reached and driveline almost stops turning. So for me transmission mounts, mine were all spilt and yes I had a slight clunk if I was how shall we say "gettin on it" engine and driveline was dropped out for head gasket so was a no brainer. Don't rule out out worn diff gears and driveshaft and even suspension bushes but this is less likely.

-

Correct thomas the smaller pipe which is 6mm outer dia and 4mm inner dia I reused and just bought the 6mmx13mm pipe to connect to the smaller pipe and down onto the wastegate. Fits nicely and not a squeak of air leak can be heard after. Perfect. Looking forward to driving after rebuilding CV joints and boots tomorrow. Will do a picture and write up of driveshaft rebuild for the sake of it.

-

Correct no horns and other issues related to the alarm, keys range, memory settings, locks lights inside and out are all classic rear comfort convenience module (ccm) problems. Some have had them replaced, some have had them reloaded with new updated firmware and soft ware, some live with the related issues, I have "check tail light" and "brake light fault" warning when pressing brake pedal with lights on, only if voltage is lower than 13.3 volts from other loads on; otherwise it works fine, also the horn for lock and unlock is mute. I've tried recoding it with my vagcom, it works, the new code that is, but the problems aren't fixed. I would try a used ccm but needs key coding and I think only Piwis can do this.

-

Hearing a noise on thursday sounds like a leak only under boost conditions. So Today I practised what I preached. Did intake Hill Billy style smoke test through the MAP sensor hole with air box pipes plastic bagged closed, which was fine no leaks, also quickly checked the dv vac pipes no leaks. But when pressurising the wastegate vac pipe from n75 valve could hear loads of air leaking out both sides. Just running my hand along the pipe down to the wastegate could feel the pipe was split almost identically on both side vac pipe. Both vac pipes are very brittle I tried to cut of a bit and reconnect but no dice. So jumped in the dad's ford (pos) and headed for the hydraulic pneumatic shop. Found the 6mm id x 13mm od pipe and swap both section either side, lucky it fits nice over the wastegate spigot stub pipe without a clip cos heck I can't get my fat fingers in there let along a tool to fit a clip on the pipe. The best thing is the new pipe allows the smaller pipe section which run up to the T and into n75 to just slide inside and with some "Ear clamps" I bought pinches nicely around to make an air tight seal for just $4. Bargain! I also replaced that little flexible piece of pipe on the bottom vac pipe of the n75 valve as it broke twice and I couldn't cut it any shorter lol. So guys don't buy expensive new pipes from Porsche for $100's just get a size sample and head down to you local hydraulic pneumatic shop. Also changed the oil and filter today. Oil was very thin and black after just 4k km. Also the filter was full of crap and bit of I don't know what but not metal. I think left over grim from the head gasket job 6 months ago. Glad I did it the filter must have been near blocked by the look of it. I refilled with a "cost effective" German made vw approved brand Ravenol 10w40 as I think this aging engine and it's variocam system required a thicker viscosity as it wears in later life. Being only semi synthetic means a earlier change but here in middle east I never go above 10k and would be changing this oil after another 5-6k km. Some comments on oils for older ctt would be interesting if anyone cares or has info to share pls?

-

This is the best article I've found so far on testing maf, I'm going to do it tomorrow if I get time. Using the Vagcom voltage of the maf is not entirely accurate maybe? Also will try a full acceleration log graph of the maf reading and see if it is looking correct. Will post my findings.......... http://easyautodiagnostics.com/vw/1.8L/maf-sensor-tests-1

-

My friend You have inadvertently tested the n75 valve and vacuum pipes to each wastegate and NOT the DV's which will be tucked under and to the right of the red arrow 1" and down 2". But not to worry, the blue pipe is indeed the bleed off air return to the turbo inlet so open is correct, the Green is the control pressure air to open the wastegates obviously just splits off at the T red arrow to each turbo wastegate. Now to open the wastegates you need between 7-12psi and I'm sure you can't blow that hard, so use a air Compressor regulated to 10psi and pulse gently into green arrow pipe, you should hear no air leak at all or bingo you found a problem with either the vac pipes or the wastegate(s) diaphragm split. When you get the air pressure in the green pipe you can hear the wastegates creaking as they move, the sound should be simultaneous both side or something is not right. Again any air leak is going to cause running issues like for example over boost code and limp home reduced performance will start. To find the DV vac pipe it is this one in my zoom in of your picture dead centre of my first picture running vertically with the mini metal clamp, this runs along the manifold from the change over valve at the back of the engine. At the bottom end of the pipe you will find the T, it's hidden under the intake pipe in your picture. Mine is exposed as I lifted it above and next to the purge valve when I had it all apart, its so easy to check now routinely.

-

On other Vag turbo cars I've owned when you put a cold air intake on it your can hear the Flutter of air noise from the wastegate flap opening and bypassing the exhaust gas around the turbo. The standard air box muffled and mutes this quiet well but intakes don't. Flutter noise is normally one of both of the diverter valves on our cars. If the diaphragm is split (most likely) or not operating correctly because the vacuum pipe is split or the changeover valve is not functioning correctly they can make strange noises, some describe as honking, this when the boost leaks around the dv and back into the turbo intake pipe. A simple test to check the dv is disconnect the T piece of the vacuum pipes which is just to the right side of the throttle Y pipe under the "turbo" cover. Pull apart the vac pipe from the right dv and blow hard, repeat on the open T pipe end also, if you can blow any air through you have a leak or a broken dv.

-

When I replaced my directional lights (same like you one bulb knocks out two) my wiring was also a little crispy and flaky, I tried to move it a least I could to do the swap as the more I moved the more bare world I could see. I put some electrical tape back over any exposed areas and buttoned it all back up. Been working for 7 months so fingers crossed won't give me anymore lip.

-

Wow big headache and you done well to fix a lot so far. The brake light switch is in fact a hydraulic pressure switch on the brake master cylinder which will send a signal to Rear Comfort control module (located right side of boot with CD changer same place) or via the abs module first but not sure. The fact you found so many corroded or broken wires will either mean you have some more to find or the component(s) associated got damaged during the wiring issues time. Sorry can't be more help this is nightmare fix without Porsche software. Good luck and keep us posted.

-

Injection cleaner probably won't help, hot and cold starting with blocked injectors is the same symptoms really. I would be looking at temp sensor malfunction or compression possibly whilst checking spark plug condition too. Another possibility is fuel pressure regulator not holding the line pressure but 8second is still too long to wait the pressure to build up I think. More like 2-3 second to build and then start.

-

Yes 12volts is either very flat battery or its toast. Read this from the Touareg forum, they say if not battery voltage its the kessy unit and/or door handles faulty conflicting with the the shifter selector to give "move selector to P position" dash warning.!!!!!! http://www.clubtouareg.com/forums/f43/move-selector-lever-to-position-p-19031-5.html I also know the kessy antennas and door handle sensors can drain batteries when faulty. Maybe all related problems Thomas?