Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

-

Posts

8,588 -

Joined

-

Last visited

-

Days Won

190

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Posts posted by JFP in PA

-

-

Have your system pressure tested; takes 15 min. and will confirm if there is a leak, and may even be able to see it.

-

More to the point, if whatever Jake developed actually works, and I have no reason to think it does not, it would be very useful to anyone with an M96/97 from late 2005 on until the introduction of the shaft less replacement. On these engines, the IMS bearing cannot be changed without totally disassembling the cases, which ain't exactly cheap, pretty much eliminating "preemptive" IMS replacements. But if you owned one, and there are a fair number of them, and this system has warned you of an impending failure, you would be thankful for the information, and then able to take appropriate steps to save the engine...................

-

At one time, PPBB was probably the most Boxster focused; but with its founder's death, it kind of went off the beam and eventually was shut down. I'd have to agree that from an even handed technical perspective, RennTech is probably your current best bet, although there are other "pretenders" to the title.................

-

The cylinder head has a plug about that size but I think if it blew out you would have coolant/oil mix as it's under the valve cover area.

That's what I was thinking; if any of the plugs in the engine came out, there should be "consequences", but you haven't mentioned any. I wonder if it was an "extra" left in there when the unit was assembled?

-

For general use on multiple vehicles, look at Actron, great value for the money. For the best data and utility on a Porsche, go Durametric.

-

We have several customer's running the Accusump system, some which we installed. Is there something specific you want to know?

Two things:

Where have you mounted them?

What pressure do you them for?

I'm new to forums. Do you own / work at a Porsche repair or engine building business. I ask because of the reference to customer's cars. Thank you.

In the rear boot.

Slightly above max oil pressure ~60-80 PSIG.

Yes, I own a business.

-

Ok fellas, to all that helped with my other posts about the no start problem, thanks. Now I picked up my boxster yesterday, starts, runs fine, but the trans in now in limp mode. I have a feeling that somewthing happened when at my mechanics, as when I went to pick it up, the spoiler was deployed as well. Before I took it, he put it back on the diagnostics, but could find nothing. I babied it home, now I will try to trouble shoot this. Maybe find another mechanic. Lol

Pulled 2 codes with the OBD2

P0600 - CAN timeout (or bus error) - present

P0706 - Multi-function switch - signal implausible

Any ideas?

Also, I've done some research, reading, etc, and was wondering if anyone has any experience with the durametric software for porsche, and will it pull the error codes for the tiptronic?

TIA again

Jim

P0600 is a Tip code, indicating that the CAN bus cannot communicate with the Tip's control module. Could be a harness unplugged, broken wiring, or the Tip control module itself.

-

I sincerely doubt that the DME needs re-flashing.

-

Check and make sure you did not dislodge or damage the leads to the crank position sensor (on the bell housing). If the CPS is disconnected, the DME does not know the engine is rotating, and it will not fire......

-

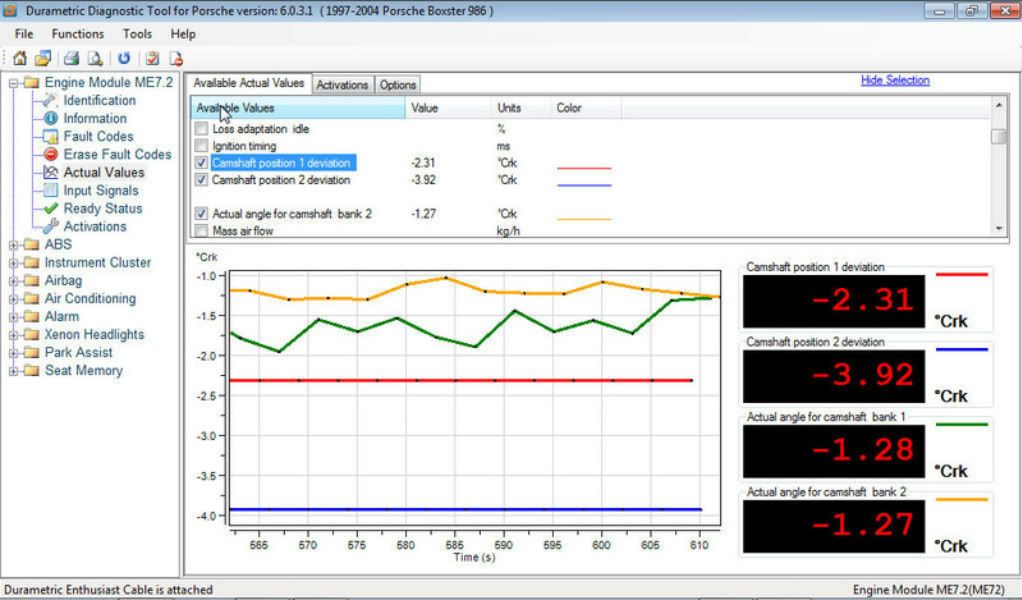

The software system is reading the cam position sensors vs. the crank position sensor to determine the cam positions. I'd be looking at the VarioCam reluctor, the cam sensor on that side and the VarioCam solenoid on the same side. With the Durametric system, you can trigger the VarioCam solenoid with the engine idling, and should see the cam angle jump when you do; if it does not change, it could be at least part of your issue, as it may be stuck in one position. These, along with visually checking the cam slots can be done with the engine in the car. If the cam has mechanically jumped time, it would probably be easier to pull the engine to correct the issue, although it has been done in the car, albeit with difficulty.

When the rear IMS bearing starts to get loose and wobble, the cam drive chains go slack, causing the "death dance" in the cam deviation values. Eventually, if the IMS does not totally fail, the chains get loose enough to start jumping time. Unfortunately, this entire process often only lasts a second or two before pistons start bending or breaking valves, totaling the engine (the M96/97 is an "interference" engine and cannot tolerate too much change in the cam angles before disaster strikes).

-

If the cam time has actually moved, it is both "not a good thing", and somewhat complicated to correct. Can it be done in the car? Yes, depending upon why it jumped, and in any case is a nightmare to do. One of the common causes of strange cam timing issues is a wobbling IMS bearing; typically the beginning of the "death dance". The cam deviation values should be rock steady at idle, as in the posting above; if they are not, it is usually the IMS on the way out.

Cams do not bend, they break; the VarioCam flange bends, throwing off the cam position sensor. This can be a relatively simple repair.

-

I'd bet more on the drain being blocked by either debris or mold, common on these cars in very hot, humid climates. Wurth and others make some stuff that you can spray into the system that will both clean it and kill any odors at the same time. You can see the drain line from below the car and can blow some air through it to clear it before spraying in the cleaner.

-

The sensor has a test diagnostic (voltage should read between 100 and 800 mV, ohmmeter on pins 1 & 2 should read 1.8-2.5 ohm, pin 1 to sensor housing should read infinite ohms ), test it to see if it is good or not; if it checks out, you probably have a wiring issue elsewhere.

-

To my knowledge, Flat Six (Jake Raby) keeps records on the cars they actually do. LN may have records of who they sold the bearings to, but without verification by the shop that actually installed it , anyone can claim to have the upgrade. We get requests for this from time to time and provide a written record of when it was done. And, no, there is no way to verify if a car has one without pulling the gearbox, clutch and flywheel out..................

-

Thanks Where can i purchase it? also how will i know what size insert

Most good auto parts shops carry them, and they can help you with the size. Shops like Fastental (all they sell is fasteners) are an excellent source as well, and the inserts are also available on line.

-

Considering the number of Rolex and Cup series cars that use ATE, I really have to wonder what the issue is here.................

-

You do realize that activating the ABS/PSM system during a brake flush is not necessary? It is only required if you have gotten air into the system controls or pump during service to the system, otherwise the system is simply flushed like any other vehicle………

-

Timesert is another source for this type of repair as well.

-

Some of the earlier years (like yours) developed a problem with the horn contact ring in the steering column, causing intermittent problems (sometimes the horn won’t blow, other times it blows all by itself) or even total failure of the horns. Problem can usually be fixed by cleaning the contact ring and the contact itself, but occasionally the parts need to be replaced. Fortunately, they are not very expensive.

-

Thanks JFP.

I found this spec in the WSM:

However i interpreted that as being the intake riser to head.

Perhaps that spec is for both the riser to the head and the plenum to the riser?

They are both the same torque specs.

-

What is annoying is the section in the fuel manual that covers the intake distributor lists the bolt just like it does in other parts of the manual. But under install notes there is not a torque value listed, just blank.

Perhaps I should just treat it like any other generic M6 fastener, and torque to 7.5 ft lbs. I don't want to damage the green o-rings.

Just to clarify, here is a picture of the bolt I'm trying to find specs for. Thanks again.

Correct torque is 9.7 Nm, or 7 Ft Lb.

-

Hi,

I need to remove about 1/2 liter of oil engine after overfilling.

After some reading, it seems that the recommended way is to remove the filter cover.

I assume I could only jack the car up on the left side, remove the wheel then remove the filter.

Is my understanding correct? (I'm concerned that the all 9 quarts will flush on the floor...)

So I would greatly prefer to remove oil from the filler in the trunk using vacuum.

Anybody ever done it?

What is the diameter & length of the pipe to use?

Thanks guys

Chris

Removing the filter housing will not cause you to lose all the oil, and the housing only holds about 1/2 quart or so. Be sure to install a new o-ring. And you will never get the oil out using a vacuum system from the filler.

-

1

1

-

-

"This is our promotion vehicle."

Pehaps a little bit of "viral marketing" as well...............

-

More to the point, thermodynamics would predict that the energy required to separate hydrogen would be more than the energy released by then burning it. As this system adds both weight and complexity to the vehicle, plus generating nearly 20 amps is going to add to the alternator’s parasitic drag on the engine, this is starting to sound more like a perpetual motion device………..

Touch up paint

in 987-1 Boxster Convertible Top Issues and Solutions

Posted

Did you shake it well before using?