Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

rennbod

Contributing Members-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by rennbod

-

--- UPDATE for the archives --- Not been back here for a while.. But it seems the problem was solved. Having loaned my friend the PIWIS for the last few months to be able to keep looking at live data and actual values and generally hack about with the electrics, the problem was found through a shot in the dark and false diagnosis by a main dealer! He experienced problems with his remote key head which was only a couple of months old, so took the car into the local Bournemouth main dealer to resolve under warranty... They claimed it must have been a problem with the main security control unit, not the remote and installed a new one. The bad news (for the main dealer) is that it did not solve the problem with the key remote, that turned out to be the key remote being faulty and replaced under warranty. The good news (the the owner) is he left the main dealer with a new working key remote, and the new alarm control unit at no cost.. But the best news is this somehow also fixed his delayed warm start issue. The last bit of bad news is he just dropped off my PIWIS back to me, now missing its main OBDII cable which he has lost somehow!!! Anyway, for the archives, I guess the immobiliser was delaying telling the DME to "GO!" and for some reason the DME was omitting an occasional spark to the coil packs, but not a regular spark without that code.. or it is something else.. But the replacement of the Porsche alarm/access system fixed the problem!

-

PST2 & PIWIS test step aborted

rennbod replied to rennbod's topic in Diagnostics, Tips and Diagnostic Tools

--- Update for the archive --- Following some help from an amazing chap in here who sent me a copy of the pinouts for the PST2, I can confirm that the problems with programming the Bosch 5.2.2 DME, and therefore the system error codes (not DME fault codes), were down to my PST2 lead missing a couple of pins being connected within the OBDII lead, which had the result of the PST2 failing to verify blocks had been programmed when it read them back. So error code 71 will be a "Data not successfully written" error of the PST2. I would name the helpful chap, but he had asked me to not mention it, so unless he wants to wave his hand, he will remain nameless but a superstar!- 6 replies

-

- pst2

- test step aborted

-

(and 2 more)

Tagged with:

-

Hi, I have a Bosch KTS650 cloned as a PIWIS (1), which was working great until loaned out to a local friend to delve into a problem he had on his 997 which had a delayed start problem (that I posted about last year on here).. Unfortunately, when the unit came back, it was without the main OBDII lead!! So I have some questions for the collective here who may know.. 1 - Is there a difference between the KTS650 and KTS520 connectors and pinouts for the OBDII cable. 2 - Is there a difference between the correct PIWIS OBDII cable and the Bosch KTS Versions and clones? 3 - Does anyone here have a pinout for a standard Bosch KTS650 or KTS520 OBDII Cable? 4 - Does anyone here have a pinout for a PIWIS cable? I know with the PST2 that I have, there is an important few differences between the standard KTS cable and the PST2 Cable, which an awesome member of this site helped me with before.. So before I go making up a new lead (I have just ordered the connector and a 16 way OBDII open ended cable with connector) I will need some pinouts... I have found a place in Germany who is selling a KTS520 cable, which they say works on a PIWIS based on a KTS520, but I am not sure if it will be missing features, or if it will even be right on a KTS650 based PIWIS clone... In particular I experiment with control unit programming and reverse engineering, so I really could do with it being the right lead, so I do not end up chasing my tail with programming errors like I did with the PST2 until I found out I did not have a complete lead.. However, any lead which semi works will be better than no lead at all! Please help!!! Its is pretty useless without the cable!

-

Absolutely, that is what I mean.. Crank position sensor has been swapped with the new one, and the signal checked at the DME connector, all seems to be good. Interestingly, if I go to start the car, but do not let it crank for more than a turn, then switch off the ignition and then back on and into the start position it always starts within a couple of revolutions of the engine... If though, when hot, I just try to start it, it cranks and cranks and cranks for about 10 seconds and then fires up. It is almost as if the Porsche access system is delaying sending the immobiliser code to the DME for about 10 seconds after the key turns to the start position.. I know the 996 models alarm and DME package works in such a way as that the DME does not allow start (starter motor use) or run until it has the immobiliser code from the alarm control unit, so on a 996 this theory would not hold water.. But I am not sure if the DME in the 997 blocks the starter with a relay as well as run.. If it only blocks run, it is perhaps possible that the PAS is delaying in sending the immobiliser code and that is why the DME will not activate the coils or injectors until a few seconds have passed. Other than this, I am at a bit of a loss.

-

I have borrowed an automotive scope and am not entirely sure I am using it correctly, but it does seem that there is no signal at any of the coil packs when the engine is cranking until several seconds have passed. The scope only has one channel so I can not duel trace both cam sensors or the coils to see their relationship side to side at the same time, but the crank sensor and both cam sensors seem to be generating a waveform which only changes in frequency as the engine fires and cranking, but is there as soon as you start cranking the engine. I am beginning to suspect that either the security system is sending the immobiliser code to the DME late, or the DME has an internal fault. I know that with my 996 the immobiliser/alarm sends the immobiliser code to the DME as soon as the ignition is switched on, and it is the DME that allows the starter block relay to close and allow the starter signal to get to the starter motor.. I am not sure if the 997 DME does the same thing? In which case, if it does, I can rule out the security system sending a delayed immobiliser code, because the car is cranking on the starter motor fine. I even had a theory for a while that perhaps the DME was not getting a permanent live, so every time it was started it was being powered just off of an ignition live, which would maybe then cause the DME to perform its own housekeeping tasks, such as trying to initialise the throttle body adaption for the first few seconds (just as if the battery had just been connected) so may have been refusing send ignition signals to the coils.. But I have checked that it has both a permanent and ignition live..

-

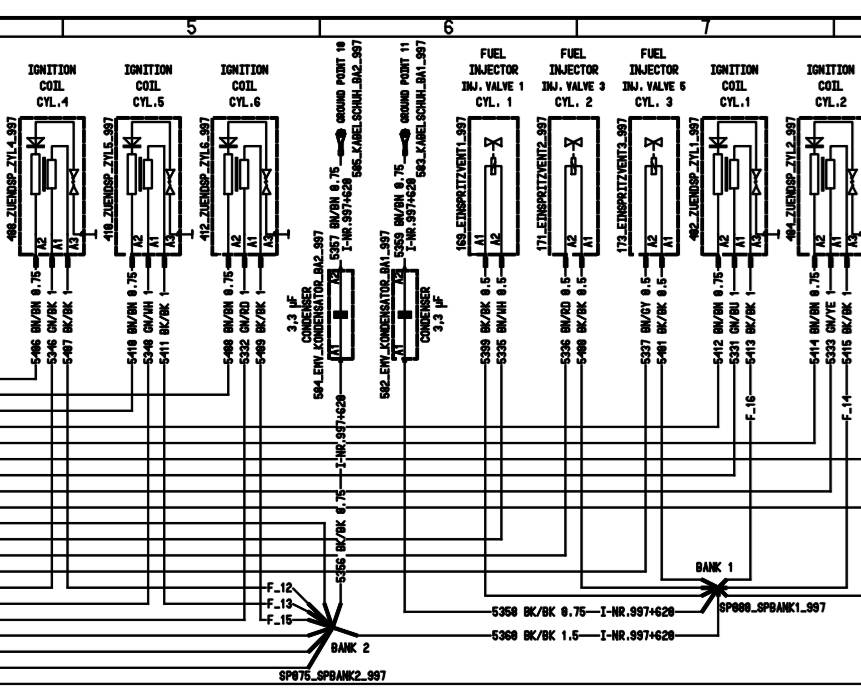

Well exactly, but in this wiring diagram.. Which is from the Porsche PIWIS-TIS system shows the car should have a 3.3uF capacitor which it labels as a "condenser" on the earth wire of the coils.. over to the right you can see the same arrangement for the injectors... which is odd because I am more used to EFI cars having a common power and the DME fires the injectors by grounding the other side... I might somehow of pulled up the wrong wiring diagram, but it does seem to be the correct engine wiring diagram from a 2006 997 C4S as input to the system using the chassis number.. I have checked the harness and there is no component with two terminals between the coil pack grounds and the ground point, so unless like a resistor wire the capacitor/condenser is a special section of wire, it does not make much sense!

-

Another odd thing I have just realised in the wiring diagrams, which I have never noticed before... The coil wiring has terminal A3 from each coil going into a black wire to a join where one black wire exits, it then goes to terminal A1 on a "condenser 3.3uF" and exits on terminal A2 of the same component as a brown wire to the ground point 10. In the diagram the injectors have the same scheme with a condenser.. I have looked at the wiring on this car, and it seems that each bank has its own join for the coil grounds (x3 plus one exit) and no condenser to be found... I was hoping I was onto something here and perhaps the condenser needed to build up a charge as some kind of fault if left for 5 mins to discharge fully... But no condenser. Ive not seen a condenser in the modern car since they had points in a distributor!!

-

On the fuel pressure gauge it looked like it we were getting.. Engine stopped - Fuel pump activated by PIWIS - 3.7 Bar Engine stopped - Fuel pump switched off on PIWIS - 3.7 Bar Engine stopped - 20 mins after fuel pump shut down - 3.5 Bar Engine stopped - 40 mins after fuel pump shut down - 3.2 Bar Engine running - 3.7 Bar During prolonged cranking - rapidly shoots up to 3.7 Bar from wherever it was within a second. The interesting thing is the spark... No spark at all, other than a single pulse (on whichever coil we check) once every 3 seconds. Then as it starts, it has rapid sparks, which obviously continue while it is running (albeit missing a bit because one coil pack isn't hooked up to the spark plug in the cylinder) This to me makes me think that the DME is looking for something and not seeing it until many seconds after initial cranking if the engine has been shut down for more than 5 mins... Or, the DME has a fault and is in a deep sleep until the engine has been cranking for several seconds. Once the engine has run within the last 5 mins it will start perfectly within a second. Part of me thinks it might be a component fault within the DME. Another part of me thinks it could be either the DME is getting a delayed signal (via can bus?) that the engine is cranking? Other than the crank sensor, is it told by the ignition switch box or the security system that the key is in the start position? And another theory is that the alarm/immobiliser/security system is not sending the immobiliser code immediately on ignition on, and there is a delay and perhaps if the DME has seen that immobiliser code within the last 5 mins it does not need it again? I am a bit foxed to be honest.

-

A friend and I have been struggling with a strange problem with his 2006 997 4S with tiptronic transmission. When you start his car you need to turn the key and let it crank on the starter motor for around 10 seconds before it will start, and when it does it seems to be a bit lumpy for the first second or two. However, if you shut it down while it is running and restart it right away it fires straight up within a second. We have pulled off a coil pack and put a new plug into it (earthed out with a jump lead) and observed that while it is cranking there is no spark, apart from maybe one every 3 seconds, and then rapid sparking at the plug as soon as it fires up. We have also hooked up fuel pressure monitoring kit to the car, and the fuel pressure seems to be right, as I thought it may be the fuel pump check valve or pressure regulator bleeding off pressure, but then we discovered what was happening with the spark not being there until 10 or so seconds of continuous cranking. We have hooked the car up to the PIWIS and PIWIS-2 that the local Porsche approved bodyshop loaned to us, and there are no fault codes anywhere. We also had hoped to watch the live data while cranking, but it seems that communication disconnects during starter motor cranking, which we are told is normal. The strange thing is that the car idles fine, runs fine, no hesitation, we have followed the Porsche test plan for checking the mass airflow sensor, we have used a smoke machine on the intake to look for vacuum leaks, we have even checked the various temperature sensors on the PIWIS and all seem to be reporting good temperatures. While we had the PIWIS-2 we even reprogrammed the DME with the latest software, which it said was already loaded but we did it anyway in case something was corrupted. We have even disconnected the battery over night and tried the various re-training adapting methods on the internet. Fuel trims are all hovering around 900 and 1.1 We have even changed the crank sensor for a new one and no difference. If it were not for the loss of spark, I would be tempted to say it was the fuel pressure bleeding off, because it is a little like it is trying to get fuel back up to the injectors when cranking, which would also explain the way it only has this problem 5 mins after shutting the engine down, but not less than 5 mins. Does the 997 DME monitor oil pressure before it supplies a spark? My reason for asking is that this would also be something which would match up with the symptoms, once the oil pressure has bled off completely, it would take a few cranks to regain it, especially if the oil circuit had a fault... But when running the oil pressure is good, however it does seem to be that the oil pressure is at the bottom on the instruments when cranking and either it shoots up and then the engine runs, or maybe it just shoots up due to the engine running at a faster speed than starter motor cranking. We even worried it may be cranking a little slower than the DME was happy with, so even replaced the dreaded alternator/starter motor/charging harness on the engine.. Which now has it cranking a fraction faster, but still the same problem. Having compared the cranking speed to my Boxster and 996, it seems to be turning over at the same kind of speed. Any ideas anyone??

-

Been on the forum asking an unrelated question and thought I would update this for anyone who finds the question on Google, but can't find the answer. The issue turned out to be an issue that the Durametric is missing an option to set in the rear body control unit that the PIWIS does automatically. From the chassis number the PIWIS knows the year, and so is able to set several other bits in the rear body memory/coding to say which transmission it has. The later transmission has the microswitches in a different part of the sweep, so the rear body control unit needs to know which year it is so it also knows if to stop the motors when that microswitch closes, or when it closes and then keeps going until it opens again. I played with every option in the Durametric to get this to work, but in the end coding the roof with a PIWIS worked right away, without having to set any options, the PIWIS knew what to do right away with the minimum of information.

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

PST2 & PIWIS test step aborted

rennbod replied to rennbod's topic in Diagnostics, Tips and Diagnostic Tools

Ohhh.. I need to find a copy of those then.- 6 replies

-

- pst2

- test step aborted

-

(and 2 more)

Tagged with:

-

PM Sent. I have always wondered about the pinouts as my cable does not have a pin connected to the OBDII for software voltage which would have been required for the programming of a 5.2.2 DME, however it has always been happy to read the vehicle data fine from a DME. About two weeks ago windows/dos was grumbling about a corrupt file, which I told it to repair, but the machine seemed to still run fine afterwards, now I am wondering if the error might translate to "File name not found" in PST2 talk, as that is similar to "expected block title not arrived"

-

PST2 & PIWIS test step aborted

rennbod replied to rennbod's topic in Diagnostics, Tips and Diagnostic Tools

Have looked in the 986 manuals and do not recall seeing the error codes mentioned in the 996 manuals. Do you have any clues where they may be?- 6 replies

-

- pst2

- test step aborted

-

(and 2 more)

Tagged with:

-

24.0

-

Moving on from my question about the "test step aborted" code numbers. One other thing I find, if I try to read the vehicle data from a DME 5.2.2 I get a pop up window that says... Fehlercode 7014 Fehler: erwarteter Blocktitel nicht eingetroffen (C_SD_FZ_KWP_2000::receivelstwert) With an "OK" button under it... If I hit the enter key, the PST2 reboots... Anyone know what this means? I am begging to think that perhaps a file or data on my PST2 might be corrupt!

-

I have had my PST2 for about ten years now, and would you believe I have never pressed the F1 key on the first screen and so had no idea it had the manual built in!! I had the paper version of the manual and quick start with it when I brought it and looked after those manuals as if they were gold dust, and all along there was a built in manual!! I had to just boot it up and try it, I feel like such a dumbass! You learn something every day!

-

Sometimes when programming the DME or Alarm control unit with the PST2 or PIWIS, you will get an error of "Test Step Aborted" followed by an error number, such as 3, 21, 25, 71 etc. I have the PST2 manuals, as well as the KTS manuals and the 986 and 996 Dealer manuals, but one thing I have not been able to find in any of them is a list of error codes that follow the "test step is aborted message" Sometimes, I have had the errors when I have put in an incorrect "old immobiiser code", or "old learning code", which kind of make sense.. But I often get the error when programming a control unit (yes I do have 14v onto the control unit and pin 60 powered up on the DME when it is a 5.2.2 DME) Has anyone ever found a list of the error codes and what they mean, or even worked out what they mean? When programming a DME 5.2.2 for example, I can often get to about 90 percent on the progress screen before it bombs out with one of these codes. The unit will still start the car etc if it bombs out, so I don't think it is a bricked DME, but I am just curious about the meaning of the error codes Anyone have any clues? or is my curiosity sending me towards a massive mission of discovery in an unwalked path? lol

- 6 replies

-

- pst2

- test step aborted

-

(and 2 more)

Tagged with:

-

Bought a new 2005 type transmission and installed it into the car, everything is fine and dandy. Can also confirm that the 2005 and 2008 transmissions have exactly the same ratios. Will continue investigating this though and post any results... I would like to get the right transmission back in my car, but also to de-mystify the mysteries of coding and what actually goes on at a data level... Might have to investigate in a CanBus analyzer.. If anything from this thread is useful or interesting, would love for my reputation score to go up :)

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

Well this is the interesting thing, I was worried about this as I had read it elsewhere about coding a 987 as a "non convertable"... However if you code the rear control unit as a convertable the roof works, as soon as you code it as "non convertable" it stops responding to input the to roof switches. On checking my friends 2005 car, I have found that its rear module is also coded as "convertable present" I did however find that in the gateway that it is coded as non convertable (it may have been in the instrument cluster, but I am sure it was the gateway). and that was coded in both cars as "convertible not active", which would make sense as it seems the gateway would be the one to decide if the car has an extra module such as the 997 one... However, the roof switches (both the cabin and transmission/roof ones) in the 987 are wired into the rear control unit, and then power up relays to activate the motors.. But the same control unit is in the 997, where the rear control unit would have to send those signals to the roof control module by canbus, so you would think that the rear control unit would need to know if that control unit is there or not... However, once again, there is a coding entry on the durametric for "997 or 987" so maybe that is how it is coded there.. I have that set to 987 in mine and as my friends 2005 987 was also coded. I am currently considering that each coding unit is actually an individual bit, a one or a zero, which is set within a byte or group of 8 bits for example, in the control module, which will have some flash ram space for these "bits", it could be that durametric codes these "bits" in sequences of bytes, so even if you set one change in the coding screen, it actually transmits the entire sequence of bytes with the changed "bit" within the stream, and there is a good chance they have not reverse engineered all the bits, and one of them could actually be "Late transmission" or "early transmission" which the PIWIS would automatically set on the basis of the identification of the control unit being in my 2008 case ending in 08, and on the earlier cars ending in 04... So in effect when I code up my later unit, one of the bits being set by the durametric is actually what Durametric have not reverse engineered and they assume it is the same in all the control units, not knowing that the different control units pair up with different transmissions, with a different range of movement. If this guess is correct, I believe the later rear control unit when coded properly does not use one microswitch to say "Im up", or one to say "Im down", but for the roof being "up" it waits to see the "up" microswitch, followed by the second other microswitch also being made... and from seeing them activate in the right sequence, it knows the roof is up and therefore able to inform other modules like the gateway that it is up. I have had a chat with a local Porsche specialist who is a technical advisor to the two main UK Porsche clubs, and he was a big help in trying to figure out the above, it seems the PIWIS coding is much simpler with less options than the Durametric, and it was he who suggested that maybe not just one "bit" is changed when you change an option, but a whole sequence, that the durametric may be assuming the settings for some of them, whereas the PIWIS maps them all out to be the correct ones for the right units each time it sends them. He has emailed Durametric with details of my problem, as they might be a little more helpful to him as a pro-user with a pro kit, rather than me as a pro-user (licence) but an enthusiast. However, what you are saying about the communication errors really is resonating with me.... Setting the coding in the rear unit on this boxster really does completely dissable the roof, probably assuming the car is a Cayman at that point, so it needs to be set to "convertible active" but perhaps there is one of the settings I do not understand, such as this "SAD" option which is confusing me, which needs to be set along with "convertible inactive" for things to work... I am not sure... More experiments I guess. Nice to have some feedback though, I was begining to think I should just keep updating this thread for any future owners going through the same pain in the future may find it via google or a direct search here.. But if nothing else what I find may be of use to lots of people in time.. However hearing from someone now with some input, or even just to say "Thats interesting" makes it all a bit more worthwhile. :o)

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

Ok following some in depth investigation, it seems I am moving into uncharted territory, hopefully this will help someone else oneday. The two transmissions I have are ... 987.561.179.02 from my 2008 Boxster 987.561.179.00 from the 2005 boxster The differences between the two transmissions are relatively minor. Microswitch assembly inside the transmissions... The 2005 item has a rocker assembly which opperates two microswitches which opperates on the rotary cam inside the transmission The 2008 has has just two microswitches, mounted closer to the cam, without the rocker part, which are directly opperated by the rotary cam Hub which the shallow V shaped arms bolt to with the large bolt The 2005 item has two slots with the V arm having two teeth which engage together to fix the position.. this V arm can be mounted in two different positions, 180 degrees apart. The 2008 item has a multi toothed face with a single keyway tooth, with the shallow V arm having these multi teeth and a slot for the keyway tooth. Metal frame Although physically similar, there are slight differences in the metal frame plate which forms the main chassis of the transmissions, although they look similar, the main difference is the position of holes which locate the microswitch assembly. Otherwise they could be interchanged. The gears inside the transmissions, seem to be identical, as is the main rotary cam which opperates the microswitches. However, due to the differences in the microswitch assemblies, the later transmission will stop earlier in its cycle than the earlier transmission... Now it gets interesting.. It would seem, that as the earlier transmission has a rocker assembly (2005), the microswitch being activated for either mode, open, or close, is the opposite microswitch to the one in the later transmission (2008) without a rocker assembly.. It seems the designer got around this by the multi connector being swapped around so the notch in the connector is the other way round.. So it would seem that pinouts would be the same. Pinouts seem to be, the central pin is the common and connected to both microswitches, and the pin furthest from the notch in the connector is for the roof up position, the pin furthest from it is the roof down position. Both microswitches are wired so you have continuity when the microswitches are at rest and go open circuit when contacted.. so as they would say in electrical circles, these are "normally closed" polarity switches. although to be precise, the switches are both 3 pin, and could be wired in another application as "normally open" As a side note for anyone in the future with a faulty microswitch, the microswitches are individually identical and carry the part number 1055/58 (unsure about the 58, need to check with a microscope as the print is very small) and are made by a company called Marquardt which I found by doing some more digging. Anyway, not much closer to finding out the source of my problems, as I still do not know what might be the fault with my car and why with a 2008 transmission my car does not completely close the clamshell with the roof up, but if I use the 2005 transmission the clam shell closes properly. Which makes me wonder if on the PIWIS there is an option to select which transmissions you have when you code up the rear body control module, and therefore this module runs the motors for a short while after the microswitch has been contacted if coded correctly, but the durametric maybe does not have this option. Or... The durametric does have the option, but it is one of the numerous options which can be selected in the coding screen for this module which do not seem to make sense, such as the "SAD Enabled" or one of the others... Really odd.. I will keep digging, and for the sake of some other crazy fool who might be in my position in the future, I will try to keep this updated.

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

As an update... A friend has a 987 and today he popped over to help me look at my Boxster and we took the plunge into swapping parts between the cars. As mine is a 2008 it has the rear control unit ending in 08, whereas his had the control unit ending in 04.. His has the arms that go onto the transmissions with the two keyways so the arms can be put on 180 degrees out by mistake, mine has the teeth with a notch where the arms go onto the transmission, which can only be put on the right way. With his transmissions installed, my clamshell closes all the way!!! But here is the odd thing.. I have taken my transmission apart, checked it out and the microswitches are undamaged, the gears are not damaged, everything is fine and I can not see how it can skip a tooth or even be assembled in a different way.. His transmissions end in a part number of 01, mine end in a part number of 02 and apparently the ones you get if you order them from Porsche end in 03. So are the parts interchangable? More importantly, do they have different ratios... On the one hand, I could say my transmission is faulty.. even though everything seems fine with it on inspection... So I really do not know if I should buy an 01 transmission which I know will fix the fault, but may have a different gear ratio, meaning I have to buy two of them. Or.. I could buy an 02 transmission, only to find out it will do exactly the same thing as my current transmission does (not closing the clamshell all the way).. but it is likely I will get an 03 transmission and I am unsure if I need to buy them in pairs. Not sure if anyone is reading this, but I will keep it updated so anyone in the future with the same problem may find the answers they need

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

There are a few items on the coding page for the rear control unit which I can't figure out.. Things like "SAD" activated or not... hmmm.. Not sure what "SAD" is on the car.. But my personal coding seems to have "SAD" enabled right now! lol

- 8 replies

-

- 987body control unit

- rear control unit

-

(and 5 more)

Tagged with:

-

What do you use Richard? Is it a Durametric or a PIWIS/PIWIS2? Still getting to grips with my Durametric and I do wonder what I am missing out on being able to do with a PIWIS.. Sods law says the one time I need something doing, it will be something like programing a key or alarm control unit on the 987 and will need to take it to the dealer anyway, leaving me thinking the Durametric was a waste of cash. Although, if a problem I have with the car at the moment is purely mechanical, there is a chance the Durametric has just paid its way a little bit by coding up a new rear control unit.. But I still suspect it may need a PIWIS visit to calibrate the roof or something.

-

Oil fed intermediate shaft bearing upgrade?

rennbod replied to rennbod's topic in 987-1 Series (Boxster, Boxster S)

So you take off the rear cover with the 3 bolts (obviously once the transmission and flywheel is out of the way), then hook the seal out of the bearing and put the cover back on? Or do you have to take the engine apart to do that?