Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

Contributing Members-

Posts

926 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by lewisweller

-

Right side pump installed and also inspected the tank, all pipes and all connection for any damage or mistakes. Fuel was quite warm and the rightside punp was hot. I really thought this was going to be golden. Everything done properly started her up and........ It's the same!! Arrrgggghhb I don't know what else to look at now or what diagnostic to do without any direction to search. Just to list the ticked boxes for either service item, repair item found broke or just a waste of money maybe ....... in no particular order: 1. New mafs, air filters and oil changes every 7k km 2. New oem Divertor valves Bosch 710p 3. New fuel pumps, filter and regulator 4. New 3 way check pcv valve 5. New purge valve and gas cap 6. New n75 and change over valve with all pipes checked and some replaced. 7. Plenty of gaskets throttle body, intake/exhaust, turbo to IC, injector seals etc when both head gaskets was repalaced 8. New coils and plugs beru oem gapped at spec 0.8mm and 0.7mm with no improvement and now ngk iridium BRK7EIX with standard gap from factory 0.75mm 9. New Temperature sensor and oem Bosch bank 1 pre cat wide band lambda o2 sensor. 10. New seals in valve covers around camshaft actuators 11. New battery and alternator 12. Engine earth and under seat battery and power distribution connections all cleaned and tight. 13. Smoke tested intake for leaks many times. Checked all little vacuum check valves, Cleaned map sensor, leak checked wastegates and other pipes. Only actual leak I can find is the turbo breather pipes at the back of engine. Seen in the image below and zoomed image. This leak is so small and would add minimal amount of air into the pc system I can belive it is the cause. Also why would the car sometime drive ok for a short time then back to usual rough stutter? It's something electrical it temperamental but don't know where to look? YBE you said crankshaft sensor and that's the first place I intend to investigate now. I am ruling out the camshaft sensors for now as it's effect is on both banks and not just one bank runs rough. Also the rpm roughness at 1000 and 2-2200 rpm is weirdly related to rotation speed but so is a lot of engine stuff. Again no codes ever!

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

No my test means both pumps are running but not sure how well. Where is this check valve in the engine bay? I can't see anything there and nothing on any diagrams or parts mentioning this, I thought the only check valve is in the fuel filter and or the regulator?

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

I just went down to the car to check if it is actually running the left side pump (half tank of fuel still) just in case it failed but nope I pulled the fuse and it does die. Then cycled the ignition and started on right pump engine run the same ok idle as was on the left pump. I then replaced the left pump fuse and switched off again. Did the throttle reset sequence as this sometimes has by fluke or not made the car run better for a short time at least. But after restart its the same idle and has the same stumbling rpm at 1000 and around 2-2200 rpm. Its like at that particular rpm it vibrating more and doesn't sound happy or clean revving, I didnt go for a drive though. What I do notice is I have a lot more ticky almost direct injection diesel type rattle and tap, feeling the injectors rail there is what feels like more vibration than I would expect or can remember feeling before. Testament to low pressure quite possibly? Also that tappy ticky noise is what I here at low rpm acceleration when it stumbling up through the rev range, pinking sound "pre detination" perhaps cause of the lean mixture. Anyway until I get the right pump replaced on wednesday and recheck all piping, I won't be able to rule out that as the cause. On hinds sight I should have gone to a garage a long time back and done a pressure test before going down this road. I'm pis*ed off I could not find the simple fittings here to make my own kit and could only find a whole kit that was the same cost as the two pumps anyway. Lesson learned!

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

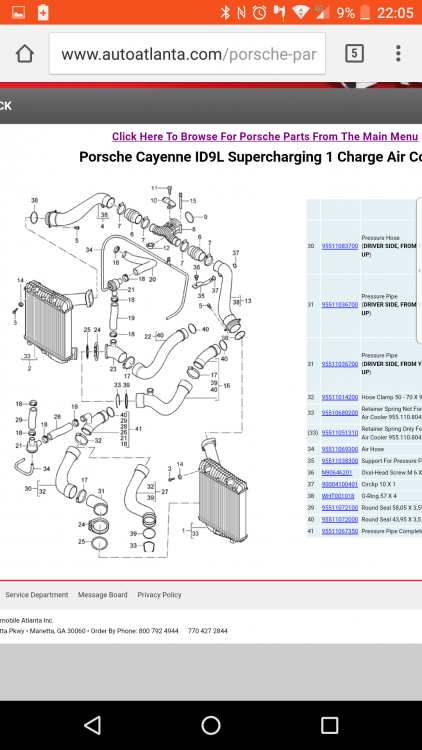

Bad news in fact the better running lasted for two days only and then it all came back like some bad nightmare. I don't know what happened but I have some theories that the right side pump non return valve inside the pump is leaking the pressure off from the left pump or I got a pipe somewhere in there split or I'm totally wrong and it's nothing to do with the fuel. For the sake of ruling out all fuel related issues now and for the foreseeable future I own the car I have already bought a new right side pump which I will install on Wednesday as I'm trying to run the tank back down to empty nearly. I have new filter and regulator with flange gaskets a few months back. I found a great diagram from someone else's post about fuel pump issues. Notice the red line from each pump that joins before going to the filter, my theory is if the right side pump is not running (ie usual part load driving and not too low fuel level) and the check valve built inside is leaking, the pressure and flow from the left pump is bleeding off and doesn't deliver correctly to the engine. Possibly when I did the left pump swap I inadvertently mad ethereal check valve work for a little while and then it started leaking again. It's a far fetched but possible theory I have to eliminate now. The only other thing I can think of is the turbo breather pipe at the rear is leaking for sure but that little bit of air can't do all this sporadic running problems and an ok idle and high rpm rev with a stumble at around 1000 and 2000 rpm when stationary parked holding the rpm is just not making any sense. My mind has run through so many possibilities and I've probably read over 2000 posts and technical informations about everything A-Z. I'm so sick of reading a long thread which ends with.... "and then I read the very helpful DTC code and replaced the coils and all was fixed" ahhhhhhggg if only it was that simple for me.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

As per my last email the side hose should be closed, this means you have a hose leak or a leaking wastegate actuator diaphragm. I replaced both side as they were cracked and leaking a bit. If you check my post you will find it. Thomas has also replaced all his with blue silicon hoses and pipes. Basically they are brittle but also hard to pull off the spigot fitting on the turbo and I just sliced down the side or the hose with a Stanley blade (feeling around as you can't see really). My new pipes fitted well enough I didn't have to use any securing clip or clamp.

-

Try checking some fuses. Left side fuse panel number 16 and 42 Right side panel fuses 36 and 42. With you ignition off the battery should read at least 12.6 volts after being sitting for 1 hour with car locked, unlock vehicle then test voltage using the engine bay terminal connections provided. With engine at idle or any rpm 13.7-14.2 volts should measured and stable. Also look for wet carpet under the driver and passenger side and corroded broken wires under there too.

-

So as not to leave this thread open ended for anyone reading in the future.... Don't you hate that! I replaced the left side fuel pump and the running issues are 85-90% Fixed. Its drives much much better. Idle Dip alittle when coming to quick stop and very very slight roughness on acceleration I feel sometimes as the boost comes in. No more egg sulphur smell either.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Thanks Thomas. And to all who posted with support and advice. :) I will continue to search for the last remaining slight running issues but I'm know not worried about the car running so lean it melts the engine down. Also the cat now doesn't stink of sulphur egg smells when I accelerate hard, which also tells me fuel was the issue for sure. Ive got three other projects, strip and rebuild the front air struts, investigate the check tail light further inside the control module and also look into the "four wheel drive system faulty" warning on dash which are both voltage related I know.

-

It fixed ......almost :) This is my old and new left side pump. Both are vdo but the new pump part numbers and vw audi logo are scratched off. This is not the original pump either as it dated 21/10/10! So this is the third pump at least. The car runs soooo much better I would say 85-90% Fixed the bad running. Hooray. :) Still have some small roughness and the idle Dip is still there. I'm trying to research the actual true function and sequence for the pumps running to determine if the right side pump could affect the fuel delivery even if not running when the tank level is above 1/2 tank for example and the left primary pump is solely running. Does anyone know the answer to this conundrum? Ie if under hard acceleration does the second pump cut in quickly or is it possible it is faulty and allowing the pressure and flow from the left pump to bleed / leak off?? Another theory I have is the possibility the injectors are blocked a small amount, this was maybe exacerbated by the low fuel pressure previously. I have run a few bottles of cleaner through before some months ago with no change. I think if someone drove the car they might not notice anything is wrong and maybe for a 11 year old twin turbo car I am expecting too much and too smoother power delivery and running. I don't know as I have never driven a cayenne turbo before to compare it to.

-

I did the regulator and fuel filter replacement already, also vdo brand I used which had the vw toureg part numbers "erased" from the top Covers and the invoiced used the porsche part numbers. Lol some dealer service type parts are a real scam to the unwitting owner. 6psi ? Not sure where that info came from but thats not enough pressure to wash your hands well under a tap. 58psi or 4 bar came from the workshop manual. And also 3 bar after 10 mins and 2 bar after 1 hour it should hold in the line after the ignition is switched off (this checks that the non-return valve is working to stop the fuel draining back to the tank causing longer cranking times in certain circumstances).

-

The pump is from vdo they are the oem manufacturer without the Porsche or vw price tag for the same pump inside the box. I paid 740 dhs which is 144 euros. It's so hot here I think both my pumps are just knackered and don't deliver the correct pressure and maybe volume too. The specification says each pump individually 58psi or 4bar pressure at idle and flow of 800ml after 15seconds equivalent to 3.2 litres per minute. I wish I could test the pump to really prove if the pressure is down but I lost patients with trying to find the fittings and the cost of special fittings here is half the pump cost anyway, so pointless to fight it any longer. Tomorrow we shall know all about the left pump if bad or not. FYI both pumps work but the car runs crappie on either or both which ever way meaning neither are in spec anymore. But as the left pump is only required to provide the pressure and flow and the right is to transfer fuel from the right side and for a back up then for now I just need one pump the left to fix the problem. Remember my other post I started saying the car ran good sometimes on less than 1/4 tank?? Well maybe I wasn't going crazy as the right pump was kicking in to cover the lack of pressure from the left pump and just enough to cover the poor running. That was 3 months ago and now I think pumps are finally f**ked. If the right pump was not working then I would be replacing both pumps for sure (may do it in the near future anyway for peace of mind) or you can't run under 1/4 tank without running out of fuel unexpectedly).

-

The pump is from vdo they are the oem manufacturer without the Porsche or vw price tag for the same pump inside the box. I paid 740 dhs which is 144 euros. It's so hot here I think both my pumps are just knackered and don't deliver the correct pressure and maybe volume too. The specification says each pump individually 58psi or 4bar pressure at idle and flow of 800ml after 15seconds equivalent to 3.2 litres per minute. I wish I could test the pump to really prove if the pressure is down but I lost patients with trying to find the fittings and the cost of special fittings here is half the pump cost anyway, so pointless to fight it any longer. Tomorrow we shall know all about the left pump if bad or not. FYI both pumps work but the car runs crappie on either or both which ever way meaning neither are in spec anymore. But as the left pump is only required to provide the pressure and flow and the right is to transfer fuel from the right side and for a back up then for now I just need one pump the left to fix the problem. Remember my other post I started saying the car ran on sometimes on less than 1/4 tank?? Well maybe I wasn't going crazy as the right pump was kicking in to cover the lack of pressure from the left pump and just enough to cover the poor running. That was 3 months ago and now I think pumps are finally f**ked. If the right pump was not working then I would be replacing both pumps for sure (may do it in the near future anyway for peace of mind) or you can't run under 1/4 tank without running out of fuel unexpectedly).

-

Two days I Searched this whole useless town for M16 or Schrader valve adaptor fittings to make a fuel pressure testing kit and totally frustrated to find nothing will work. Should have ordered a kit online I guess but wtf this isn't even any complicated fittings. I'm tired of this s**t now and the car is running terrible (i mean like a total dog , so lean I'm thinking it might melt a piston) and still no codes at all, unbelievable, OBD11 where are you now #*;/*+-==+*/!*(+--= ????? F**k it, New Vdo left side primary pump is in the boot ready to fit tomorrow. Paying 200 dollars for my sanity was cheap.

-

Cayenne 2009

lewisweller replied to Seraj's topic in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Good luck, do report back the Fix is confirmed and what part number it was. -

Doesn't make sense to me that the aos would foul only one plug on one cylinder. I think this cylinder 8 is scored. Only way to check is to bore scope it and do compression test and leak down test. Maybe valve stem oil seal is leaking pass the valve but less likely. Well documented issue with the S, is the cylinder lining coating defect. Could try a thicker oil to reduce the oil quantity escaping passed the piston rings but its really not a solution. Rebuild is expensive and some owners just run it until it's dead. Some pictures is always helpful!

-

Most likely yes. http://www.pelicanparts.com/techarticles/Porsche-Cayenne/67-ENGINE-Repairing_the_Air-Oil_Separator/67-ENGINE-Repairing_the_Air-Oil_Separator.htm You can buy the membrane for 30 dollars from https://vanos-bmw.com/membrane-94810513107-porsche-cayenne-45l-450ps As for the misfire it's more likely a coil issue try swapping the coil from 7 to 8 and clean both plugs and see what happens, if 8 is OK and 7 is now fouling then you know the coil is the issue. More unlikeky is the no' 8 injector (dripping/blocked) or piston rings worn or cylinder scored or a valve not closing and not sealing properly.

-

Fishing the T out from just around the surrounding components for a quick blow is not that hard, pipe to the change over valve at back maybe nestled in or under the purge valve which I rearranged so it is above and easy to access for quick routine checks. Actually replacing the pipes is a bit more involved but dead easy. The T to change over valve pipe (8mm id) runs along the bank 2 injectors so whipping off the beauty covers and coil cover, then unplug the injectors and follow the pipe from the T back u clipping as you go until it connects to anothrr piece of pipe and then into the change over valve(has a rubber strap thing which hooks on a metal support which you can pull off to get better access). The clips/clamps are reusable so just flick them open with a small flat blade and use pliers to snap them closed on reinstallation. The vacuum tubing (4mm id) to each divertor. Passenger side (left hand drive) unscrew the wheel arc front only pull back and you will see the intercooler and the divertor easy pull off and feed in a new piece of pipe running through engine bay in same place as old one. The driver side is a bit harder. Crawl under neath remove bottom plastic/metal engine covers. At the end of the radiator you will see the piping to the turbo and the divertor valve with vac pipe fed down from the top area. I smoke tested the intake via the map sensor hole with a 2l bottle, two thick food bags, duck tape and a few cigarettes. And air comprrssor set at 10-15psi.

-

Yep found that epoxy glued back together when they did the head gaskets. Replaced the black piping for new Porsche one. That pipe itself doesn't leak but Im sure those metal pipes which run to each turbo oil collector block are leaking on those crimp type floating adaptors (from metal to hose piping). I can see the oil and dirt build up there but despite this which yes would be a vacuum leak of a relatively small amount I think, if I blow or sick the pipe I could get any air in or out. Im not sure house that oil collector block and vac metallic and hose line really work. The pipe goes the valve covers left and right so it sacking the oil vapors from the lubrication oil of the turbo's so as not to build up pressurised vapors around the turbo oil supply and return lines. That's my best guest. So worst case is I've got small amount of extra air going in the system. If I pull the oil cap the engine vacuum is very good, the idle will burble and hunt a bit as the throttle tries to stabling the rpm. The aos at the time can also be heard to quietly whistle some air inside because the oil cap is off and extra air is entering. To summarise I do have some small leak at the back there, it is not enough to cause the running issues I have at the moment.

-

I had low boost and found the 8mm ID 10mm OD vac pipe which runs along the injectors from the change over valve located at the back of the bank 2 block had two melted holes in it. After replacing that pipe and adding heat shrink wrap along its length also to protect from heat and melting I haven't had low boost since. See item number 4. Also second diagram vac pipe 4mm ID 6mm OD item number 34 which goes to each divertor valve had a split and I changed that also. Buy all vac pipes (black polypropylene I think) for a couple of dollars a meter from a hydraulic/pneumatic supplier shop and save yourselves 100's of dollars in oem parts. Very simple test for all these pipes is find the Tee of the pipe 34 which is just to the right side of the intake Y pipe in between the check valve to the right, pull it apart as per my picture attached and blow down the pipe and the open Tee end in turn, no air should be heard escaping and you should NOT be able to blow any air through, almost like it's totally shut. If this turns out not to be the issue then there are numerous other things to check off which I think I've done them all! Let us know how you get on.