Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

Contributing Members-

Posts

927 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by lewisweller

-

Thank you for the tips, will be doing the bypass power up check asap. I noticed in my receipts from previous owner it had a new compressor 4 years ago at a whopping cost from Porsche. Omg pls not again I'm so broke.....sniffle sniffle ......

- 14 replies

-

- ac compressor

- not blowing cold

-

(and 3 more)

Tagged with:

-

Yes I'm back with another problem. Ctt 06 with 4 zone climate control, 45 degrees in dubai and the AC starts to blow hot. Had new gas 1050 grams as per spec after the head gaskets were done 4 months ago, vac test showed no leaks then. I had to keep turning it off and on to get it to kick back in which is suspiciously like the compressor clutch not kicking in. So questions: Possibilities of the cause of intermitted fault? Can compressor be repaired if removed? Will be swapping the relay later from the rear defogger (same part number 40a relay) to make sure it not that and yes a trip to the local shop for gas volume check and leak test. Ruling out the control flaps as when I increase temp to 29 it is blowing super hot and all the control flaps and noises can be heard switching, and back to low setting gives hot air but much less roasting.

- 14 replies

-

- 1

-

-

- ac compressor

- not blowing cold

-

(and 3 more)

Tagged with:

-

The change over valve I ordered a week or so ago coma me in stock so have picked that up today and for the hell of it a new gas cap for $25. Will fit these tomorrow morning and see what happens. Not expecting miracles ........but you never know with weird illusive problems like this.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Done some more reading and a strong possibility is the fuel pressure regulator. This being faulty would explain the stutter as when the regulator is failing it can't maintain the fuel line pressure through varying rev ranges as the injector firing frequency increases and this fluctuates the line pressure apparently, hence rich and weak mixtures. Still the tank level I don't see how it plays a role in this issue really. Being 114,000km I may change the filter and regulator now. The pumps are expensive so hope its not them at fault, as the fuse test didn't make any difference in running on either pump singularly I'm thinking it isn't a pump issue. Still need to do pressure test .............to many jobs.........

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Interesting read thanks. Yesterday I pulled fuse 13 and 14 running on 1 pump left and right to see what was the difference. Summary idle the same fairly stable, revving was stuttering at 1k 2k 3k 4k approx rpm. So didn't really prove anything conclusive except obviously there is only 1 fuel filter and regulator so maybe one of these is the issue. No choice need to do fuel pressure test and pressure drop test.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

This theory would indicate a low tank level would or could cause reduced pump performance and heating issues, but my problem is the reverse of that, given a lower tank level I have better running not worse.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Thanks Thomas interesting info, what a weird fuel pump setup Porsche have! Lol. So what still begs the question, if one of my pumps (namely the secondary right side passenger no'2 pump) is not delivering flow and or pressure properly what does that have to do with fuel level in the tank?

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

In fact no I haven't. I haven't the fittings and gauge to do the test, but I guess I need to asap. Anyone got a DIY for testing fuel pressure? IIRC 4 bar at idle and 4.5 bar at 2000rpm? Regulator Should hold in the line 3 bar after 60 seconds after switch off? Also I'm thinking along the lines of tank vent or related component causing a fuel delivery issue when tank level is higher than 1/4 tank but that doesn't sound logical to me.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

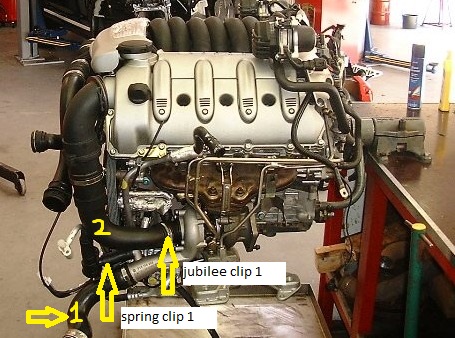

Hi Mike see attached. Working from the underneath remove sump guard cover(s), then remove pipe numbered 1 (jubilee clip each end) and then squeeze the spring clip 1 on the small Diverter valve hose and pull the dv out of the small hose, then from the topside disconnect pipe 2 top end where it connect to air box two torx pins which line up and pull out, remove air box front cover and filter, loosen jubilee clip 1 and the pipe numbered 2 can be removed with the dv still attached. You then can get your hand inside far enough to pinch the pipe clips and release the pipe. If you have mini hands you may not need to remove pipe 2 but I very much doubt it. Whilst out remove and test the DV, simple test push the brass disk inside effectively opening the valve and then hold your finger tight on the vacuum nipple, it should hold the brass spring loaded diaphragm open until you release your finger and it will snap shut under spring pressure). Also blow in each end and it should be shut unless the diaphragm is split. More info here.......... from Thomas, myself and a few other contributors. 0 Quote Edit

-

If I run the car at less than 1/4 tank full it's very smooth great acceleration and responsiveness. With engine running I went and filled up with 99 octane as usual and straightaway the engine stutter comes back!!!!!!!! Fyi it is NOT fuel quality. I've started a new thread for this but it's an old problem mentioned in previous posts and unresolved. Basically the ctt 06 with 114,000km has been hesitating and stuttering for a while when accelerating particularly under boost in lower gears through the rev range of 2k 3k 4k ish rpm, it also will vibrate and stutter revving the same rpm in neutral/park when stationary. (which is very weird). So after a lot of finding issues which helped the car overall none of them sorted this stutter out. Quick list, New oem Coils, plugs, n75 valve, air filters, purge valve, and Dv's, Fixed a lot of vac and pcv pipes which leaked Smoke tested intake no leaks boost is +0.8 Head Gaskets done a few 1,000 km all new parts gasket Seals etc. (problem was present before and after head Gasket work). I had a suspicion that the lower fuel level was playing a part in this but I can't work out why a fuller tank would cause running issues?

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Yes still getting this stutter in acceleration. Nightmare to find the cause. The PU tubing you can buy at any good pneumatic/hydraulic parts equipment shop. 4mm internal diameter and 6 mm outer diameter will work for our vac lines. If you need to fit it over a barbed connector or T you just warm the end with a lighter flame and push a screw driver or something of suitable size down the warmed and softened pipe end. Once about the right size, warm a final time and quickly slide it on the connector for a easy airtight fitment. Warning if you give too much heat it will melt and leak lol. Ask me how I know?

-

Hi Thomas. I did some work today on the Pig. Check my AOS and looks the same as yours. Also check my check valve again all ok. Cleaned my MAP sensor again and checked the passenger side recently new DV was still in good shape and replaced the vacuum pipe to the DV as a precaution. I use 4x6 mm PU tubing for all vac line replacements it dirt cheap and good stuff. I also checked my wastegates audibly using an compressed air source to activate the wastegate via the pipe disconnected from the N75 valve. All seem to work well no sticking, both opened at the same time at 5psi and 10psi and no leaks to be heard. Disconnected the battery for 30mins and then fired it up. Put my vcds on it to check for codes nothing showing. Running is rubbish as usual and worse now until adaption will smooth out some of the splutter hesitation. Fuel trims are bang on, no misfires, timing is 6degrees at idle. The new n249 change over soelonid valve on order gives me slim hope this might somehow but the faulty component but I'm not that confident.

-

I think the valve should be shut if you blow from this end shown in your picture. It does look like the membrane has perished perished is stuck partly around the seat of the valve. My thinking to how it works is under acceleration the turbo will suck in air via the pipe which connected to the bottom of this check valve and draw in pcv air and gasses to recycle through the engine. So effectively effectively the turbo suction opens this check valve. If in doubt replace it!

-

Misfires

lewisweller replied to mbagge01's topic in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

Ok so got a new n75 valve for £20 not bad! I checked the pipework and everything looks to be spot on. Fitted the new n75 valve and guess what...... no difference! Unbelievable, if I disconnect it no misfire hesitation when revving in neutral and smoother acceleration but of course lower boost as the wastegate is not being helped to stay shut and build boost so it runs flat at 0.4bar only max boost. Plug the n75 valve back in new or old one and then it stutters through 2k 3k 4k and less noticeable but 5k rpm as well under boost. F***ing annoying and not a pleasurable driving experience. This must be a very uncommon problem as believe me I have read 1000's of forum posts, technical literature and applied my own Engineering knowledge (garages here are pants Fyi and the stealership is mega expensive). What I tried yesterday was to disconnect the vacuum pipe from the Diverter valves to just see what it did. As expected the DV released boost at about 0.6bar (as much as the spring can hold without the vacuum pipe which is in fact positive manifold pressurised when on Throttle, switched via the n249 change over valve) the jerky stutter and hesitation was worse even though I had less max boost which is normally +0.8bar needle off the dial slightly. So what did this teach me? Well either I have a weird n249 valve or associated piping issue or the wastegate one or both has some issue which I have no idea what would cause these symptoms. Sticky maybe? Not leaking as I blow down the vac pipes and no leaks through. In my desperation to get to the bottom of this I have ordered a new n249 valve against my better judgement of throwing parts at the problem. The Porsche parts guy here is now a good mate so I'm able to get trade prices inline with what Auto Atlanta and Pelican can offer minus the horrendous air freight shipping cost to the uae. A side note for any one who didn't follow or could be bothered to read all the history behind this (don't blame you), this fault was present when I bought it, after some tlc servicing coil plugs filters etc it started overheating and head Gasket on bank 1 was disaginosed. After a complete engine out new head gaskets, all the trimmings, vac pipes, Seals thermostat water pump temp sensor the whole hog, no corners cut promise. They gave me it back all running and not overheating or anything.......but the hesitation and stutter was still there which I was sure was head Gasket related, wouldn't you? The indy German garage German engineer/Manager even said to me this was normal! Haha Sorry I'm not an idiot customer. His durametric and another indy Piwis my v-checker pro and ross tech original vcds showed NO fault codes at all ever throughout the whole saga. How frustrating! Following the head gasket repair I then found: Vacuum pipe between DV and change over soleniod valve was split (replaced that) and got full boost +0.8bar previously only got 0.6bar. Then found the DB drivers side was split diaphragm replaced both bosch 710 P revision (same as what was in there already in fact left side wasn't leaking so kept it as my emergency spare), cleaned the MAF's, MAP sensor, new n75 valve, smoke tested intake no leaks, couple of tanks of techron, always use 99 octane fuel. So come on guys Wtf am I missing here PLEASE someone read this that knows what could be the cause. Quick symptom example: Accelerate (lower gears from lower speed is worse).....boost comes in hits 0.4bar quickly rises to over 0.8bar and holds perfect....bucks hesitates and surges through 2k rpm then 3k rpm then around 4k and less noticeable around 5k then to red line it's smooth and perfect. Everything above is yelling coil packs or boost control requested vs actual hence the n75 valve control I suspected but seemingly not? -

Wow that is a brain teaser. Only related area is the intake pipe is removed for both manifold removal and to spray cleaner inside. Any possibility of a leak crack weak pipe connection???? Tried spraying carb cleaner around intake and throttle body whilst at idle?? I can't see the either of these works has any impact on the variocam. Also a vacuum leak wouldn't affect wot acceleration either. My brain hurts........ Thank God my audi is a dream, no breakdowns no drama.

-

Hi Thomas, I just check something and need to correct myself about the PCV issue causing both side to have oil carry over, this is not strictly true. See the elbow in the image where pipe 13 plugs directly into the oil/air separator (represented by my blue circle) and the pipe connects down to the turbo charger inlet pipe (represented by red circle) number 15. So my point is check your oil/air separator rubber diaphragm before even thinking about dreaded turbo issues! a new diaphragm is only $20 and 30minutes work . Could be as simple as that to fix this issue? Fingers crossed.

-

The Maf test you did does confuse me as the engine although the dme has preset references for lack of a maf signal it should show a difference in running condition even if a little rough and jittery. Strange. Looking back through you lengthy repair history I'm wondering if when fixing one problem it inadvertently created another? Ie the Throttle body cleaned/manifold removed then after the gasket not sealed properly hence cylinder 3 misfire maybe? And sorry for me replacing the battery is the first thing I would do. $150 compared to your list of costly repairs so far is a small investment in reliability and possibly the root cause to "some" strange electrical issues ie D illumination, sensor fault codes and psm warning after some battery draining etc. Did you try misting some water or even some carb cleaner around your intake manifold and Throttle body to check for leaks? I don't think your smoker test was comprehensive especially as the Throttle is closed and likely the smoke and pressure of smoke wouldn't migrate to the manifold well.

-

The DV is not the cause of the oil problem. If you have full boost then probably the DV's are not split either (although when I found a "small" tear in my DV I did still have full boost surprisingly but how accurate is our dash boost gauge?). Anyhow back to the oil, is the other side MAF also covered in oil too? If not I think this is the turbo seal problem. If the other maf is oily then pcv problem carrying over oil in the vacuum line to turbo. When you let off Throttle under boost the DV opens and circulate the boost around the turbo inlet and outlet causing the turbo to free wheel and prevent stalling, if their is oil in the Air flow it will invariable coat the nearby pipes and maf sensor as well.

-

Hi Thomas you asked me a few days ago how to removed this DV. see attached. working from the underneath remove sump guard cover(s), then remove pipe numbered 1 (jubilee clip each end) and then squeeze the spring clip 1 on the small Diverter valve hose and pull the dv out of the small hose, then from the top loosen jubilee clip 1 and the pipe numbered 2 can be removed with the dv still attached. I found this was the easiest way. Even if the DV is faulty or not is regardless, the Oil is either carry over from the turbo or more likely the PCV system (is your air/oil separator in good condition?). Porsche apparently "drain" the oil residue from the intercooler(s) bottom hose connection as routine maintenance because of oil carry over. before getting to worried I would clean everything, ensure the dv is working, (simple test push the brass disk inside effectively opening the valve and then hold your finger tight on the vacuum nipple, it should hold the brass spring loaded diaphragm open until you release your finger and it will snap shut under spring pressure).

-

Must be stuck Thomas. Mine came out fairly easily, they slide out inwards direction, can't go the other way out as they are tapered I think. Spray a bit of wd40 on the pin (don't get it on the discs and pads). When you reassemble use some Cooper grease or castrol optimoly to lube the pin lightly so next time it's not a hassle.

-

You disconnected the maf and it stayed the same? Well I would have expected it would change unless the maf has something to do with the issue(s)! When I disconnected mine the engine bogged when revving and the idle had trouble stabilising but did settle. Definitely get the battery replaced these cars are renowned for electrical issues due to battery and charging problems and you could chase your *** for months unnecessarily. The coils are negatively switched so 12vdc should be present with ignition on, on one of the pins of the connector, probe from the back with a straightened paper clip connected to red lead of multimeter and black lead on a good engine earth.