Hi all,

Hoping to provide some clarity on replacing the crankshaft position sensor on a 986 WITH Tiptronic transmission as I have not seen (or was unable to find) any good/clear pictures of the process to find the sensor. As I found out, it is hiding well behind the plug/receptacle for the Oxygen sensor on the right side of the vehicle. I read all kinds of guides pointing me to the correct general location, but they all pretty much said it was obvious and I knew exactly what I was looking for. I spent well over an hour searching because I could not see it, and found out that on a Tiptronic, you have no direct line of sight to the sensor unless you move the oxygen sensor plug/receptacle. Hopefully these pictures will help anyone else trying to replace the CPS no a tip.

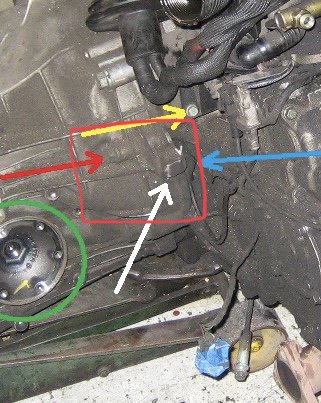

In order to see the CPS you must unplug the oxygen sensor, remove the receptacle mounting bolt and push both cables and mount/receptacle out of your way. The view shown here is from underneath the car looking up towards the wheel well and CV joint.

A wider view of the area you need to look into remove the oxygen sensor, receptacle, and bracket. You can follow the cable from the oxygen sensor to the bracket in order to find it more easily.

This is your entry point and trajectory. Just beside the right rear brake caliper, under the brake fluid line, past the coolant reservoir drain hose. The extension is probably all of 18 inches to get you deep into where you need to be to unscrew the bolt holding the CPS in place. I used the light you see plus a large work light on the floor to finally visualize the sensor. The only way I was finally able to find the sensor was to identify the cable from the sensor and follow it by hand and light. That is when I realized I could not see it due to the oxygen sensor plug being in the way.

This is just a wider shot of the entry using the light as a reference and the brake caliper is in the foreground.

Here is a view of the CPS still in place, but the bolt has been removed. The oxygen sensor plug and receptacle have also been removed and pushed out of the way. Once you see the CPS, it is obvious that is what you've been looking for. What I think are coolant hoses are very close to the trajectory you need to access the bolt. My extensions were pushed up right next to these hoses and I had to push on them with the tool in order to get access to the bolt.

Just a couple of other tips and tricks. The bolt of the CPS is held on by thread locker. Make sure you have good engagement with your male hex into the screw head during removal, otherwise it could strip. I recommend ordering a new screw for the CPS while you're at it, the newer ones are torx and less likely to strip. Once you locate the CPS you will find that you can actually reach in there with your fingers through a path in order to push it out of and into the hole. When you go to put in your new CPS, place it in first without the bolt. You can wiggle it into the hole reasonably easy with your fingers through the aforementioned path. When you go to place the bolt, either use a magnetic tool or tape the bolt to your male hex so that it doesn't fall off. Yours truly lost the original bolt and still have yet to find it. Luckily it is a pretty standard M6x16 available at your local hardware store. But I have no clue where that bolt ended up. I searched by every means possible including a powerful magnet around the area of loss and still could not find it.

Hope this helps save you the hour or so of searching in your 986 Tiptronic for the CPS. Remove that O2 sensor harness first and you'll save a bunch of time and frustration!