Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

1schoir

Contributing Members-

Posts

2,739 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by 1schoir

-

How to remove side panels in door to get to Window?

1schoir replied to TXGold's topic in 996 TT, 996 TT S, 996 GT2

Ryan: If your '02 TT has similar door panels to a Boxster, check out the following link. It has some very excellent photographs and detailed steps on how to remove the fasteners to get the door panel off. The trickiest one is the plastic cover that is around and forward of the door latch. I found that in addition to the illustrated instructions on that point, that, once you have that piece off at the forwardmost portion of it, if you press down hard on top of the rearmost part and then rotate the piece, it will easily come off without breaking off that little tab. Study the photos and you will understand that little part and how it comes off. Here's the link: http://www.ecoutez.net/boxster/door-panel-removal/ Good luck! Regards, Maurice. -

More great advice... Eetz Feegkzed! (Germ-english for, it's fixed!!) It was the double relay up above the fuses on the driver-side. ( I won't bore you with details of how deduced this) I will tell you that I "hacked" it thoug, in the crudest sense of the word. Unlike every other relays I've messed with (an electromagnet and a couple of electrical contacts) this had a circuit board and two tiny little un-openable boxes inside. I surgically cut them partially open. They were tiny relays. I measured some voltages, cleaned some contacts with a sliver of sand paper. Popped it back in and VIOLA!! IT WORKS!! Need to fiddle with relays as it doesn't seem to really stop itself in either the full-up or full-down positions. Thought I had checked them... maybe I need a new double relay for the circuit board part that does all the magic, but for now, the relay part works and for the first time in years my top goes up and down. Yeah! The thing seems to be synced just fine, adjusted the tie rods a bit, pretty much maxed out there length with center bolt, that's it. Small disappointment is that my remote doesn't work for the top (works for the locks though). The light blinks on my key and on the dash, it just doesn't do any thing. Anyway (Maurice), thanks a TON for all your patience and great detailed advice! Stay tuned cause I'm not done yet (sorry). Regards, Peter P.S. Should the top open and close with "one-touch" or do you have to hold it down through the whole cycle? Peter: Is that like "Farfik Nugen" (the old VW ad) ? That's great news! I admire your persistence and your ingenuity and I am glad I was able to contribute to the solution. You do have to hold the open/close button down through the whole cycle. You are supposed to stop pressing the button when the "convertible top up light" on the dashboard goes out. On your car, does that light go on when the top first starts to open and also when it first starts to close (from the completely open position with the clamshell down on it) ? As far as the hack that you did on the relay, or how you deduced that was the problem, it would be useful if you could post the details when you have a chance. I can't tell you how helpful I have found even the most obtuse sentence that someone posted about their solution to be. Sometimes I find myself reading one sentence over and over (like my law books) and then it just clicks. Anyway, great job and I'm sure that with the help of others on this board we can figure it out to a successful (and rewarding) conclusion. Regards, Maurice.

-

996 Chrome Wheels Flaking

1schoir replied to jtwright's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Jim: If your wheels are actually chromed for some reason (as opposed to the polished ones that Loren describes), then you will find that the areas where the flakes have come off will be a sort of copper/orange color. That happened to me about a year ago, although I was not the original owner of the chromed wheels. I got estimates on repairing (rechroming) them and they ran about $200 each. Haven't had them done yet. Regards, Maurice. -

Pretty outrageous story. Considering the cost of all new 02 Bosch Brand sensors (i.e., no wiring modifications of any kind needed) is about $150 X 4, or about $600.... The really outrageous part is that he would be charging you $600 more dollars to essentially unscrew and rescrew the equivalent of four threaded bolts. I guess screw is the operative word. It sounds like this certified Porsche mechanic has not only been working on P cars since 1980, but that he has been working them over as well. Good job on figuring out and doing the repair yourself. Regards, Maurice.

-

Boxster top parts question...HELP!

1schoir replied to mikes_box's topic in 986 Boxster Convertible Top Issues and Solutions

yeah when mark and checked it, it was okay that's why we were able to reattach the ball....don't know if using a larger bolt and possibly it being too tight could have caused the break...it's on the driver side.... Mike: I spoke to and went to see a friend of mine who works in the parts department of a local Porsche dealer here in NY and this is what we were able to come up after also talking to the techs at that dealer: It looks like the part is one component of the "Main Folding Top Bow" and has a part number of 986 561 037 0070C and that it sells for over $2,000. I checked with Sunset, and their price is $1,594.56. The smaller part (where your steel ball broke off a little "ear") does not have a separate part number that we could locate on the system. OUCH!!! I asked my friend to let me know if they get a top in that they have to remove as I would like to have a look at that individual part directly and see if it has a part number that can be looked up. Sorry I don't have better news. Regards, Maurice. -

That's exactly right! As soon as they see a Porsche all pricing methods fly out the window and the 'custom' (read EXPENSIVE) quote is given... Yup, I am still hoping I can find a small shop with a reasonable, experienced welder. They're out there, but it takes a while to find the right place. It's even harder to find someone since it is such a custom job. Phone conversations lead nowhere, I have to be there in person and show them what I mean most of the time. Julian: It's worthwhile to wait for the right shop. You only want to do this job once. Regards, Maurice.

-

Julian: Not surprised at your experience with the body shop(s). Usually, they see Porsche and, if you look in their eyes, you will see the $$ signs there, like in the cartoons. LOL. Maybe you should try to have a shop that does welding (look in the yellow pages or try to get a recommendation for a local shop) give you an estimate. One thing you can generally be sure of is that the guys who have been doing welding for a number of years will be able to come up with a solid solution. The job should be based on their hours of labor, not the fact that you brought in a Porsche. Regards, Maurice.

-

Peter: The top only opening and not closing (together with the dash button only spinning the motor in one direction) sounds like a problem with either the B-Pillar microswitch or the Main Relay, or a combination of the two. Once you have the top in the open position, try this to reverse the direction that the motor spins and the related direction of travel of the V-Levers: Pull off the carpeted plastic panel that covers the seat belt spoon and the B-Pillar microswitch. Then, using either a small hook tool or a small piece of wire that you can wrap around the back of the small metal lever of the microswitch, pull and hold the small metal lever forward (so that it trips the microswitch [you should be able to hear the mair relay click in the driver's side footwell]) and then press the open/close button on the dash. That should reverse the direction of travel of the motor. Keep an eye on the V-lever on the driver's side and note its direction of rotation while the top is traveling down to the open position. When you pull the small metal lever forward and hold it, the V-lever should start to spin in the opposite direction. Believe it or not, you can operate your top that way to its complete open or closed position so that you can function on a temporary basis. Let us know what results you get with that. As far as the cost of the convertible top relay goes, it's about $75 from Sunset. The B-pillar microswitch is about $50. (both plus shipping). Let me know if you need part numbers. As I mentioned in another post, the V-levers are supposed to be completely straight and true. A bend could impact the white plastic cups popping off. As far as testing the motor wiring, what you described sounds like a properly working motor. With the main relay installed on its receptacles, open the clamshell and pull off the electrical plug that is plugged in to the side of the motor. Connect the positive lead of your voltmeter ot the black wire and the negative lead to the green wire. Then connect a jumper wire between terminals 2 and 3 at the plug connection. Switch on the ignition and press the "open" button. You should get a reading of about 12 volts (battery voltage). Now reverse the connections to the green and black wires, with everything else the same. Switch on the ignition and press the "close" button. You should get a reading of about 12 volts again. You may recognize these two steps as the end of the PDF document you mentioned, and I was able to successfully perform those two tests a while ago on my top. As to the rest of the tests described in that PDF document, I did not understand the basic concept of how to perform those tests, so perhaps you can educate me on that. Lastly, as to the initial position of the V-Levers, I mentioned in an earlier post on the predecessor thread, that if you "draw in" extending lines to the marking notches, you will see the correct position of the "V" as it will not then cross "over" the lines formed thereby. Hope this helps, although I know you also will have to resolve the issue of the orientation of the transmissions in your other thread. It's amazing how something that appears so simple when everything is working properly can get so complicated when even one of its components gets out of whack, but I guess that's the price we pay for the "automatic" versus manual operation. Regards, Maurice.

-

Hey Marice, Discovered something else that dosn't look so great. The transmisions, when cinched down are not really horizontal from the ground. That is if you look straight down into the convertable top comaptment they appear to be tweaked, the bottom bumped out. I guess the eastest way to describe it is tha the exsposed faces of the transmisions are in no way parralell to each other in any direction, allong any axis. If I didn't know better, I would say the transmision had been tugged weird by unsychronization and pulled the sheet metal they mount to katty-wampus. Should they be fairly straight looking (front to back, top to bottom)? Thanks as always Peter Peter: It looks like you have run into a similar problem recently discovered by another member of this forum (Azzar0). After much wrangling with his top problem, he got most of it resolved by replacing the Version A transmissions with Version B transmissions and associated parts that he bought on eBay. He remained with a persistent problem which manifested itself by the white plastic ball cup popping off at the very end of the cycle after the top reached its "closed" position. He noticed that at that point the transmissions would move with what appeared to be a "flexing" of the sides where the transmissions were mounted. So, in answer to your question, they should be straight front to back and top to bottom. See if they move or if the sides flex. If they do, you may have to go down the same road as Azzar0. He was able to remove the air intake covers on the side of the car and pull some material back in order to have a look at the backs of the transmissions. He discovered that that area had tears and holes in the sheet metal that were the cause of his transmissions ending up in a less than vertical position. The last time I posted back and forth with him, he had contacted a body shop that was going to devise a solution by welding additional support pieces behind the transmissions to keep them rock steady and aligned. I asked if he could try to post photos of the job so that it might help others on this forum in the future, but I had no idea someone would run into this so soon. I know he is in the process, so you may have to wait to see how he works it out. To his credit, he has been very diligent and I am sure he will have his top completely fixed at the end of all of this. I guess this may become a more common occurence as the early (MY 97-99) boxsters get older. I will also try to answer some of the questions in your other "new" thread on the "Convertible Top Woes" saga. Regards, Maurice.

-

Strange top problem

1schoir replied to kostasclk's topic in 986 Boxster Convertible Top Issues and Solutions

Kostas: I am not sure whether this might solve or ameliorate your problem with the top latch hitting the windstop on the way down, but it might be worth a try. The push rods (or "joint arms") that connect each V-levers to the metal ball on the bottom of the B-pillar on each side have an adjustment that affects the way the front of the convertible top aligns its two tongues with the two receptacles on the top edge of the windshield frame. AFTER YOU MARK THE ORIGINAL POSITIONS AND LENGTHS OF THESE PUSH RODS, loosen the 10mm nut (with thick washer) and try in turn to elongate or shorten overall length of each push rod and see if that has any effect on any clearance between the top latch and the windstop. If it does, you might be able to fine-tune it so that it clears the windstop and also still engages the receptacles on the top of the windshield frame. Just a thought, since you say you are going crazy, and it might help. Regards, Maurice. P.S. Curious as to how many Drachmas or Euros the dealer charged for that job. -

DIY guide for removing interior plastic pieces?

1schoir replied to panameras's topic in 986 Series (Boxster, Boxster S)

Here is a link that will guide you on door panel removal, with some detailed photos and instructions. This should help you with the door pocket lids, and speaker grilles, along with the door handle pull trim "surround" and that little half-circle piece just forward on the door pocket lids. http://www.ecoutez.net/boxster/door-panel-removal/ Regards, Maurice. -

Hell, Those are quite dramartic. My v arms are just not flat...slight bend. do I need to bother? I'm going to say I'm off 3/16 or so of being completly flat. I don't even know if they are not supposed to be off a bit/ Thanks Peter Peter: The V-Levers are not supposed to have any bend in them at all. They are supposed to be completely flat and true. A bend, depending on the severity, could contribute (in conjunction with too much pressure either pulling or pushing) to the white plastic ball cups popping off. Best to heat them up and hammer them straight. Regards, Maurice.

-

Boxster top parts question...HELP!

1schoir replied to mikes_box's topic in 986 Boxster Convertible Top Issues and Solutions

Mike: One other thing I forgot to mention. From your brief description, it sounds like only one pushrod broke. Be VERY CAREFUL after you install the new pushrod to verify that both sides did not get out of sync. If the sides are out of synch you could cause major damage (read $$$$) , including bending the clamshell. Don't operate the top by the button for more than a second at a time until you have verified this. Regards, Maurice. hi, unfortunately its not the push rod.... i replaced that last month because it broke... the new one was the one with the white top... the reason why the first one broke was because the metal ball that it attaches to fell off because the bolt on the back came lose... this time the piece that holds the metal ball broke off... check the white push rod and for some reason its still intact... i need to find out the part that the metal ball screwed into because that's the part that broke....help please... Mike: Sorry I misunderstood what the problem was. I don't know that part number, but I will try to find out and let you know. Did the psgr side or driver's side break? Regards, Maurice. -

Convertible Top Woes

1schoir replied to 1schoir's topic in 986 Boxster Convertible Top Issues and Solutions

Peter: From the list of steps that you made, it looks like you have everything covered. 1) The center screw. Just make sure it is snug. I would hold the center shaft steady with a small regular screw driver and tighten down the nut. 2) Add White Lithium Grease to the parts that mesh: Half-moon gear tooth surfaces will transfer the lithium grease onto the worm gear. 3) The way to tell that you are not 180 degrees off is by making sure that the V-lever arms are lined up (and that each edge of each side of each V-Lever arm is) parallel with the marking notches. In other words, if you are 180 degrees off, the arms of the V-Lever will cross the marking notches, not continue along them. Try to picture extending the marking notches towards the middle and towards the edges of the transmission housing. If you do that, you will see that you cannot put them in upside down. Again, make sure that the tabs on the back of the center of the V-Levers are temporarily SEATED into the slots in the center of the half-moon gear part that shows through the transmission housing. Looking at your images, it's definitely not "A", and will end up, I believe, somewhere between "B" and "C". But again, don't try to judge it from the half-moon gear side, look at it from the marking notches perspective with the V-Levers temporarily installed. I say temporarily installed because you will have to remove the V-Levers to press the foam lining and the black plastic (round) friction plate back in position before installing the V-Lever in its final position. Finally, be careful not to overtighten the 3 nuts that hold each transmission in place on the body. The correct torque is only 16 ft/lbs. The torque value for the 19mm bolt that fasten the V-Levers onto the center of the half-moon gear is 59 ft/lbs and originally had (blue ?) loctite. Regards, Maurice. -

Boxster top parts question...HELP!

1schoir replied to mikes_box's topic in 986 Boxster Convertible Top Issues and Solutions

Mike: One other thing I forgot to mention. From your brief description, it sounds like only one pushrod broke. Be VERY CAREFUL after you install the new pushrod to verify that both sides did not get out of sync. If the sides are out of synch you could cause major damage (read $$$$) , including bending the clamshell. Don't operate the top by the button for more than a second at a time until you have verified this. Regards, Maurice. -

Boxster top parts question...HELP!

1schoir replied to mikes_box's topic in 986 Boxster Convertible Top Issues and Solutions

Mike: The parts (left and right side are the same) are called push rods (or joint arms to differentiate them from the black hydraulic pushrods that operate the clamshell). Part number is 986-561-279-02 for Boxster MY97-04. Cost between about $40 to $75 each, depending on where you get them. Must buy the whole pushrod, they won't sell just the white plastic ball cup (used to be red plastic in the early years). PM me if you want address and phone number of where I found reasonable price. Regards, Maurice. -

Good luck with the filler tube. The connection at the trunk side is hard to reach. I did the trunk side from underneath as I had the big parts out of the way, but still have the wounds on my wrist from rubbing against all the hoses in the way. I recall someone mentioning that you could get to this connection by working from the coolant reservoir in the trunk. I replaced a leaky coolant reservoir earlier this summer and the oil filler section of the reservoir is a separate part that can be removed, but it will take some effort to do this as you will have to unbolt and disconnect some parts to get enough play to disengage the oil filler section of the reservoir. I believe the oil filler section of the reservoir is the part that the oil filler tube attaches to with a spring clip in the engine compartment. Although I hope I don’t have to replace the filler tube for another 9 years, I would think others will appreciate any insight you gain on how to make what should be a simple procedure easier. You can gain some additional access (and viewing) through the large round opening in the trunk firewall that has a large rubber plug going through it. It's located just to the left of the coolant tank. There is a bundle of wires routed there to the computer which is mounted on the driver's side top of the firewall. If you pull that plug (including the wires) rearwards, you can see and you can reach in there if your hands are small enough. It's an additional access that helped me when removed/replaced my coolant tank. Regards, Maurice.

-

Top anatomy, physiology, and fix

1schoir replied to masterbm's topic in 986 Boxster Convertible Top Issues and Solutions

The Porsche Factory Technical Manual, in its volume called "Group 6, Body Equipment, Exterior" has some detailed diagrams, but the language is somewhat arcane and overall not too clear in its instructions. The Bentley Manual, although not as detailed, is an excellent place to start in understanding the various components of the convertible top (see, for example, p. 354). It has some good terminology in referring to the various components of the top. This forum has some posts that discuss/use various terms for the parts, and although there are some terms that are possible to interpret as referring to two different parts (example: pushrods [referring to the black hydraulic cylinders that operate on the clamshell] [["convertible top compartment lid" in Bentley]] and pushrods (referring to the two-part black joint arms that operate on the canvas part of the top), you can generally be understood. You get the idea... Regards, Maurice. -

I would not rely on the dealer's word in this instance. This is a common problem with Boxsters. It is the exception rather than the rule to the entire housing to have to be replaced. 99% of the time it is only the switch itself, and it can be bought from any Audi dealer for less than $30 to $40. It is Audi part # 4A0 905 849 B. It is an easy DIY, except that you have to be nimble and be able to do contortionist tricks to get into the proper position under the dash. There is an excellent write up at this link with detailed photos: http://industryfigure.com/berkeley/Porsche...itionswitch.htm Good Luck! Regards, Maurice.

-

98 Top Stuck in UP position

1schoir replied to azzar0's topic in 986 Boxster Convertible Top Issues and Solutions

I didn't think there was an TSB on this issue either. The guy told me he'll give me a price range with a low and a high, depending on what he thinks needs to be done, etc. Thanks for the battery reminder - I'll tell them when I drop the car off. Julian: Sounds good. Any possibility of taking photos of the repair for the board's future reference? As these early Boxsters get older, I'm sure there will be others who will run into this situation and it would be invaluable to them. Regards, Maurice. -

Convertible Top Woes

1schoir replied to 1schoir's topic in 986 Boxster Convertible Top Issues and Solutions

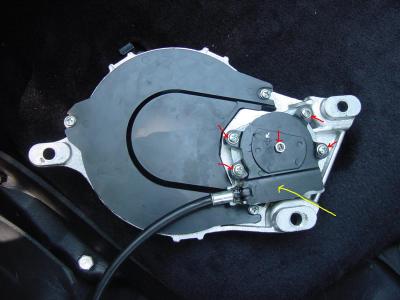

Peter: The slot in the V-lever is actually the center of the back part of the half-moon gear. Don't worry about which position the slots are facing, because when you temporarily install the V-Lever and its base sits in the slots, having the V-Lever positioned between the marking notches (by rotating each cable in turn) the slots will also be positioned correctly. The photo that shows the half moon gear exposed is actually the back side (outboard when mounted in the car) of the transmission after a black plastic cover is removed (with three small screws). Here's a photo of the the back side with the cover still on: The three small phillips screws with no arrows pointing towards them are the ones that hold the half moon cover on. If you unbolt the transmissions from the car, and inspect the back of each one, make sure that you snug up the five other phillips screws to which the red arrows are pointing. If those screws (with the red arrows) are not tight, the worm gear under that cover can skip. The yellow arrow is pointing to the housing for the worm gear that is turned by the other end of the cables. The white arrow shows a BMW emblem embossed into that small plastic cover. I have wondered if this mechanism is used in BMW convertibles but don't know yet. The one broken red plastic ball cup push rod should be adequate to use to approximate the length of the two new (white plastic ball cup) push rods you will have to get. They can be adjusted for length with the 10mm bolt and thich washer that holds them together. You can also make a fine adjustment by turning the plastic ball cup on its threaded rod (but not more than 1 1/2 to 2 turns). As I posted before, that adjustment will come last and it allows you to line up each side of the front edge of the convertible top so that the two tongues fit into the slots onto the top frame of the windshield. The movement of the convertible top is controlled by the main relay that is located in the relay carrier above the fuse box in the driver's side footwell. It controls the top stopping and starting through the tripping of the microswitches in the B-Pillar and in the lever over the motor (under the clamshell). There are two other microswitches that are located in the latch mechanism, and one of those two controls the "dipping" of the windows when the latch is unlocked. The main relay also causes a short period of "after running time" which briefly continues after the clamshell presses down on that lever on top of the motor. A poster named JPorter posted a detailed procedure, with photographs, on how to adjust this pre-programmed after running time by adding some custom-made electronic components but I don't think you are in a position to consider that yet. It does make for some educational reading though. There are no adjustments in the B-pillar microswitch or in the microswitch above the motor, but the small metal lever arm of the B-Pillar microswitch can bend and that will cause the switch to trip earlier or later, and that will in turn change the direction of travel of the top. I'm not sure about how many degrees the half moon gear will rotate before it "falls off" at the last of its 50 teeth, but if you align the V-lever between the marking notches it should have enough teeth on each side to operate properly. If you disconnect the cable for one side (at the motor), as the manual says, I believe it refers to the fact that the opposite side can then be aligned by pushing the button on the dash board. I have found it more accurate to use a drill (lowest torque setting) to spin each cable in turn. It also doesn't drain the car battery. Regards, Maurice. -

Watched it burn today

1schoir replied to Chuck Jones's topic in 996 Series (Carrera, Carrera 4, Carrera 4S, Targa)

Chuck: So sorry to hear about your unfortunate event. Glad that you weren't banged up any worse than the shot you got from the airbag. Fire is a very scary thing, and the advice you give about having a halon fire extinguisher is worth its weight in gold. What's the situation with your insurance? As the other members have said, can't think of any better therapy than a TT. Regards, Maurice. -

Me Three. Regards, Maurice.

-

First place to start is definitely by checking to make sure that both of the drive cables (on the side that goes into the motor which is in the center, under the clamshell,...If both sides appear to be operating in the opposite direction from each other as you describe, is it possible that you installed one of the V-levers 180 degrees off. With the keyed cutouts, it is possible to install the V-levers in only two positions: either the correct way or 180 degrees off. Regards, Maurice. Hi Maurice Thanks for the quick reply. I did stumble on that thread and, it and others were extremely helpful. Told me a lot, I almost took this post down. 1 point, even after the wreck, the top still worked just fine. Currently I’ve disconnected the tie rods. Opening and closing is purely manual (lift the hatch, undo the latch & pull the top back and down, hatch back down). As to your questions, my drive cables appear to be the “new” (bumpy) variety. That is the variety where sheathing presumably doesn’t stretch. Also, as I recall (when I attempted to fix this thing a couple years ago) there was no obvious “shortcoming” in the cable length and they did definitely drive the transmissions…aggressively. The car is a 99. As far as the version of the transmission, my manual describes versions references both “A” & “B”. By extrapolation I think I have an “A” in that it has raised bumps for aligning the “drive lever”, whereas in the “B” model, they talk about measuring down to the ball on the drive lever (illustrations are inconclusive). As to the steps I followed: I’ll try to attach them…makes it look so easy. As to the transmissions running in reverse to each other, that’s just what it sounded like might be happening, it would just make a grrrr -( painfull, loud:)-THAaUNK!-grrrr… with the top going nowhere. Needless to say I didn’t’ try it many times. Having seen on some thread here, the guts of the type “A” transmission, I guess what had me vexed, that’s the free wheeling section of the half moon gear…just couldn’t visualize it. That may help me visualize it into the correct position. Aside from ineveditable pratfalls, it really seems easy. But with so many threads on this topic . I anticipate I’ll be around this forum for some time while I try to get this thing working. Questions: Assuming I have all my ducks in a row after aligning drive levers into position, how should the rear clam-shell/cover and convert top be positioned for attachments of tie rods? Also why, how, and when do I adjust the length of these rods? Feel free to comment or impart any tidbits of wisdom. Thanks, Peter Peter: I'm familiar with the description in the manual that talks about measuring down to the ball on the drive lever. You can also use that measurement to double check (after getting the V-Levers into position with the marking notches) that both V-levers are in the same position relative to that rail. Again, if you have the half moon gears, you definitely have the "Version A", early style transmissions. The clamshell pushrods are not adjustable, but they do extend when they are under pressure from the V-levers. That is what keeps the clamshell down tight on top of the open and retracted convertible top. That is also why it is sometimes incredibly difficult to separate the pushrods from the corresponding metal ball on the V-Levers. So, once you align the V-levers into position, start out with the clamshell almost closed and then pull on the arms of the clamshell in either direction until you can get the ball cup on each pushrod to pop onto the metal ball on the V-Lever. Once you do both of them, the clamshell can only be in one position with the V-levers rotated at that starting position. Again, you cannot adjust the length of those (black hydraulic tube) pushrods, but you can adjust the other pushrods that operated on the base of the B-Pillar of the convertible top. Be sure to mark the length with which you start out so you can re-assemble them to that length as a starting point. The reason I dissassemble them is that it is much easier to pop those on (the white plastic ball cup part) that way when the top is almost completely up. Then you can re-assemble them with the 10mm bolt and thick washer. In time sequence, this is the last step before you try to operate the top. The adjustment that those pushrods (with the white plastic ball cup) provide is to adjust where the two tongues on the front of the convertible top engage the receptacles in the top frame of the windshield. When you have everything together, if you can have someone else push the button with you standing behind the car, you will easily be able to judge is the two sides are synchronized, especially from the motion of the clamshell. Regards, Maurice.

-

98 Top Stuck in UP position

1schoir replied to azzar0's topic in 986 Boxster Convertible Top Issues and Solutions

Maurice, I went to a body shop today and the guy I talked to said he was going to contact Porsche and find out if they have a TSB out for this issue or if there is a known procedure for reinforcing the sides. He said if he can't find out anything from Porsche he'll take the car in and scratch his head and try to come up with a best procedure. He will call me tomorrow and let me know. They charge $44/hr; with no real parts cost, I think I am looking at anywhere between $150 - $350 (3 - 8 hours of work / best case - worst case scenarios). I'll keep you all posted. I don't mind spending that much (on top of the ~ $600 already spent on transmissions, push rods, cables, etc) as long as the top will work without any more problems. I would be very upset if I put $400 more into it and still be where I am now though. But we'll see... Julian. Julian: To the best of my knowledge, there is no TSB on this particular problem. I remember looking through all the TSB on convertible top related issues and there was nothing on this one. Maybe your body shop guy will get lucky if the dealer can point him to whoever it is that they refer these types of job to. I'm pretty certain that a dealer would not do this kind of work themselves without some kind of a kit from Porsche. That $44/hr rate looks pretty good to me from up here in New York. As far as geting upset, look at it this way: There is no way that you could continue with your top with the present condition of the transmission supports, so that's definitely the best way to proceed. With any luck, that will also be the end of it. Oh, one last thing. It would not hurt to get a "maximum" price from the body shop guy before he starts. And remember the caution about disconnecting the battery before any welding takes place. Regards, Maurice.