Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

Contributing Members-

Posts

926 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Store

Everything posted by lewisweller

-

A picture of that vacuum piping diagram would be good please. Really I have to take off the manifold again and cut off those rigid pipe adaptors and put in a hydraulic pipe instead with jubilee clamps. Maybe I will find something else wrong whilst I'm looking in there. Any one have some info about exactly how the transfer case works? If I drop into neutral the car seems so smooth in gear it's a stumbling pig. Engine and or drive train I'm not sure.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

I see your post on Rennlist about this. I'm also reading on Bimmer forum the X3 has transfer case issues which produces Jerky acceleration!. The clunk or "Release Thump" I have is mentioned in the tsb attached. Could it be the jerks (stuttering) and thumps all are related to the transfer case and a update tcu module will fix all these problems? I can verify that I have the newer revision "C" stepper motor (older 03-04 maybe 05 cayenne need newer stepper motors apparently) so from my understanding only a newer revision control module is required to alleviate the issue. "Plug and play" in this instance apparently. Can someone share their experiences of fixing this transfer case issue please.

-

Hello, you may have been reading some of the post which related to my issues of stuttering and Jerkiness under acceleration and idle Dip when pulling to a stop which developed more recently. This all happens when engine is warm/hot but it runs perfect when cold about 5 mins in dubai weather. So my question to you is when you start from dead cold does it jerk? Does the jerk get worse after you are at full temp and you sit and idle for a while then drive off it will jerk bad? How does the engine respond to slow speed light throttle conditions? I also get "four wheel drive faulty" warning at random times. But never had a psm fault and never any codes related either. You should try and get the codes read when faulty psm is on, these faults tend not to throw a code unfortunately and a key cycle will reset them.

-

Fuel level issue was simply the pipe of the left pump was resting on top of the sensor pinning it down to the bottom of the tank. Repositioned it. Fuel gauge now reads correct. Fuel tank was full as I wanted to see the floats position as it is in the faulty condition. I will be happy to never have to get inside those tanks again. I stink of fuel and hands are sore.

-

Interesting stuff. The stutter is worse up hill but I think more to do with the load rather than the angle and fluid slosh. Downhill better obviously less load but not a miracle Fix or even close to being. The whole day was driving and idling and driving stop and then again driving. The car hates to be at idle for a while then drive, its a real pig at that time. Light throttle also it hates. Thrashing it all the time is the only way it feels ok. It almost like it wants to clear it's throat. Light throttle cruising with small increase and decreases in speed and load is also crap, roughness and shudders with a vibration feeling and sounds like it's missing if you give a brief bit of gas. Bucks if you boot it at that point as the boost comes in and it takes off. I also get a quite Jerky and bang noise during lift off like it wasn't ready for it. I may remove the inlet manifold and address the rear turbo vent pipes which are obviously leaking a bit from the crimped metal to hose floating adaptors fitting. Maybe I find something I didn't find last time I had it off. My engine whines does yours? In sequence with the rpm so it's something rotating. Other people have said the same they hear it and have looked for the source of the whine without finding.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

With psm off it inadvertently disguises the issue as the rpm is held higher. If shifting manually psm off or on its not much different really, I would say marginally better only for the fact when you WOT it won't kick down and this generally mean the rpm and boost build slower and more steadily possibly allowing for a better mixture and combustion in that particular circumstances verses being in auto and it kicks down and flies off with a stutter upon pickup. Transmission is a good out to the box idea, the fluid is Toyota type iv and around 8 litres or so went in with new filter etc and new mounts, when head gaskets where done. Also transfer fluid replaced just recently 1 litre of type iv. I do get the "four wheel drive faulty" warning sometimes not necessarily at any logical time. This is the stepper motor and or control unit faulty so I've read. I just ignore it and next time I cycle ignition it's gone again and never found a code. I have to say the transmission is very smooth especially for 11 year old car after 125k km. Smoother than the Audi s-tronic in certain circumstances. This morning I disconnected the bank 2 precat lambda sensor and no check light or perceivable difference in driving the last 20km. Strange! Will check for a code which will obviously say open circuit........ Bank 2 sensor 1. So for now only thing to do is replace this sensor and recheck.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Yep great summary this is. Pretty much details my trouble shooting journey. I have new mafs and have to admit it made absolutely no difference except long term I could rule out a failure. My fuel trims are always bang on LT +- 1-2%, ST +-3% accumulated less than 6%. The bank 2 sensor precat is the only thing left which is suspect given its slow reaction to snap throttle compared to the new bank 1 sensor. Blocked or partially blocked injectors or electrically failing due to heat soak is something I considered! Any thoughts?

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Brainz006 Thanks for the reply and sharing your experiences and tips. I do wonder sometimes if anybody reads these long post with what some might consider mumbo jumbo or just some guy stabbing in the dark for a solution. Lol. Well I was just finishing up installing the new coils and test driving when I got your reply. Try to keep this short ( yeah right) here goes: 1. Did the new coils Fix the stutter? No! 2. Did the coils make the power and rpm smoothness after the stutter has cleared at higher rpm better? Yes! (Not a complete waste of money then gladly and they tested very different with the multimeter old vs new coil) 3. Did disconnecting and plugging the purge valve pipe to engine as per suggestion work for me? No! (The purge valve was new last year and I think it works fine and no codes except when I unplugged it, but worth a try thanks). 4. Whilst doing the purge valve test I found the driver side intercooler outlet to plastic pipe before the Y pipe was loose and had some oily dirt covering it. Did tightening this Fix the stutter? No! (Feels even better at high rpm, the boost doesn't feel like its tapering off so much or just my imagination). The engine seems to love being thrashed, if I drive it like a animal it's lovely and flies really well. If I'm on over run down a slope to a set of traffics lights and coast to a stop it will idle Dip for sure and then after a short time at idle waiting for the light to change I pull away and its the worse stutter and hesitation as I build speed light boost comes in at light to medium or progressive throttle inputs. If I redline it then I doesn't have a chance to stutter as the rpm stays high. Brainz006 you mentioned o2 sensor precat (wide band lambda type o2 sensor in fact for us) which does make very good sense. The sensor is used for partial load and throttle demands, it goes closed loop at idle after you let off from heavy acceleration and over run to standstill. When cold the engine dotent stutter or idle Dip. I've already changed the passenger bank 1 pre cat sensor which was "lazy" and the other day I graphed the driver side bank 2 sensor doing the same thing! This b * tch is so close to being right its even more the frustrating for me. Bosch dealer here is strangely cheap so I may enquire about if they can get the sensor ordered in for me now as they could get anything before until March which now isn't far away. If this sensor isn't the final piece to this puzzle then I will stop looking and just drive it as it is. Well my wife will and she won't notice anything is wrong ......... Lol I'm having my Audi back.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Today I Took out the regulator to look for the reason why the tank level won't show full when it is full. It seems the right float level could have hit a pipe (return fuel from sucking jet on left side) but can't be sure. I adjusted it and refixed everything. With 1/4 tank I wouldn't know if this was the Fix until I refilled. I started the car and it started fine. Thought I best test each pump individually. Left pump was fine. But the right pump would idle but spluttered and coughed and back fires when trying to rev. Something was not right. I thought I best remove the right pump and put in the old one thinking the pump maybe at fault unless something else popped up like a broken pipe etc. When tearing back into it again, I needed to remove the filter to unplug the pipe from the right pump. I then notice the rightside suckjet return pipe which picks up fuel from the right side and dumps it into the left pipe casing was kinked! I repositions and locked in the pump anti clockwise some degrees and all looked to be good plus it was looking possible that pipe could have interfered with the left side fuel float as well when coming near full. Going back to the recently new right side pump I pulled it out and measured resistance and it was same as old pump 0.4ohms. I then rechecked the piping connections and realised one pipe (small pipe from right pump for the sucking jet over on the left side) I didn't disconnect it which means it was already disconnected I think it blew off at some point because the right pump did run on its own when new I tested it! So I used the recently new right pump and refitted it after finding this obvious problem. The car runs the same with the right pump only now just fine. But sadly no smoking gun for the stutter hesitation. The kinked pipe return on the left side pump from the right side sucking jet was the reason I'm pretty sure it stalled and would not restart last week. My explanation is the left side tank was empty and the fuel wasn't being sucked from the right side of the tank to replenish it, (despite a small amount from the fuel pressure regulator return pipe coming back to the left pump it wasn't enough) being 1/4 tank or just under the right side pump wasn't yet called in for operation by the dme. When on the tow truck either the fuel sloshed around to balance the fuel from the right side over to the left or the angle the flat bed was sat at prior to unloading me when I decided to try and start the engine again was allowing the fuel level sensor floats to tell the dme the tank was nearly empty and then both pump would run and as if by magic it starts.

-

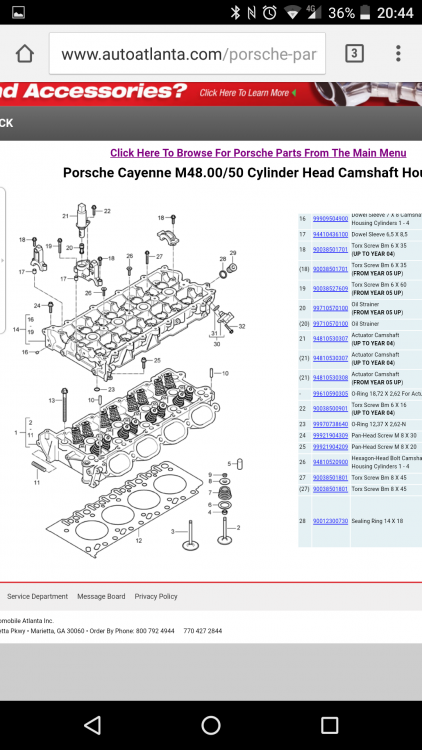

Oh I nearly forgot,..... take out your cam solenoid actuators part 21 and clean oil strainer 20. Its one bolt 22 and 10 mins work. In the future they will never be blocked with oil sludge debris etc and stop the variocam working! Pls take pictures of this and other stuff like the broken cam chain guide, stretched chain etc. It's great for the forum and a nice way to give something back. Thumbs up Omg if only I had known what I do know when I had my engine out on the floor.

-

The SAI themselves? or the metal check valve on the back of the engine?. Part number 10. They get clogged and stick open causing rapid sai failure as the exhaust heat and soot wrecks the sai pump. Ask me how I know. One more thing is the thermostat, it's 25 bucks and really not worth the hassle if you have to change it later.

-

Picking up tomorrow the remaining 7 new beru zse012 coils which are same as 94860210421. Also I have between 1/2 and 1/4 tank now so will be diving back into the tank to see what can be found causing the fuel tank to read not quite full when its actually fuel to the brim. And maybe explain the sudden stall and no start event last week which hasn't returned and no codes ever appeared.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Revision 22! Could you possibly measure the resistance of the new coil? Red lead on pin 4 (far right as you look inside). Black lead on pin 2 should be in the Kohms range. Then move black lead to pin 1 (far left), not sure what reading but I think it high Kohms or low Mohms. Thanks. If your doing the DV maybe you might want replace the vaccum pipes as well, 6mm OD and 4mm ID get pipe from any pneumatic shop cheap as chips.

-

As your going the whole hog may I suggest two things, buy some 10dollar vac hoses and replace all the pipe from the turbo wastegates to the n75 valve, also buy some oring and change them for the turbo to IC and IC to Y pipe. Its so much less hassle and total cost will be less than 50dollars. Also I would replace the alternator, Aux belt tensioner and pulleys. Also check the SAI check valves at the back. They can be cleaned easy now, but when engine is refitted it's a real pain. I wish I had done all these job when my engine was out.

-

https://www.ecstuning.com/b-beru-parts/pencil-type-ignition-coil-priced-each/94860210421~beu/?trk_msg=OJ8O112A43G454TL2JV90E1M00&trk_contact=31PA2H8PO6BUCUB8193NOSO5HS&trk_module=bna&trk_sid=0F37GP8D2608JUBU4HKA9P81VC&utm_source=listrak&utm_medium=email&utm_term=SHOP+NOW&utm_campaign=SCA+Program&utm_content=Browse+Abandonment+2 These coils are listed on ecs as 94860210421 which if you look at the picture is labelled beru ZSE012 which is exactly the coil I bought the other day to replace coil number 2 which was the melted one. Still trying to scrap up some cash to buy another 7 coils and see if the end to this long saga is the true end.

-

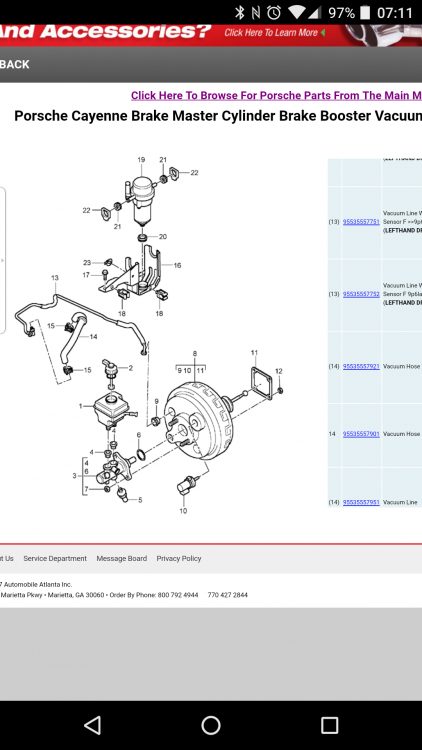

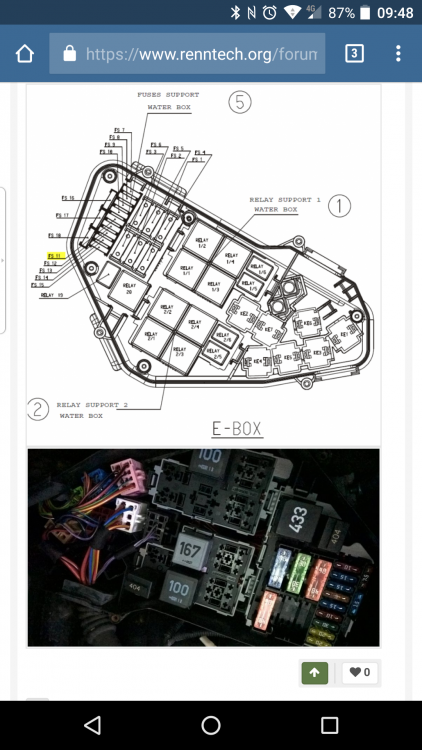

You can watch YouTube video But if you have little to no mechanical knowledge I would not recommend you start diving into a fuel tank. Stalling after 30 seconds does sound like a left fuel pump issue because on start up both pumps run and the assuming you don't have low fuel level only the left pump carries on running. If the left pump is faulty the car will not run for long. Normally the car will know the pump is having a fault and kick the right pump to run after the key is cycled. Easy check is to do, underneath the scuttle panel is the "Ebox" fuse box, remove fuse 14 left pump and run the car. Then replace and remove fuse 13 right pump, cycle the key between removal, see which pump it will run on tells you which pump is faulty. If this has no effect it could be the filter is blocked or totally un-fuel related. I really recommend you go back to the garage.

-

Bourses cars

lewisweller replied to Bourne cars's topic in 9PA, 9PA1 (Cayenne, Cayenne S, Cayenne Turbo, Cayenne Turbo S)

75w90 GL5 differential gear oil. Assuming you don't have locking differential the oil is the same for the front and rear differential. -

Whilst you waiting for the parts unplug both maf sensors and idle for a while and go for a drive. I bet it's a whole different story. Then plug in on maf and check if no different unplug again and plug in the other one. If that produces same running as before you probably identified the bad maf or maybe both are bad (more unlikely). The other possible fault I heard about was hydraulic lifters getting stuck, this caused one cylinder to misfire unexplainably until they stripped the engine bank 1 down and found the lifter stuck. As you have multiple misfires on random cylinder I doubt this is the case.

-

The dummy key has nothing inside its just plastic and a generic shape I believe so you can buy another one without any hassle of coding blah blah. The kessy system of keyless entry works simply by external antennas sensing the person with the key on them, they can pull any door or boot handle and it automatically unlocks and will allow opening. (The doors require two pulls). Locking the car is done by pressing once any handle button (with the key on you of course) If all the handles don't work then likely the kessy module is faulty like mine was and I soldered in 2 new mosfets and 6 new MELT resistors. Works perfect now. Big thread on this is here if just search "kessy" You need to get a dummy key as well to check if the internal antennas are working.

-

Yes that is the correct sensor for our cars. The fault code relates to an electrical issue and considering this is a new sensor and Same fault it has to be either the wiring loom or dme issue. You could get the dme pin diagram and test resistance between plug pins and dme pins.

-

This guy is good, I watched a lot of his videos. One thing to note, the Porsche Cayenne precat lambda sensor produces a measurable milliamp current not voltage for the dme to read. Higher current means richer the mixture and less air is being sensed, lower current is lean mixture and more air sensed. The idea is that the dme should maintain a Lambda 1. Snap throttle will show rich higher current. The sensor should respond within 100ms and both sensors should look very similar when graphed. The post cat o2 sensor produces voltage.