Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

lewisweller

Contributing Members-

Posts

927 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Events

Forums

External Paint Colors

Downloads

Tutorials

Links Directory

Collections

Classifieds

Store

Everything posted by lewisweller

-

This guy is good, I watched a lot of his videos. One thing to note, the Porsche Cayenne precat lambda sensor produces a measurable milliamp current not voltage for the dme to read. Higher current means richer the mixture and less air is being sensed, lower current is lean mixture and more air sensed. The idea is that the dme should maintain a Lambda 1. Snap throttle will show rich higher current. The sensor should respond within 100ms and both sensors should look very similar when graphed. The post cat o2 sensor produces voltage.

-

Whats the lambda sensor part number your using? Should be 0258007174 as the Bosch part number.

-

I personally think the S and the turbo will run fine on the 948........03 or 05 or 08 or 09, or 12 or 21 revision, but some website state different parts 980....... And that is not turbo suitable I don't believe. I think the websites listings are incorrect. I tend to follow the porsche part from the vin and I trust autoatlanta for their part numbers and it's 948602104??(revision number). What is actually different inside I don't know, but when testing the one new coil revision 05 against the previously 8 new coils revision 21 the measurements were very different and I don't know why.

-

Took car out for first time since break down, car started up lumpy and not sounding that good. After a few minutes it sorted it self out and ran ok to fuel station. I filled up to full but the fuel gauge said between 3/4 and full so I know I have some pipe in the way of the sensor on one of the sides. Need to check this when fuel is down a bit later in the week. I'm trying to imagine how this could cause a stall and no start and then later work fine with the fuel light not even coming on yet. Maybe it drained one side only and ran out. Then on flat bed it sorted itself out!? Strange. New coils for remains 7 cylinders also on the list to do as I now believe the newish coils got damaged when the head gaskets blew and car got overheated for many km whilst trying to pin point why.

-

The coil you bought ecs Tuning and Porschegeek both say they don't fit cayenne turbo or turbo S, they are for cayenne s or carrera. The attached screen shot is from autoatlanta and they list only 948........09 as the coil for our turbo. Fyi the turbo and turbo s is the same coil. I think you have been sold the wrong coils. Incidentally when I bought my newish coils from Porsche back in March 2016 they ended in 21. I bought one new coil last week ends in 05. All beru oem originals. I also now beleive all my coils or at least bank 1 which had head gaskets failure had fried my coils and could be the whole reason why I have running issue when warm but with no code ever recorded. I'm going to stump up another 400 dollars and replace the remaining 7 coils with the 05 revision number and see if that's the smoking gun I been searching for for nearly a year believing my new coils couldn't be to blame. Aside from this you still likely have an air leak somewhere but not sure where. If I remove my oil filler cap I can hear air sucking via the aos internally which I know is not split and when cap is on the noise is gone. What this does confirm is you have a leak somewhere still for sure. You checked the Y pipe for splits that open up and close which are hard to see! Also have heard some manifolds can split and gasket can leak.

-

Divertor valves won't affect idle. But will affect how high the boost can go and hold. You should be having 0.9 bar. Assuming you haven't had the manifold off, the list of top likely leaks for me is: 1. AOS 2. Pipes 4, 5, 14 3 throttle body dirty and or gasket 9 leaking 4 Check valve 13 leaking or 25 or small pipe from 14 all are check valves. The fact you have to modulate the throttle to keep running after cold start has kicked off suggests to me it a dirty throttle butterfly. Easy to remove and gasket is cheap. Also check the pipe under it for damage splits and check the two small black check valves working as they should. (Arrow tells you the flow direction, reverse flow should be closed) After cold start is finished briefly Smell your tail pipe (well ventilated area of course). Is it air or is it fuel smell. If you have a fuel issue it will likely not smell rich. If you have air leaks or lack of air entering for the engine it will be rich smelling. A Lambda sensor only can detect the presence of oxygen so a misfire will also see as lean whether its actually rich ignition misfire or lack of compression, unburnt air is still seen or lean misfire lack of fuel extra unburnt oxygen is still seen) the codes are being generated by lambda sensors. When you get your icarsoft you can look at fuel trims which will identify lean or rich pretty quick.

-

Yeah my gut instinct when it happened was fuel is either run out or pump is dead. This could be a few possibilities then: 1. The fuel pump relay for the the left pump failed (intermittently) if this was the case then cycling the ignition would have run right pump and engine would have run. 2. The left fuel pump got hot or failed temporally again right side pump should have ran after cycling the ignition, unless the dme didn't see the failed pump as an actual issue and therefore would not know to switch the right pump on. This is more probable! 3. Low fuel is ruled out and considering the left pump sucking jet pulls fuel from the right side of the tank, one side going empty is not likely. 4. Totally un-fuel related issue of which I have no idea where to start?

-

Well it isn't out of fuel. The fuel light just came on and both pumps are running. Removed fuse for left pump and it kept running on right pump. Engine changed pitch and running slightly when removing fuse and replacing fuse. Swapped melted coil cylinder 2 and can't tell any difference. Checked for codes again and also looked at lambda sensors and fuel trims. Only thing I see is the bank 2 lambda sensor is not producing as high amperage when snap throttle test is done. I had this issue with bank 1 sensor a few months back and replaced the sensor, so now it seem bank 2 is also had enough and getting lazy. I did order 2 sensors before but the ebay supplier lied saying they had stock but only was able to supply 1. So I'm at a loss why the car stalled and wouldn't restart yesterday! Very frustrating and now scared to drive somewhere and get stuck.

-

I got one new coil to replace a melted one which I found a few weeks ago, will swap that real quick and go to fuel station and fill up. I remember after changing the right pump I filled up and it only said just over 3/4 full. After that when I filled up it was full everytime and I dismissed it. Maybe the float was stuck but I'm thinking how does the right side float getting stuck stall the car . Then later it runs fine? Cycling the ignition will run both pumps and the car will start briefly on both pumps (hot start is 15 seconds) then it reverts to the left pump unless there is less than 15litres in the tank and both pumps run continously. So this doesn't make sense! I'm going to pull the left side fuse and check if the right side pump is running. And then the right side fuse. Which brand pumps did you buy? I used vdo.

-

This is very weird! I just had my 06 ctt towed home due to a stall at the lights and it wouldn't restart. It was like I ran out of fuel cranking but just wouldnt start. Lucky a Tow truck was right next to me as I backed up the traffic which all gave me the horn lol. Towed home just 10 mins away. I jumped in to back it off the flat bed and I thought I bet it starts now, and the son of b*tch did! And no codes and no sign it ever stopped working. Ffs this is the worse breakdown type, as who knows when it will happen again? I have a also done some weeks back replaced both pumps and a longer while before that the regulator and further back the filter. At least 4000km since filter and regulator. Also fuel pumps don't find any issues with the old ones. At least 1500km since both pumps changed. No codes is a joke!!!

-

Penguin The cayenne v8 is a bit of a bi*ch to bleed air without the right equipment but it is doable. For starters be real careful as driving around with air in the heads will just give you blown head gaskets real soon. To get air out there are a few tricks I found worked, the heaters needs to be on full hot and assuming the thermostat is working, no blockages, and the water pump is good here we go. 1. squeeze the radiator top hoses with the expansion cap off (requires cold coolant startup for this and mine your fingers on the rotation belt and rad fans) you will find one pipe is cold and the other is hot because the thermostat is not open yet, keep squeezing and topping up coolant so it doesn't suck air in via the expansion tank. I found an alternating squeeze sequence worked well when both pipes where warm. As the coolant warms up the other hose will get warm and even more air will bleed if you keep squeezing hoses. 2. If you have rear AC (4zone) you also need to help that bleed too, under the car driver side (lhd) is metal plate under panels (maybe different of yours) remove panel and you will see water pipe and AC refrigerant. Squeeze the hose and you will feel the air purge out and heat start to circulate through the exchanger. Some uphill parking engine bay up of course will a jack lifting the passenger side where the expansion tank (handbrake on, bricks behind rear wheels) is will also help. 3. Lastly when you think all the air you can get out is gone and all the coolant you can force in is in then you need to drive it up to temp and then cool over night. Next day unscrew expansion tank and surely the level will be down, top off and repeat for a many days as it takes to see the level stay at max. Keep those heaters on hot! Failing all this hassle get a vacuum bleeder! But sometimes even with the bleeder you still need some of the above to get all air out. Caution when the coolant gets warm the expansion tank will start to spill over as the air pushes it out and the water starts to boil without the aid of the pressure which should be built up if the cap was on. Before the coolant spills over you need to put the cap on quickly and shut off engine to cool. After cooling open and squeeze hoses again with engine off this time, top up, then close and go for a drive always monitoring the temp gauge. Man... This is time consuming!

-

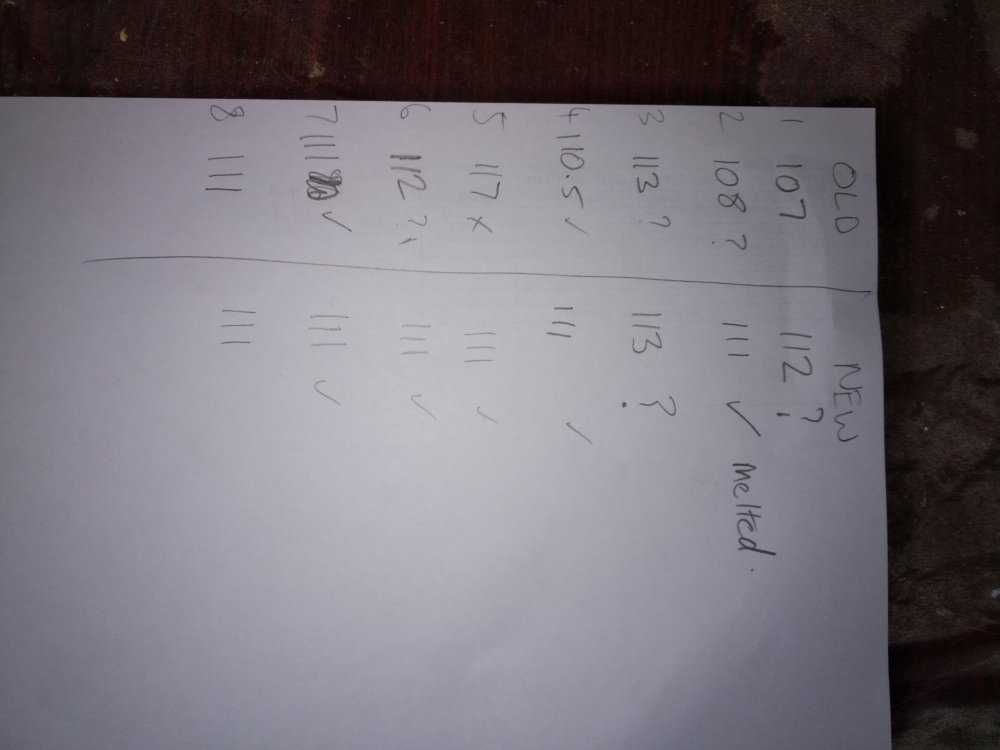

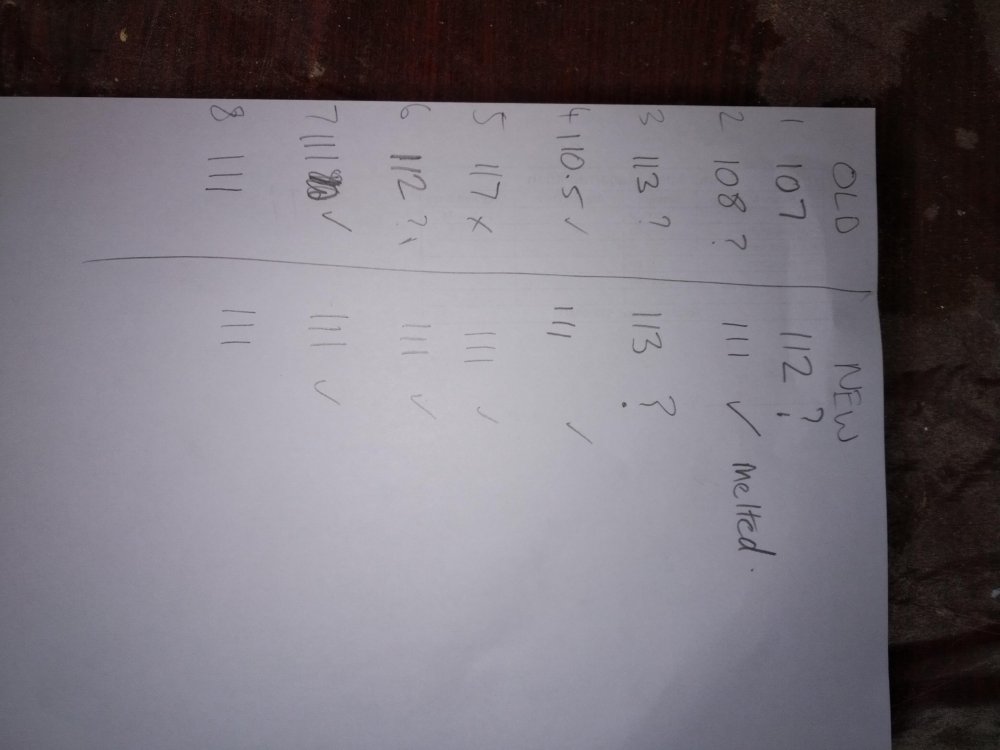

Just to update this post, the new fuel pump left and the right side did NOT fix the hesitation and stutter. It always comes back when hot and heat soaked running. I have recently suspected the newer coils (fitted 8months ago and 10k km) may have some issues. When I installed the old cracked coils the problem was the same symptoms but just worse misfire under load. Testing them for resistance across pin 1&3 gave the attached ohms reading and newer coils 1 2 & 3 are suspect for hight ohms and 2 is melted on pin, as per picture. I now intend to replace 123 coils and retest.

-

Lost patients with Porsche trying to make money from warranty claim so for now decided to put newer coils back in as older one are much worse misfire. I decided to try and test some ohm measurements and attached is the pin 1&3 measurement for each old vs new coil for each cylinder. Note the bank 1 is where I had head gaskets blown between 2&3 cylinder show some difference in the resistance which it seem 111kohms is correct higher may spell an issue but I really can't be sure and have no reference to follow for info. The other pin combinations are high Mega ohms or open circuit. Also note the newer coil 2 is melted on the forth pin. I cleaned this melted stuff out and checked the plug connector which looks fine. I think I should replace coils 1, 2 and 3 and see of the issues are resolved. Driving feels the same less harsh misfire than the old cracked coils but stutter hesitation the same. What does anyone think about this? Any technical literature to share please on coil testing? Will be appreciated.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Looks clean enough but I would be looking over the past 8 years of service history and receipts with a fine tooth comb. Although low mileage the components which may become problematic over time could well be the biggest potential cost hindrance for your maintenance and up keep budget. This is certainly a smarter buy than a 955 v8 in my opinion. Needs a set of rims to fill those arches!

-

I have thought about it and eliminated it for two reasons: 1. A blocked cat will usually cause issues at high rpm for obvious reasons of flow restriction. At high rpm it flies with good performance. 2. The post cat o2 sensor is reading very stable on both banks and the dme reports the cats both pass test and readiness. Pls correct me if this is faulty diagnosis.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

That says a lot from a German man, living in Germany with two German cars. If I could have any guarantee that they would be able to fix the problem I would really save up the money and do it to end my misery but I'm sure they won't find anything in the conventional manner and knowing the level of expertise here in uae they won't even go beyond my tech ability. And that's not being big headed it's just a fact of this part of the world and the level of experience and creative thinking here for anything "outside of the box". You watch you tube video's of Scannerdanner, now thats what a top automotive technician is!

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Valid point and I don't doubt the porsche dealership has much better capabilities than most, although the car has been to two indy's, the first has genuine PIWIS (German owner) and I watched with great interest as they scanned and viewed all the systems looking for faults and particularly misfires there was none. The second indy (German manager) has duremetrics and they also did the head gaskets for me. Long story short neither could find one single problem with the car which is a bitch when its obviously not right. So couple that with my genuine vcds from Ross tech which despite its crossover issues from vagcom and shared Porsche vw modules does deliver codes and data to an extent just fine also has never popped a misfire code. I've unplugged stuff and made codes pop, I've has a split pipe to n75 and got overboost code, I've got a SAI code which comes if I have a rare cold cold start, (sai are pneumatically fudged so I get "insufficient flow"). Subsequent to these indy's work I found the following faults and fixed them but never fixed the misfire. 1. Split pipes from change over valve to DV's 2. DV drivers side split diaphragm 3. Cracked coils 4. Alternator died 5. Battery dead (now on the 3rd under warranty defect and going strong) 6. Few other things I can't remember just now. So this is a unique issue in the fact it's not giving up itself in the conventional manner and I feel a day in Porsche workshop at 800 per hour will run me into 4000-5000dhs without any resolve. Without codes they are just as dumbfounded as me and any other garages.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Dealer where I bought the coils from want to have the car in for testing of the coil. I said that's fine but don't expect to be sending me a workshop bill. He said he would call me later to confirm. Calls later and says 800dhs to test the car in their workshop. I promptly reminded him the parts only cost 1500dhs so really I'm not happy with this Cock and Bull approach to a warranty claim. I said take the coils which I already have packed in a bag ready, and fit them in a known working cayenne turbo. If the fault is now present in the known working car then it's the coils. Of course they won't do that because they can't get my vehicle in there workshop and charge me. Anyway I'm going to see the manager tomorrow or Thursday and try to twist his arm.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

I just removed the new coils and put in the old cracked ones. (4 out of 8 were cracked) The verdict is it drives the same but with worse misfire stutter. I drove it around for a while nice and hot and did some light cruising and some heavy acceleration which produces the same kind of stumbles and even harsher stutter misfire when boost and load comes in. So it really feels like coils misfiring under loads and lean mixture conditions is the reason. I got back to the parking and plugged in the vcds to check for codes which I was sure there must be something for all the bucking it did but nothing. Unbelievable! Obd2 is w*nk. I'm going to take these new coils back to Porsche parts desk tomorrow and ask them to have them tested either on another known good vehicle or send them for technical testing. I will be pushing hard for warranty replacement but I know the first answer will be no.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Overheating at idle cos Head gaskets blew on bank 1. Replaced head gaskets on both banks.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Something I'm making a big big assumption on is the "new" BERU coils are working properly. What's the chances these little defective God forsaken pieces of s**t are faulty even though they are (were 8 months and 10k) new???? I still have the old ones. Tomorrow I'm going to put black tape on any of the cracked ones and throw all of the old ones back in. Thinking I was being the ever mindful new cayenne owner, when I bought the car the coils and plugs was the first job I did but come to think of it the car actually ran better on the test drive before I bought the car (boost was down cos divertor valve was split) but it didnt stutter like a fffffff**king Jim Davison joke. If these turn out to be faulty my mate at the porsche parts desk may not be a mate for long if they don't honour a warranty claim for defective parts. Lol but I'm serious FYI I have inspection the new coils at least 3 times for any cracks or signs of anything wrong with them. "Apparently" when hot the internal resistance can increase or the windings can shorten increasing current draw and causing misfires. There is a transistor inside as well which can fudge when hot.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with:

-

Ok, well I did some tests and have a conclusion! Engine cold not started since yesterday. 1. Measures the resistance of each solenoid actuator both are exactly 10.7 ohms. 2. Connected some wire to earth and battery + and activated the solenoid (Engine still off), I hear a quiet but definite click so they both seem to work. 3. I reconnected the solenoid plugs and started the engine, starts fine, during the warm up period I disconnected the plugs on each solenoid and nothing happens. Engine idles same. 4. I reconnected the plugs and put my ammeter clamp around the brown and red strip + wire to measure the amperage the solenoid is drawing. At idle the amps was 0.45A (bank 1) and 0.36A (bank 2) dropping to 0.28A (both banks same) when engine was fully warm, when revving the amps would peak to 0.81A showing the solenoid is being activated more as the revs increase. 5. Went for drive with both disconnected, instantly I can tell there is no low rpm power or torque! Power doesn't come until up around 4000rpm. (Feels like a crappy vtec engine) The stutter is still there but much less pronounced as low rpm power delivery is less and less agrresive and not because it has fixed the problem I don't think. 6. Reconnected the bank 2 solenoid and drove for a short distance still doesnt feel powerful at low rpm but a little better, it's trying to deliver power. 7. Reconnected bank 1 solenoid and power is back to normal low rpm good and high rpm as normal good. Stutter is still present through the lower rpm pickup and acceleration especially when boost comes in. 8. Disconnected the MAP sensor to drive without boost and stutter is less pronounced but still there. So what did I learn. ???? Variocam is working I'm pretty sure this is conclusive. The system from my new understanding works like this. 1. The inlet cam is always in the retarded position. The cam solenoid actuators when activated make the inlet cam advance giving a bigger valve overlap which encourages more power especially at low rpm when air flow is slower (hence when I disconnected them at idle it doesn't make any difference and when revving the amperage increases proportionality ie the actuator is energised and opening the oil flow to the cam phaser). 2. The terms used "variocam fails on the low side" means it fails in the retarded normal position. The solenoid doesn't advance the inlet cam when rpm increased. "Low side" refers to low rpm maybe? 3. The oil flowing through the actuator pushes the cam phaser and helical gear to move the inlet cam to the advanced cam angle position as rpm increases beyond something around 1500rpm roughly? All the above is based on some assumptions and not on actual facts ( except the measurement taken and results of tests) so pls correct me if anyone knows better.

- 161 replies

-

- fuel system

- hesitation

-

(and 5 more)

Tagged with: