Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to donate. All donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual donation to keep this site running.

Here are some of the features available - once you register at RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

-

OBD II P-Codes - Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's FREE

Contributing Members also get these additional benefits:

(you become a Contributing Member by donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 06/06/2025 in all areas

-

1 point

-

I came across this old post in a Google search and thought I'd provide an update. The Porsche part number for the adjustable linkage is 986-424-931-06 and is available from Pelican Parts for about $250. Numeric Racing makes an all-metal version for $130. The adjustment procedure for the adjustable-length linkage is available in the Porsche OEM Service Manual.1 point

-

1 point

-

We have installed many B&M shifters over the years, and they have proven to be one of the best when it comes to durability, and in fact we have never had to replace one. More likely, you have a cable or cable end issue.1 point

-

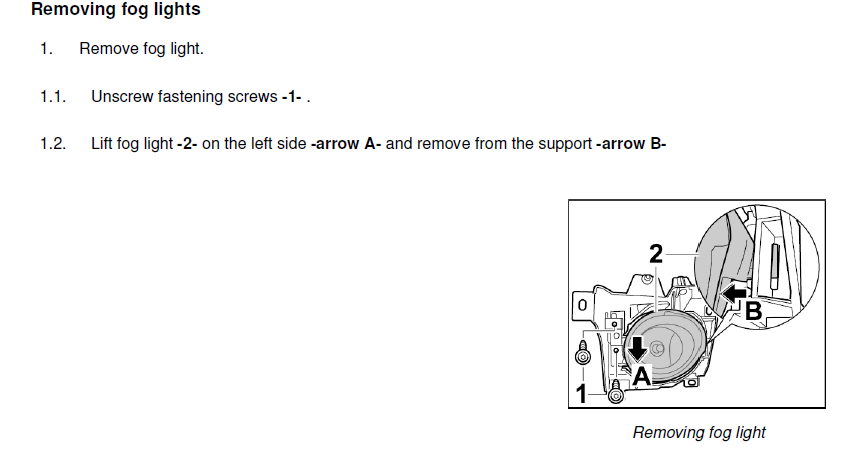

Hi, I have a 2021 CTT. I replaced the passenger fog light this summer without removing the front bumper. Yes there is a cooler in the way. A lot of patience and you can work around it. I also uncliped a few harness clips to get a little more leeway around the back of the fog light. If I do It again, I won't use the original mounting holes. You will see the fog light is attached using two mounting screws, but the fog light has four attachment points, one at each corner. If I recall correctly, the original mounting points were 2o'clock and 7o'clock. One went in very easily. One was a royal pain to get started. Next time i'll use the mounting points with easier access, 11 and 5. I may have these positions reversed, can't remember for sure, but you'll see right away the fastener with horrible access. I can't figure out how to post illustrations, so see the attached PDF. I will also mention, the part from FCPEuro was a perfect fit and come with a lifetime guaranty for when the next rock comes flying in. cayenne service history fog lights.pdf1 point

-

The RHS rear window regulator on my 02 C4 Cab broke last week too. Above posts were helpful to get this thing out and in quickly. My remaining problem was that I had that quick replacement for the broken regulator was not as simple as I thought (not much supply on intact used items, and rebuilds will take at least a few days back & forth). Short on patience, I analyzed the technical problem itself it turned out that the upper roll and rear string guide were compromised ((cracked in two pieces and missing at all resp.)). I ended up making a custom roller and guide from some old in-line skate-type rollers (yes, including one ball bearing) and another Polyamid block for the guide. The rest was some filing / cutting (I had a lathe to cut the string grove , but otherwise I used hand tools), and after about two hours later, I had the roll-arch-drive back to life assembled. The drive runs very good, and I think the bearing is a real upgrade to the drive, and possibly will outlast many other bits on the car. Since it was really no big deal to get this fixed much quicker that ordering anything- here a few pictures for those who may consider a DIY - fix of the drive parts as well. iH1 point

-

I bought my Short Shifter throughPelican Parts and I believe it was a Porsche product, It didn't shift any faster, but was crisp through the gates. A good upgrade...1 point

-

OK. With a "little" poorly documented and explained help from this forum I managed to remove my right rear window regulator from my 2003 Carrera 4 Cabriolet. I am going to provide as many pointers here as I can to make this effort much easier on the next DIY mechanic. Thoroughly read this and other forum posts first. Convertible top needs to be down or in the service position. Remove rear seat cushion, rear interior panel and rear window trim piece as described in this post or others. Rear seat back should be in the up position. For removal of the regulator itself...The total of number bolts and or nuts to remove is 9 (13mm) (possibly 2 more(11mm) if your window is stuck in a down or partially up position). For total of 11. (2) 13mm nuts - Convertible top hydraulic piston; (1) from the rear piston mount point and (1) from the front piston mount point. (3) 13mm bolts - Seat belt pillar; (2) from the face of the pillar and (1) from the top of the pillar where the seat belt loop is mounted to the pillar. (remove the loop and seat belt pillar insert to allow regulator to eventually be removed. (1) 13mm bolt - center of the convertible top support bracket; this is required to allow the bracket to be pried away from the pillar (see 30mm block of wood) to create clearance for the regulator to be removed. With a pry bar of some kind you should set the block in place at this step. (3) 13mm nuts/bolts - window regulator mounting points (recommend removing these last); (1) nut at the bottom accessed by removing a rubber plug; (2) each at the top; (1) one rear and one front. For the rear remove a styro foam plug to access with socket. For the front; if the window is in the fully up position access through the aligned opening in the convertible top support bracket. (IMPORTANT) If the window is stuck down or partially up this front bolt/nut is not accessible. The window blocks access to it through aligned opening in the convertible top support bracket. Follow these steps... you will need to use a goose neck closed end 13mm (6 point) wrench; loosen and remove this bolt/nut. Place or stuff a rag just under this nut/bolt to prevent it from falling to the bottom of the body cavity should you lose a handle on it. remove rag, regulator should now be free to move upward but not out all of the way out BECAUSE the window (still attached to the regulator) CANNOT clear the seat belt pillar. move the window and regulator upward sufficiently enough so the window mounting nuts (the (2) additional 11mm noted above in item 1) are accessible with the 11mm socket; loosen to free the window from its regulator seat. (be careful not to scratch or break the window by applying to much force) Carefully remove the window from the regulator and you will now have sufficient clearance to remove the regulator from the car. Remove the regulator by pulling it up first (free the bottom mounting bolt from its bracket) and then towards the rear (got to get the motor to clear the body) then straight up. Take it slow. It will come out. Good luck. Its not really that difficult once you see what needs to be free.... and the window itself is out of the way.1 point

-

Those struggling with that lower nut- there is a rubber plug which when pulled provides access to the nut.1 point

-

I did install the the the less expensive C4 fan (996 624 135 00) in the C4S with the following results. 1. Fan is the same diameter and size. 2. Motor diameter and flanges are the same size and will bolt into radiator shroud. 3. Offset of motor flanges are different, moves the fan 1/4 inch closer to radiator. 4. Changed style rubber grommets in shroud to gain 1/8 more clearance, but fan is still closer to the radiator than the stock fan. I'll let you know if the spacing gives me any problems.1 point

-

1 point

-

I recently replaced the coolant pipes in my car. I needed to do the job myself because there was simply no way I was going to shell out anywhere from $1500 to $3500 in labor to have it done by the dealership or an independent shop. Plus, having read about the job, I knew they would be tearing through a ton of stuff and I really feared the "oh, it also needs this" scam. I did a LOT of research on the various forums before undertaking this job. Reading and printing out anything I thought was useful information. I would highly encourage anyone reading this to do the same. Fortunately, I was not in the position that the pipes simply failed and dumped all of the coolant. I just had a semi-slow leak… dropping about a gallon of coolant every two to three weeks. So, I had time to order the parts and prepare. Prior to doing this the most complicated thing I had done myself was change the oil, replacing the brake pads and swapping out some plastic bits in the car. I had absolutely no prior mechanic experience whatsoever. However, I do work in IT, and am by nature a very technical person (I'm sure every mechanic reading this just rolled their eyes). My job is troubleshooting very complex problems on very large networks, and I think that experience probably lent itself to a successful outcome here. I'm also patient, and that is critical to getting this job done. I will say that I now have a much greater appreciation for mechanics and their skill set. This was hard. I want to caution anyone reading this that this is a BIG job and it will take a long time. My goal in writing this is so that my fellow Cayenne owners can be spared a lot of the mistakes I made and be better prepared than I was. I will say I am relieved to have this done. I feel a ton better about my car now that I don't need to worry as much about some catastrophic failure hitting me unexpectedly. One rule that I really appreciated was to only place metal on metal when working (until you actually get to removing the pipes). This prevents you from breaking plastic or tearing rubber with something metal. Trust me, pay attention to that rule. I am breaking this down into tasks, because I think it's easier to follow that way. This is how I did it. I am sure there are other ways that may even be easier, but this worked for me and my schedule. I ended up working 4-6 hours at a stretch in the garage with breaks every couple of hours. Step 1: Contribute to this forum I have absolutely no affiliation with this forum whatsoever other than I am a contributing member. The advice on this forum has personally saved me thousands of dollars, and being in IT I know the time and money it takes to run a site like this. So, contribute to the cause. However, there is a second reason to contribute, and that's to get the Porsche TSBs. The TSB for this job contains some diagrams that give you a better idea how all the replacement parts go in to place, and I thought that was handy to have. As an aside, I searched some other issues in the TSBs and found answers to some things the dealership didn't even know… such as there being a $33 replacement latch for my armrest. They wanted to sell me a whole new armrest for $750. Step 2: Obtain the Parts I looked around on the Internet and called some local sources and found a dealership that provided the parts for $550, and that included two gallons of coolant shipped to my door. To me, that was a fair price, and when I received the parts I really thought it was a fair price... there's a lot of quality stuff in there. I'm sure there may be cheaper 3rd party sources. I would just be sure they include all gaskets and such that don't necessarily need to be replaced, but should be replaced if you're tearing everything apart. Once you get the parts, pull them out of the box and examine them. Look at the pics in the forum and look at the TSBs. Get a feel for what you are replacing. Step 3: Verify you have the tools I found the following tools very handy to have, and frankly, necessary. I suggest going to your local auto parts store for most of them and get mechanic grade tools. Socket Wrench 3" Socket Extension 6" Socket Extension Metric Socket Set Torx Socket Set (think of this as a "male" Torx Socket set, you will need #27 & #40) E-Torx Socket Set (think of this a "female" Torx Socket set) Screwdriver that accepts interchangeable bits (there are times this is easier than a socket wrench) Torx Bit Set (Specifically you need a #27 and #40, I just bought a set) Locking Long Nose Pliers (6" is fine, no need for anything bigger) Regular set of pliers Wrench Set (somewhat optional) Real flat head screwdrivers Very long flat head screwdriver (this came in handy a lot) Needle Nose Pliers Small Chisel Set Hammer Tin snips Safety Glasses Mechanics Gloves One of those extension things with a magnet on the end One of those extension things with a mirror on the end WD-40 Some all-purpose grease, like White Lightning Baggies to store the screws in Masking tape/Painters Tape to cover up any exposed openings Old Bath Towels (used to protect the car) Good flashlight Lint free rags Shop Vac Two gallons of distilled water Drain pan (needs to hold 4 gallons) Shop lights A small block of wood, about 2" x 4" x ¾" A radio playing energetic music of your choice Advil and Tylenol Hope and a prayer (optional but doesn't hurt) Step 4: Book the Time I know some people say you can have this job done in less than 8 hours, but being a beginner this took me much longer. If I took out all the time running back and forth to the store for tools and such, and had a guide like the one I am writing, I still think it would have taken 10-12 hours. I ended up removing all of the engine covers on one weekend night, and then doing the actual job the following weekend. I then drove the car for a week with the new pipes and finally put all the engine covers back on over the weekend (I cleaned the covers and the engine thoroughly with a damp rag at the same time to pretty it up a bit). You don't really need to do it that way, but that split the work up a bit. I work in an office in front of a PC all day; I'm not used to working in a hot garage for 8-10 hours at a time... I'm a skinny computer geek : ) When I did the work, I draped some old bath towels over the sides and front of the car to protect it. The last thing I wanted to do was mess up the paint on a zipper or with a dropped tool/screw. Step 5: Remove the Engine Covers There are really two parts to this. You have the decorative covers over the actual engine, and then you have the covers that border the engine. You'll want to remove all of the covers around the border first. There are five of them in total. They all have these little black plastic plugs that you just turn 90 degrees. They should just pop up at that point, but you might have to give them a little lift with a screw driver. While you're removing those covers you might want to pay attention to how they go together and where they slide in to place. You'll also want to remove the windshield washing fluid cap (use the masking tape to cover up the exposed hole) before you remove the cover that surrounds it. Those little things are $4.25 each from the dealership, so try not to lose them. Now you have the three silver looking decorative covers; one on each side of the engine and one towards the front middle with the engine type on it. First, you need to unbolt the two secondary air injection units. Those are the round things with the plastic covers near the back of the engine compartment. You do not need to disconnect them from anything, just unbolt them (three screws each) and then move them off to the side. It might be a good idea to get some labeled baggies to store the screws in. Once those are removed you can get to the side engine covers a little easier. The engine cover in the front middle you just lift off, just work it back and forth a little and it should pop off. Take note that there are four little plugs that fit into holes on the cover itself, you'll need to find them again when replacing it. Now remove the one on the driver's side. It's pretty easy to remove. There are four screws towards the bottom that need to be removed, and then the cover will just come off. The one on the passenger side is a bit different. You have the engine mount right in the middle of things. Assuming you have the tools, you can unscrew the engine mount and get it out of the way. That will let you get to each of the four screws easily on the cover and remove it. I wasn't so lucky here (didn't have the right tools at the time), so I just got the four screws out of the cover and ended up wedging it out. While doing that, the piece of the cover under the engine mount snapped off. I wasn't too concerned about this, because where it snapped is hidden by the engine mount. When I put everything back together I just slid it back and screwed it in. You can't tell at all that it was ever snapped in half. Step 5a: Remove Fuel Pump Fuses You'll want to check your manual (you can also download the manual from this site), but you need to remove a couple of fuses for the fuel pump. Right in front of the driver under the hood there is a small compartment. Remove the cover, and then remove a second cover to expose the fuses. Mine were fuse 14 & 15 for the fuel pump. Store them somewhere safe. Once those are removed, start your car. It will run for a few seconds and die. Congrats, you just removed most of the fuel from the fuel line. I know some people don't disconnect the fuel rail or anything, but to me that's a bad idea. I had a lot of time to try it that way and honestly I'm glad I got it out of the way. Step 6: Disconnect the fuel line The fuel line is near the back center, it's just one tube running to the fuel rail. You'll disconnect it by using a wrench and a pair of pliers. You're unscrewing the part on the left (the thin part) from the part on the right (the wide part) which shouldn't turn as it is part of that tube. Once unscrewed, the fuel rail is only connected to the manifold. A little residual fuel might leak out, so you might want to have a rag handy to wipe it up with. Use masking tape to cover up any exposed holes. It wouldn't be a bad idea to disconnect the batteries now either. I didn't, but that was probably stupid. Step 7: Remove the Y-Pipe that goes to the Throttle Body This plastic Y-Pipe is right up front so it's very easy to get to. There are two flexible pipes on either side you need to remove first; just use a screwdriver to loosen the two clamps on each of them and you should be able to compress them enough to remove them. The Y-Pipe itself is attached to the throttle body via two long, plastic bolts. They have a screw head on them but they are not screws, they're more of a key. You just turn them a bit to line the key at the bottom (use a flashlight and you'll see it move as you turn it with the screwdriver) with the slot. When it's lined up, use a pair of needle nose pillars to lift it straight out. It's plastic and may be brittle, so be a little careful. You will need to remove an electric connection to the throttle body in order to get to one of them. There is a tube connected to the bottom of this y-pipe, so you can't just lift it out. It has some give to it, but not a lot… just enough to get your hand under there once you pull the y-pipe off the throttle body. You have to press the buttons on each side of the tube in order to get it off the y-pipe. Step 8: Remove Emission Tubes & Electrical Connections from Throttle Body There are two emission tubes crossing the throttle body, Porsche refers to them as "vent tubes." I know this because one snapped in half when I removed it, and the dang thing was $130 to replace. To remove them, you just need to press the clips at either side of the end of the tube together and then pull it straight out. I don't think mine had ever been removed, and in retrospect a bit of WD-40 used sparingly here might have been a good idea. I think I used too much force and that's why the small one snapped. I have read that some people have replaced this broken tube with a more generic tube from a hardware store. I just spent the $130 and did it right. There is a third tube connected to the throttle body, you just need to remove that one end of it. You will also have two electrical connections to remove. One you had to remove to get the y-pipe off in the previous step. Just remove the second one and then you're done. Step 9: Remove the Throttle Body The throttle body is connected to the manifold via four bolts. Remove those four bolts and it will come off. You sort of have to wiggle it out because of that thin metal bracket that's holding it there, but it will come out easy enough. Some people take this opportunity to clean it. You'll probably see some gunk on the back side of it on the inside. Step 9: Remove the Electrical Connections to the Fuel Injectors There are eight fuel injectors connected between the fuel rail and intake manifold. Mine were blue plastic, and there is an electrical connection running to each of them. There is a metal clip at the bottom that you just need to press up. I placed a flat head screwdriver between this clip and my index finger, and pushed up and pulled at the same time to disconnect it. Once you remove one you'll get the trick and the rest will come right off. Step 10: Remove the Intake Manifold with Fuel Rail Attached I know a lot of people have different ideas here, some people want to remove the fuel rail independently, and that was the first way I tried it. In retrospect, it's much easier to just leave it attached. There are four screws that hold the fuel rail to the intake manifold. I would recommend leaving these alone, especially since the one at the back on the passenger side is nearly impossible to get to. These screws are $6+ each… I know because I lost one. :P There are 10 bolts that need to be undone to remove the manifold. They don't come all the way out, they'll stay attached to the manifold. Once you loosen them enough they sort of come free and wiggle around. The one at the back on the passenger side was a bear to get to. I ended up placing the Torx Socket bit on top of it using the magnetic extension thing. I then put the 3" extension on top of it, and finally attached my socket wrench to it. I kind of built it all up I guess. I then went really, really slowly and loosened it up. Once loose, make sure to vacuum up any debris on the engine. When you pull the intake manifold off you will have eight gaping holes right down to your cylinders, you don't want anything falling in there. You can now scoot it forward a bit to get to the tubes you will need to disconnect. There are two tubes at the back of the manifold… a firm one and a flexible one. The firm one is just like the one under the y-pipe, and is easy enough to remove IF you can get enough pressure on the connector. The flexible one was just kind of stuck on mine and I left it on. You kind of have to scoot the manifold forward and angle it out, but it will come out with the fuel rail attached. You may have to remove some tubes and such from their guides or brackets. That flexible tube was long enough that I just put the whole thing on the driver's side of my engine and left it there. It didn't seem to be sitting on anything that couldn't support it. I'm sure it can be removed, but at this point in the job I was tired, hot, and just wanted to keep going. Once off, IMMEDIATELY cover up the exposed intake holes with long strips of tape. Cover them completely, and make sure they STAY COVERED. Shine a flashlight in each hole first to make sure nothing fell down there. If so, get it out as delicately as possible. Vacuum up any other debris you see. You can now see the infamous coolant pipes. Step 11: Assessment At this point, you can see the coolant pipes and should be ready for the meat of this repair. The starter is right there too… right under the leaking pipes. Brilliant, isn't it? This may not be true for you, but I had an AMAZING amount of debris in here… honestly looked like a bird had built a nest. I have no idea how it all got in there, but some where at some point tons of debris got in here, and now it was all soaked in coolant. I think my coolant leaking may have been mitigated because the wet debris probably acted as a mud and sealed everything up a bit. I vacuumed it up with a shop vac prepped for a wet cleanup. Now you need to decide if you will see this repair through or not. Once the next step is taken, there is no going back, and honestly the toughest part of this job by far is getting the old pipes out. Step 12: Drain the Remaining Coolant Your first goal is removing as much coolant from the car as you can. On the V8's, there is a drain plug at the bottom of the car, but on the turbo's you won't have one. That drain plug required an allen bit that was larger than I had on hand or could even find at a hardware store. Honestly, in retrospect I wouldn't have even bothered locating it. I'm sure there's a pipe down there you could remove, but I didn't waste time looking for. I took a tip I found on a forum, and drilled a hole right in the middle of the center coolant pipe (of three) and used a siphon with a hand pump to drain out every bit I could. I repeated this process on the larger lower pipe. DO NOT SIPHON BY USING YOUR MOUTH. Coolant is dangerous, nasty stuff. Make sure there are no animals or kids around while you are doing this. WEAR SAFETY GLASSES AT ALL TIMES! Doing it this way you're going to spill a lot of coolant, but it is what it is… they've been leaking all over everything anyway. I used my shop vac to vacuum up anything I could that escaped the siphon. I've also read of people renting professional vacuum pumps to suck it all out, but again, that's more complicated than it needs to be. I did some research, and coolant is not currently controlled by the EPA for disposal, and it can't be recycled. The unofficial advice I got was to dump it in the woods and douse the area with a hose for a bit. Do not dump it down the drain or dump it where animals could readily drink it. Don't dump it in a stream. Presumably it breaks down fast enough on the ground that there isn't a long lasting effect. Step 13: Remove the Three Upper Coolant Pipes The first pipe you need to remove is the long skinny pipe with three connectors. This one is easy enough to remove, and you should have a replacement as part of the kit. One of the connectors broke off in the hole, and I had to very carefully remove the pieces. Relatively speaking this was easy compared to the rest. There is a compression ring that needs to be removed for the connection at the back of the engine, use the locking pliers to do that. Cover up the exposed holes with masking tape. You now have to remove the three upper coolant pipes. There is a bracket at the back of the engine holding the three pipes. There are also two clips attached (you'll be looking at the back side of them) to that bracket that just support a hose at the back (just has electrical connections in it, and it's probably already split so you don't have to be super careful). Pinch the connectors with a pair of needle nose pliers and they'll come off. You now have to remove three bolts from it to remove the upper half of that bracket. I removed two of them but couldn't get to the third without snapping the thing in half. Porsche was kind enough to provide a new one in the kit so I wasn't worried about it. You will now see three rubber hoses attached to the plastic pipes. They are held on to them with compression rings. Use the locking pliers on the rings to loosen them (they need to be squeezed together to loosen) and slip them back over the pipes. I did one at a time, completely removing the ring and setting it off to the side for safety. The locking pliers really excelled here. When using them, attempt to come at the ring from the top instead of the side, the grooves on the pliers will then secure the ring quite nicely. You might have to adjust the pliers a couple of time to get the right amount of the compression for the ring to move freely. With those ends free, I used the shop vac to suck out a lot more coolant. Once done, cover up the exposed holes with masking tape. Once those three ends are free, you'll need to free up the other ends. Here's the deal, they are probably going to break when you try to remove them, and probably going to snap off at the spot where they connect to the coolant reservoir. I twisted and pulled and sure enough, they snapped off. You can remove the lid of the coolant reservoir by removing several screws, a small aluminum pipe on top, and the rubber pipes towards the front of the car. The small aluminum pipe has a single screw that needs to be removed. There is probably a lot of corrosion here so you may need to use a flat head screwdriver to pry it out. Be careful, it's flexible enough to come out and get out of the way but just barely. There is a compression ring on each of the rubber pipes that is easy enough to get to, just loosen and slide it down the pipe. Suck out any coolant and cover the exposed pipes with masking tape. Once you have that lid out, you'll see the remaining plastic bits in the holes. It's difficult to move, but those plastic bits are just in there with pressure, they aren't glued or anything. I used a small chisel and the hammer to break them out. As I got to the o-rings I pulled on those with needle nose pliers and in one instance the whole chunk came out. I also used a lot of WD-40 to work everything out. What you don't want to do is take any risk of chiseling into the metal of the lid, so be careful. This is all about removing the plastic material. Each bit you remove gets you one step closer to freeing up enough pressure to get the remaining bit out. Once it's all clean, leave it off to the side while removing the big pipe. Step 14: Removing The Big Pipe This one is tough. Make sure you're rested, well fed, and cooled down a bit. If you're aggravated already, walk away and relax a bit. You will need to break this pipe into two pieces. I used a boring bit to drill a big hole in the top, and then used tin snips to cut chunks out until I got it in two parts. Again, I used a shop vac to suck out any remaining coolant as I went along. Really, anything will work… you could even use a chisel to break it out. It's coming out one way or the other, no need to be pretty about it. Once it's in two pieces, you can probably rotate the two halves apart. Use WD-40 generously on the ends first though, and give it a bit to work in there. Regardless, when I went to pull out the two ends, they ended up snapping off… leaving their end pieces in the hole. If you read through the three forums, different people use different techniques to try and avoid this with mixed results. This is the worst case scenario though, so lucky for you I fought through it and have plenty of advice. Assuming your pipe broke off as mine did, you will see a metal ring in each end, with black plastic between it and your car. That metal ring was an inner support ring for the original pipe and needs to be removed. This is a violent procedure. IMPORTANT: I cut up some lint free cloths and stuffed one into each end as far as I could so that any material from the following procedure wouldn't go any further. Once done with the procedure below, I vacuumed up anything I could and then removed those cloths. Again, use WD40 a LOT. I sprayed and sprayed as a worked, and I think it helped. READ THIS CAREFULLY: Removing the plastic and metal ring from each end is all about removing material. You are trying to get as much plastic out as possible. If you get the ring out first, great, but it's not 100% necessary. The plastic is what needs to come out, and you need to get it out from all around it. In addition to the plastic, there are two o-rings in there, so they are just adding more friction preventing this from moving. You'll get bits of that out as you work, and that's good. Eventually, you get enough bits out that the rest will just fall out. Use a hammer and chisel to collapse the metal ring on the top and sides as much as possible. I used to the chisel to cut in to it a bit too. Once I got it that far, I switched to the long screwdriver, hammering the end of it into the plastic over, and over, and over again. I pried as much as I could and worked out bits of material. This took a long time, but sometimes you'll get a big chunk out and that will give you renewed hope. Again, this is all about material removal. Keep telling yourself that. Every bit you get out makes this easier. Once you get enough plastic out, you'll see the metal ring move a bit as you work. This is a great sign and you are almost done. Ultimately, you should be able to pry it out with the screwdriver. NOTE: When working you want to work as much towards the metal ring as possible. You want to avoid scraping the inside of the hole where your new pipes will go. I did scrape up mine a bit, it's unavoidable, but regardless my new pipes don't leak. When you go to remove the bits closest to you, you're working somewhat blind and it is hard. This part almost broke me, but I used a mirror to check and recheck my work as I went along. Bright lights help here too. Honestly, I really can't say enough how hard this part was and how long it took in comparison to everything else. It was the part that had me the most worried, but I got through it. Once it's all out, remove the cloths from inside the pipe and vacuum a lot. Now is the time to clean stuff up too, as you're about to put the new pipes in. As a best practice, you should clean up the inside of those holes. I used some steel wool; I know some people used scotch bright or even buffing pads. I didn't go overboard with this; I just want to get any grime out of there. Step 15: Install the New Big Pipe At this point you should be elated. You're through the worst. Installing these pipes are a bit difficult, but not bad. If they are not already on there, put the O-Rings on the small pipe. Use the White Lightning grease or whatever you bought and coat the inside of the hole on the engine and the outside of the pipe. Use it liberally. A bit of WD40 wouldn't hurt either. Press it into the hole at the back of the engine and do your best to get it all the way in. This is where a small block of wood and a hammer come in handy; you can use those to tap it in the rest of the way. Do not put the rubber sleeve on it. For the big pipe, install the o-rings and lube everything up good with the grease, both the hole it goes in and the pipe itself. You will also need to grease up the end the rubber part goes on and the other end of the short pipe that the rubber sleeve will slip over. Place the tightening rings over the rubber sleeve as well. Slide the rubber sleeve as far as it will go over the pipe. Push the pipe into the hole, I found a twisting action worked well. I also used my metal screwdriver against the bottom of the engine bay as a lever to slide it in the rest of the way (it required a lot of pressure). You then need to rotate it to line it up with the short end of the pipe. You'll slide the rubber sleeve over it and then tighten up the two rings. NOTE: Be sure to rotate the rings as far down as possible so that the screw does not interfere with the three pipes you're about to place on top of it. The new big pipe should be in place, and you're now done with the hardest part of this job. Step 16: Install the Three Pipes You'll want to put the lid back on the coolant reservoir (replacing the seals Porsche included with the kit), reattach the pipes and tighten up the screws. DO NOT OVERTIGHTEN THE SCREWS. I snapped one clean off. Make sure they're tight, but don't put all your muscle into it. Once on, you are ready to slide those pipes in. You do not need to put the lower bracket at the back on first; I did it after installing the pipes. Again, make sure everything is lubed up well so that any points of friction are well covered. Slide the pipes in. I used by long screwdriver again as a lever to apply the necessary pressure. On both these pipes and the big pipe it looked like I could have gone another 16th of an inch, but nothing leaks so I guess it was far enough. Put the bracket on at the back before you attach the hoses. You'll use your locking pliers again to attach the compression rings. With the bracket in place it is obvious how far up the hoses go. You'll put the upper bracket on, using the spacers for the screws and screwing it down tight. Don't forget to attach the two brackets that hold that electrical cable in place. Not a big deal if you do forget. Step 17: Install Final Pipe Now install that skinny pipe. This one is easy. Don't forget about the small compression ring that goes at the far end. Everything else just clips in. Step 18: Assess Your Work Look over everything and make sure it all looks right. At this point you should have a sealed coolant system. Check all your connections and make sure everything is solid. At this point you're home free, and you should be feeling pretty darn good. Step 19: Fill Up Coolant I use a 50/50 water to coolant ratio… so I mixed everything up with what I had and filled up the coolant tank. Once it was full, I left it overnight and checked in the morning for any fresh coolant. I was totally beat from a long day of working on it and thought putting everything back together fresh in the morning was a good idea. Step 20: Put Everything Back Together You tore it apart, now put it back together. I cleaned everything as I went, so now my engine looks great and I think that's a good idea. You don't need to go overboard, just use some lightly damp, lint free rags and wipe everything down. Porsche should have also provided new seals that go on the bottom of the intake manifold. I replaced mine dutifully, and I am glad I did. The old ones just looked worn out, no way they weren't leaking. Putting everything together is pretty straightforward once you've taken it apart. Just be careful and make sure you get all electrical connections and hoses in back on securely and in the right places (hard to mess that up). Also make sure you remove every bit of masking tape as you go. Final Thoughts I am very, very glad I did this project for two reasons. One, it saved me a ton of money and two, I now know tons more about the engine. Doing this project means I could replace my fuel injectors, spark plugs, injection coils and a host of other things when and if I have to. I know where the throttle body is, and if it's sticking I know where to go to clean it. If I need to replace the starter, I know where it is and how to get to it. I can now take my car on trips without fear of a massive coolant leak. This was the last "major" Cayenne defect for me that needed to be fixed. The water pump & drive shaft were already replaced. With 116,000 miles, I have quite a bit of faith in my car not having a catastrophic failure (knock on wood). At the end of the day, I'm pretty proud of myself for getting this all accomplished, and I hope I've saved some other poor soul a ton of time by writing all of this down. If it does help you out, please reply to this post and let me know.1 point

-

Dave, As Silver said, it should not be too difficult to track down the problem(s). All you need is a $15 multimeter. Run your engine till warm and the low voltage shows up, then let it idle and turn on the a/c and the low beam. The current draw from the alternator should now be ~50A. You can then do the following tests. I drew a diagram with the corresponding parts. Test #1: check voltage drop between point "C" (alternator casing) and "B-" (call that V(C, B-)). Note "B+' and "B-" are the actual battery terminals, not the cable connectors on the terminals. This test shows total voltage lost between the alternator and the battery on the ground side. Expect 0.2v or less. If your ground strap is bad, it will show up in this test. Test #2: check V(A, B+) where "A" = alternator output at the back of the alternator that you can't see (use an inspection mirror) and expect ~0.5v or less. "A" is hard to get to. I fabricated a J-shape hook using a stiff insulated wire and just literally probe it blindly from behind. Wear protective goggles here since you will be close to the drive belt, a hot engine, and the always LIVE "A". This test shows total voltage lost between the alternator and the battery on the power side. Test #3: check V(A, J) and expect ~0.2v. This tests #21, which is the infamous cable that can corrode and Porsche has also revised it. Test #4: check V(J, B+) and expect ~0.3v or less. Test #5: check V(A, C), your alternator output and expect 13.5v or higher. Your problem is gonna show up in one of the tests above.1 point

-

So i have had this annoying display with my 2004 CTT that my rear glass is open, when it really isn't. It would sometimes go away but could come back if i hit a large enough bump in the road. The particular annoyance happens every time you stop and start, it will beep at you again....OR the fact that you cannot lock and arm the car with the glass "open." Anyways this is how you can potentially resolve that issue: Tools needed: Your hands Adjustable wrench Step 1: Open the glass and remove the small plastic cover on the glass side as shown. You will want to get your fingers behind the TOP first, then pull the entire cover free. the clip are pretty strong, so it takes some force, just work it free evenly and slowly. Step 2: Now you have access to the latch on the left (metal hoop). You will want to use the adjustable to loosen the latch or nut. Once it's loose, you can turn it either in or out to make the adjustment needed. For me, i had to turn it OUT, loosening the latch. My guess is the rubber seal has become stiffer over the years, so it was pulling the latch away from the sensor. Reinstall plastic once you get the positioning correct and enjoy no more annoying messages or alarms every time you stop at a light.1 point

-

I have a 2005 Carrera S with 68,000 miles. I recently started having problems with a large white cloud appearing only at start-up and some poor throttle response at low rpms. I had also noticed for the last few months that the oil consumption seemed a faster than usual for my car. After a little reading I found that it might be due to the AOS. My Durametric program was giving some RKAT and misfire codes, but the check engine light (CEL) was not on - of course, after I checked the codes, the CEL came on. With the engine running, I tried to remove the oil filler cap but couldn't - I would have had to pry it off the tube. So it really did seem to the AOS. Apparently when the AOS goes bad, it causes a high vacuum in the crankcase (hence can't pull off the oil filler cap) and this pulls oil into the recirculation system that drains into the intakes (hence the white cloud at start-up and high oil consumption). I looked around and found some information on Rennlist discussing AOS replacement on a 996 (http://forums.rennli...labor-time.html). People discuss dropping the transmission or lowering the engine to help with this. I'm my case only removing the engine would have helped. The hose clamps are pointed towards the back of the car so I would not have been able to do this from the transmission side. You should know that the 997 S uses a different AOS than the non-S 997 or the 996. Based on all this information I ordered from Zim's (www.allzim.com) AOS for ~$150 3 intake gaskets (~$8) (didn't use these in the end) one throttle body gasket (~$7) as well as a new serpentine belt, and all three idler pulleys (pullies?) because I thought I would do this at the same time. Tools are shown and with some listed at the bottom. First, the pre-picture . Obviously I have a fabspeed cold air kit. The red color sticks out like a monkey-butt, but I like the sound. The AOS on the 997s is under the passenger side intake manifold about halfway to the front of the engine. So some things have to come off... the air box needs to come out, there is a good air filter replacement tutorial here on Renntech. This picture shows the air box partially out and rotated over so that you can see the connections. I also zoom in here just to show the vacuum connection on the solenoid, one of the electrical connections on the solenoid (already disconnected), and the mass air flow (MAF) sensor connector. Just ignore the broken wire clip. Some gremlin must have done that... Now the throttle body has to come off - there are four E-10 bolts, and the bottle left one has a bracket that hold a little rubber bumper attached to it. Only the four E-10 bolts need to come out. There is also an electrical connector at the top (runs from left to right) and if you squeeze it just right on a tuesday with a full moon, it will pop off. Here are two pictures of the throttle body off the car, note that there is oil on the inside and both the inside and outside need cleaning. Now to get the intake pipe out from between the left and right manifolds. You can see that there is the plastic Y splitter that the throttle body attaches two, and then two short rubber hoses that attch the plastic splitter to the intake manifolds. There is a recirculation hose connected to the top left of the splitter. The other end of this hose is connected to the AOS. Porsche was VERY nice when they made these hoses, if you squeeze the two textured parts together the hoses pull off easily - no wire hose clamps. Yeah Porsche! Also notice that this splitter piece has the groove where a new throttle body gasket should go. Each rubber hose has two large hose clamps on it. In order to get the splitter out, I recommend loosening only the two outer most clamps, that is the clamps on closes to each intake manifold, because then you can rotate the splitter up or down to help break the seal of the rubber hoses on the intakes. Then I removed the inner two clamps and broke the seal of the rubber hoses to the splitter. To get everything off, I pushed the rubber hoses as far onto the intake manifolds as I could (essentially pushing the two rubber hoses father apart) , and then the splitter came out from between the hoses. In retrospect - and after putting all this back together, I would have pushed the rubber hoses closer together onto the splitter and then taken out the splitter with the hoses attached as it went back on this way pretty easy. Here is the splitter And here is where the splitter was... In this last picture you can see the short rubber hose segments, the disconnected recirculation hose, and the back crossover tube that also connects the two intake manifolds. If you follow the disconnected recirculation hose down, you can see the top of the AOS. I could see that a fair amount of oil had collected in the intake system. I also removed the power steering reservoir - there is a 10mm bolt on the right side holding it to the right intake manifold and a plastic tub that connects down to the pump. That tube has a nice twist connector on it, twist it to the left (counterclockwise) about a quarter of a turn and the whole thing will just pull out. This picture shows where it was, and the black plastic tube that has a green o-ring is where that reservoir was connected. Now I removed the 4 E-10 bolts that held down the right intake manifold to the cylinder head. This is where things may have been easier on the non-S or the 996? My intake manifolds are one piece with the injectors attached to the bottom. There are 4 bolts, one on each end and one between each pair of cylinders. If we number them from rear of car to front, number two was the real pain to get out. There is a sensor embedded in the manifold directly above this bolt which made it difficult, but eventually the right combination of extensions and u-joint made it possible (it was harder to replace than to remove). I couldn't really get a good picture here. I couldn't easily figure out how to get the fuel supply line and injectors disconnected, so I couldn't pull out the intake. Removing the intake bolts did left me move it around some which was helpful, but I'm note sure it was actually necessary to get the AOS out. Also, since I couldn't get it off, I couldn't change the gaskets - so I'll keep my fingers crossed that the old gaskets are still in place. This picture shows that I've removed the old AOS - you can see the recirculation hoses that attach to it (there are three - two on the left and one on the back), and then two small coolant hoses (both on the left). What it doesn't show is that there are two small T20 screws that hold the AOS to a bracket on the cylinder head. See the diagram below for better idea. I sure hope your hands are any larger than mine... I used a T-20 bit and a small ratcheting monkey wrench to get to these. If I hadn't loosened the right intake manifold, then I'm not sure that I could have gotten my hand in there to do this. There are the two coolant hoses that have to come off, one of them come from the water pump and there is a small segemnt of it that is rubber with a spring clamp right at the water pump fitting. This picture shows where I'm talking about. In retrospect I don't think I had to take this off, but it was easy. Please ignore the broken oil-pipe filler. Who did that? Turns out that this filler just sticks out into space and it is really easy to put too much pressure on it with your arm when trying to work on the intake. It snaps with a nice crisp pop that reminds you of a broken bone. Turns out it is a $40 dollar part that has to be ordered and it looks like the alternator has to come off to replace it. I think I'll keep my serpentine belt and pulleys for a future weekend when I get to change the filler pipe. Also, here I want to show the water hose connection, again an excellent job by Porsche. The blue piece on the end of the hose is a tab, than when pushed releases the connection and the hose comes right off. I only lost about 1/ 4 cup of coolant when disconnecting both water hoses. Lastly, here is a picture of the space where the AOS was sitting. You can see the opening in to the crankcase where the bottom tube of the AOS fits. A little wiggling and the new one slides right in. I cleaned everything using a carb cleaner and P21 citrus cleaner. Now that everything is apart, it's time to put it together. 1. new AOS in, connecting coolant hoses first and then getting the t20 screws into the AOS from the right side of the engine. 2. connect recirculation hoses to the aos, and the coolant hose back to the water pump fitting. 3. reconnect the rear crossover tube by pushing the rubber hoses as far as possible onto the intakes - again this helped that my intake was loose (take special care to get the vacuum connection reattached - I had to disconnect this vacuum hose over on the left intake manifold so that I could get enough slack to work with it, once it was back on I reconnected the vacuum hose on the left intake manifold. 4. put the bolts back into the right intake manifold, I did each hand tight with a socket extension and then torqued each to 7.5 ft-lbs (this seems right) - I also had to reconnect the sensor connector over that #2 bolt. 5. then I adjusted the rear crossover tube and then tightened the hose clamps (not too tight). 6. Then I put the front intake splitter and rubber hoses back on, to do this I pushed the hoses all the way onto the splitter and fit it between the intake openings and then separated them onto the intakes. Worked pretty well. 7. lined everything up and tightened the hose clamps (not too tight). 8. connected the recirculation hose to the splitter 9. Replaced the power steering reservoir, twisted the pipe connection to lock and replace the bolt into the right intake manifold 10. put new gasket on the splitter to throttle body face. 11. put throttle body back on the splitter - (torqued these to 7.5 ft-lbs also) 12. replace the air box with the two electrical connections and the vacuum connection. (13. duct tape the crap out of the oil filler tube to hold it and seal the vacuum until I can replace it) I'll say, there is some satisfaction in knowing that part of my $100k car is held together with duct tape. I started the car and filled my garage with white smoke - there was still some oil in the system from the last time it was stopped, but the car idles lower, better low end response, and I can get the oil filler cap off without giving myself an aneurysm. The posts I've seen say that it will continue to smoke on start up until the oil is cleared out. Might have done differently: 1. Not sure if I had to take the intake manifold bolts out - I had hoped to remove it, but in the end I couldn't. 2. Probably would remove the belt, and alternator in order to take off the oil filler pipe and get it out of the way - that would have kept me from braking mine.. 3. and if I did #2 above, I would have changed the pulleys and belt at the same time. Time: about 7 hours split over two days, next time might take 5 hours. Tools: here is everything that I used. Note the diet coke, this was necessary in copious amounts. Lots of 1/4 and 3/8 inch extensions and adapters to make different lengths. 7mm, 10mm, and 13mm sockets. An E-10 star socket and a T-20 torx bit (or a star bit) I have both of these from a kit sold by harbor freight. Also came in handy when I changed the spark plugs and coils a year ago. The magnet and mirror are indispensable. I hope you have as much fun as I did. Someone described it like having your hand up a cow's backside, and there are times that made me chuckle. It is always nice to learn a little more about my car. I am in Dallas, and if anyone needs help or has questions, just let me know.1 point

-

Not really, I don't think the bolts will completely come out with the coolant pipe in the way.0 points

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)