Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 01/20/2025 in all areas

-

If the oil cap is hard to remove, you have a high vacuum level in the sump, which is bad for a variety of reasons, including lean stalling. The correct way to access the AOS is to fully warm up the engine by driving the car for 10-15 min, then replace the oil cap with the one in the picture above with a hose that connects to the digital manometer. If the vacuum level exceeds 6-7 inches of water vacuum, the AOS is leaking air into the intake system, causing the lean stall conditions. The normal level of vacuum is typically 4-5 inches of water, which is a really weak vacuum level, so it doesn't take much of a leak to cause problems, which is why we always checked every car that passed thru the shop with the manometer.3 points

-

2 points

-

Welcome to RennTech If you do not have access to a wiring diagram for the vehicle, probably the easiest way to check the ground is to pull the bulb in the light and use a multimeter to check the condition of the ground at the bulb socket.2 points

-

We have used them here in the US for years at MUCH colder temperature's than you get without ANY issues. Put on the adaptor, add external magnets such as the Filter Mag, and enjoy both better filtration and peace of mind.......2 points

-

Welcome to RennTech The factory radio had a ground wire that had to be attached to the car's chassis under the dash as a simple anti theft device. If that ground is not there, the immobilizer will prevent the car from starting.2 points

-

I recently replaced the coolant pipes in my car. I needed to do the job myself because there was simply no way I was going to shell out anywhere from $1500 to $3500 in labor to have it done by the dealership or an independent shop. Plus, having read about the job, I knew they would be tearing through a ton of stuff and I really feared the "oh, it also needs this" scam. I did a LOT of research on the various forums before undertaking this job. Reading and printing out anything I thought was useful information. I would highly encourage anyone reading this to do the same. Fortunately, I was not in the position that the pipes simply failed and dumped all of the coolant. I just had a semi-slow leak… dropping about a gallon of coolant every two to three weeks. So, I had time to order the parts and prepare. Prior to doing this the most complicated thing I had done myself was change the oil, replacing the brake pads and swapping out some plastic bits in the car. I had absolutely no prior mechanic experience whatsoever. However, I do work in IT, and am by nature a very technical person (I'm sure every mechanic reading this just rolled their eyes). My job is troubleshooting very complex problems on very large networks, and I think that experience probably lent itself to a successful outcome here. I'm also patient, and that is critical to getting this job done. I will say that I now have a much greater appreciation for mechanics and their skill set. This was hard. I want to caution anyone reading this that this is a BIG job and it will take a long time. My goal in writing this is so that my fellow Cayenne owners can be spared a lot of the mistakes I made and be better prepared than I was. I will say I am relieved to have this done. I feel a ton better about my car now that I don't need to worry as much about some catastrophic failure hitting me unexpectedly. One rule that I really appreciated was to only place metal on metal when working (until you actually get to removing the pipes). This prevents you from breaking plastic or tearing rubber with something metal. Trust me, pay attention to that rule. I am breaking this down into tasks, because I think it's easier to follow that way. This is how I did it. I am sure there are other ways that may even be easier, but this worked for me and my schedule. I ended up working 4-6 hours at a stretch in the garage with breaks every couple of hours. Step 1: Contribute to this forum I have absolutely no affiliation with this forum whatsoever other than I am a contributing member. The advice on this forum has personally saved me thousands of dollars, and being in IT I know the time and money it takes to run a site like this. So, contribute to the cause. However, there is a second reason to contribute, and that's to get the Porsche TSBs. The TSB for this job contains some diagrams that give you a better idea how all the replacement parts go in to place, and I thought that was handy to have. As an aside, I searched some other issues in the TSBs and found answers to some things the dealership didn't even know… such as there being a $33 replacement latch for my armrest. They wanted to sell me a whole new armrest for $750. Step 2: Obtain the Parts I looked around on the Internet and called some local sources and found a dealership that provided the parts for $550, and that included two gallons of coolant shipped to my door. To me, that was a fair price, and when I received the parts I really thought it was a fair price... there's a lot of quality stuff in there. I'm sure there may be cheaper 3rd party sources. I would just be sure they include all gaskets and such that don't necessarily need to be replaced, but should be replaced if you're tearing everything apart. Once you get the parts, pull them out of the box and examine them. Look at the pics in the forum and look at the TSBs. Get a feel for what you are replacing. Step 3: Verify you have the tools I found the following tools very handy to have, and frankly, necessary. I suggest going to your local auto parts store for most of them and get mechanic grade tools. Socket Wrench 3" Socket Extension 6" Socket Extension Metric Socket Set Torx Socket Set (think of this as a "male" Torx Socket set, you will need #27 & #40) E-Torx Socket Set (think of this a "female" Torx Socket set) Screwdriver that accepts interchangeable bits (there are times this is easier than a socket wrench) Torx Bit Set (Specifically you need a #27 and #40, I just bought a set) Locking Long Nose Pliers (6" is fine, no need for anything bigger) Regular set of pliers Wrench Set (somewhat optional) Real flat head screwdrivers Very long flat head screwdriver (this came in handy a lot) Needle Nose Pliers Small Chisel Set Hammer Tin snips Safety Glasses Mechanics Gloves One of those extension things with a magnet on the end One of those extension things with a mirror on the end WD-40 Some all-purpose grease, like White Lightning Baggies to store the screws in Masking tape/Painters Tape to cover up any exposed openings Old Bath Towels (used to protect the car) Good flashlight Lint free rags Shop Vac Two gallons of distilled water Drain pan (needs to hold 4 gallons) Shop lights A small block of wood, about 2" x 4" x ¾" A radio playing energetic music of your choice Advil and Tylenol Hope and a prayer (optional but doesn't hurt) Step 4: Book the Time I know some people say you can have this job done in less than 8 hours, but being a beginner this took me much longer. If I took out all the time running back and forth to the store for tools and such, and had a guide like the one I am writing, I still think it would have taken 10-12 hours. I ended up removing all of the engine covers on one weekend night, and then doing the actual job the following weekend. I then drove the car for a week with the new pipes and finally put all the engine covers back on over the weekend (I cleaned the covers and the engine thoroughly with a damp rag at the same time to pretty it up a bit). You don't really need to do it that way, but that split the work up a bit. I work in an office in front of a PC all day; I'm not used to working in a hot garage for 8-10 hours at a time... I'm a skinny computer geek : ) When I did the work, I draped some old bath towels over the sides and front of the car to protect it. The last thing I wanted to do was mess up the paint on a zipper or with a dropped tool/screw. Step 5: Remove the Engine Covers There are really two parts to this. You have the decorative covers over the actual engine, and then you have the covers that border the engine. You'll want to remove all of the covers around the border first. There are five of them in total. They all have these little black plastic plugs that you just turn 90 degrees. They should just pop up at that point, but you might have to give them a little lift with a screw driver. While you're removing those covers you might want to pay attention to how they go together and where they slide in to place. You'll also want to remove the windshield washing fluid cap (use the masking tape to cover up the exposed hole) before you remove the cover that surrounds it. Those little things are $4.25 each from the dealership, so try not to lose them. Now you have the three silver looking decorative covers; one on each side of the engine and one towards the front middle with the engine type on it. First, you need to unbolt the two secondary air injection units. Those are the round things with the plastic covers near the back of the engine compartment. You do not need to disconnect them from anything, just unbolt them (three screws each) and then move them off to the side. It might be a good idea to get some labeled baggies to store the screws in. Once those are removed you can get to the side engine covers a little easier. The engine cover in the front middle you just lift off, just work it back and forth a little and it should pop off. Take note that there are four little plugs that fit into holes on the cover itself, you'll need to find them again when replacing it. Now remove the one on the driver's side. It's pretty easy to remove. There are four screws towards the bottom that need to be removed, and then the cover will just come off. The one on the passenger side is a bit different. You have the engine mount right in the middle of things. Assuming you have the tools, you can unscrew the engine mount and get it out of the way. That will let you get to each of the four screws easily on the cover and remove it. I wasn't so lucky here (didn't have the right tools at the time), so I just got the four screws out of the cover and ended up wedging it out. While doing that, the piece of the cover under the engine mount snapped off. I wasn't too concerned about this, because where it snapped is hidden by the engine mount. When I put everything back together I just slid it back and screwed it in. You can't tell at all that it was ever snapped in half. Step 5a: Remove Fuel Pump Fuses You'll want to check your manual (you can also download the manual from this site), but you need to remove a couple of fuses for the fuel pump. Right in front of the driver under the hood there is a small compartment. Remove the cover, and then remove a second cover to expose the fuses. Mine were fuse 14 & 15 for the fuel pump. Store them somewhere safe. Once those are removed, start your car. It will run for a few seconds and die. Congrats, you just removed most of the fuel from the fuel line. I know some people don't disconnect the fuel rail or anything, but to me that's a bad idea. I had a lot of time to try it that way and honestly I'm glad I got it out of the way. Step 6: Disconnect the fuel line The fuel line is near the back center, it's just one tube running to the fuel rail. You'll disconnect it by using a wrench and a pair of pliers. You're unscrewing the part on the left (the thin part) from the part on the right (the wide part) which shouldn't turn as it is part of that tube. Once unscrewed, the fuel rail is only connected to the manifold. A little residual fuel might leak out, so you might want to have a rag handy to wipe it up with. Use masking tape to cover up any exposed holes. It wouldn't be a bad idea to disconnect the batteries now either. I didn't, but that was probably stupid. Step 7: Remove the Y-Pipe that goes to the Throttle Body This plastic Y-Pipe is right up front so it's very easy to get to. There are two flexible pipes on either side you need to remove first; just use a screwdriver to loosen the two clamps on each of them and you should be able to compress them enough to remove them. The Y-Pipe itself is attached to the throttle body via two long, plastic bolts. They have a screw head on them but they are not screws, they're more of a key. You just turn them a bit to line the key at the bottom (use a flashlight and you'll see it move as you turn it with the screwdriver) with the slot. When it's lined up, use a pair of needle nose pillars to lift it straight out. It's plastic and may be brittle, so be a little careful. You will need to remove an electric connection to the throttle body in order to get to one of them. There is a tube connected to the bottom of this y-pipe, so you can't just lift it out. It has some give to it, but not a lot… just enough to get your hand under there once you pull the y-pipe off the throttle body. You have to press the buttons on each side of the tube in order to get it off the y-pipe. Step 8: Remove Emission Tubes & Electrical Connections from Throttle Body There are two emission tubes crossing the throttle body, Porsche refers to them as "vent tubes." I know this because one snapped in half when I removed it, and the dang thing was $130 to replace. To remove them, you just need to press the clips at either side of the end of the tube together and then pull it straight out. I don't think mine had ever been removed, and in retrospect a bit of WD-40 used sparingly here might have been a good idea. I think I used too much force and that's why the small one snapped. I have read that some people have replaced this broken tube with a more generic tube from a hardware store. I just spent the $130 and did it right. There is a third tube connected to the throttle body, you just need to remove that one end of it. You will also have two electrical connections to remove. One you had to remove to get the y-pipe off in the previous step. Just remove the second one and then you're done. Step 9: Remove the Throttle Body The throttle body is connected to the manifold via four bolts. Remove those four bolts and it will come off. You sort of have to wiggle it out because of that thin metal bracket that's holding it there, but it will come out easy enough. Some people take this opportunity to clean it. You'll probably see some gunk on the back side of it on the inside. Step 9: Remove the Electrical Connections to the Fuel Injectors There are eight fuel injectors connected between the fuel rail and intake manifold. Mine were blue plastic, and there is an electrical connection running to each of them. There is a metal clip at the bottom that you just need to press up. I placed a flat head screwdriver between this clip and my index finger, and pushed up and pulled at the same time to disconnect it. Once you remove one you'll get the trick and the rest will come right off. Step 10: Remove the Intake Manifold with Fuel Rail Attached I know a lot of people have different ideas here, some people want to remove the fuel rail independently, and that was the first way I tried it. In retrospect, it's much easier to just leave it attached. There are four screws that hold the fuel rail to the intake manifold. I would recommend leaving these alone, especially since the one at the back on the passenger side is nearly impossible to get to. These screws are $6+ each… I know because I lost one. :P There are 10 bolts that need to be undone to remove the manifold. They don't come all the way out, they'll stay attached to the manifold. Once you loosen them enough they sort of come free and wiggle around. The one at the back on the passenger side was a bear to get to. I ended up placing the Torx Socket bit on top of it using the magnetic extension thing. I then put the 3" extension on top of it, and finally attached my socket wrench to it. I kind of built it all up I guess. I then went really, really slowly and loosened it up. Once loose, make sure to vacuum up any debris on the engine. When you pull the intake manifold off you will have eight gaping holes right down to your cylinders, you don't want anything falling in there. You can now scoot it forward a bit to get to the tubes you will need to disconnect. There are two tubes at the back of the manifold… a firm one and a flexible one. The firm one is just like the one under the y-pipe, and is easy enough to remove IF you can get enough pressure on the connector. The flexible one was just kind of stuck on mine and I left it on. You kind of have to scoot the manifold forward and angle it out, but it will come out with the fuel rail attached. You may have to remove some tubes and such from their guides or brackets. That flexible tube was long enough that I just put the whole thing on the driver's side of my engine and left it there. It didn't seem to be sitting on anything that couldn't support it. I'm sure it can be removed, but at this point in the job I was tired, hot, and just wanted to keep going. Once off, IMMEDIATELY cover up the exposed intake holes with long strips of tape. Cover them completely, and make sure they STAY COVERED. Shine a flashlight in each hole first to make sure nothing fell down there. If so, get it out as delicately as possible. Vacuum up any other debris you see. You can now see the infamous coolant pipes. Step 11: Assessment At this point, you can see the coolant pipes and should be ready for the meat of this repair. The starter is right there too… right under the leaking pipes. Brilliant, isn't it? This may not be true for you, but I had an AMAZING amount of debris in here… honestly looked like a bird had built a nest. I have no idea how it all got in there, but some where at some point tons of debris got in here, and now it was all soaked in coolant. I think my coolant leaking may have been mitigated because the wet debris probably acted as a mud and sealed everything up a bit. I vacuumed it up with a shop vac prepped for a wet cleanup. Now you need to decide if you will see this repair through or not. Once the next step is taken, there is no going back, and honestly the toughest part of this job by far is getting the old pipes out. Step 12: Drain the Remaining Coolant Your first goal is removing as much coolant from the car as you can. On the V8's, there is a drain plug at the bottom of the car, but on the turbo's you won't have one. That drain plug required an allen bit that was larger than I had on hand or could even find at a hardware store. Honestly, in retrospect I wouldn't have even bothered locating it. I'm sure there's a pipe down there you could remove, but I didn't waste time looking for. I took a tip I found on a forum, and drilled a hole right in the middle of the center coolant pipe (of three) and used a siphon with a hand pump to drain out every bit I could. I repeated this process on the larger lower pipe. DO NOT SIPHON BY USING YOUR MOUTH. Coolant is dangerous, nasty stuff. Make sure there are no animals or kids around while you are doing this. WEAR SAFETY GLASSES AT ALL TIMES! Doing it this way you're going to spill a lot of coolant, but it is what it is… they've been leaking all over everything anyway. I used my shop vac to vacuum up anything I could that escaped the siphon. I've also read of people renting professional vacuum pumps to suck it all out, but again, that's more complicated than it needs to be. I did some research, and coolant is not currently controlled by the EPA for disposal, and it can't be recycled. The unofficial advice I got was to dump it in the woods and douse the area with a hose for a bit. Do not dump it down the drain or dump it where animals could readily drink it. Don't dump it in a stream. Presumably it breaks down fast enough on the ground that there isn't a long lasting effect. Step 13: Remove the Three Upper Coolant Pipes The first pipe you need to remove is the long skinny pipe with three connectors. This one is easy enough to remove, and you should have a replacement as part of the kit. One of the connectors broke off in the hole, and I had to very carefully remove the pieces. Relatively speaking this was easy compared to the rest. There is a compression ring that needs to be removed for the connection at the back of the engine, use the locking pliers to do that. Cover up the exposed holes with masking tape. You now have to remove the three upper coolant pipes. There is a bracket at the back of the engine holding the three pipes. There are also two clips attached (you'll be looking at the back side of them) to that bracket that just support a hose at the back (just has electrical connections in it, and it's probably already split so you don't have to be super careful). Pinch the connectors with a pair of needle nose pliers and they'll come off. You now have to remove three bolts from it to remove the upper half of that bracket. I removed two of them but couldn't get to the third without snapping the thing in half. Porsche was kind enough to provide a new one in the kit so I wasn't worried about it. You will now see three rubber hoses attached to the plastic pipes. They are held on to them with compression rings. Use the locking pliers on the rings to loosen them (they need to be squeezed together to loosen) and slip them back over the pipes. I did one at a time, completely removing the ring and setting it off to the side for safety. The locking pliers really excelled here. When using them, attempt to come at the ring from the top instead of the side, the grooves on the pliers will then secure the ring quite nicely. You might have to adjust the pliers a couple of time to get the right amount of the compression for the ring to move freely. With those ends free, I used the shop vac to suck out a lot more coolant. Once done, cover up the exposed holes with masking tape. Once those three ends are free, you'll need to free up the other ends. Here's the deal, they are probably going to break when you try to remove them, and probably going to snap off at the spot where they connect to the coolant reservoir. I twisted and pulled and sure enough, they snapped off. You can remove the lid of the coolant reservoir by removing several screws, a small aluminum pipe on top, and the rubber pipes towards the front of the car. The small aluminum pipe has a single screw that needs to be removed. There is probably a lot of corrosion here so you may need to use a flat head screwdriver to pry it out. Be careful, it's flexible enough to come out and get out of the way but just barely. There is a compression ring on each of the rubber pipes that is easy enough to get to, just loosen and slide it down the pipe. Suck out any coolant and cover the exposed pipes with masking tape. Once you have that lid out, you'll see the remaining plastic bits in the holes. It's difficult to move, but those plastic bits are just in there with pressure, they aren't glued or anything. I used a small chisel and the hammer to break them out. As I got to the o-rings I pulled on those with needle nose pliers and in one instance the whole chunk came out. I also used a lot of WD-40 to work everything out. What you don't want to do is take any risk of chiseling into the metal of the lid, so be careful. This is all about removing the plastic material. Each bit you remove gets you one step closer to freeing up enough pressure to get the remaining bit out. Once it's all clean, leave it off to the side while removing the big pipe. Step 14: Removing The Big Pipe This one is tough. Make sure you're rested, well fed, and cooled down a bit. If you're aggravated already, walk away and relax a bit. You will need to break this pipe into two pieces. I used a boring bit to drill a big hole in the top, and then used tin snips to cut chunks out until I got it in two parts. Again, I used a shop vac to suck out any remaining coolant as I went along. Really, anything will work… you could even use a chisel to break it out. It's coming out one way or the other, no need to be pretty about it. Once it's in two pieces, you can probably rotate the two halves apart. Use WD-40 generously on the ends first though, and give it a bit to work in there. Regardless, when I went to pull out the two ends, they ended up snapping off… leaving their end pieces in the hole. If you read through the three forums, different people use different techniques to try and avoid this with mixed results. This is the worst case scenario though, so lucky for you I fought through it and have plenty of advice. Assuming your pipe broke off as mine did, you will see a metal ring in each end, with black plastic between it and your car. That metal ring was an inner support ring for the original pipe and needs to be removed. This is a violent procedure. IMPORTANT: I cut up some lint free cloths and stuffed one into each end as far as I could so that any material from the following procedure wouldn't go any further. Once done with the procedure below, I vacuumed up anything I could and then removed those cloths. Again, use WD40 a LOT. I sprayed and sprayed as a worked, and I think it helped. READ THIS CAREFULLY: Removing the plastic and metal ring from each end is all about removing material. You are trying to get as much plastic out as possible. If you get the ring out first, great, but it's not 100% necessary. The plastic is what needs to come out, and you need to get it out from all around it. In addition to the plastic, there are two o-rings in there, so they are just adding more friction preventing this from moving. You'll get bits of that out as you work, and that's good. Eventually, you get enough bits out that the rest will just fall out. Use a hammer and chisel to collapse the metal ring on the top and sides as much as possible. I used to the chisel to cut in to it a bit too. Once I got it that far, I switched to the long screwdriver, hammering the end of it into the plastic over, and over, and over again. I pried as much as I could and worked out bits of material. This took a long time, but sometimes you'll get a big chunk out and that will give you renewed hope. Again, this is all about material removal. Keep telling yourself that. Every bit you get out makes this easier. Once you get enough plastic out, you'll see the metal ring move a bit as you work. This is a great sign and you are almost done. Ultimately, you should be able to pry it out with the screwdriver. NOTE: When working you want to work as much towards the metal ring as possible. You want to avoid scraping the inside of the hole where your new pipes will go. I did scrape up mine a bit, it's unavoidable, but regardless my new pipes don't leak. When you go to remove the bits closest to you, you're working somewhat blind and it is hard. This part almost broke me, but I used a mirror to check and recheck my work as I went along. Bright lights help here too. Honestly, I really can't say enough how hard this part was and how long it took in comparison to everything else. It was the part that had me the most worried, but I got through it. Once it's all out, remove the cloths from inside the pipe and vacuum a lot. Now is the time to clean stuff up too, as you're about to put the new pipes in. As a best practice, you should clean up the inside of those holes. I used some steel wool; I know some people used scotch bright or even buffing pads. I didn't go overboard with this; I just want to get any grime out of there. Step 15: Install the New Big Pipe At this point you should be elated. You're through the worst. Installing these pipes are a bit difficult, but not bad. If they are not already on there, put the O-Rings on the small pipe. Use the White Lightning grease or whatever you bought and coat the inside of the hole on the engine and the outside of the pipe. Use it liberally. A bit of WD40 wouldn't hurt either. Press it into the hole at the back of the engine and do your best to get it all the way in. This is where a small block of wood and a hammer come in handy; you can use those to tap it in the rest of the way. Do not put the rubber sleeve on it. For the big pipe, install the o-rings and lube everything up good with the grease, both the hole it goes in and the pipe itself. You will also need to grease up the end the rubber part goes on and the other end of the short pipe that the rubber sleeve will slip over. Place the tightening rings over the rubber sleeve as well. Slide the rubber sleeve as far as it will go over the pipe. Push the pipe into the hole, I found a twisting action worked well. I also used my metal screwdriver against the bottom of the engine bay as a lever to slide it in the rest of the way (it required a lot of pressure). You then need to rotate it to line it up with the short end of the pipe. You'll slide the rubber sleeve over it and then tighten up the two rings. NOTE: Be sure to rotate the rings as far down as possible so that the screw does not interfere with the three pipes you're about to place on top of it. The new big pipe should be in place, and you're now done with the hardest part of this job. Step 16: Install the Three Pipes You'll want to put the lid back on the coolant reservoir (replacing the seals Porsche included with the kit), reattach the pipes and tighten up the screws. DO NOT OVERTIGHTEN THE SCREWS. I snapped one clean off. Make sure they're tight, but don't put all your muscle into it. Once on, you are ready to slide those pipes in. You do not need to put the lower bracket at the back on first; I did it after installing the pipes. Again, make sure everything is lubed up well so that any points of friction are well covered. Slide the pipes in. I used by long screwdriver again as a lever to apply the necessary pressure. On both these pipes and the big pipe it looked like I could have gone another 16th of an inch, but nothing leaks so I guess it was far enough. Put the bracket on at the back before you attach the hoses. You'll use your locking pliers again to attach the compression rings. With the bracket in place it is obvious how far up the hoses go. You'll put the upper bracket on, using the spacers for the screws and screwing it down tight. Don't forget to attach the two brackets that hold that electrical cable in place. Not a big deal if you do forget. Step 17: Install Final Pipe Now install that skinny pipe. This one is easy. Don't forget about the small compression ring that goes at the far end. Everything else just clips in. Step 18: Assess Your Work Look over everything and make sure it all looks right. At this point you should have a sealed coolant system. Check all your connections and make sure everything is solid. At this point you're home free, and you should be feeling pretty darn good. Step 19: Fill Up Coolant I use a 50/50 water to coolant ratio… so I mixed everything up with what I had and filled up the coolant tank. Once it was full, I left it overnight and checked in the morning for any fresh coolant. I was totally beat from a long day of working on it and thought putting everything back together fresh in the morning was a good idea. Step 20: Put Everything Back Together You tore it apart, now put it back together. I cleaned everything as I went, so now my engine looks great and I think that's a good idea. You don't need to go overboard, just use some lightly damp, lint free rags and wipe everything down. Porsche should have also provided new seals that go on the bottom of the intake manifold. I replaced mine dutifully, and I am glad I did. The old ones just looked worn out, no way they weren't leaking. Putting everything together is pretty straightforward once you've taken it apart. Just be careful and make sure you get all electrical connections and hoses in back on securely and in the right places (hard to mess that up). Also make sure you remove every bit of masking tape as you go. Final Thoughts I am very, very glad I did this project for two reasons. One, it saved me a ton of money and two, I now know tons more about the engine. Doing this project means I could replace my fuel injectors, spark plugs, injection coils and a host of other things when and if I have to. I know where the throttle body is, and if it's sticking I know where to go to clean it. If I need to replace the starter, I know where it is and how to get to it. I can now take my car on trips without fear of a massive coolant leak. This was the last "major" Cayenne defect for me that needed to be fixed. The water pump & drive shaft were already replaced. With 116,000 miles, I have quite a bit of faith in my car not having a catastrophic failure (knock on wood). At the end of the day, I'm pretty proud of myself for getting this all accomplished, and I hope I've saved some other poor soul a ton of time by writing all of this down. If it does help you out, please reply to this post and let me know.2 points

-

On occasion during the most humid months of the year, the air coming out of the vents of my nearly 8-year-old car would smell a little 'off.' Since the a/c condensation was draining just fine and the odor wasn't ever-present, it wasn't a major concern to me. However, surfing the web I found a variety of A/C refresh kits that seemed worth a try, if for no reason other than to experiment and see if it was any benefit. But, no good deed goes unpunished. There are a variety of kits out there, some seem OE but most are aftermarket. I found them to have so much in common that I began to think they were made by only one or two manufacturers. The kits I was considering are two products: 1) a foaming spray that you inject into the evaporator housing through the condensation drain, and 2) a spray that you empty into the external air intake while changing the HVAC settings. The kits state or imply that they will clean the evaporator of crud that comes from dirt, mold, mildew, etc. and kill whatever causes odors in the venting. As I mentioned, the kits seemed nearly identical to each other so I bought one based on convenience at a local parts supplier for about $18. For another point of reference, there is a Toyota kit, part number 00289-ACRKT, that you can find here for instance. The product I used was the following: Note: This attempt to clean an HVAC system was for my particular 2003 986S. Other vehicles may be different and there are safety risks involved in doing mechanical or electrical work on a vehicle. What's presented here is a general overview of my DIY project, not a complete step-by-step set of instructions. Please obtain, understand, and follow the necessary repair and installation procedures in order to work safely, avoid damaging anything, and achieve a safe result. Preparation steps: I raised the vehicle up onto four(4) jack stands. Then I loosened or removed numerous underbody panels to expose the area under the passenger side floor pan. The location of the condensation drain is identified by an arrow in the photo below: First use the larger can of "evaporator foaming cleaner." You can read the instructions on the can in one of the photos above. I had to use another piece of tubing between the tapered nozzle and the condensation drain because the drain tube is not flexible and wouldn't hold the nozzle. That should have been the first indication to stop. Notice the grommet around the drain tube in the photo above and how the tube is inconveniently situated between the hot water supply/return for the heater core. As I was trying to force the tubing onto the drain, I pushed the drain tube and grommet into the passenger compartment. I knew it was going to be a pain to put it back, and it was. I had to remove the umbrella trim along the passenger-side door threshold, loosen the floor carpeting, and shove my arm under the carpet to reinstall it. Photos of the attachment and foam injection below: The foam went in, it seemed to sit for a while, it liquefied a bit, and then it drained out. The photo below was taken at a moment just as it was starting to drain: The liquid in the bucket was mostly clear, with a little particulate matter--nothing worth photographing. It didn't have much of a smell; it was slightly medicinal, like disinfectant. Following the instructions on the can, the next step is to use the "a/c intake refresher." Take out the pollen filter and spray into the air intake. You are supposed to change the vent settings between spraying intervals so that the mist runs through different duct work. Again, it has a slight disinfectant smell--pleasant but not flowery and not too strong. Not too bad, right?... Well, I was too preoccupied with the camera to realize what was happening inside the car: After all the effort for something that wasn't really necessary… I had to laugh. I was doing this process as I was preparing the car for winter storage. It was about 40° F (4° C) in my garage. Obviously, a lot of the foam didn't liquefy and drain. If I were to do this again, I would warm up the HVAC system beforehand, or just do the whole process at a higher ambient temperature. I'd also let the evaporator core drain longer (a lot longer) before doing the 2nd can. The photos above are the worst of it; only a little came out of the other vents. I blasted the system for a long time after that and it cleaned up without a problem--no damage to any surfaces. A few days ago I fired up the car for the season. No issues. Live and learn and pass it on. --Brian2 points

-

1.) Un-screw the one phillips head screw at top center of side air intake... 2.) The molded air duct and the intake grill are still attached by three delicate plastic tabs at the three points... The best way to remove this is gently insert your fingers through the grills into the intake at the points circled in red and gently try to free the tabs... All three points come forward towards you, but if one is stuck or gets caught it will break... 3.) Inside the drivers side air duct you will find a snorkle... The snorkle is added to most US cars for noise restrictions. Now this piece is attached by no screws or tabs, but it most likely will give you some troubles removing... The best way is to remove this, just grab a hold of the long snorkle (not the small dish on the end)... Now wiggle it from left to right and vice versa while pulling out towards you. This works, but might take a little effort. 4.) This is what the intake is going to look like after the snorkel is removed... Just carefully insert the three tabs back into their points... Make sure that all three are tightly in by pushing the airduct cover (not the grill)... Insert your 1 screw into top center of cover and you are done.2 points

-

Be sure to use some protective material on the mirror base. Set the pliers with the protecting parts to the windshield to the diameter of the mirror base and secure to the mirror base. Turn the rearview mirror through 90 degrees at the mirror base using the pliers. Then, unclip the base of the interior rearview mirror from the retainer plate on the windshield. When you reinstall the mirror be careful not to go beyond the 90 degrees locking point. If you remove the mirror base from the windshield you will need a special cleaning/glue kit from Porsche to reinstall it.2 points

-

See if any of the fault codes have changed. If not, then I would still go the path based on the FRAU readings.1 point

-

P2189 Lambda control adaptation FRAU (lower load range) (FRAU > 0.7) - below limit value Possible fault causes - Incorrect main filling signal from hot-film mass air flow meter - Fuel pressure too high - Injection valve faulty (dripping) - Tank vent faulty (does not close completely) P2189 Lambda control adaptation FRAU (lower load range) (FRAU > 1.3) - above limit value Possible fault causes - Intake system leaking (secondary air) - Incorrect main filling signal from hot-film mass air flow meter - Leak in exhaust system - Fuel pressure too low - Fuel injector faulty (stuck) - Fuel pump delivery too low P2187 Lambda control adaptation FRAU (lower load range) (FRAU > 0.7) - below limit value Possible fault causes - Incorrect main filling signal from hot-film mass air flow meter - Fuel pressure too high - Injection valve faulty (dripping) - Tank vent faulty (does not close completely) P2187 Lambda control adaptation FRAU (lower load range) (FRAU > 1.3) - below limit value Possible fault causes - Intake system leaking (secondary air) - Incorrect main filling signal from hot-film mass air flow meter - Leak in exhaust system - Fuel pressure too low - Fuel injector faulty (stuck) - Fuel pump delivery too low1 point

-

1 point

-

Non, push down with one hand, squeeze the ribbed bottom ring with the other hand and pull up, this is not as easy as it looks, succes.1 point

-

Manual is a huge component of my attraction to Porsche. Where I live, 2 similar spec 997.1 vs .2, the price difference is $15,000. i chose a .1 four and years ago. That 15k delta was left in the stock market (S&P 500) and has atleast doubled. Meanwhile my cars only trip to a shop has been a gashed tire caused by road debris. I’ve done all small repairs and major maintenance. (Although I have new issue today) Do you see yourself keeping this car for a year or 2? Or 10 years or more? If you plan on keeping a .1 I’d recommend the following: Swap to a low temp thermostat X51 baffle upgrade in the sump. consider upgrading AOS to aftermarket Ultimate AOS. 50 weight oil instead of factory 40 add 3rd radiator. ignore ALL internet boogeyman stories about the IMS. 2008 era, it is just another moving part. However if you ever drop engine for a clutch or rear main seal then have a seal removed such that IMS is no longer sealed and engine oil will splash in to lubricate it.1 point

-

Do this someplace safe... Put in Neutral and see if the noise continues or not. If it does not continue then it is likely in the drivetrain (transmission, transfer case, driveshaft, rear end}. If it does continue then it is likely in the running gear (wheel bearing, axle shaft, or even warped brake discs).1 point

-

Here is the documentation from the Porsche DME manual P0327 210 Knock sensor 1 - below limit Diagnosis conditions • Engine speed more than 3600 rpm • Engine load greater than 45 % Possible fault cause ♦ Break in wiring or short to ground ♦ Contact corrosion on the connector ♦ Knock sensor loose ♦ Short circuit to B+ ♦ Knock sensor ♦ When a fault is stored, the ignition angle is retarded for all cylinders in the range in which knock control is active. ♦ Knock control adaptation is inactive. ♦ If knock control becomes active here, this may indicate engine damage (increased noise level) Affected terminals Terminal III/49 and III/50 Diagnosis/troubleshooting1 point

-

Lost Radio Codes DO NOT START A NEW TOPIC FOR A LOST RADIO CODE. DO NOT EMAIL ADMINS. Please read the Lost Radio Code FAQ FIRST before posting - then post in the one thread. This topic is closed.1 point

-

Does the battery have a vent port and did you connect the vent tube?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Not back then - newer cars specify a bit more but the best thing is to do a factory build database check. I checked and your build code is 993330 which is a Carrera 2 wheel drive.1 point

-

1 point

-

Time to run a parasitic drain test, which has been written up multiple times, but there are also a ton of online videos : . Basically, after the car has been sitting for about an hour or so, there should be a 45 - 60 milliamp current drain on the battery from necessary things like the clock and the alarm system; any higher than that and you have a parasitic drain on one or more of the electrical circuits.1 point

-

1 point

-

Hi, I have a 2021 CTT. I replaced the passenger fog light this summer without removing the front bumper. Yes there is a cooler in the way. A lot of patience and you can work around it. I also uncliped a few harness clips to get a little more leeway around the back of the fog light. If I do It again, I won't use the original mounting holes. You will see the fog light is attached using two mounting screws, but the fog light has four attachment points, one at each corner. If I recall correctly, the original mounting points were 2o'clock and 7o'clock. One went in very easily. One was a royal pain to get started. Next time i'll use the mounting points with easier access, 11 and 5. I may have these positions reversed, can't remember for sure, but you'll see right away the fastener with horrible access. I can't figure out how to post illustrations, so see the attached PDF. I will also mention, the part from FCPEuro was a perfect fit and come with a lifetime guaranty for when the next rock comes flying in. cayenne service history fog lights.pdf1 point

-

I'm heading to the track for the first time and Shenandoah circuit at Summit Point apparently has a little crest where some people catch air. I don't want the rollover bars to scare the crap out of me while on the track. Any ideas?1 point

-

Perhaps, but then every day you get to make all new friends..........................😱1 point

-

Thanks. Flipped a coin and replaced the seals in the other cylinder. That did it. The original seals came out shredded. New o-rings returned the top to smooth performance.1 point

-

1 point

-

Today I did front final drive gear oil change. This DIY will show you how I did it. Since I had a hard time to access the drain plug, I removed fill plug and used a pump to suck out the final drive oil. Worked really well, and helped avoid messy drain, which puts oil onto the lower axle carrier frame too. FSM calls for change quantity of 0.42L, and I managed to remove about that much from the drive, so I feel confident I got it all. Used empty oil can go suck old oil into it, and another empty oil can to put same amount of new oil it, making sure I fill with what I removed. I actually filled the new oil can with maybe 1/4" more oil, to accommodate for some oil that pump cannot take out of can, and some oil left in tubing. Oil used for change: Mobil Delvac 1 full synthetic gear oil 75W-90 (direct cross reference to Shell TF0951 - factory fill oil) Oil refill quantity: 0.42L (bit less than half a quart) New fill plug part number: N 902 818 02 Fill plug tighten torque: 25.8 ft/lbs Fill plug removal tool: ratchet, extensions (at least 6"), 5mm hex socket, shop towels Look at this DIY before you do the change. Make sure you have all materials and time to do it. Expect about an hour to hour and a half to complete. Let us know if you have comments. Thank you.1 point

-

Oh man, I hope you have a better result than I did with my 09 2S. Mine failed when I tried to pull away from a traffic light a year ago. Got the transmission emergency run on the dash. Car wouldn't move forward or backward. The gear indicator flashed back and forth between 1 and 2 when I had it in drive but the car wouldn't move. Couldn't clear it with Durametric while at the traffic light. Shift rod 3 failure. Towed the next day to a PIWIS which cleared some of the codes but could not clear the Shift rod 3 error. Tech tried first to run PIWIS calibration routine and then to reflash it - both to no avail. I was out of warranty and ended up paying for PCNA re-manufactured unit to be installed. Based on other failures he had seen, tech thought the issue was in the hydraulic section of the box but of course Porsche doesn't share what they found when the failed unit was opened up in Germany. What part of the country are you from?1 point

-

Filter location underneath the rear seat behind the driver side Replacing the filter: Recommended to do this job while the fuel tank is almost empty Fuel tank located underneath back seat Gain access to fuel filter need to flip back seat and look under the carpet Pull the seat buckle below the seat and flip the seat bottom Remove seat mount hinge, note you need special socket to fit the nuts Find below a round cut made on carpet, open Find round stainless steel caver with four screws, open it Then you will see the filter Use special tools to open the lock ring or use big flat screw driver with light hummer to remove the ring, slowly slowly, hit from different angles and corners to distribute the hummer pressure, Then disconnect fuel hose and electrical connection from top, be careful fuel house might be under pressure Note: petrol smells very strong and harmful, do this job in good ventilated area Note: there is a house connected between fuel filter on the left side of the fuel tank and fuel bump at the right side of fuel tank. Go to the right side of rear seat and flip the seat Find carpet cut same as left seat Remove seat mount hinge, note you need special socket to fit the nuts Open the stainless steel cover Find the plastic cover same as fuel filter housing Open the lock ring Then disconnect electrical connection and fuel house from top of plastic cover Be careful fuel might be under pressure Pull the plastic cover up, look down you will find a house that going to the filter at left side and some other house going to fuel bump, pull the house which is going to filter side several times back and forth to make sure it is the correct house going to filter side Then go to filter side on the left and remove the filter and note the house going to the right side, and pull to make sure that this is the right house going to left side After you are sure of the right hose Go back to right side are and tight the house with a string (or any available robe) before pulling the house this string will help you pull back the new house for the new filter back to the right side, Unplug the house go to left side and slowly pull the filter and un plug the other house and wire connection at the bottom of the filter side and make sure to tight the house and wire connection with strings to make sure not to fall down inside the tank bottom, Note: much petrol will comes out from filter After removing old fuel filter bring the new filter and first thing to do is to tight the string we all ready have from the old filter house side and insert in the fuel tank and pull slowly to right side Then connect back house and wire connection of the filter. Go to right side pull the string until you catch the new filter house and connect back to the plastic cover and put back all parts. Go to right side and put back every thing once an again.1 point

-

P0455 Leakage in fuel tank system Diagnostic conditions D Vehicle speed = 0 km/h D Engine speed = 0 rpm D Correction factor, height > 0.73 D Coolant temperature upon starting the engine may be no more than 6.8 K above ambient temperature D Coolant temperature when engine starts > 3.8 °C D Period for which the engine needs to have been running before ignition is switched off > 20 minutes D Ignition has been switched off for at least 10 seconds. D Ambient temperature 4 … 35.3 °C D Active charcoal filter load < 3 for minor leak D Fuel tank fuel level 10 … 54 litres D Battery positive voltage 11.02 ... 14.5 V D No fuel tank filling D No faults detected for ambient pressure sensor, coolant temperature sensor, vehicle speed sensor D No output stage faults detected for DMTL pump motor, DMTL switch-over valves and tank vent D No fault detected for tank vent (flow) E The diagnostic conditions can also be established using the PIWIS Tester via the short test "tank leakage test". After the test has begun, the ignition must be switched off. F NOTE E In this context, please also observe the function description. Possible fault causes E Tank cap not closed correctly, leaking or missing E Purge air line leaking E Tank vent leaking E DMTL (Tank Leakage Diagnostics Module) leaking E Leakage in fuel tank system Page 140 of 398 07/20/2006 Function description Tank leakage test/DMTL – Tank Leakage Diagnostics Module F Note E The tank leakage test is performed only on USA vehicles. Construction of the tank leakage diagnostics module: The diagnostics module consists of an electric motor with a small air pump, switch-over valves and a reference nozzle. In addition, the modul is heated so as to prevent the forming of condensation and ice. Procedure of the function: E The pump is operated via an electric motor and conveys air through the reference leak. The power consumed during this process is determined. E The switch-over valve switches and the air current is now directed into the fuel tank. The power consumed during this process is also determined. After a waiting period dependent on the fuel tank fuel level, it must be at least as high as the power consumption was during the reference leak test if the tank system is leak-free. E The system is identified to by leaking if the power consumption is lower during the actual leakage test as it was during the reference leak test. E An evaluation of the power consumption levels when the pump is started and after the switch-over valve has switched serves to identify faults within the tank leakage diagnostic module (e.g. pump blocked, motor spins at idle speed, valve does not switch etc.). E The diagnosis of heating, motor and switch-over valve is performed via the output stage of the DME control module. P0456 Leakage in fuel tank system Diagnostic conditions D Vehicle speed = 0 km/h D Engine speed = 0 rpm D Correction factor, height > 0.73 D Coolant temperature upon starting the engine may be no more than 6.8 K above ambient temperature D Coolant temperature when engine starts > 3.8 °C D Period for which the engine needs to have been running before ignition is switched off > 20 minutes D Ignition has been switched off for at least 10 seconds. D Ambient temperature 4 … 35.3 °C D Active charcoal filter load < 3 for minor leak D Fuel tank fuel level 10 … 54 litres D Battery positive voltage 11.02 ... 14.5 V D No fuel tank filling D No faults detected for ambient pressure sensor, coolant temperature sensor, vehicle speed sensor D No output stage faults detected for DMTL pump motor, DMTL switch-over valves and tank vent D No fault detected for tank vent (flow) E The diagnostic conditions can also be established using the PIWIS Tester via the short test "tank leakage test". After the test has begun, the ignition must be switched off. F NOTE E In this context, please also observe the function description. Possible fault causes E Tank cap not closed correctly, leaking or missing E Purge air line leaking E Tank vent leaking E DMTL (Tank Leakage Diagnostics Module) leaking E Leakage in fuel tank system Function description Tank leakage test/DMTL – Tank Leakage Diagnostics Module F Note E The tank leakage test is performed only on USA vehicles. Construction of the tank leakage diagnostics module: The diagnostics module consists of an electric motor with a small air pump, switch-over valves and a reference nozzle. In addition, the modul is heated so as to prevent the forming of condensation and ice. Procedure of the function: E The pump is operated via an electric motor and conveys air through the reference leak. The power consumed during this process is determined. E The switch-over valve switches and the air current is now directed into the fuel tank. The power consumed during this process is also determined. After a waiting period dependent on the fuel tank fuel level, it must be at least as high as the power consumption was during the reference leak test if the tank system is leak-free. E The system is identified to by leaking if the power consumption is lower during the actual leakage test as it was during the reference leak test. E An evaluation of the power consumption levels when the pump is started and after the switch-over valve has switched serves to identify faults within the tank leakage diagnostic module (e.g. pump blocked, motor spins at idle speed, valve does not switch etc.). E The diagnosis of heating, motor and switch-over valve is performed via the output stage of the DME control module.1 point

-

About 3 weeks back I started getting a CEL with a Code 0335 Crankshaft Position Sensor "A" Circuit. Upper Limit Exceeded. After clearing the code it kept coming back within a day or two and the car stalled on two occasions. Based on research on the forums, this seemed very much in line with sensor failures on 955's and a DIY existed for these model years, but not the 957. My 957 now has around 120k miles, and the engine runs incredibly well, aside from this one recent anomaly. I ordered a replacement sensor, from Pelican Parts which arrived the next day (very impressive service) :lowdown: thanks Pelican Crankshaft Sensor Brand: Bosch Note: Engine Type: 4.8L 4806cc V8 (3.78x3.27; 96.0x83.0) (2008 Porsche Cayenne S Sport Utility) Part #: 0-261-210-292-INT As there was no info available on this DIY for a 957 so I'm hoping the following will help others get this done easily when needed, and in particular so you can save the 2 hours extra it took me to figure out where and how everything was located, as well as how to get to it. Which I did while I was waiting for the new part to arrive However once that research was done, the actual job of replacing the sensor took about 45 minutes. The main challenge is that the connector is difficult to access as it is behind and below the fuel pump on the right hand side as you face the front of the car. Even with an inspection scope it was difficult to locate. It was only once I looked from under the car that I could see where it was located. Also the connector plug is attached to a rectangular section of plastic tubing/conduit on the wiring harness, by a clip which is very rigid. After multiple attempts to release this clip it broke off. I think give the location it gets very hot and over the years becomes brittle. You should remove the engine compartment trim at the rear of the engine for better access. I also borrowed a few pics of an engine on the web to mark the location: I also found that removing the harness from the engine made it easier to get my hands around the connector to get the two ends separated. Once you have the old sensor disconnected, attach the new one and and tape the end of the new sensor tip with some painters tape just for protection and slowly lower it down into the engine compartment. It will end up either side of the primary cat where it is easily accessible from below. Also let the old sensor cable drop into the engine bay as you will then extract it from below. Now move to underneath the vehicle. I only needed to jack up the front left of the vehicle (jack stand + jack for extra safety). No wheels need to be removed. Do not jack up the car before dealing with the connector at the top of the engine bay as it will make it difficult to reach. Between the connector and the sensor, the cable is secured at 3 locations. See pictures below. The cable is pretty easy to remove and secure from below the vehicle and it can be seen and accessed without removing any of the under trays (depending on your level of flexibility). The lowest retaining clip is a push in type retaining clip where you simply press the cable into the tensioned clip. The two upper retaining clips are circular in shape and hinge open and closed. With a built of gentle persuasion you can pull them open and the cable comes out easily. I could not get the uppermost one in the pics but it is similar to the 2nd one shown in the pics. The sensor is held in place with a single torx T5 screw. Once you have the old sensor off you can pull it out and put it aside and attach the new one. I suggest attaching the sensor first and the attaching the cable to the retaining clips. Very rewarding and inexpensive fix, and everything is back to normal. No more codes and the car runs beautifully!1 point

-

Although embarrassing to air my mistake, I thought I would post this in hopes I might save someone else from the same problem: If you have adjustable coilover shocks, do not attempt to change your car's ride height unless you are doing it while corner balancing with scales. I rationalized that if I set the ride height using the factory measuring method (documented in multiple places on this site) I would get "close enough" to a balanced car for a 996 that isn't tracked. Wrong. I worked on a level floor, with a full tank of gas (per spec), new tires with factory-recommended tire pressures, using the factory-recommended ride height measurement points, drove the car a few yards after each change to settle the suspension, and after a lot of hard work I was dead on with each of the four measurements. A local indie shop, not really performance oriented, vetted my approach and said it should be fine, it's what they would do. Even after a perfect-to-the-spec alignment this morning the car pulls to the right, enough at 40 mph with hands off the wheel to change lanes in less than 50 yards. My effort was wasted and I'm out the cost of that alignment. The car goes in for a pro corner balance to correct the issue and I'll end up paying for another alignment. Lesson learned. In truth, the effort wasn't entirely wasted because I learned about the stiffness of the chassis, how even a minute change of 1mm in shock adjustment can affect all four wheels, and how each of the wheels is affected. Dialing in the ride height was a PITA but a learning experience that I believe transfers to doing a corner balance. If you install height-adjustable shocks, you must corner balance for optimal handling even if your car is a daily driver and not tracked. Bless you suspension techs who do corner balancing for a living!1 point

-

Uwon, 1. i'm not particularly patient. at some point, it became evident to me that the problem was beyond my control 2. first water pump failed and was replaced around 32,000 miles. 3. the low-temp thermostat: oil temps appear to heat up just as quick but the oil temp is much quicker to cool down when things get hot (>225 degrees Fahrenheit) .1 point

-

A word to the wise on transmission service and drain plugs: Never remove the drain plug until you get the fill plug out; if you take out the drain plug first, and then cannot get the fill plug out, you are officially in very deep yogurt because you cannot refill the gearbox. Get the fill plug out first.1 point

-

My guess is that the top was replaced. The cover looks like the original color of the top and the top looks like a lighter blue. IMHO1 point

-

Helen: The "temperamental" nature of the problem that you describe points to either bad/degraded connections at a number of possible points, or a hairline crack at the parallel strips microswitch inside of the convertible top latch assembly or a deformed plunger-type microswitch, also inside that latch assembly. You must first verify that the parking brake light on the dashboard is actually lit up when you pull up on the parking brake. Then double check that your fuses at B6 (supplies power to the convertible top double relay) and at D3 (supplies power to the convertible top motor) are intact AND that there is no corrosion at their respective spades on at the female receptacles on the fuse panel into which they are pressed. You can clean up any corrosion in those areas with a small piece of fine emery cloth. Next, double check for and clean up any corrosion on all of the male spades of the convertible top double relay, and the same for the female receptacles in the relay tray that accept the double relay spades. You can also tap the double relay on the ground a couple of times sharply, as that sometimes "revives" a sticking relay. If you have done all of the above and still get no reaction at all, you can then move to the convertible top latch assembly and its two microswitches. When you unlatch the top, the latch releases the plunger type microswitch inside the latch assembly and that causes it to ground. When it is grounded, a signal is sent to drop the windows about 4 inches. Poke your finger or a pencil eraser into that depression in the latch assembly and see if you get any reaction from the windows. If you don't, you will have to open up the latch assembly to access the two microswitches. Try the above steps first and report back. If there is no improvement, we can proceed with instructions on how to remove the latch assembly, etc... Regards, Maurice.1 point

-

I could not disagree more. You want the TB to be dry as only air passes over it.1 point

-

Note: Part numbers sometimes change without notice. Always double check with your supplier that you have the latest part numbers. A third (center) radiator is standard on the Porsche GT3, Boxster S and all Carrera's or Boxster's with Tiptronic transmission. As well, the third radiator is now standard on all X51 Carrera Power Kit (engine power upgrade). Although the Tiptronic radiators are plumbed differently it is obvious that Porsche did this to increase the cooling capacity of these cars. Having great concern for my engine, specifically it's cooling in the hot California weather and... knowing that what Porsche does for it's competition cars is usually a good (yet sometimes expensive) idea for our street (sometimes tracked) cars. I decided to add the GT3 radiator to my 1999 Carrera Coupe (w/factory aerokit). The goal being that extra amount of protection that the additional cooling capacity adds. Initial tests show that the highest temperatures (after hard driving) have gone down 10-20°F (7-12°C) after this installation. Here is my installation procedure: It took me 4-5 hours taking pictures and cleaning. I would expect this can be done in 3-4 hours (or less). Parts you will need GT3/996 Radiator Kit (available as a kit from Carnewal.com) consisting of: 1 ea 996 106 037 51 Radiator 1 ea 996 106 666 52 Radiator Hose (right side return line) 1 ea 996 106 665 55 Radiator Hose (left side intake line) 1 ea 996 575 141 02 Air Duct (center) (for MY02 and newer 996 575 141 04) 1 ea 996 504 485 02 Retaining Frame (bottom) 1 ea 996 504 487 02 Retaining Frame (top) 4 ea 930 113 430 00 Rubber Grommets (for retaining frame) 2 ea 999 507 550 02 Speed Nut M6 (for retaining frame) 2 ea 900 378 036 09 Bolts M6 (for retaining frame) 2 ea 999 512 552 00 Screw Type Hose Clamps (now included in kit) 4 ea 999 591 869 02 Speed Nut M8 (for mounting bracket on the car) 4 ea 900 378 074 09 Bolts w/washers M8 (final mounting bolts for the assembly) Other items you will need: 4 ea 999 512 551 00 Screw Type Hose Clamps (large, do not reuse the spring clamps) 2 liters 000 043 203 78 Porsche HMZ Coolant Tools you will need Jack Jack stands 19 mm socket for wheel bolts Key for security wheel bolt Metric sockets - 10 mm, 13 mm Regular screwdriver Phillips screwdriver Torx bit- T25 Torque wrench (97 ft-lb) to tighten wheel bolts Utility Knife Cooling line mounting paths (what it will look like). The parts kit from Carnewal.com. Two views (second one courtesy of Scott Mandell). Pre-assemble the Radiator. Using the numbers in the illustration you can pre-assemble some of the radiator parts using the rubber grommets (4) and the M6 Speed Nuts (6) and M6 Bolts (5). Note the radiator outlet positions and the retaining frame top and bottom (see parts list for p/n). The radiator hose connections face the car and are on the top. The top retaining bracket (2) has tabs with small hooks. The tab hooks point towards the car and the tabs themselves angle away from the car. The bottom bracket (3) has tabs that face the car. When mounted the radiator will NOT be vertical it will be at a slight angle up. Raise the car and remove the wheels. Start by jacking the car up and placing jack stands under the front wheel jack mounts. This really puts the car at a more comfortable height to work on. Next remove the front wheels. Remove the side markers. Move the wheel well liners back. Remove from the wheel well the 3 plastic rivets and the 10 mm nut. Pull the wheel well liner back as shown (I used twine). Remove the front bumper cover. There are two screws on each side at the side marker area. One is at the forward part where the side marker assembly attaches, the other is behind the side marker. Remove the screws and rivets under the nose (2 rivets and 7-9 screws). Remove the plastic cover over the front trunk latch. This is held in place by four plastic fasteners. You just rotate these 90 degrees to remove them. Carefully pull the cover off over the latch handle. Finally remove the 2 screws (now visible). Detach the air temperature sensor cable. Lift the bumper cover off and place on a padded surface to avoid scratches. Remove the air scoops. There are 5 torx screws on the scoops to remove them. On the right side you will need to feed the rubber grommet (for the temperature sensor) through the scoop to remove it. Clean the radiators. Detach the air conditioning condensers (2 torx screws) and use a soft brush and vacuum to clean the radiators and air conditioner condensers well. Loosen the radiator assembly on each side. Remove the two bolts (13 mm) under the support bracket. Then remove the (13 mm) nut that holds the bracket (inside the wheel well). This will now allow the whole assembly to move about 6 inches down and to the side allowing enough room to change the hoses. Replace the lower hose on right (passenger side) side. Using pliers slide the hose spring clamps back on the hose but don't remove the hose yet. Place a clean container (about 2 quarts should be enough) to catch the coolant when you carefully remove the hose at the radiator end first. Coolant. This about the quantity of coolant you should expect when you remove the lower hose. I would guess slightly more than one radiator capacity. Right side (passenger side) Hoses. Old hose on left new hose on right. Place the clamps on the hoses and re-attach. Before tightening down the hose clamps rotate the hose so that the small hose is correctly positioned at to the top center of the car (for the new radiator). Replace the upper hose on left (drivers side) side. Place the clamps on the hoses and re-attach. Before tightening down the hose clamps rotate the hose so that the small hose is correctly positioned at to the top center of the car (for the new radiator). This one is a little trickier but you should see the hose path as it sits up and under the fender. Left side (drivers side) Hoses. Old hose on left new hose on right. Attach the center radiator to the car. Using the M8 speed nuts place them on the brackets on the car and attach the radiator (assembly) loosely using just the top 2 bolts. Attach the small hose to the center radiator. To easily attach the left hose remove the bolt from the left side mounting (now only supported on the right) and attach the hose and tighten the clamp. Do the reverse on the other side (place bolt back in left side and remove right bolt). Finally tighten down all 4 M8 bolts to hold the radiator firmly in place. Re-attach the radiators. Carefully re-position the radiators and replace the 2 bolts and nut that holds the assembly in place. Take care to line it up as it was previously. Reattach air conditioner condensers and tighten the 2 torx screws that hold them in place. Test for leaks. Start the engine and run for at least 5 minutes while checking for leaks. If everything is tight and leak free proceed with the rest of the re-assembly. Attach center air duct. Carefully position the air duct such that the 6 protrusions snap into the places on the radiator frame. Reattach the side air scoops (5 each torx screws). Remove the center plug in the bumper cover. This may sound easier than it is. Seems Porsche uses a black silicone type sealant on this. I found the best way was to use (carefully) a utility knife to cut away as much of the sealant as possible and then carefully pull until I got a corner up and worked my way around the edges. Note: For standard (non-aerokit) front bumpers; cut the inside gasket along the line. Remove the center plug as shown in these images (courtesy of Scott Mandell) Or, you could replace the rubber bumper insert with: 996 505 553 05 01C Air Inlet for Tiptronic (or for MY02 and newer 996 505 561 02 01C). This replaces the original insert and installs across width of stock 996 bumper. Re-attach the bumper cover. Basically, the reverse of removal. Re-attach wheel well covers. Ditto, basically the reverse of removal. Re-attach the side marker lights, wheels, lower car. Again, the reverse of removal. Add coolant, check for leaks (again), and bleed system... Add a mixture of antifreeze and water using the HMZ coolant. Antifreeze in coolant: 50% gives protection down to -31°F (-35°C) 60% gives protection down to -58°F (-50°C). Be careful not to overfill (it will get pushed out on the floor). Lift the bleed valve. Start the engine and allow it to get to full operating temperature (I also ran the air conditioning to force circulation). The coolant warning light will likely start to flash. Shut the engine off and WAIT until the engine and coolant has cooled enough to remove the coolant tank cap. Then add coolant to the tank and repeat the process. You made need to do this 2-3 times. When the coolant level fails to fall then the system is bled and you can close the bleeder valve. Enjoy your "cool" car. Just to be safe it might make sense to check the coolant level a couple of times in the next one or two days. I found under heavy (track) driving in hot weather my coolant temps run 10 to 20°F (7 to 12°C) cooler now.1 point

-

I am going to take another look - but the short answer is yes. The fuses are all fine, and the ground point looked okay by a quick visual inspection, but I will take it off and clean it to be sure. However, I did do the following: removed the fuses from the area of the box I have been describing, then tested the ground connection there by running power from another connection through it. It appeared to be fine, which is the point when I ruled out the ground connection as the failure (which was what I suspected first). Mark1 point

-

I have a '00 C2, 6-speed, Canada version. I keep an eye on the operating temperature, using the OBD hack rather than the gage. In traffic, the car has always run pretty warm, regularly over 100 C in the spring-summer-fall. Last night, it was up over 105 C, and I thought I'd hop out and check to see if the cooling fans had switched to high speed as they are supposed to at this temperature. On the passenger side of the car, the fan was loud and you could feel air being moved. On the driver side, the fan was on but quieter, and less air was moving. Is this normal? If not, can you suggest an explanation? I can imagine losing a fan altogether, but I can't figure out why it would just refuse to switch speeds. TIA, Bruce.1 point

-

They "pop" off, you can use two flat screwdrivers, a door trim clip disposer fork, or similar tool.1 point

-

Happy New Year everyone! It was cold and foggy here in Sacramento so I decided to do something about the yellowish headlights on my 03 996 C4S. I got the car about 3 weeks ago and it looks great but the headlights were somewhat yellowish. Looking at them closely, I noticed that there were very fine cracks and oxidation on the surface and decided to try to polish them. I found a "headlight lens restoration system" by 3M for $20 at Autozone. I removed the headlights and cleaned them well. Then I used a 500 grit disc (dry) on a drill to remove heavier scratches: The headlight looked completely ruined after sanding them with the 500 grit sand paper disc :o Then I used the 800 grit disc (dry) also on a drill to remove the scratches left by the previous disc: The headlight was not looking any better yet. The next step was to use a 3000 grit Trizact disc but I decided to wetsand using 2000 grit paper before: Then I used the 3000 grit disc (wet) on a drill. The disc is part of a thin foam pad so it stayed wet and worked nicely: The it was time to use the polishing compound on a foam pad. Just a little went a long way: This is the passenger's side headlight after polishing: And the driver's side headlight after polishing: I didn't take any photos before polishing them but I compared them after polishing only one and the difference was amazing. It removed all the yellowish tint from them. I'm going to buy some UV block for plastic tomorrow and see how long they stay clear and shinny. It took me about an hour and a half to do both headlights. So, if your headlights are not as clear as you would like, don't be afraid to sand them ;) Oscar1 point

-

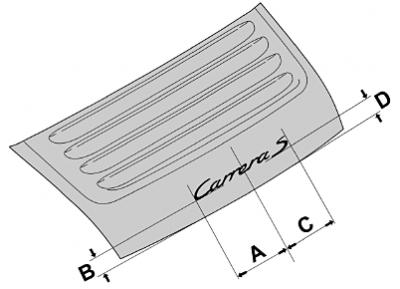

997 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A and C Carrera logo dimension 129.6 mm+/−1 mm and B Carrera logo dimension 45 mm−1 mm and stick on lid. 997S 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A Carrera S logo dimension 175.6 mm+/−1 mm and B Carrera S logo distance 45 mm−1 mm and stick on lid. 3. Position logo S with the dimensions C Carrera S logo dimension 175.6 mm+/−1 mm and D Carrera S logo distance 39 mm+/−1 mm and stick on rear lid. 9974S 1. Find the middle of the lid. 2. Position logo Carrera with the dimensions A Dimension: 175.6 mm +/-1 mm and B distance: 45 mm -1 mm and stick on lid. 3. Position logo 4 with the dimensions C Dimension: 19 mm +/-1 mm and D Dimension: 2 mm +/-1 mm and stick on rear lid. 4. Position logo S with the dimensions E Dimension: 190 mm +/-1 mm and F Dimension: 3 mm and stick on rear lid.1 point

-