Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 01/24/2025 in all areas

-

If the oil cap is hard to remove, you have a high vacuum level in the sump, which is bad for a variety of reasons, including lean stalling. The correct way to access the AOS is to fully warm up the engine by driving the car for 10-15 min, then replace the oil cap with the one in the picture above with a hose that connects to the digital manometer. If the vacuum level exceeds 6-7 inches of water vacuum, the AOS is leaking air into the intake system, causing the lean stall conditions. The normal level of vacuum is typically 4-5 inches of water, which is a really weak vacuum level, so it doesn't take much of a leak to cause problems, which is why we always checked every car that passed thru the shop with the manometer.3 points

-

2 points

-

Welcome to RennTech If you do not have access to a wiring diagram for the vehicle, probably the easiest way to check the ground is to pull the bulb in the light and use a multimeter to check the condition of the ground at the bulb socket.2 points

-

We have used them here in the US for years at MUCH colder temperature's than you get without ANY issues. Put on the adaptor, add external magnets such as the Filter Mag, and enjoy both better filtration and peace of mind.......2 points

-

Welcome to RennTech The factory radio had a ground wire that had to be attached to the car's chassis under the dash as a simple anti theft device. If that ground is not there, the immobilizer will prevent the car from starting.2 points

-

I recently replaced the coolant pipes in my car. I needed to do the job myself because there was simply no way I was going to shell out anywhere from $1500 to $3500 in labor to have it done by the dealership or an independent shop. Plus, having read about the job, I knew they would be tearing through a ton of stuff and I really feared the "oh, it also needs this" scam. I did a LOT of research on the various forums before undertaking this job. Reading and printing out anything I thought was useful information. I would highly encourage anyone reading this to do the same. Fortunately, I was not in the position that the pipes simply failed and dumped all of the coolant. I just had a semi-slow leak… dropping about a gallon of coolant every two to three weeks. So, I had time to order the parts and prepare. Prior to doing this the most complicated thing I had done myself was change the oil, replacing the brake pads and swapping out some plastic bits in the car. I had absolutely no prior mechanic experience whatsoever. However, I do work in IT, and am by nature a very technical person (I'm sure every mechanic reading this just rolled their eyes). My job is troubleshooting very complex problems on very large networks, and I think that experience probably lent itself to a successful outcome here. I'm also patient, and that is critical to getting this job done. I will say that I now have a much greater appreciation for mechanics and their skill set. This was hard. I want to caution anyone reading this that this is a BIG job and it will take a long time. My goal in writing this is so that my fellow Cayenne owners can be spared a lot of the mistakes I made and be better prepared than I was. I will say I am relieved to have this done. I feel a ton better about my car now that I don't need to worry as much about some catastrophic failure hitting me unexpectedly. One rule that I really appreciated was to only place metal on metal when working (until you actually get to removing the pipes). This prevents you from breaking plastic or tearing rubber with something metal. Trust me, pay attention to that rule. I am breaking this down into tasks, because I think it's easier to follow that way. This is how I did it. I am sure there are other ways that may even be easier, but this worked for me and my schedule. I ended up working 4-6 hours at a stretch in the garage with breaks every couple of hours. Step 1: Contribute to this forum I have absolutely no affiliation with this forum whatsoever other than I am a contributing member. The advice on this forum has personally saved me thousands of dollars, and being in IT I know the time and money it takes to run a site like this. So, contribute to the cause. However, there is a second reason to contribute, and that's to get the Porsche TSBs. The TSB for this job contains some diagrams that give you a better idea how all the replacement parts go in to place, and I thought that was handy to have. As an aside, I searched some other issues in the TSBs and found answers to some things the dealership didn't even know… such as there being a $33 replacement latch for my armrest. They wanted to sell me a whole new armrest for $750. Step 2: Obtain the Parts I looked around on the Internet and called some local sources and found a dealership that provided the parts for $550, and that included two gallons of coolant shipped to my door. To me, that was a fair price, and when I received the parts I really thought it was a fair price... there's a lot of quality stuff in there. I'm sure there may be cheaper 3rd party sources. I would just be sure they include all gaskets and such that don't necessarily need to be replaced, but should be replaced if you're tearing everything apart. Once you get the parts, pull them out of the box and examine them. Look at the pics in the forum and look at the TSBs. Get a feel for what you are replacing. Step 3: Verify you have the tools I found the following tools very handy to have, and frankly, necessary. I suggest going to your local auto parts store for most of them and get mechanic grade tools. Socket Wrench 3" Socket Extension 6" Socket Extension Metric Socket Set Torx Socket Set (think of this as a "male" Torx Socket set, you will need #27 & #40) E-Torx Socket Set (think of this a "female" Torx Socket set) Screwdriver that accepts interchangeable bits (there are times this is easier than a socket wrench) Torx Bit Set (Specifically you need a #27 and #40, I just bought a set) Locking Long Nose Pliers (6" is fine, no need for anything bigger) Regular set of pliers Wrench Set (somewhat optional) Real flat head screwdrivers Very long flat head screwdriver (this came in handy a lot) Needle Nose Pliers Small Chisel Set Hammer Tin snips Safety Glasses Mechanics Gloves One of those extension things with a magnet on the end One of those extension things with a mirror on the end WD-40 Some all-purpose grease, like White Lightning Baggies to store the screws in Masking tape/Painters Tape to cover up any exposed openings Old Bath Towels (used to protect the car) Good flashlight Lint free rags Shop Vac Two gallons of distilled water Drain pan (needs to hold 4 gallons) Shop lights A small block of wood, about 2" x 4" x ¾" A radio playing energetic music of your choice Advil and Tylenol Hope and a prayer (optional but doesn't hurt) Step 4: Book the Time I know some people say you can have this job done in less than 8 hours, but being a beginner this took me much longer. If I took out all the time running back and forth to the store for tools and such, and had a guide like the one I am writing, I still think it would have taken 10-12 hours. I ended up removing all of the engine covers on one weekend night, and then doing the actual job the following weekend. I then drove the car for a week with the new pipes and finally put all the engine covers back on over the weekend (I cleaned the covers and the engine thoroughly with a damp rag at the same time to pretty it up a bit). You don't really need to do it that way, but that split the work up a bit. I work in an office in front of a PC all day; I'm not used to working in a hot garage for 8-10 hours at a time... I'm a skinny computer geek : ) When I did the work, I draped some old bath towels over the sides and front of the car to protect it. The last thing I wanted to do was mess up the paint on a zipper or with a dropped tool/screw. Step 5: Remove the Engine Covers There are really two parts to this. You have the decorative covers over the actual engine, and then you have the covers that border the engine. You'll want to remove all of the covers around the border first. There are five of them in total. They all have these little black plastic plugs that you just turn 90 degrees. They should just pop up at that point, but you might have to give them a little lift with a screw driver. While you're removing those covers you might want to pay attention to how they go together and where they slide in to place. You'll also want to remove the windshield washing fluid cap (use the masking tape to cover up the exposed hole) before you remove the cover that surrounds it. Those little things are $4.25 each from the dealership, so try not to lose them. Now you have the three silver looking decorative covers; one on each side of the engine and one towards the front middle with the engine type on it. First, you need to unbolt the two secondary air injection units. Those are the round things with the plastic covers near the back of the engine compartment. You do not need to disconnect them from anything, just unbolt them (three screws each) and then move them off to the side. It might be a good idea to get some labeled baggies to store the screws in. Once those are removed you can get to the side engine covers a little easier. The engine cover in the front middle you just lift off, just work it back and forth a little and it should pop off. Take note that there are four little plugs that fit into holes on the cover itself, you'll need to find them again when replacing it. Now remove the one on the driver's side. It's pretty easy to remove. There are four screws towards the bottom that need to be removed, and then the cover will just come off. The one on the passenger side is a bit different. You have the engine mount right in the middle of things. Assuming you have the tools, you can unscrew the engine mount and get it out of the way. That will let you get to each of the four screws easily on the cover and remove it. I wasn't so lucky here (didn't have the right tools at the time), so I just got the four screws out of the cover and ended up wedging it out. While doing that, the piece of the cover under the engine mount snapped off. I wasn't too concerned about this, because where it snapped is hidden by the engine mount. When I put everything back together I just slid it back and screwed it in. You can't tell at all that it was ever snapped in half. Step 5a: Remove Fuel Pump Fuses You'll want to check your manual (you can also download the manual from this site), but you need to remove a couple of fuses for the fuel pump. Right in front of the driver under the hood there is a small compartment. Remove the cover, and then remove a second cover to expose the fuses. Mine were fuse 14 & 15 for the fuel pump. Store them somewhere safe. Once those are removed, start your car. It will run for a few seconds and die. Congrats, you just removed most of the fuel from the fuel line. I know some people don't disconnect the fuel rail or anything, but to me that's a bad idea. I had a lot of time to try it that way and honestly I'm glad I got it out of the way. Step 6: Disconnect the fuel line The fuel line is near the back center, it's just one tube running to the fuel rail. You'll disconnect it by using a wrench and a pair of pliers. You're unscrewing the part on the left (the thin part) from the part on the right (the wide part) which shouldn't turn as it is part of that tube. Once unscrewed, the fuel rail is only connected to the manifold. A little residual fuel might leak out, so you might want to have a rag handy to wipe it up with. Use masking tape to cover up any exposed holes. It wouldn't be a bad idea to disconnect the batteries now either. I didn't, but that was probably stupid. Step 7: Remove the Y-Pipe that goes to the Throttle Body This plastic Y-Pipe is right up front so it's very easy to get to. There are two flexible pipes on either side you need to remove first; just use a screwdriver to loosen the two clamps on each of them and you should be able to compress them enough to remove them. The Y-Pipe itself is attached to the throttle body via two long, plastic bolts. They have a screw head on them but they are not screws, they're more of a key. You just turn them a bit to line the key at the bottom (use a flashlight and you'll see it move as you turn it with the screwdriver) with the slot. When it's lined up, use a pair of needle nose pillars to lift it straight out. It's plastic and may be brittle, so be a little careful. You will need to remove an electric connection to the throttle body in order to get to one of them. There is a tube connected to the bottom of this y-pipe, so you can't just lift it out. It has some give to it, but not a lot… just enough to get your hand under there once you pull the y-pipe off the throttle body. You have to press the buttons on each side of the tube in order to get it off the y-pipe. Step 8: Remove Emission Tubes & Electrical Connections from Throttle Body There are two emission tubes crossing the throttle body, Porsche refers to them as "vent tubes." I know this because one snapped in half when I removed it, and the dang thing was $130 to replace. To remove them, you just need to press the clips at either side of the end of the tube together and then pull it straight out. I don't think mine had ever been removed, and in retrospect a bit of WD-40 used sparingly here might have been a good idea. I think I used too much force and that's why the small one snapped. I have read that some people have replaced this broken tube with a more generic tube from a hardware store. I just spent the $130 and did it right. There is a third tube connected to the throttle body, you just need to remove that one end of it. You will also have two electrical connections to remove. One you had to remove to get the y-pipe off in the previous step. Just remove the second one and then you're done. Step 9: Remove the Throttle Body The throttle body is connected to the manifold via four bolts. Remove those four bolts and it will come off. You sort of have to wiggle it out because of that thin metal bracket that's holding it there, but it will come out easy enough. Some people take this opportunity to clean it. You'll probably see some gunk on the back side of it on the inside. Step 9: Remove the Electrical Connections to the Fuel Injectors There are eight fuel injectors connected between the fuel rail and intake manifold. Mine were blue plastic, and there is an electrical connection running to each of them. There is a metal clip at the bottom that you just need to press up. I placed a flat head screwdriver between this clip and my index finger, and pushed up and pulled at the same time to disconnect it. Once you remove one you'll get the trick and the rest will come right off. Step 10: Remove the Intake Manifold with Fuel Rail Attached I know a lot of people have different ideas here, some people want to remove the fuel rail independently, and that was the first way I tried it. In retrospect, it's much easier to just leave it attached. There are four screws that hold the fuel rail to the intake manifold. I would recommend leaving these alone, especially since the one at the back on the passenger side is nearly impossible to get to. These screws are $6+ each… I know because I lost one. :P There are 10 bolts that need to be undone to remove the manifold. They don't come all the way out, they'll stay attached to the manifold. Once you loosen them enough they sort of come free and wiggle around. The one at the back on the passenger side was a bear to get to. I ended up placing the Torx Socket bit on top of it using the magnetic extension thing. I then put the 3" extension on top of it, and finally attached my socket wrench to it. I kind of built it all up I guess. I then went really, really slowly and loosened it up. Once loose, make sure to vacuum up any debris on the engine. When you pull the intake manifold off you will have eight gaping holes right down to your cylinders, you don't want anything falling in there. You can now scoot it forward a bit to get to the tubes you will need to disconnect. There are two tubes at the back of the manifold… a firm one and a flexible one. The firm one is just like the one under the y-pipe, and is easy enough to remove IF you can get enough pressure on the connector. The flexible one was just kind of stuck on mine and I left it on. You kind of have to scoot the manifold forward and angle it out, but it will come out with the fuel rail attached. You may have to remove some tubes and such from their guides or brackets. That flexible tube was long enough that I just put the whole thing on the driver's side of my engine and left it there. It didn't seem to be sitting on anything that couldn't support it. I'm sure it can be removed, but at this point in the job I was tired, hot, and just wanted to keep going. Once off, IMMEDIATELY cover up the exposed intake holes with long strips of tape. Cover them completely, and make sure they STAY COVERED. Shine a flashlight in each hole first to make sure nothing fell down there. If so, get it out as delicately as possible. Vacuum up any other debris you see. You can now see the infamous coolant pipes. Step 11: Assessment At this point, you can see the coolant pipes and should be ready for the meat of this repair. The starter is right there too… right under the leaking pipes. Brilliant, isn't it? This may not be true for you, but I had an AMAZING amount of debris in here… honestly looked like a bird had built a nest. I have no idea how it all got in there, but some where at some point tons of debris got in here, and now it was all soaked in coolant. I think my coolant leaking may have been mitigated because the wet debris probably acted as a mud and sealed everything up a bit. I vacuumed it up with a shop vac prepped for a wet cleanup. Now you need to decide if you will see this repair through or not. Once the next step is taken, there is no going back, and honestly the toughest part of this job by far is getting the old pipes out. Step 12: Drain the Remaining Coolant Your first goal is removing as much coolant from the car as you can. On the V8's, there is a drain plug at the bottom of the car, but on the turbo's you won't have one. That drain plug required an allen bit that was larger than I had on hand or could even find at a hardware store. Honestly, in retrospect I wouldn't have even bothered locating it. I'm sure there's a pipe down there you could remove, but I didn't waste time looking for. I took a tip I found on a forum, and drilled a hole right in the middle of the center coolant pipe (of three) and used a siphon with a hand pump to drain out every bit I could. I repeated this process on the larger lower pipe. DO NOT SIPHON BY USING YOUR MOUTH. Coolant is dangerous, nasty stuff. Make sure there are no animals or kids around while you are doing this. WEAR SAFETY GLASSES AT ALL TIMES! Doing it this way you're going to spill a lot of coolant, but it is what it is… they've been leaking all over everything anyway. I used my shop vac to vacuum up anything I could that escaped the siphon. I've also read of people renting professional vacuum pumps to suck it all out, but again, that's more complicated than it needs to be. I did some research, and coolant is not currently controlled by the EPA for disposal, and it can't be recycled. The unofficial advice I got was to dump it in the woods and douse the area with a hose for a bit. Do not dump it down the drain or dump it where animals could readily drink it. Don't dump it in a stream. Presumably it breaks down fast enough on the ground that there isn't a long lasting effect. Step 13: Remove the Three Upper Coolant Pipes The first pipe you need to remove is the long skinny pipe with three connectors. This one is easy enough to remove, and you should have a replacement as part of the kit. One of the connectors broke off in the hole, and I had to very carefully remove the pieces. Relatively speaking this was easy compared to the rest. There is a compression ring that needs to be removed for the connection at the back of the engine, use the locking pliers to do that. Cover up the exposed holes with masking tape. You now have to remove the three upper coolant pipes. There is a bracket at the back of the engine holding the three pipes. There are also two clips attached (you'll be looking at the back side of them) to that bracket that just support a hose at the back (just has electrical connections in it, and it's probably already split so you don't have to be super careful). Pinch the connectors with a pair of needle nose pliers and they'll come off. You now have to remove three bolts from it to remove the upper half of that bracket. I removed two of them but couldn't get to the third without snapping the thing in half. Porsche was kind enough to provide a new one in the kit so I wasn't worried about it. You will now see three rubber hoses attached to the plastic pipes. They are held on to them with compression rings. Use the locking pliers on the rings to loosen them (they need to be squeezed together to loosen) and slip them back over the pipes. I did one at a time, completely removing the ring and setting it off to the side for safety. The locking pliers really excelled here. When using them, attempt to come at the ring from the top instead of the side, the grooves on the pliers will then secure the ring quite nicely. You might have to adjust the pliers a couple of time to get the right amount of the compression for the ring to move freely. With those ends free, I used the shop vac to suck out a lot more coolant. Once done, cover up the exposed holes with masking tape. Once those three ends are free, you'll need to free up the other ends. Here's the deal, they are probably going to break when you try to remove them, and probably going to snap off at the spot where they connect to the coolant reservoir. I twisted and pulled and sure enough, they snapped off. You can remove the lid of the coolant reservoir by removing several screws, a small aluminum pipe on top, and the rubber pipes towards the front of the car. The small aluminum pipe has a single screw that needs to be removed. There is probably a lot of corrosion here so you may need to use a flat head screwdriver to pry it out. Be careful, it's flexible enough to come out and get out of the way but just barely. There is a compression ring on each of the rubber pipes that is easy enough to get to, just loosen and slide it down the pipe. Suck out any coolant and cover the exposed pipes with masking tape. Once you have that lid out, you'll see the remaining plastic bits in the holes. It's difficult to move, but those plastic bits are just in there with pressure, they aren't glued or anything. I used a small chisel and the hammer to break them out. As I got to the o-rings I pulled on those with needle nose pliers and in one instance the whole chunk came out. I also used a lot of WD-40 to work everything out. What you don't want to do is take any risk of chiseling into the metal of the lid, so be careful. This is all about removing the plastic material. Each bit you remove gets you one step closer to freeing up enough pressure to get the remaining bit out. Once it's all clean, leave it off to the side while removing the big pipe. Step 14: Removing The Big Pipe This one is tough. Make sure you're rested, well fed, and cooled down a bit. If you're aggravated already, walk away and relax a bit. You will need to break this pipe into two pieces. I used a boring bit to drill a big hole in the top, and then used tin snips to cut chunks out until I got it in two parts. Again, I used a shop vac to suck out any remaining coolant as I went along. Really, anything will work… you could even use a chisel to break it out. It's coming out one way or the other, no need to be pretty about it. Once it's in two pieces, you can probably rotate the two halves apart. Use WD-40 generously on the ends first though, and give it a bit to work in there. Regardless, when I went to pull out the two ends, they ended up snapping off… leaving their end pieces in the hole. If you read through the three forums, different people use different techniques to try and avoid this with mixed results. This is the worst case scenario though, so lucky for you I fought through it and have plenty of advice. Assuming your pipe broke off as mine did, you will see a metal ring in each end, with black plastic between it and your car. That metal ring was an inner support ring for the original pipe and needs to be removed. This is a violent procedure. IMPORTANT: I cut up some lint free cloths and stuffed one into each end as far as I could so that any material from the following procedure wouldn't go any further. Once done with the procedure below, I vacuumed up anything I could and then removed those cloths. Again, use WD40 a LOT. I sprayed and sprayed as a worked, and I think it helped. READ THIS CAREFULLY: Removing the plastic and metal ring from each end is all about removing material. You are trying to get as much plastic out as possible. If you get the ring out first, great, but it's not 100% necessary. The plastic is what needs to come out, and you need to get it out from all around it. In addition to the plastic, there are two o-rings in there, so they are just adding more friction preventing this from moving. You'll get bits of that out as you work, and that's good. Eventually, you get enough bits out that the rest will just fall out. Use a hammer and chisel to collapse the metal ring on the top and sides as much as possible. I used to the chisel to cut in to it a bit too. Once I got it that far, I switched to the long screwdriver, hammering the end of it into the plastic over, and over, and over again. I pried as much as I could and worked out bits of material. This took a long time, but sometimes you'll get a big chunk out and that will give you renewed hope. Again, this is all about material removal. Keep telling yourself that. Every bit you get out makes this easier. Once you get enough plastic out, you'll see the metal ring move a bit as you work. This is a great sign and you are almost done. Ultimately, you should be able to pry it out with the screwdriver. NOTE: When working you want to work as much towards the metal ring as possible. You want to avoid scraping the inside of the hole where your new pipes will go. I did scrape up mine a bit, it's unavoidable, but regardless my new pipes don't leak. When you go to remove the bits closest to you, you're working somewhat blind and it is hard. This part almost broke me, but I used a mirror to check and recheck my work as I went along. Bright lights help here too. Honestly, I really can't say enough how hard this part was and how long it took in comparison to everything else. It was the part that had me the most worried, but I got through it. Once it's all out, remove the cloths from inside the pipe and vacuum a lot. Now is the time to clean stuff up too, as you're about to put the new pipes in. As a best practice, you should clean up the inside of those holes. I used some steel wool; I know some people used scotch bright or even buffing pads. I didn't go overboard with this; I just want to get any grime out of there. Step 15: Install the New Big Pipe At this point you should be elated. You're through the worst. Installing these pipes are a bit difficult, but not bad. If they are not already on there, put the O-Rings on the small pipe. Use the White Lightning grease or whatever you bought and coat the inside of the hole on the engine and the outside of the pipe. Use it liberally. A bit of WD40 wouldn't hurt either. Press it into the hole at the back of the engine and do your best to get it all the way in. This is where a small block of wood and a hammer come in handy; you can use those to tap it in the rest of the way. Do not put the rubber sleeve on it. For the big pipe, install the o-rings and lube everything up good with the grease, both the hole it goes in and the pipe itself. You will also need to grease up the end the rubber part goes on and the other end of the short pipe that the rubber sleeve will slip over. Place the tightening rings over the rubber sleeve as well. Slide the rubber sleeve as far as it will go over the pipe. Push the pipe into the hole, I found a twisting action worked well. I also used my metal screwdriver against the bottom of the engine bay as a lever to slide it in the rest of the way (it required a lot of pressure). You then need to rotate it to line it up with the short end of the pipe. You'll slide the rubber sleeve over it and then tighten up the two rings. NOTE: Be sure to rotate the rings as far down as possible so that the screw does not interfere with the three pipes you're about to place on top of it. The new big pipe should be in place, and you're now done with the hardest part of this job. Step 16: Install the Three Pipes You'll want to put the lid back on the coolant reservoir (replacing the seals Porsche included with the kit), reattach the pipes and tighten up the screws. DO NOT OVERTIGHTEN THE SCREWS. I snapped one clean off. Make sure they're tight, but don't put all your muscle into it. Once on, you are ready to slide those pipes in. You do not need to put the lower bracket at the back on first; I did it after installing the pipes. Again, make sure everything is lubed up well so that any points of friction are well covered. Slide the pipes in. I used by long screwdriver again as a lever to apply the necessary pressure. On both these pipes and the big pipe it looked like I could have gone another 16th of an inch, but nothing leaks so I guess it was far enough. Put the bracket on at the back before you attach the hoses. You'll use your locking pliers again to attach the compression rings. With the bracket in place it is obvious how far up the hoses go. You'll put the upper bracket on, using the spacers for the screws and screwing it down tight. Don't forget to attach the two brackets that hold that electrical cable in place. Not a big deal if you do forget. Step 17: Install Final Pipe Now install that skinny pipe. This one is easy. Don't forget about the small compression ring that goes at the far end. Everything else just clips in. Step 18: Assess Your Work Look over everything and make sure it all looks right. At this point you should have a sealed coolant system. Check all your connections and make sure everything is solid. At this point you're home free, and you should be feeling pretty darn good. Step 19: Fill Up Coolant I use a 50/50 water to coolant ratio… so I mixed everything up with what I had and filled up the coolant tank. Once it was full, I left it overnight and checked in the morning for any fresh coolant. I was totally beat from a long day of working on it and thought putting everything back together fresh in the morning was a good idea. Step 20: Put Everything Back Together You tore it apart, now put it back together. I cleaned everything as I went, so now my engine looks great and I think that's a good idea. You don't need to go overboard, just use some lightly damp, lint free rags and wipe everything down. Porsche should have also provided new seals that go on the bottom of the intake manifold. I replaced mine dutifully, and I am glad I did. The old ones just looked worn out, no way they weren't leaking. Putting everything together is pretty straightforward once you've taken it apart. Just be careful and make sure you get all electrical connections and hoses in back on securely and in the right places (hard to mess that up). Also make sure you remove every bit of masking tape as you go. Final Thoughts I am very, very glad I did this project for two reasons. One, it saved me a ton of money and two, I now know tons more about the engine. Doing this project means I could replace my fuel injectors, spark plugs, injection coils and a host of other things when and if I have to. I know where the throttle body is, and if it's sticking I know where to go to clean it. If I need to replace the starter, I know where it is and how to get to it. I can now take my car on trips without fear of a massive coolant leak. This was the last "major" Cayenne defect for me that needed to be fixed. The water pump & drive shaft were already replaced. With 116,000 miles, I have quite a bit of faith in my car not having a catastrophic failure (knock on wood). At the end of the day, I'm pretty proud of myself for getting this all accomplished, and I hope I've saved some other poor soul a ton of time by writing all of this down. If it does help you out, please reply to this post and let me know.2 points

-

On occasion during the most humid months of the year, the air coming out of the vents of my nearly 8-year-old car would smell a little 'off.' Since the a/c condensation was draining just fine and the odor wasn't ever-present, it wasn't a major concern to me. However, surfing the web I found a variety of A/C refresh kits that seemed worth a try, if for no reason other than to experiment and see if it was any benefit. But, no good deed goes unpunished. There are a variety of kits out there, some seem OE but most are aftermarket. I found them to have so much in common that I began to think they were made by only one or two manufacturers. The kits I was considering are two products: 1) a foaming spray that you inject into the evaporator housing through the condensation drain, and 2) a spray that you empty into the external air intake while changing the HVAC settings. The kits state or imply that they will clean the evaporator of crud that comes from dirt, mold, mildew, etc. and kill whatever causes odors in the venting. As I mentioned, the kits seemed nearly identical to each other so I bought one based on convenience at a local parts supplier for about $18. For another point of reference, there is a Toyota kit, part number 00289-ACRKT, that you can find here for instance. The product I used was the following: Note: This attempt to clean an HVAC system was for my particular 2003 986S. Other vehicles may be different and there are safety risks involved in doing mechanical or electrical work on a vehicle. What's presented here is a general overview of my DIY project, not a complete step-by-step set of instructions. Please obtain, understand, and follow the necessary repair and installation procedures in order to work safely, avoid damaging anything, and achieve a safe result. Preparation steps: I raised the vehicle up onto four(4) jack stands. Then I loosened or removed numerous underbody panels to expose the area under the passenger side floor pan. The location of the condensation drain is identified by an arrow in the photo below: First use the larger can of "evaporator foaming cleaner." You can read the instructions on the can in one of the photos above. I had to use another piece of tubing between the tapered nozzle and the condensation drain because the drain tube is not flexible and wouldn't hold the nozzle. That should have been the first indication to stop. Notice the grommet around the drain tube in the photo above and how the tube is inconveniently situated between the hot water supply/return for the heater core. As I was trying to force the tubing onto the drain, I pushed the drain tube and grommet into the passenger compartment. I knew it was going to be a pain to put it back, and it was. I had to remove the umbrella trim along the passenger-side door threshold, loosen the floor carpeting, and shove my arm under the carpet to reinstall it. Photos of the attachment and foam injection below: The foam went in, it seemed to sit for a while, it liquefied a bit, and then it drained out. The photo below was taken at a moment just as it was starting to drain: The liquid in the bucket was mostly clear, with a little particulate matter--nothing worth photographing. It didn't have much of a smell; it was slightly medicinal, like disinfectant. Following the instructions on the can, the next step is to use the "a/c intake refresher." Take out the pollen filter and spray into the air intake. You are supposed to change the vent settings between spraying intervals so that the mist runs through different duct work. Again, it has a slight disinfectant smell--pleasant but not flowery and not too strong. Not too bad, right?... Well, I was too preoccupied with the camera to realize what was happening inside the car: After all the effort for something that wasn't really necessary… I had to laugh. I was doing this process as I was preparing the car for winter storage. It was about 40° F (4° C) in my garage. Obviously, a lot of the foam didn't liquefy and drain. If I were to do this again, I would warm up the HVAC system beforehand, or just do the whole process at a higher ambient temperature. I'd also let the evaporator core drain longer (a lot longer) before doing the 2nd can. The photos above are the worst of it; only a little came out of the other vents. I blasted the system for a long time after that and it cleaned up without a problem--no damage to any surfaces. A few days ago I fired up the car for the season. No issues. Live and learn and pass it on. --Brian2 points

-

1.) Un-screw the one phillips head screw at top center of side air intake... 2.) The molded air duct and the intake grill are still attached by three delicate plastic tabs at the three points... The best way to remove this is gently insert your fingers through the grills into the intake at the points circled in red and gently try to free the tabs... All three points come forward towards you, but if one is stuck or gets caught it will break... 3.) Inside the drivers side air duct you will find a snorkle... The snorkle is added to most US cars for noise restrictions. Now this piece is attached by no screws or tabs, but it most likely will give you some troubles removing... The best way is to remove this, just grab a hold of the long snorkle (not the small dish on the end)... Now wiggle it from left to right and vice versa while pulling out towards you. This works, but might take a little effort. 4.) This is what the intake is going to look like after the snorkel is removed... Just carefully insert the three tabs back into their points... Make sure that all three are tightly in by pushing the airduct cover (not the grill)... Insert your 1 screw into top center of cover and you are done.2 points

-

Be sure to use some protective material on the mirror base. Set the pliers with the protecting parts to the windshield to the diameter of the mirror base and secure to the mirror base. Turn the rearview mirror through 90 degrees at the mirror base using the pliers. Then, unclip the base of the interior rearview mirror from the retainer plate on the windshield. When you reinstall the mirror be careful not to go beyond the 90 degrees locking point. If you remove the mirror base from the windshield you will need a special cleaning/glue kit from Porsche to reinstall it.2 points

-

1 point

-

Remember the new ride height will be 10 mm lower than the stock height - plus the springs, struts and swaybars will all be firmer than the stock items. As I said before another option PSS-9 (adjustable) Coilovers - likely easier to find as either OEM or aftermarket.1 point

-

1 point

-

I have a '99 Carrera and I'm struggling here... I just replaced the gas filler vent valve and I was still having trouble filling. I did a search and read about re-installing the reed sensor. I pulled the fender liner and vent valve, but I can find the reed sensor anywhere. Where is the connector for the sensor? There are no loose wires anywhere to be found and I didn't tuck away or see anything dangling when I removed the original vent valve. I find this so strange.1 point

-

I put it in my 2004 Turbo Cab and it works great. plug and play though playing content through your iphone is not as loud as the normal stereo... you don't have to purchase the NAV card; you can use apple carplay... works a treat. Hope that helps.1 point

-

Still Fighting the misfire, local shop checked some things and found that my battery cable, the bolt that goes through the fire wall and starter / alternator cable needs to be replaced ( starter also ) before they go farther with diagnostics. $720 for diagnostics and $4000 to replace above parts (parts included) Payed for diagnostics and did all work myself. Still same problem - misfire on cyl-1 and sometimes on 3 ( misfire on 4 was just loose coil from my sloppy install ) work in progress 😞1 point

-

I replaced the crankshaft position sensor and so far, seems to have fixed the problem. The engine has started a lot quicker when cold and when warm. One of the easier jobs I have done on this vehicle. Although I do have one of these lifts I purchased about 8 years ago, it sure helps a lot (made in Germany): Scissor lifts WWW.TWINBUSCH.DE Scissor lifts1 point

-

Just to close this thread. The alternator died sitting on a shelf for 6 weeks while other work was being done. A new alternator fixed my issues. I hate when something goes wrong simultaneous with other issues.1 point

-

1 point

-

1 point

-

1 point

-

I came across this old post in a Google search and thought I'd provide an update. The Porsche part number for the adjustable linkage is 986-424-931-06 and is available from Pelican Parts for about $250. Numeric Racing makes an all-metal version for $130. The adjustment procedure for the adjustable-length linkage is available in the Porsche OEM Service Manual.1 point

-

You need a Porsche specific scan tool to see the faults, something like the Durametric system or a PIWIS system, no other scan tools will be able to see the faults.1 point

-

1 point

-

1 point

-

1 point

-

The valve lift system, like the Vario Cam system, are hydraulicly operated using the engine oil pressure network. One of the biggest problems with all of these systems is that they were designed with very small oil passages, making them very susceptible to problems with particles of debris in the oil blocking the passages. The fact that you found debris in the valve lift screen points to where the issue probably lies.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Recently ran into this issue as my mirror fell off. (Thankfully it didn't break.) For those to whom this happens, the method above will not quite work. If your mirror falls off (with the base attached), clean the residual glue off and identify the metal circular base, which extends about a .25 to .125 from the base. For tools, I used a crescent (vice) wrench like the one above pictured. I also used channel locks, a microfiber towel, and (importantly) gloves. Last thing you want is the tool to shear off and bang your hand up. Attach the crescent wrench to the metal base. Wrap the microfiber towel around the mirror base housing and get the channel locks affixed. Twist the metal base COUNTERCLOCKWISE 90*. This will unlock the metal base from the mirror base housing. Acquire some glue (I used the 3M high bond adhesive), clean the working surfaces and reattach. Done.1 point

-

Hi, I am new to writing posts in forums so be gentle…. I will try to add as much relevant information as I can. Firstly I would like to thank some of the other forum members who have helped me so far to try and diagnose the problem I am currently having. I amongst others I have read: https://rennlist.com/forums/cayenne-955-957-2003-2010/1056770-kessy-unit-drain-my-battery.html https://www.renntech.org/forums/topic/37055-keyless-kessy-entry-problem-fixed-after-5-dollars-and-1-hour-o/ Although these posts have helped me to narrow down what the issue I am having might be, they haven’t solved the power drain problem I am having. My troubles started a few months ago after buying a 2003 Porsche Cayenne Turbo 955. The car is low mileage for its age (74k) but is suffers from a flat battery after standing for roughly 2 days. The previous owner used to keep the car on a constant trickle charger stating “These old cars all have flat batteries after 1-2 days”. I knew that isn’t true but as someone with previous experience with parasitic power drain issues with cars I didn’t get too worried about the problem. The battery on the car is new (bought by the previous owner, it’s the correct size and I have a receipt to prove its age!). Things I have done so far: · Used a battery tester to fully verify the battery is good. · Pulled fuses to confirm which fuse was the culprit. I did this after connecting an analogue ammeter between the battery and the car. After waiting for the initial current spike to calm down I found that Fuse 41 (KESSY) on the left hand side fuse panel was causing a 2 amp draw. After removing the fuse the current draw dropped to almost nothing (that I could read using the analogue readout). · After finding out that Fuse 41 was the culprit I removed the fuse and wired in a remote control relay as a temporary fix to stop the power going down when the car is not in use. o This “bodge” solved the power drain problem, however it’s not fixed the original issue, it’s just a sticking plaster! o After reading another post it was mentioned that the KESSY transmitters/receivers which are in the doors and the bumper can cause a parasitic power drain where that’s a faulty unit. I have since removed all of the KESSY units from the car and…. No luck. o I had a quick look today to see about replacing the KESSY ECU itself but it looks like a pig to get to (it’s above the driver side foot well) there is a thick as your arm wiring loom coming from the bulkhead going right underneath where you could remove it. So I am not keen on replacing… also a call to a Porsche main dealer mentioned that they have only sold a handful of replacement KESSY ECUs so they suggested that’s unlikely to be fix the issue, however I'm not sure. I am now completely out of ideas. Anyone else had a similar problem(s) who could offer some advise? Thanks very much in advance, Chris.1 point

-

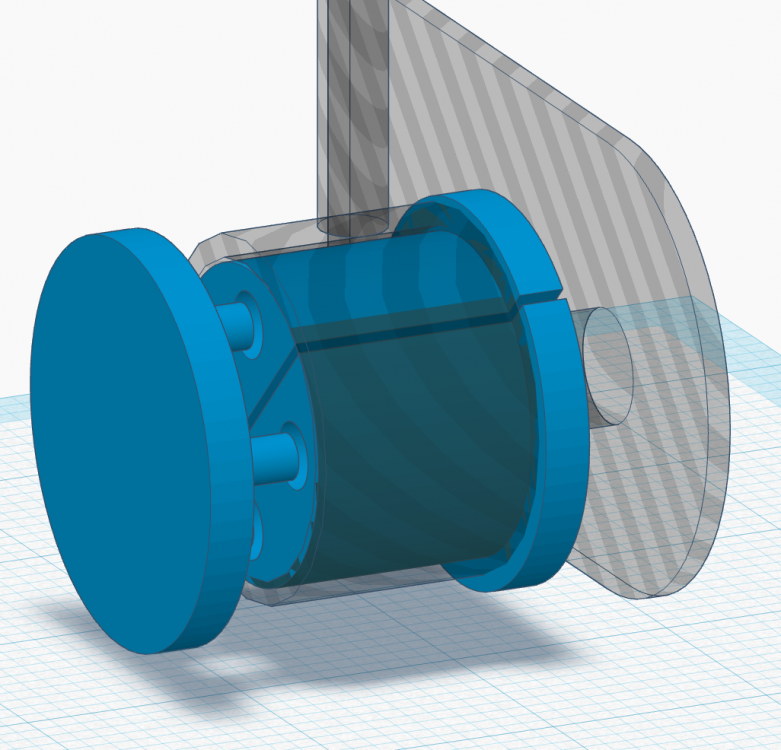

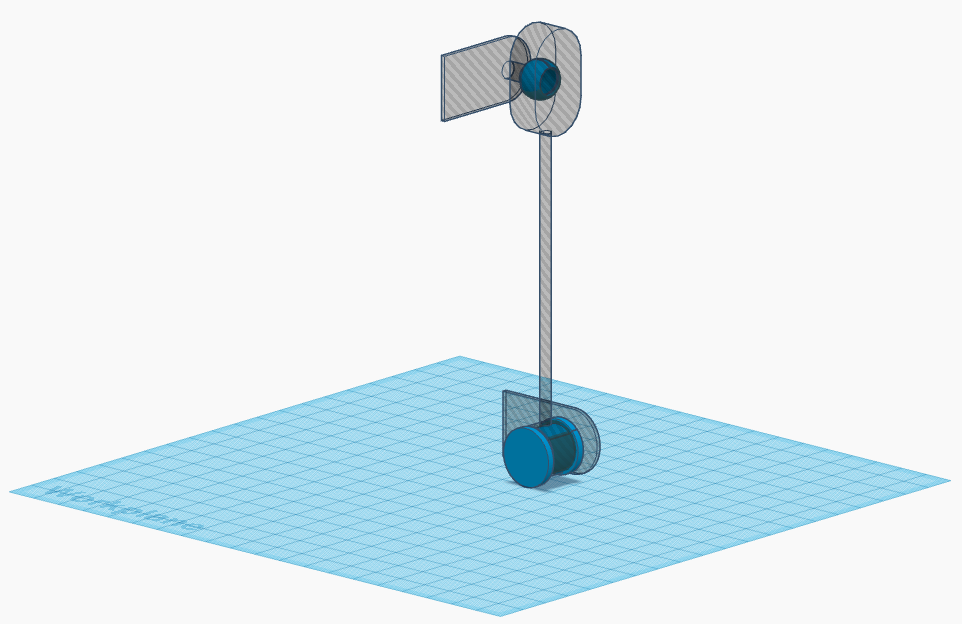

The RHS rear window regulator on my 02 C4 Cab broke last week too. Above posts were helpful to get this thing out and in quickly. My remaining problem was that I had that quick replacement for the broken regulator was not as simple as I thought (not much supply on intact used items, and rebuilds will take at least a few days back & forth). Short on patience, I analyzed the technical problem itself it turned out that the upper roll and rear string guide were compromised ((cracked in two pieces and missing at all resp.)). I ended up making a custom roller and guide from some old in-line skate-type rollers (yes, including one ball bearing) and another Polyamid block for the guide. The rest was some filing / cutting (I had a lathe to cut the string grove , but otherwise I used hand tools), and after about two hours later, I had the roll-arch-drive back to life assembled. The drive runs very good, and I think the bearing is a real upgrade to the drive, and possibly will outlast many other bits on the car. Since it was really no big deal to get this fixed much quicker that ordering anything- here a few pictures for those who may consider a DIY - fix of the drive parts as well. iH1 point

-

The MY05 Carrera Owners Manual is now online and available for download. You can download it here (special thank you to Viken) (corrected link)1 point

-

OK. With a "little" poorly documented and explained help from this forum I managed to remove my right rear window regulator from my 2003 Carrera 4 Cabriolet. I am going to provide as many pointers here as I can to make this effort much easier on the next DIY mechanic. Thoroughly read this and other forum posts first. Convertible top needs to be down or in the service position. Remove rear seat cushion, rear interior panel and rear window trim piece as described in this post or others. Rear seat back should be in the up position. For removal of the regulator itself...The total of number bolts and or nuts to remove is 9 (13mm) (possibly 2 more(11mm) if your window is stuck in a down or partially up position). For total of 11. (2) 13mm nuts - Convertible top hydraulic piston; (1) from the rear piston mount point and (1) from the front piston mount point. (3) 13mm bolts - Seat belt pillar; (2) from the face of the pillar and (1) from the top of the pillar where the seat belt loop is mounted to the pillar. (remove the loop and seat belt pillar insert to allow regulator to eventually be removed. (1) 13mm bolt - center of the convertible top support bracket; this is required to allow the bracket to be pried away from the pillar (see 30mm block of wood) to create clearance for the regulator to be removed. With a pry bar of some kind you should set the block in place at this step. (3) 13mm nuts/bolts - window regulator mounting points (recommend removing these last); (1) nut at the bottom accessed by removing a rubber plug; (2) each at the top; (1) one rear and one front. For the rear remove a styro foam plug to access with socket. For the front; if the window is in the fully up position access through the aligned opening in the convertible top support bracket. (IMPORTANT) If the window is stuck down or partially up this front bolt/nut is not accessible. The window blocks access to it through aligned opening in the convertible top support bracket. Follow these steps... you will need to use a goose neck closed end 13mm (6 point) wrench; loosen and remove this bolt/nut. Place or stuff a rag just under this nut/bolt to prevent it from falling to the bottom of the body cavity should you lose a handle on it. remove rag, regulator should now be free to move upward but not out all of the way out BECAUSE the window (still attached to the regulator) CANNOT clear the seat belt pillar. move the window and regulator upward sufficiently enough so the window mounting nuts (the (2) additional 11mm noted above in item 1) are accessible with the 11mm socket; loosen to free the window from its regulator seat. (be careful not to scratch or break the window by applying to much force) Carefully remove the window from the regulator and you will now have sufficient clearance to remove the regulator from the car. Remove the regulator by pulling it up first (free the bottom mounting bolt from its bracket) and then towards the rear (got to get the motor to clear the body) then straight up. Take it slow. It will come out. Good luck. Its not really that difficult once you see what needs to be free.... and the window itself is out of the way.1 point

-

Hi Everyone, Well, I finally managed to purchase my first Porsche - a 2004 Turbo Cayenne with 86k miles and most of the normal out of warranty work already done (coolant tubes, cardan shaft, etc) and am thrilled to be a member of the Porsche community! Prior to purchasing it, I read through many articles on Porsche ownership to get an idea of normal problems and remedies. Renntech has been a treasure of information and I would now like to give back a little bit to the community. The dreaded CEL arose after 2 months of ownership and I took the CTT into O'Reillys (thanks O'Reillys) to get a fault code read out. It showed that my passenger side pre-cat O2 sensor was bad so I order a new one and proceeded to read through as many DIY articles as I could find on the topic. This one and the one on Pelican Parts were most helpful and are what I used as my basis. My initial plan was to remove the inner wheel well per sswong98"s good details above. I started down this path, took off the wheel and decided to take a peek underneath before removing the wheel well simply to assess how much room I had to work with. To make a long story short, I ended up being able to remove and replace the O2 sensor within the very confined space given and without removing the wheel well. In all, it took 90 minutes after jostling about quite a bit and trying different tools. I thought this might be another alternative of value to offer to this community so I'll describe it briefly here. 1) Follow SSwong98's steps of: a) jack up vehicle B) turn wheels right to wheel lock c) remove front passenger tire d) remove 02 sensor electrical connection at firewall. At this point you can see how much room I had to work with between the body, suspension, etc. The photo with the end of the 3/8 ratchet extension shows where to view and then subsequent photos show the amount of clearance and the 02 sensor. Basically, I was able to use a 22mm open ended wrench and get it into the space shown in the photos. Lying on my back, I was able to get the wrench between the suspension and inner wheel well and break the 0@ sensor loose. Once I had it broken loose, I could use my fingers to unscrew the O2 sensor, again lying on my back and from underneath the vehicle. Unscrewing the )2 sensor was not difficult but took about 5 minutes as I could only turn it slightly, then re-grip the sensor so that the wire did not cause it to screw back in, and then continue this process until it was removed. I could have also cut the sensor wire which would have eliminated some of the torque produced by the wire and made it slightly easier to unscrew the sensor. Once the sensor was out, I removed the original heat shield from the original O2 sensor wire by cutting it lengthwise. My goal was to reuse it on the new sensor. I then drilled 4 small pilot holes on both side of this heat shield (sorry, forgot to take photos) and placed a pop rivet into each in order to have it hold in place around the O2 sensor wire. The most challenging part was getting the new 02 sensor started into the mounting hole. I dropped the sensor in from the top of the engine and was able to locate the sensor quite easily. I was also able to reach up from underneath the vehicle, grasp the sensor with a thumb and finger and get the O2 sensor into the mounting hole. However, once again, the sensor wire created a torque that prevented me from being able to start the sensor correctly into the threading. After trying various options for 5 minutes, I called in the calvary... I asked my son to hold the sensor wire from the engine bay side and to turn the wire slightly in a clockwise manner so that the sensor wire torque worked in my favor. I also repositioned myself so that I could get a much better grasp of the sensor. Instead on lying on my back looking up at the sensor, I sat down in front of the caliper and was able to reach the sensor through the same opening as before. While I could not see the sensor, I had it placed into the mounting hole from before so all I needed to do was to get it to start threading properly. In this seated in front of the caliper position, I was able to much more easily grasp and turn the sensor and got it threaded within a few seconds. At the same time, I told my son to slowly keep tuning the sensor wire. Once the sensor was hand tight, I used the 22mm open ended wrench to tighten it. All told, it took about 90 minutes from wheels up to wheels down. Some other notes: I ordered the special O2 sensor socket from Pelican (same one shown in SSWONG98's write up) but, very oddly, could not get enough room from the top or bottom to be able to get it onto the sensor. Removing the inner fender well would have helped here. I also would suggest getting a stubby 22mm open ended wrench as this would allowed more freedom for movement. The one I had was about 14 inches long. I also had a line wrench (shown in one photo) that was a bit shorter in length and worked very well. Well, I hope that this is some value to this great community1 point

-

1 point

-

Well... I replaced the hinge on the center console today. After reading all that was available, I went with doing it without removing a lot of stuff like the TSB. All done sitting in the back. Not hard to do. You will have to take a hack saw blade and cut off the unbroken hinge collar, then file both spots till they are flat. The U shaped rivet supports take a needle nose plier to put in place. Knock the shaft out from right to left. Vacuum the aluminum curlies out after you do the drilling.1 point

-

1 point

-

1 point

-

Changed the master clutch cylinder and the noise is gone. Thanks for all of your comments. Carrera3.2, When I did the clutch/flywheel, I also replaced the: - IMS bearing and flange with LN Engineering upgrade - All 3 cam chain tensioners - RMS - AOS - Water pump - LN engineering Low Temp thermostat - Slave cylinder - Clutch master cylinder - Sparkplugs and all 6 coil packs - Cardan Shaft (the rubber guibo on my original shaft was cracked) - Coolant reservoir tank and cap - Changed Trans and front diff fluid - Changed oil and filter Hope this helps. If I can think of anything else I did, I'll add to the list. My car drives amazingly well now. Britt1 point

-

You have no Range 2 over revs - you can not ask for better. Range 1 over revs were caught by the rev limiter and don't mean much since the rev limiter protected the engine. Range 2 are the bad over revs.1 point

-

1) Heat is not bad. If your car were actually running at 185 you would be perfect. If you were running at 160, that would be bad. The motors are designed to operate at peak efficiency of about 180ish. 2) By "Government", do you mean this and the 11 other states with strict state standards? Or the federal government with weaker standards? They're both irrelevant. All the motors in this country and I believe the world, run at the same temp as your motor. 3) The theory is that Porsche actually thinks they have to run these motors at 210 to pass emissions. So you don't freak out, they jigger the gauge to read a false 180ish when it's actually 210. 180 is good. 210 is to hot and shortens the life of the motor. Little do they know, so the "160" theory goes and as I understand it, they could actually run them at a true and safe 180 (with a 160 thermostat), add years to the life of the motor and, still pass emissions. And so by extrapolation, after some 20 years developing this motor, they haven't figured that out yet. So the theory goes. Regards, PK1 point

-

I found it......if anyone wants to know....it is directly underneath the driver side intake "plenum".....with the line going into the the intake, right after the throttle body towards the passenger side of the car.1 point

-

Thank you so much for this, I have had a compressor replaced (under warranty) and expect another before I am thru so this will help avoid that. Also look out for the struts on 04's, I had one blow up, that was expensive. Mike1 point

-

Wow, this is one from the past. Use some caution when dealing with a stripped drain plug as they are made of some pretty soft metal. I was just finishing up an oil change and when I attempted to torque the bolt its head split. This happened before I was near the torque specs. With half the bolt head broken off it makes getting the remainder off a little tricky. :)1 point

-

Thanks dmcole for the write up, great job. I would like to incorporate my photos to your words. I hope I don't butcher it. When putting things back together I did something a little different as my light switch did not have enough wire length. First things first: 1) Completely disconnect the battery. I can’t prove that total disconnection was necessary, but I also didn’t have the alarm go off suddenly. Better safe than deaf or shot by the neighbors. 2) Remove the rubber gasket around the ignition key. I could pull mine off just using my fingers. 3) Remove the left hand vent. There’s a nice writeup on this already; so I won’t repeat all of that here. http://www.renntech.org/forums/index.php?a...ost&id=6617 Here are the basic steps from the link: Insert narrow screwdriver into hole under the switch. Turn blade up, not flat. Here is what it looks like from the backside. Remove 3 screws from the above areas. Give a gentle pull from the top. mine was a little stuck. Disconnect plug connection, I had to pry with a screwdriver as my wires were not long enough to let my hands get behind the vent. keep this in mind as we get to the end of this DYI. 4) Once the vent is removed, remove the screw straight in the back back that holds the vent tube in place. 5) Now reach or crawl under the dash and remove the center horizontal vent tube under the steering column and the vertical one you just freed up in the step above. 6) Put on a long sleeve shirt. After working through the vent hole for a couple of hours, my forearm is pretty beat up today. I’ll save you the same realization… You’re now ready to start working on the issue at hand. 1) Reach to the back and disconnect the wiring harness from the ignition switch. It just goes straight off the back; no special clips there and don’t twist it. Looking through the vent hole A little closer look. 2) Remove the immobilizer. It’s the black box on top of the steering lock housing. Unclip the little wiring harness on the front right. This one has a little catch on it so don’t just pull it out. There is a little plastic Phillips head near the key that you give a quarter-turn. Mine had ‘wings’ on the Phillips head that I could turn by hand. Once you’ve turned this, slide the immobilizer straight toward you along the top of the steering lock housing. That will free it up to remove. Here is what it looks like removed. 3) Remove the key cylinder. Around the key hole is a silver beauty ring. Around the edge of that ring is a small hole. Make sure the hole is near the 7 o’clock position instead of near 1 o’clock. Mine had turned 180 degrees at some point and made this cylinder removal impossible until I figured that out. Insert your valet key (it’s just easier, but your regular remote key will work) and turn to position 1. Now stick a straightened paper clip (I used one of the larger, sturdier clips instead of a standard one) in as far as it will go. The cylinder should virtually fall out if you’ve done this right. If you’re having to tug on the key to pull it, try again. Carefully disconnect the electrical clip from the key cylinder. Leave both the key and clip in the cylinder and set the thing aside. My switch was in the 1 o'clock position when I started but went back in at 7 o'clock position.??? 4) Disconnect the steering lock housing mounting screw near the key. This requires the same Torx bit you used to remove the side vent cover. I didn’t have a stubby Tork driver; so I clamped the bit into a pair of needle-nose Vise-Grips to get it loose. Once loosened, I could unscrew it by hand. Once the screw is out, swing the vertical mounting strut up and out of the way. 5) Disconnect the mounting bolt next to the steering column. A small 10mm ratchet worked for me. I didn’t have to put a wrench on the nut, but I had to use a bit of hand work to finally get the nut off and the bolt out. 6) Remove the steering lock housing. The trick here is that there is a spring-button that locks the housing into the steering column. You can see what you’re up against by looking at your replacement part. You depress the spring through a small hole on the steering column. I used a 2mm allen wrench to depress the button so that I could wiggle the housing out. Now you need to prep the new part. 1) Remove all of the clips from the old housing and attach them to the new one. There is a metal clip that secures the mounting screw near the key hole and two plastic wiring guide clips. I removed the plastic clips by punching out the center pins from the bottom (they are small and actually come completely out; don’t lose them) and then carefully squeezing the prongs until the clip came off. Attach them to the new part. 2) Put a little lubricant (just a light surface wiping, nothing more) on the housing surfaces that insert into the steering column. Install the new steering lock housing: 1) If the shiny silver steering lock ‘spear’ is extended from the housing, use a large flat blade screwdriver in the center of where the key cylinder would go and simulate turning the car on. This will retract the spear. 2) Insert the end of the housing into the steering column. This was the hardest part for me. I don’t know if the new part was just thousandths of an inch bigger or what, but it was 20 minutes of wiggling and jiggling that thing to get it in. Don’t forget that you will have to depress the little spring pin once it gets to the flange. I wasn’t sure I heard the spring pin pop into place in that hole; so I crawled under the dash to inspect it to be sure I seated the thing completely. 3) Replace the mounting screw near the key hole. By the way, I never replaced the 10mm bolt at the steering column. I couldn’t figure out how to restart the nut on the bolt, plus with that spring pin engaged, I can’t see how the housing could ever come out under normal use. 4) Reconnect the wiring harness to the ignition switch in the back. 5) Reconnect the immobilizer and its wiring clip. 6) Push the key cylinder in firmly (aligning it in the little guide on the top left of the steering lock housing) and pull the paper clip. It should be secured. Remove the key. Reconnect the tiny wiring clip to the key cylinder. 7) Reconnect the battery. 8) Start the car at this point to ensure that you’ve done everything right. If the car won’t start, something didn’t get reconnected properly or you have a different issue. Note: it is not necessary to have the headlight switch reassembled to start the car. If the car starts at this point, start replacing the rest of the stuff you pulled out. Start with the vent tubing. It was helpful to loosely attach the vertical tube with its screw before reconnecting the horizontal tube underneath. Once done underneath, tighten the vertical tube and replace everything else. Be very careful with the headlight switch reattachment as that lighted ring looks pretty fragile and the little bulbs have to fit exactly right into the plastic ring that covers it. Start ‘er up and hope that the new part is a thousand times more reliable than the one you replaced. Additions: Below are a couple of steps that I went through to put back the vent and light switch back together. I removed the switch from the vent and attached it back onto the plug. Insert the switch through the vent assy and twist to lock into postion. make sure that you connect the remaining ring plug and replace vent and screws. reattach the ring and put the nut and knob back on. now go get some Band-Aids to cover your banged up knuckels. :lol: BTW the part cost me $135 but if you plan in advance you can get much cheaper at Sunset Imports. I am not sure what I would have saved in labor. It was a fun project that took me a bit longer due to photos and dinner. (4 hrs) Enjoy, Halo1 point

-

td: Bank 1 refers to the side of the engine with cylinders 1, 2, and 3 on a 6 cylinder car. On a 996, that side is the driver's side. (Boxster engines are turned around 180 degrees, so bank 1 on those is on the passenger's side). Regards, Maurice.1 point

-

Hi, yes Mobil 1 5w-50 is the only SAE50 viscosity lubricant Approved by Porsche. It is an excellent lubricant with a long history. It ia available in most Countries except the USA Mixing most Mobil 1 products to achieve a "supplementary" viscosity can be done without the risk of loosing the benefits of the overall base fluid/additive package There are two exceptions to this however. M1 0w-40 and M1 Turbo Diesel Truck 5w-40 (non Approved) should not be mixed with other Mobil 1 lubricants if you wish to retain their unique and quite sophisticated formulation I use the "parent" of M1 TDT 5w-40 - it is a Commercial lubricant called Delvac 1 5w-40 Regards Doug1 point

-

1 point

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)