Welcome to RennTech.org Community, Guest

There are many great features available to you once you register at RennTech.org

You are free to view posts here, but you must log in to reply to existing posts, or to start your own new topic. Like most online communities, there are costs involved to maintain a site like this - so we encourage our members to subscribe or donate. All subscriptions and donations go to the costs operating and maintaining this site. We prefer that guests take part in our community and we offer a lot in return to those willing to join our corner of the Porsche world. This site is 99 percent member supported (less than 1 percent comes from advertising) - so please consider an annual subscription or donation to keep this site running.

Here are some of the features available - once you subscribe RennTech.org

- View Classified Ads

- DIY Tutorials

- Porsche TSB Listings (limited)

- VIN Decoder

- Special Offers

- Paint Codes

- Registry

- Videos System

- View Reviews

- and get rid of this welcome message

It takes just a few minutes to register, and it's quality Porsche information at a low cost.

Contributing Members also get these additional benefits:

(you become a Contributing Member by subscribing or donating money to the operation of this site)

- No ads - advertisements are removed

- Access the Contributors Only Forum

- Contributing Members Only Downloads

- Send attachments with PMs

- All image/file storage limits are substantially increased for all Contributing Members

- Option Codes Lookup

- VIN Option Lookups (limited)

Leaderboard

Popular Content

Showing content with the highest reputation since 01/09/2025 in all areas

-

If the oil cap is hard to remove, you have a high vacuum level in the sump, which is bad for a variety of reasons, including lean stalling. The correct way to access the AOS is to fully warm up the engine by driving the car for 10-15 min, then replace the oil cap with the one in the picture above with a hose that connects to the digital manometer. If the vacuum level exceeds 6-7 inches of water vacuum, the AOS is leaking air into the intake system, causing the lean stall conditions. The normal level of vacuum is typically 4-5 inches of water, which is a really weak vacuum level, so it doesn't take much of a leak to cause problems, which is why we always checked every car that passed thru the shop with the manometer.3 points

-

2 points

-

Welcome to RennTech If you do not have access to a wiring diagram for the vehicle, probably the easiest way to check the ground is to pull the bulb in the light and use a multimeter to check the condition of the ground at the bulb socket.2 points

-

We have used them here in the US for years at MUCH colder temperature's than you get without ANY issues. Put on the adaptor, add external magnets such as the Filter Mag, and enjoy both better filtration and peace of mind.......2 points

-

Welcome to RennTech The factory radio had a ground wire that had to be attached to the car's chassis under the dash as a simple anti theft device. If that ground is not there, the immobilizer will prevent the car from starting.2 points

-

I recently replaced the coolant pipes in my car. I needed to do the job myself because there was simply no way I was going to shell out anywhere from $1500 to $3500 in labor to have it done by the dealership or an independent shop. Plus, having read about the job, I knew they would be tearing through a ton of stuff and I really feared the "oh, it also needs this" scam. I did a LOT of research on the various forums before undertaking this job. Reading and printing out anything I thought was useful information. I would highly encourage anyone reading this to do the same. Fortunately, I was not in the position that the pipes simply failed and dumped all of the coolant. I just had a semi-slow leak… dropping about a gallon of coolant every two to three weeks. So, I had time to order the parts and prepare. Prior to doing this the most complicated thing I had done myself was change the oil, replacing the brake pads and swapping out some plastic bits in the car. I had absolutely no prior mechanic experience whatsoever. However, I do work in IT, and am by nature a very technical person (I'm sure every mechanic reading this just rolled their eyes). My job is troubleshooting very complex problems on very large networks, and I think that experience probably lent itself to a successful outcome here. I'm also patient, and that is critical to getting this job done. I will say that I now have a much greater appreciation for mechanics and their skill set. This was hard. I want to caution anyone reading this that this is a BIG job and it will take a long time. My goal in writing this is so that my fellow Cayenne owners can be spared a lot of the mistakes I made and be better prepared than I was. I will say I am relieved to have this done. I feel a ton better about my car now that I don't need to worry as much about some catastrophic failure hitting me unexpectedly. One rule that I really appreciated was to only place metal on metal when working (until you actually get to removing the pipes). This prevents you from breaking plastic or tearing rubber with something metal. Trust me, pay attention to that rule. I am breaking this down into tasks, because I think it's easier to follow that way. This is how I did it. I am sure there are other ways that may even be easier, but this worked for me and my schedule. I ended up working 4-6 hours at a stretch in the garage with breaks every couple of hours. Step 1: Contribute to this forum I have absolutely no affiliation with this forum whatsoever other than I am a contributing member. The advice on this forum has personally saved me thousands of dollars, and being in IT I know the time and money it takes to run a site like this. So, contribute to the cause. However, there is a second reason to contribute, and that's to get the Porsche TSBs. The TSB for this job contains some diagrams that give you a better idea how all the replacement parts go in to place, and I thought that was handy to have. As an aside, I searched some other issues in the TSBs and found answers to some things the dealership didn't even know… such as there being a $33 replacement latch for my armrest. They wanted to sell me a whole new armrest for $750. Step 2: Obtain the Parts I looked around on the Internet and called some local sources and found a dealership that provided the parts for $550, and that included two gallons of coolant shipped to my door. To me, that was a fair price, and when I received the parts I really thought it was a fair price... there's a lot of quality stuff in there. I'm sure there may be cheaper 3rd party sources. I would just be sure they include all gaskets and such that don't necessarily need to be replaced, but should be replaced if you're tearing everything apart. Once you get the parts, pull them out of the box and examine them. Look at the pics in the forum and look at the TSBs. Get a feel for what you are replacing. Step 3: Verify you have the tools I found the following tools very handy to have, and frankly, necessary. I suggest going to your local auto parts store for most of them and get mechanic grade tools. Socket Wrench 3" Socket Extension 6" Socket Extension Metric Socket Set Torx Socket Set (think of this as a "male" Torx Socket set, you will need #27 & #40) E-Torx Socket Set (think of this a "female" Torx Socket set) Screwdriver that accepts interchangeable bits (there are times this is easier than a socket wrench) Torx Bit Set (Specifically you need a #27 and #40, I just bought a set) Locking Long Nose Pliers (6" is fine, no need for anything bigger) Regular set of pliers Wrench Set (somewhat optional) Real flat head screwdrivers Very long flat head screwdriver (this came in handy a lot) Needle Nose Pliers Small Chisel Set Hammer Tin snips Safety Glasses Mechanics Gloves One of those extension things with a magnet on the end One of those extension things with a mirror on the end WD-40 Some all-purpose grease, like White Lightning Baggies to store the screws in Masking tape/Painters Tape to cover up any exposed openings Old Bath Towels (used to protect the car) Good flashlight Lint free rags Shop Vac Two gallons of distilled water Drain pan (needs to hold 4 gallons) Shop lights A small block of wood, about 2" x 4" x ¾" A radio playing energetic music of your choice Advil and Tylenol Hope and a prayer (optional but doesn't hurt) Step 4: Book the Time I know some people say you can have this job done in less than 8 hours, but being a beginner this took me much longer. If I took out all the time running back and forth to the store for tools and such, and had a guide like the one I am writing, I still think it would have taken 10-12 hours. I ended up removing all of the engine covers on one weekend night, and then doing the actual job the following weekend. I then drove the car for a week with the new pipes and finally put all the engine covers back on over the weekend (I cleaned the covers and the engine thoroughly with a damp rag at the same time to pretty it up a bit). You don't really need to do it that way, but that split the work up a bit. I work in an office in front of a PC all day; I'm not used to working in a hot garage for 8-10 hours at a time... I'm a skinny computer geek : ) When I did the work, I draped some old bath towels over the sides and front of the car to protect it. The last thing I wanted to do was mess up the paint on a zipper or with a dropped tool/screw. Step 5: Remove the Engine Covers There are really two parts to this. You have the decorative covers over the actual engine, and then you have the covers that border the engine. You'll want to remove all of the covers around the border first. There are five of them in total. They all have these little black plastic plugs that you just turn 90 degrees. They should just pop up at that point, but you might have to give them a little lift with a screw driver. While you're removing those covers you might want to pay attention to how they go together and where they slide in to place. You'll also want to remove the windshield washing fluid cap (use the masking tape to cover up the exposed hole) before you remove the cover that surrounds it. Those little things are $4.25 each from the dealership, so try not to lose them. Now you have the three silver looking decorative covers; one on each side of the engine and one towards the front middle with the engine type on it. First, you need to unbolt the two secondary air injection units. Those are the round things with the plastic covers near the back of the engine compartment. You do not need to disconnect them from anything, just unbolt them (three screws each) and then move them off to the side. It might be a good idea to get some labeled baggies to store the screws in. Once those are removed you can get to the side engine covers a little easier. The engine cover in the front middle you just lift off, just work it back and forth a little and it should pop off. Take note that there are four little plugs that fit into holes on the cover itself, you'll need to find them again when replacing it. Now remove the one on the driver's side. It's pretty easy to remove. There are four screws towards the bottom that need to be removed, and then the cover will just come off. The one on the passenger side is a bit different. You have the engine mount right in the middle of things. Assuming you have the tools, you can unscrew the engine mount and get it out of the way. That will let you get to each of the four screws easily on the cover and remove it. I wasn't so lucky here (didn't have the right tools at the time), so I just got the four screws out of the cover and ended up wedging it out. While doing that, the piece of the cover under the engine mount snapped off. I wasn't too concerned about this, because where it snapped is hidden by the engine mount. When I put everything back together I just slid it back and screwed it in. You can't tell at all that it was ever snapped in half. Step 5a: Remove Fuel Pump Fuses You'll want to check your manual (you can also download the manual from this site), but you need to remove a couple of fuses for the fuel pump. Right in front of the driver under the hood there is a small compartment. Remove the cover, and then remove a second cover to expose the fuses. Mine were fuse 14 & 15 for the fuel pump. Store them somewhere safe. Once those are removed, start your car. It will run for a few seconds and die. Congrats, you just removed most of the fuel from the fuel line. I know some people don't disconnect the fuel rail or anything, but to me that's a bad idea. I had a lot of time to try it that way and honestly I'm glad I got it out of the way. Step 6: Disconnect the fuel line The fuel line is near the back center, it's just one tube running to the fuel rail. You'll disconnect it by using a wrench and a pair of pliers. You're unscrewing the part on the left (the thin part) from the part on the right (the wide part) which shouldn't turn as it is part of that tube. Once unscrewed, the fuel rail is only connected to the manifold. A little residual fuel might leak out, so you might want to have a rag handy to wipe it up with. Use masking tape to cover up any exposed holes. It wouldn't be a bad idea to disconnect the batteries now either. I didn't, but that was probably stupid. Step 7: Remove the Y-Pipe that goes to the Throttle Body This plastic Y-Pipe is right up front so it's very easy to get to. There are two flexible pipes on either side you need to remove first; just use a screwdriver to loosen the two clamps on each of them and you should be able to compress them enough to remove them. The Y-Pipe itself is attached to the throttle body via two long, plastic bolts. They have a screw head on them but they are not screws, they're more of a key. You just turn them a bit to line the key at the bottom (use a flashlight and you'll see it move as you turn it with the screwdriver) with the slot. When it's lined up, use a pair of needle nose pillars to lift it straight out. It's plastic and may be brittle, so be a little careful. You will need to remove an electric connection to the throttle body in order to get to one of them. There is a tube connected to the bottom of this y-pipe, so you can't just lift it out. It has some give to it, but not a lot… just enough to get your hand under there once you pull the y-pipe off the throttle body. You have to press the buttons on each side of the tube in order to get it off the y-pipe. Step 8: Remove Emission Tubes & Electrical Connections from Throttle Body There are two emission tubes crossing the throttle body, Porsche refers to them as "vent tubes." I know this because one snapped in half when I removed it, and the dang thing was $130 to replace. To remove them, you just need to press the clips at either side of the end of the tube together and then pull it straight out. I don't think mine had ever been removed, and in retrospect a bit of WD-40 used sparingly here might have been a good idea. I think I used too much force and that's why the small one snapped. I have read that some people have replaced this broken tube with a more generic tube from a hardware store. I just spent the $130 and did it right. There is a third tube connected to the throttle body, you just need to remove that one end of it. You will also have two electrical connections to remove. One you had to remove to get the y-pipe off in the previous step. Just remove the second one and then you're done. Step 9: Remove the Throttle Body The throttle body is connected to the manifold via four bolts. Remove those four bolts and it will come off. You sort of have to wiggle it out because of that thin metal bracket that's holding it there, but it will come out easy enough. Some people take this opportunity to clean it. You'll probably see some gunk on the back side of it on the inside. Step 9: Remove the Electrical Connections to the Fuel Injectors There are eight fuel injectors connected between the fuel rail and intake manifold. Mine were blue plastic, and there is an electrical connection running to each of them. There is a metal clip at the bottom that you just need to press up. I placed a flat head screwdriver between this clip and my index finger, and pushed up and pulled at the same time to disconnect it. Once you remove one you'll get the trick and the rest will come right off. Step 10: Remove the Intake Manifold with Fuel Rail Attached I know a lot of people have different ideas here, some people want to remove the fuel rail independently, and that was the first way I tried it. In retrospect, it's much easier to just leave it attached. There are four screws that hold the fuel rail to the intake manifold. I would recommend leaving these alone, especially since the one at the back on the passenger side is nearly impossible to get to. These screws are $6+ each… I know because I lost one. :P There are 10 bolts that need to be undone to remove the manifold. They don't come all the way out, they'll stay attached to the manifold. Once you loosen them enough they sort of come free and wiggle around. The one at the back on the passenger side was a bear to get to. I ended up placing the Torx Socket bit on top of it using the magnetic extension thing. I then put the 3" extension on top of it, and finally attached my socket wrench to it. I kind of built it all up I guess. I then went really, really slowly and loosened it up. Once loose, make sure to vacuum up any debris on the engine. When you pull the intake manifold off you will have eight gaping holes right down to your cylinders, you don't want anything falling in there. You can now scoot it forward a bit to get to the tubes you will need to disconnect. There are two tubes at the back of the manifold… a firm one and a flexible one. The firm one is just like the one under the y-pipe, and is easy enough to remove IF you can get enough pressure on the connector. The flexible one was just kind of stuck on mine and I left it on. You kind of have to scoot the manifold forward and angle it out, but it will come out with the fuel rail attached. You may have to remove some tubes and such from their guides or brackets. That flexible tube was long enough that I just put the whole thing on the driver's side of my engine and left it there. It didn't seem to be sitting on anything that couldn't support it. I'm sure it can be removed, but at this point in the job I was tired, hot, and just wanted to keep going. Once off, IMMEDIATELY cover up the exposed intake holes with long strips of tape. Cover them completely, and make sure they STAY COVERED. Shine a flashlight in each hole first to make sure nothing fell down there. If so, get it out as delicately as possible. Vacuum up any other debris you see. You can now see the infamous coolant pipes. Step 11: Assessment At this point, you can see the coolant pipes and should be ready for the meat of this repair. The starter is right there too… right under the leaking pipes. Brilliant, isn't it? This may not be true for you, but I had an AMAZING amount of debris in here… honestly looked like a bird had built a nest. I have no idea how it all got in there, but some where at some point tons of debris got in here, and now it was all soaked in coolant. I think my coolant leaking may have been mitigated because the wet debris probably acted as a mud and sealed everything up a bit. I vacuumed it up with a shop vac prepped for a wet cleanup. Now you need to decide if you will see this repair through or not. Once the next step is taken, there is no going back, and honestly the toughest part of this job by far is getting the old pipes out. Step 12: Drain the Remaining Coolant Your first goal is removing as much coolant from the car as you can. On the V8's, there is a drain plug at the bottom of the car, but on the turbo's you won't have one. That drain plug required an allen bit that was larger than I had on hand or could even find at a hardware store. Honestly, in retrospect I wouldn't have even bothered locating it. I'm sure there's a pipe down there you could remove, but I didn't waste time looking for. I took a tip I found on a forum, and drilled a hole right in the middle of the center coolant pipe (of three) and used a siphon with a hand pump to drain out every bit I could. I repeated this process on the larger lower pipe. DO NOT SIPHON BY USING YOUR MOUTH. Coolant is dangerous, nasty stuff. Make sure there are no animals or kids around while you are doing this. WEAR SAFETY GLASSES AT ALL TIMES! Doing it this way you're going to spill a lot of coolant, but it is what it is… they've been leaking all over everything anyway. I used my shop vac to vacuum up anything I could that escaped the siphon. I've also read of people renting professional vacuum pumps to suck it all out, but again, that's more complicated than it needs to be. I did some research, and coolant is not currently controlled by the EPA for disposal, and it can't be recycled. The unofficial advice I got was to dump it in the woods and douse the area with a hose for a bit. Do not dump it down the drain or dump it where animals could readily drink it. Don't dump it in a stream. Presumably it breaks down fast enough on the ground that there isn't a long lasting effect. Step 13: Remove the Three Upper Coolant Pipes The first pipe you need to remove is the long skinny pipe with three connectors. This one is easy enough to remove, and you should have a replacement as part of the kit. One of the connectors broke off in the hole, and I had to very carefully remove the pieces. Relatively speaking this was easy compared to the rest. There is a compression ring that needs to be removed for the connection at the back of the engine, use the locking pliers to do that. Cover up the exposed holes with masking tape. You now have to remove the three upper coolant pipes. There is a bracket at the back of the engine holding the three pipes. There are also two clips attached (you'll be looking at the back side of them) to that bracket that just support a hose at the back (just has electrical connections in it, and it's probably already split so you don't have to be super careful). Pinch the connectors with a pair of needle nose pliers and they'll come off. You now have to remove three bolts from it to remove the upper half of that bracket. I removed two of them but couldn't get to the third without snapping the thing in half. Porsche was kind enough to provide a new one in the kit so I wasn't worried about it. You will now see three rubber hoses attached to the plastic pipes. They are held on to them with compression rings. Use the locking pliers on the rings to loosen them (they need to be squeezed together to loosen) and slip them back over the pipes. I did one at a time, completely removing the ring and setting it off to the side for safety. The locking pliers really excelled here. When using them, attempt to come at the ring from the top instead of the side, the grooves on the pliers will then secure the ring quite nicely. You might have to adjust the pliers a couple of time to get the right amount of the compression for the ring to move freely. With those ends free, I used the shop vac to suck out a lot more coolant. Once done, cover up the exposed holes with masking tape. Once those three ends are free, you'll need to free up the other ends. Here's the deal, they are probably going to break when you try to remove them, and probably going to snap off at the spot where they connect to the coolant reservoir. I twisted and pulled and sure enough, they snapped off. You can remove the lid of the coolant reservoir by removing several screws, a small aluminum pipe on top, and the rubber pipes towards the front of the car. The small aluminum pipe has a single screw that needs to be removed. There is probably a lot of corrosion here so you may need to use a flat head screwdriver to pry it out. Be careful, it's flexible enough to come out and get out of the way but just barely. There is a compression ring on each of the rubber pipes that is easy enough to get to, just loosen and slide it down the pipe. Suck out any coolant and cover the exposed pipes with masking tape. Once you have that lid out, you'll see the remaining plastic bits in the holes. It's difficult to move, but those plastic bits are just in there with pressure, they aren't glued or anything. I used a small chisel and the hammer to break them out. As I got to the o-rings I pulled on those with needle nose pliers and in one instance the whole chunk came out. I also used a lot of WD-40 to work everything out. What you don't want to do is take any risk of chiseling into the metal of the lid, so be careful. This is all about removing the plastic material. Each bit you remove gets you one step closer to freeing up enough pressure to get the remaining bit out. Once it's all clean, leave it off to the side while removing the big pipe. Step 14: Removing The Big Pipe This one is tough. Make sure you're rested, well fed, and cooled down a bit. If you're aggravated already, walk away and relax a bit. You will need to break this pipe into two pieces. I used a boring bit to drill a big hole in the top, and then used tin snips to cut chunks out until I got it in two parts. Again, I used a shop vac to suck out any remaining coolant as I went along. Really, anything will work… you could even use a chisel to break it out. It's coming out one way or the other, no need to be pretty about it. Once it's in two pieces, you can probably rotate the two halves apart. Use WD-40 generously on the ends first though, and give it a bit to work in there. Regardless, when I went to pull out the two ends, they ended up snapping off… leaving their end pieces in the hole. If you read through the three forums, different people use different techniques to try and avoid this with mixed results. This is the worst case scenario though, so lucky for you I fought through it and have plenty of advice. Assuming your pipe broke off as mine did, you will see a metal ring in each end, with black plastic between it and your car. That metal ring was an inner support ring for the original pipe and needs to be removed. This is a violent procedure. IMPORTANT: I cut up some lint free cloths and stuffed one into each end as far as I could so that any material from the following procedure wouldn't go any further. Once done with the procedure below, I vacuumed up anything I could and then removed those cloths. Again, use WD40 a LOT. I sprayed and sprayed as a worked, and I think it helped. READ THIS CAREFULLY: Removing the plastic and metal ring from each end is all about removing material. You are trying to get as much plastic out as possible. If you get the ring out first, great, but it's not 100% necessary. The plastic is what needs to come out, and you need to get it out from all around it. In addition to the plastic, there are two o-rings in there, so they are just adding more friction preventing this from moving. You'll get bits of that out as you work, and that's good. Eventually, you get enough bits out that the rest will just fall out. Use a hammer and chisel to collapse the metal ring on the top and sides as much as possible. I used to the chisel to cut in to it a bit too. Once I got it that far, I switched to the long screwdriver, hammering the end of it into the plastic over, and over, and over again. I pried as much as I could and worked out bits of material. This took a long time, but sometimes you'll get a big chunk out and that will give you renewed hope. Again, this is all about material removal. Keep telling yourself that. Every bit you get out makes this easier. Once you get enough plastic out, you'll see the metal ring move a bit as you work. This is a great sign and you are almost done. Ultimately, you should be able to pry it out with the screwdriver. NOTE: When working you want to work as much towards the metal ring as possible. You want to avoid scraping the inside of the hole where your new pipes will go. I did scrape up mine a bit, it's unavoidable, but regardless my new pipes don't leak. When you go to remove the bits closest to you, you're working somewhat blind and it is hard. This part almost broke me, but I used a mirror to check and recheck my work as I went along. Bright lights help here too. Honestly, I really can't say enough how hard this part was and how long it took in comparison to everything else. It was the part that had me the most worried, but I got through it. Once it's all out, remove the cloths from inside the pipe and vacuum a lot. Now is the time to clean stuff up too, as you're about to put the new pipes in. As a best practice, you should clean up the inside of those holes. I used some steel wool; I know some people used scotch bright or even buffing pads. I didn't go overboard with this; I just want to get any grime out of there. Step 15: Install the New Big Pipe At this point you should be elated. You're through the worst. Installing these pipes are a bit difficult, but not bad. If they are not already on there, put the O-Rings on the small pipe. Use the White Lightning grease or whatever you bought and coat the inside of the hole on the engine and the outside of the pipe. Use it liberally. A bit of WD40 wouldn't hurt either. Press it into the hole at the back of the engine and do your best to get it all the way in. This is where a small block of wood and a hammer come in handy; you can use those to tap it in the rest of the way. Do not put the rubber sleeve on it. For the big pipe, install the o-rings and lube everything up good with the grease, both the hole it goes in and the pipe itself. You will also need to grease up the end the rubber part goes on and the other end of the short pipe that the rubber sleeve will slip over. Place the tightening rings over the rubber sleeve as well. Slide the rubber sleeve as far as it will go over the pipe. Push the pipe into the hole, I found a twisting action worked well. I also used my metal screwdriver against the bottom of the engine bay as a lever to slide it in the rest of the way (it required a lot of pressure). You then need to rotate it to line it up with the short end of the pipe. You'll slide the rubber sleeve over it and then tighten up the two rings. NOTE: Be sure to rotate the rings as far down as possible so that the screw does not interfere with the three pipes you're about to place on top of it. The new big pipe should be in place, and you're now done with the hardest part of this job. Step 16: Install the Three Pipes You'll want to put the lid back on the coolant reservoir (replacing the seals Porsche included with the kit), reattach the pipes and tighten up the screws. DO NOT OVERTIGHTEN THE SCREWS. I snapped one clean off. Make sure they're tight, but don't put all your muscle into it. Once on, you are ready to slide those pipes in. You do not need to put the lower bracket at the back on first; I did it after installing the pipes. Again, make sure everything is lubed up well so that any points of friction are well covered. Slide the pipes in. I used by long screwdriver again as a lever to apply the necessary pressure. On both these pipes and the big pipe it looked like I could have gone another 16th of an inch, but nothing leaks so I guess it was far enough. Put the bracket on at the back before you attach the hoses. You'll use your locking pliers again to attach the compression rings. With the bracket in place it is obvious how far up the hoses go. You'll put the upper bracket on, using the spacers for the screws and screwing it down tight. Don't forget to attach the two brackets that hold that electrical cable in place. Not a big deal if you do forget. Step 17: Install Final Pipe Now install that skinny pipe. This one is easy. Don't forget about the small compression ring that goes at the far end. Everything else just clips in. Step 18: Assess Your Work Look over everything and make sure it all looks right. At this point you should have a sealed coolant system. Check all your connections and make sure everything is solid. At this point you're home free, and you should be feeling pretty darn good. Step 19: Fill Up Coolant I use a 50/50 water to coolant ratio… so I mixed everything up with what I had and filled up the coolant tank. Once it was full, I left it overnight and checked in the morning for any fresh coolant. I was totally beat from a long day of working on it and thought putting everything back together fresh in the morning was a good idea. Step 20: Put Everything Back Together You tore it apart, now put it back together. I cleaned everything as I went, so now my engine looks great and I think that's a good idea. You don't need to go overboard, just use some lightly damp, lint free rags and wipe everything down. Porsche should have also provided new seals that go on the bottom of the intake manifold. I replaced mine dutifully, and I am glad I did. The old ones just looked worn out, no way they weren't leaking. Putting everything together is pretty straightforward once you've taken it apart. Just be careful and make sure you get all electrical connections and hoses in back on securely and in the right places (hard to mess that up). Also make sure you remove every bit of masking tape as you go. Final Thoughts I am very, very glad I did this project for two reasons. One, it saved me a ton of money and two, I now know tons more about the engine. Doing this project means I could replace my fuel injectors, spark plugs, injection coils and a host of other things when and if I have to. I know where the throttle body is, and if it's sticking I know where to go to clean it. If I need to replace the starter, I know where it is and how to get to it. I can now take my car on trips without fear of a massive coolant leak. This was the last "major" Cayenne defect for me that needed to be fixed. The water pump & drive shaft were already replaced. With 116,000 miles, I have quite a bit of faith in my car not having a catastrophic failure (knock on wood). At the end of the day, I'm pretty proud of myself for getting this all accomplished, and I hope I've saved some other poor soul a ton of time by writing all of this down. If it does help you out, please reply to this post and let me know.2 points

-

On occasion during the most humid months of the year, the air coming out of the vents of my nearly 8-year-old car would smell a little 'off.' Since the a/c condensation was draining just fine and the odor wasn't ever-present, it wasn't a major concern to me. However, surfing the web I found a variety of A/C refresh kits that seemed worth a try, if for no reason other than to experiment and see if it was any benefit. But, no good deed goes unpunished. There are a variety of kits out there, some seem OE but most are aftermarket. I found them to have so much in common that I began to think they were made by only one or two manufacturers. The kits I was considering are two products: 1) a foaming spray that you inject into the evaporator housing through the condensation drain, and 2) a spray that you empty into the external air intake while changing the HVAC settings. The kits state or imply that they will clean the evaporator of crud that comes from dirt, mold, mildew, etc. and kill whatever causes odors in the venting. As I mentioned, the kits seemed nearly identical to each other so I bought one based on convenience at a local parts supplier for about $18. For another point of reference, there is a Toyota kit, part number 00289-ACRKT, that you can find here for instance. The product I used was the following: Note: This attempt to clean an HVAC system was for my particular 2003 986S. Other vehicles may be different and there are safety risks involved in doing mechanical or electrical work on a vehicle. What's presented here is a general overview of my DIY project, not a complete step-by-step set of instructions. Please obtain, understand, and follow the necessary repair and installation procedures in order to work safely, avoid damaging anything, and achieve a safe result. Preparation steps: I raised the vehicle up onto four(4) jack stands. Then I loosened or removed numerous underbody panels to expose the area under the passenger side floor pan. The location of the condensation drain is identified by an arrow in the photo below: First use the larger can of "evaporator foaming cleaner." You can read the instructions on the can in one of the photos above. I had to use another piece of tubing between the tapered nozzle and the condensation drain because the drain tube is not flexible and wouldn't hold the nozzle. That should have been the first indication to stop. Notice the grommet around the drain tube in the photo above and how the tube is inconveniently situated between the hot water supply/return for the heater core. As I was trying to force the tubing onto the drain, I pushed the drain tube and grommet into the passenger compartment. I knew it was going to be a pain to put it back, and it was. I had to remove the umbrella trim along the passenger-side door threshold, loosen the floor carpeting, and shove my arm under the carpet to reinstall it. Photos of the attachment and foam injection below: The foam went in, it seemed to sit for a while, it liquefied a bit, and then it drained out. The photo below was taken at a moment just as it was starting to drain: The liquid in the bucket was mostly clear, with a little particulate matter--nothing worth photographing. It didn't have much of a smell; it was slightly medicinal, like disinfectant. Following the instructions on the can, the next step is to use the "a/c intake refresher." Take out the pollen filter and spray into the air intake. You are supposed to change the vent settings between spraying intervals so that the mist runs through different duct work. Again, it has a slight disinfectant smell--pleasant but not flowery and not too strong. Not too bad, right?... Well, I was too preoccupied with the camera to realize what was happening inside the car: After all the effort for something that wasn't really necessary… I had to laugh. I was doing this process as I was preparing the car for winter storage. It was about 40° F (4° C) in my garage. Obviously, a lot of the foam didn't liquefy and drain. If I were to do this again, I would warm up the HVAC system beforehand, or just do the whole process at a higher ambient temperature. I'd also let the evaporator core drain longer (a lot longer) before doing the 2nd can. The photos above are the worst of it; only a little came out of the other vents. I blasted the system for a long time after that and it cleaned up without a problem--no damage to any surfaces. A few days ago I fired up the car for the season. No issues. Live and learn and pass it on. --Brian2 points

-

1.) Un-screw the one phillips head screw at top center of side air intake... 2.) The molded air duct and the intake grill are still attached by three delicate plastic tabs at the three points... The best way to remove this is gently insert your fingers through the grills into the intake at the points circled in red and gently try to free the tabs... All three points come forward towards you, but if one is stuck or gets caught it will break... 3.) Inside the drivers side air duct you will find a snorkle... The snorkle is added to most US cars for noise restrictions. Now this piece is attached by no screws or tabs, but it most likely will give you some troubles removing... The best way is to remove this, just grab a hold of the long snorkle (not the small dish on the end)... Now wiggle it from left to right and vice versa while pulling out towards you. This works, but might take a little effort. 4.) This is what the intake is going to look like after the snorkel is removed... Just carefully insert the three tabs back into their points... Make sure that all three are tightly in by pushing the airduct cover (not the grill)... Insert your 1 screw into top center of cover and you are done.2 points

-

Be sure to use some protective material on the mirror base. Set the pliers with the protecting parts to the windshield to the diameter of the mirror base and secure to the mirror base. Turn the rearview mirror through 90 degrees at the mirror base using the pliers. Then, unclip the base of the interior rearview mirror from the retainer plate on the windshield. When you reinstall the mirror be careful not to go beyond the 90 degrees locking point. If you remove the mirror base from the windshield you will need a special cleaning/glue kit from Porsche to reinstall it.2 points

-

Blue/white marking are stock springs. For factory Sport Suspension you will need new springs, stuts, and swaybars. RoW Sport Suspension Package for 3.2S 6 speed - Carnewal WWW.CARNEWAL.COM1 point

-

I put it in my 2004 Turbo Cab and it works great. plug and play though playing content through your iphone is not as loud as the normal stereo... you don't have to purchase the NAV card; you can use apple carplay... works a treat. Hope that helps.1 point

-

P2189 Lambda control adaptation FRAU (lower load range) (FRAU > 0.7) - below limit value Possible fault causes - Incorrect main filling signal from hot-film mass air flow meter - Fuel pressure too high - Injection valve faulty (dripping) - Tank vent faulty (does not close completely) P2189 Lambda control adaptation FRAU (lower load range) (FRAU > 1.3) - above limit value Possible fault causes - Intake system leaking (secondary air) - Incorrect main filling signal from hot-film mass air flow meter - Leak in exhaust system - Fuel pressure too low - Fuel injector faulty (stuck) - Fuel pump delivery too low P2187 Lambda control adaptation FRAU (lower load range) (FRAU > 0.7) - below limit value Possible fault causes - Incorrect main filling signal from hot-film mass air flow meter - Fuel pressure too high - Injection valve faulty (dripping) - Tank vent faulty (does not close completely) P2187 Lambda control adaptation FRAU (lower load range) (FRAU > 1.3) - below limit value Possible fault causes - Intake system leaking (secondary air) - Incorrect main filling signal from hot-film mass air flow meter - Leak in exhaust system - Fuel pressure too low - Fuel injector faulty (stuck) - Fuel pump delivery too low1 point

-

Just to close this thread. The alternator died sitting on a shelf for 6 weeks while other work was being done. A new alternator fixed my issues. I hate when something goes wrong simultaneous with other issues.1 point

-

1 point

-

1 point

-

Non, push down with one hand, squeeze the ribbed bottom ring with the other hand and pull up, this is not as easy as it looks, succes.1 point

-

Your alternator is not functioning, running you should have 14.5V DC. Pull the alternator, check the wiring connections to be sure they are tight and seated, if they are you are in the market for a voltage regulator..........1 point

-

N 104 707 03 round hd. screw US MSRP $1.91 (each)1 point

-

I do not, we normally stock a variety of wire sizes and colors, heat shrink tubing, connectors, zip ties, and the like that we source from a local electrical vendor, but you can find similar supplies from multiple sources like WireCare.com | Your Local Cable Management Superstore! WWW.WIRECARE.COM WireCare is your online wire & cable management superstore. We have what you need for connecting, harnessing, & beautifying all of your electrical projects. We carry the highest quality... .1 point

-

Lost Radio Codes DO NOT START A NEW TOPIC FOR A LOST RADIO CODE. DO NOT EMAIL ADMINS. Please read the Lost Radio Code FAQ FIRST before posting - then post in the one thread. This topic is closed.1 point

-

1 point

-

You shouldn’t let the car warm up while you make coffee. The result is bore scoring due to the bottom and top of the pistons being heated at different rates. I don’t even start the car until my belt is fastened and I’m ready to put it into gear. This ensures the car will warm up the way it was designed to.1 point

-

Does the battery have a vent port and did you connect the vent tube?1 point

-

1 point

-

I think I know what happened here! I piggybacked the original poster, Andrew Howell, and he was getting the "immobilizer not ready" warning! I think we are back on track here! As in the quote that I have attached reads, you initially suggested that I check the fuel pressure and delivery rates. It went a different direction when you thought there was something in the tachometer being off and that's where the CPS fix came into to play. I understand your mixup because your tending to a lot of different threads. Moving forward. I did purchase a fuel pressure kit. Where is the fuel pressure rail? What readings should I be getting for the fuel pressure and delivery rates? I have never performed this test before. All new stuff for me, but rewarding and going through the steps. By the way, I just donated again. I do appreciate you, JFP and this site!1 point

-

Did you have it coded to the vehicle with a PIWIS system? If not, start there...................1 point

-

Please do not double post your problem in multiple forum sections, it is against forum rules, and you will get an answer when one becomes available.1 point

-

1 point

-

My first post on this site. I have been searching on several forums trying to find the location and access for the relays. I've been able to find the location and am just starting to dig into how to access them. To find out which relay panel I really need to get at I'd like to know which relays are in the panels. Found one panel up under the dash (drivers side) which looks like it will be the most difficult to get at (maybe need to remove the lower dash panel to access that one). The other appears to be in the rear behind the carpet on right side of trunk. Any help here would be appreciated. Thanks,1 point

-

Time to run a parasitic drain test, which has been written up multiple times, but there are also a ton of online videos : . Basically, after the car has been sitting for about an hour or so, there should be a 45 - 60 milliamp current drain on the battery from necessary things like the clock and the alarm system; any higher than that and you have a parasitic drain on one or more of the electrical circuits.1 point

-

To anyone that ever finds this, this was actually a really easy job. The video on YouTube (referenced above) for removing the center console (a trim removal kit helps a ton) was all I needed. Once I was down to the hand brake it was actually quite obvious how to replace it. The hardest part is a couple of the bolts are partially obstructed by the brake lever, but a wrench with an angled head did the trick. That part was slow going but ultimately successful. It only took two hours, I can't believe the dealership wanted $1800.1 point

-

1 point

-

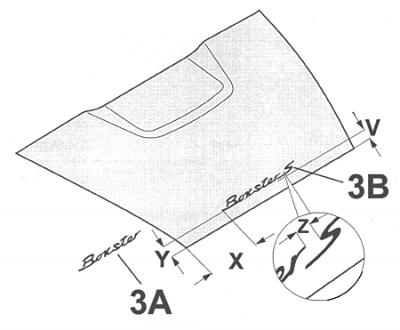

We did this for all Carrera variations so it's time we added for the Boxster's too. Measure the position of the logo with a measuring tape according to the model variant and affix it to the rear lid. Logo Boxster -- 3 A dimension X = 285 mm and Y = 45 mm Logo Boxster S -- 3 A in connection with the letter S dimension X = 245 mm and Y = 45 mm Logo S -- 3 B dimension Z = 20 mm and V = 40 mm1 point

-

Recently ran into this issue as my mirror fell off. (Thankfully it didn't break.) For those to whom this happens, the method above will not quite work. If your mirror falls off (with the base attached), clean the residual glue off and identify the metal circular base, which extends about a .25 to .125 from the base. For tools, I used a crescent (vice) wrench like the one above pictured. I also used channel locks, a microfiber towel, and (importantly) gloves. Last thing you want is the tool to shear off and bang your hand up. Attach the crescent wrench to the metal base. Wrap the microfiber towel around the mirror base housing and get the channel locks affixed. Twist the metal base COUNTERCLOCKWISE 90*. This will unlock the metal base from the mirror base housing. Acquire some glue (I used the 3M high bond adhesive), clean the working surfaces and reattach. Done.1 point

-

OK. With a "little" poorly documented and explained help from this forum I managed to remove my right rear window regulator from my 2003 Carrera 4 Cabriolet. I am going to provide as many pointers here as I can to make this effort much easier on the next DIY mechanic. Thoroughly read this and other forum posts first. Convertible top needs to be down or in the service position. Remove rear seat cushion, rear interior panel and rear window trim piece as described in this post or others. Rear seat back should be in the up position. For removal of the regulator itself...The total of number bolts and or nuts to remove is 9 (13mm) (possibly 2 more(11mm) if your window is stuck in a down or partially up position). For total of 11. (2) 13mm nuts - Convertible top hydraulic piston; (1) from the rear piston mount point and (1) from the front piston mount point. (3) 13mm bolts - Seat belt pillar; (2) from the face of the pillar and (1) from the top of the pillar where the seat belt loop is mounted to the pillar. (remove the loop and seat belt pillar insert to allow regulator to eventually be removed. (1) 13mm bolt - center of the convertible top support bracket; this is required to allow the bracket to be pried away from the pillar (see 30mm block of wood) to create clearance for the regulator to be removed. With a pry bar of some kind you should set the block in place at this step. (3) 13mm nuts/bolts - window regulator mounting points (recommend removing these last); (1) nut at the bottom accessed by removing a rubber plug; (2) each at the top; (1) one rear and one front. For the rear remove a styro foam plug to access with socket. For the front; if the window is in the fully up position access through the aligned opening in the convertible top support bracket. (IMPORTANT) If the window is stuck down or partially up this front bolt/nut is not accessible. The window blocks access to it through aligned opening in the convertible top support bracket. Follow these steps... you will need to use a goose neck closed end 13mm (6 point) wrench; loosen and remove this bolt/nut. Place or stuff a rag just under this nut/bolt to prevent it from falling to the bottom of the body cavity should you lose a handle on it. remove rag, regulator should now be free to move upward but not out all of the way out BECAUSE the window (still attached to the regulator) CANNOT clear the seat belt pillar. move the window and regulator upward sufficiently enough so the window mounting nuts (the (2) additional 11mm noted above in item 1) are accessible with the 11mm socket; loosen to free the window from its regulator seat. (be careful not to scratch or break the window by applying to much force) Carefully remove the window from the regulator and you will now have sufficient clearance to remove the regulator from the car. Remove the regulator by pulling it up first (free the bottom mounting bolt from its bracket) and then towards the rear (got to get the motor to clear the body) then straight up. Take it slow. It will come out. Good luck. Its not really that difficult once you see what needs to be free.... and the window itself is out of the way.1 point

-

This DIY tutorial covers how to remove the intake manifold on the 3.6L V6 Cayenne. Removing the intake manifold gives you access to several parts of the engine that you may need to service. Disclaimer: Perform at your own risk. This is for reference only, I am not responsible for any damage/injuries that may occur from this procedure. Please do not attempt if you are not comfortable with doing work on your car or working around the fuel system. Work in a well ventilated area as you will be releasing a small amount of gas and fumes. Difficulty: 5/10 Estimated Time: ~2 hours If you’re getting a Durametric error code P0674, you likely have a bad PCV valve that needs to be replaced. An easy way to test a bad PCV valve is to unscrew the oil fill cap on the engine while it is idling. If you feel suction on the cap and/or the idle fluctuates once the cap is removed then your PCV valve is bad. The PCV valve is built into the valve cover so your options are to buy a whole new valve cover assembly (95510513500- ~$347) or buy just the PCV membrane (aftermarket $20-25) and replace it in your existing valve cover. To get access to the valve cover, you will need to follow this DIY article to remove the intake manifold first. Other reasons to remove the intake manifold are to service your fuel injectors or to make it much easier to replace the thermostat. The thermostat can be changed without removing the intake manifold (I did it twice), however you basically need to be a contortionist to reach the bolts to remove housing and you will scrape some knuckles along the way. Tools Needed: -Flathead screwdriver -Assortment of torx bits (T20, T25, T30, 6” long T30) -Pliers -Torque Wrench -3/8” ratchet set with various extensions and a universal joint -1 1/16” Deep socket -10mm Triple Square Spline Bit -Crescent Wrench -9/16” Open End Wrench -Dental pick Parts Needed: -Brake Booster Vacuum Hose- 95535557941 (your existing hose is probably brittle and will likely crack from removing it, I recommend getting a new one) -Lower Fuel Injector Seal Kit (3X) - 95511091000 (existing seals may be brittle and once you have removed the intake manifold, they may not seal properly upon reinstallation, I recommend getting new ones, need 3 sets) Procedure: First start by removing the plastic covers surrounding the engine. Using a flathead screwdriver, remove the quarter turn plastic trim fasteners. Rotate them in either direction by 90 degrees and pop them out. Be ready to catch them as sometimes they like to jump out. Next you will need to remove the 2 torx screws on either side of the engine cover with a T25 bit and the screw under the windshield washer reservoir cap with a T20 bit. Remove the oil fill cap and front engine cover by pulling straight up. They are held on by friction rings around a stud so pulling straight up will release it. Now that you have the covers removed, it’s time to remove the intake filter box and intake piping. Using your T25 torx bit, rotate the 2 screws until the dot on the screwhead lines up with the lower indication on the filter cover. Now gently use your pliers to pull them straight out. With your flathead screwdriver, pop up the two clips to release the filter housing. Pivot the filter house towards the passenger side of the car and remove it. Remove the engine air filter as well. Next, remove the wiring harness from the MAF sensor located in the middle of the intake piping. Loosen the clamp around the intake piping on the throttle body and gently work the intake piping back and forth until it releases from the throttle body. Remove the top bolt on the engine lift bracket and loosen the lower bolt with your M10 triple square bit. Then pivot the bracket towards the front of the car. Remove the bolt next to the throttle body with your M10 triple square bit. Then unplug the wire harness from the throttle body. Remove the top bolt from the bracket on the passenger side of the engine with your M10 triple square bit. Remove the vacuum lines from the intake manifold on the passenger side of the engine. One hose requires pliers to open the hose clamp, the other can be removed by hand if you squeeze the lock ring around the hose to release it. Next, from the passenger side, reach your hand around to the back side of the engine. There is a vacuum line that goes from the bottom surface of the intake manifold to the brake booster. You will need to pull the vacuum line fitting straight down to pop it out of the intake manifold. I don't have a good picture of it so here is a diagram of it. Pull down on the elbow fitting, not the hose. Also on the back side of the engine just behind the vacuum line you removed there is a bolt that needs to be removed using your M10 triple square bit. You are working blindly so locate the bolt first by feel and guide your bit to the bolt. Remove the 3 screws holding the actuator with a T25 torx bit. Slowly pull it straight out towards the front of the car. There is an actuator arm that attaches to a shaft on the passenger side of the part. Once you have enough clearance to reach your finger in there, you need to slide the arm off the shaft as you pull the entire actuator off. Then disconnect the vacuum hose from the actuator. Now pull the coolant hoses out of their holder in the intake manifold and push it towards the driver side of the car. There is a T25 torx screw that attaches this water hose bracket near the back of the intake manifold. The screw is facing up, so you need to use your T25 torx bit and get creative with removing that screw. I used a crescent wrench to turn the torx bit while holding the torx bit in place with my other hand. With the water hose bracket free, slide the water hose bracket towards the front of the car to release it from the intake manifold. This bracket has a keyhole slot that will release once it's slid forward. Remove the oil dipstick tube bracket with a T25 torx bit. Just push it out of the way once you remove the screw. With your long T30 torx bit, remove the bolt on the intake manifold that was under the actuator. Next, there are 3 blind holes on the driver side of the intake manifold. You need to use your long T30 torx bit to loosen the screws inside those holes. Those 3 screws are captive screws so they will not come out. There are 3 bolts below the intake runners. They need to be removed with your M10 triple square bit. This is where your universal joint will come in handy. The bolt near the rear of the engine required me to use my u-joint with various entensions to acess. At this point, you will hear gas leaking out. Since you have released the pressure from the lower fuel rail to the lower fuel injectors, the pressurized gas in the rail will leak out. Make sure you are working in a well ventilated area. From the driver side of the car, reach behind the engine to remove the wire harness from the fuel pressure sensor. Using your 1 1/16” deep socket, unscrew and remove the fuel pressure sensor. Using your 9/16” open wrench, unscrew the nut that connects the metal fuel line running from the lower fuel rail. The slimmer your wrench the better. My crescent wrench did not fit here. Now that the intake manifold is completely unbolted, you can start to wiggle it free. You will need to lift the manifold up from the passenger side and pivot it up towards the driver side. You will need to wiggle the lower fuel rail loose to release the metal fuel line you just unscrewed the nut from. It is a flare fitting that pushes into the upper fuel rail assembly. Be gentle here as you don’t want to bend the fuel rail. Once the metal fuel line is free from the upper assembly, you can remove the intake manifold as described above by lifting up from the passenger side first to pivot it off. At this point, you have access to the fuel injectors if you need to service them, the thermostat housing and the valve cover. Unbolting the valve cover is straight forward from here if you need to replace the PCV valve, etc. The fuel injector seal kit comes with a rubber o-ring, Teflon o-ring, Teflon sleeve and metal clip. At the bare minimum you should replace the rubber o-ring and Teflon o-ring. Use a dental pick to remove the old o-rings. These 2 parts are the wear surface when you remove/reinstall the intake manifold and are prone to fail if you re-use them. Trust me, I learned the hard way. To install the intake manifold, reverse the steps above. Take care in sliding the lower fuel rail back onto the lower fuel injectors and lining up the metal fuel line back into the flare fitting. I found it was easier to pull the lower fuel line out of the manifold to line the flare fitting up first, then pushing it into place in the intake manifold. You want to apply even pressure on the surface as you tighten all 7 of the bolts down on the driver side. Torque the 3 triple square bolts evenly to 6 ft lbs, torque angle 90 degrees, then a final torque of 22 ft lbs. The bolts holding the engine lift bracket are 17 ft lbs, the other triple square bolts holding the manifold on the head are 15 ft lbs. Once you get it all back together, turn the key to the ON then START position without your foot on the brake. This will run the fuel pumps to build pressure back up in the fuel rail. I removed the key and repeated 2-3 times to get the fuel pressure up. The first time you restart, it may take a couple seconds to fire up due to the fuel pressure needing to build back up. If you replaced your PCV valve, it may idle rough as the ECU needs to remap since it adapted to a leaking PCV valve over time. If you did not replace the fuel injector seals and smell gas/hear it leaking after shutting off the engine, then your seals failed and you need to repeat the procedure and replace those seals.1 point

-

1 point

-

Hi All, I'm new here, but found this thread very helpful. I thought I would sign-up and share my experience. My 2009 Cayenne V6 (left hand drive) has been blowing cold air on the driver side and warm air on the passenger side for the past 2 years. All passenger side vents (center right, far right near the door, and rear center right) would blow the same warm air not matter what. With summer coming up, I thought I better revisit this issue. After reading a bunch of forums on this issue, I came to the conclusion that - 1) I have the 2 zone A/C system (meaning I have less flap motors than the 4 zone) 2) it seemed to me that the front, right mixing flap was the issue. I began by taking off the lower passenger panel - its 1 screw and the glove box and a piece of triangular trim on the passenger side of the centre console (it just pops off). Once those were off, I could see 2 flap motors. One was right where the lower panel was and easily accessible - it was attached to a white plastic arm that it moved back and forth. I turned the car on and played with all the A/C setting and could see that that motor was working - it moved the white plastic arm back and forth.... (note, when I turned on the car, there were a bunch of dash warnings including low oil pressure - they went away once everything was back together) The other motor I could see was not as accessible. It was more towards the center and higher up. It was to the right side of the nav screen, inside the dash... I could only assume that had to be the front, right mixing flap. I decided to take a shot and changing it. I ordered: 1) 7L0-907-511-AL front, right mixing flap (10) - from Volkswagen. This is the equivalent Touareg part. 2) this ratcheting screwdriver tool: http://www.amazon.com/03044A-4-Drive-Mini-size-Ratcheting-Screwdriver/dp/B000XYOUS6/ref=sr_1_1?ie=UTF8&qid=1464195744&sr=8-1&keywords=Neiko+03044A+1%2F4-Drive+Mini-Size The flap motor only has 3 screws.. they were tough to get out. It took me about 1-1.5 hours to unscrew those 3 screws... most of the time was spent finding the right position to unscrew the screws.... and there was not a lot of room to turn the ratcheting screwdriver (a regular screwdriver would 100% not work). So once I would get the torx bit to connect with the screw..I had to unscrew very slow (shallow turns) and often drop the screwdriver. Annoying... and frustrating.. but keep at it. Getting the new motor back in was a bit easier and I had figured out the best position to deal with each of the 3 screws. Make sure the motor connect properly to the white piece that it controls. putting the new motor in was probably about 30min max. I put back the trim piece, glove box and lower panel and turned one the car... and cold air was blowing out of all vents! Glad that is dealt with!.. I almost have no problems with my Cayenne now... I suspect the rear hatch struts are due to fail next!1 point

-

Thanks to Gelbster in the 986 forum for pointing me to this post by Dale_K in the Pelican forum. In fact, it was the magnetic switch which was not inserted into the space provided for it in the valve. It had fallen out when I pulled the old valve but I didn't notice. I did see it but couldn't find any information on it until I saw this post If this unit isn't working you'll have trouble filling. Also the magnetic switch. A new one comes with a new vent valve.1 point

-

2001 C4 Cab. 58k miles. I have this exact problem, ticking that happens at idle, but slightest depression of clutch pedal makes it stop. Got new clutch 4 months 4 k miles ago. The noise started a few weeks ago,. Any idea how in the world the clutch master could be making that noise? Reluctant to replace without seeing how it could be the problem. Thanks.1 point

-

A word to the wise on transmission service and drain plugs: Never remove the drain plug until you get the fill plug out; if you take out the drain plug first, and then cannot get the fill plug out, you are officially in very deep yogurt because you cannot refill the gearbox. Get the fill plug out first.1 point

-

So i have had this annoying display with my 2004 CTT that my rear glass is open, when it really isn't. It would sometimes go away but could come back if i hit a large enough bump in the road. The particular annoyance happens every time you stop and start, it will beep at you again....OR the fact that you cannot lock and arm the car with the glass "open." Anyways this is how you can potentially resolve that issue: Tools needed: Your hands Adjustable wrench Step 1: Open the glass and remove the small plastic cover on the glass side as shown. You will want to get your fingers behind the TOP first, then pull the entire cover free. the clip are pretty strong, so it takes some force, just work it free evenly and slowly. Step 2: Now you have access to the latch on the left (metal hoop). You will want to use the adjustable to loosen the latch or nut. Once it's loose, you can turn it either in or out to make the adjustment needed. For me, i had to turn it OUT, loosening the latch. My guess is the rubber seal has become stiffer over the years, so it was pulling the latch away from the sensor. Reinstall plastic once you get the positioning correct and enjoy no more annoying messages or alarms every time you stop at a light.1 point

-

For the fingertip test: Turning on the A/C to cause the low speed relays to click on and off will only happen when the coolant temperature is below 206 degrees Farenheit. If the coolant temperature is above 206 degrees, but below 215, the low speed fans will turn on (and the low speed relay will click) without pressing the A/C button on. Regards, Maurice.1 point

-

This is the support topic for the DIY Tutorial Fluctuating Idle. Please post here if you have any questions or feedback.1 point

-

I could not disagree more. You want the TB to be dry as only air passes over it.1 point

-

You have no Range 2 over revs - you can not ask for better. Range 1 over revs were caught by the rev limiter and don't mean much since the rev limiter protected the engine. Range 2 are the bad over revs.1 point

-

It was just a pleasure Mudman! :D We have all spent enough money on VAG parts ........(i have owned a couple of VW and Audi's too....) Just for the record, the compressor has a price on 1500$ at the Porsche dealer here i Norway. The same compressor for Tuareg at the VW dealer in the same area has the amazing price of almost 3000$.. :o ... (but VW sell the repair kit though). Glad too be able to help others with the same problem. Hope i avoid problem with the struts. Owned a Allroad once, which i had to change one in the front. That was a job with 600$ in parts and a couple of hours in the garage, but i believe the same parts for the Cayenne is a bit more expensive and the job a bit more complicated. Isak1 point

-

Thank you so much for this, I have had a compressor replaced (under warranty) and expect another before I am thru so this will help avoid that. Also look out for the struts on 04's, I had one blow up, that was expensive. Mike1 point

-

Who knew! I was avoiding using search criteria this specific! Thank you, Loren. Looks like the search begins at the fuse panel... Bruce.1 point

-

Replacing Switch on Transmission for Reverse Lights / Back-Up Lights Replacement Parts: 1. SWITCH, BACK-UP, part number 996.606.103.01 (This is the correct part number for my '99 911 Carrera 4. Check with your local dealer to confirm the correct part number for your car.) (Cost at my dealership on 21 Oct 2005: $8.16 + tax) Tools Required: 1. 19mm box-end wrench 2. Medium-sized flat-blade screwdriver Procedure: 1. If you are working under your pickup or SUV (and the wheels are still on) and the jack breaks or your stands slip, at least there is enough space for your body under that vehicle when it comes crashing down. Under your Porsche, there is no room for you unless you are only 3.6 inches thick. If the jack fails or the stands slip and the car falls, you will either die, or at least be crapping in a bag for the rest of your life. So lift the rear of the car up in a very SAFE and STABLE manner. I recommend the use of ramps, as shown in the picture below. Note how the front wheels are chocked, the ramps are super-sturdy and have stop blocks at the ends, and the car is in gear with the handbrake very tightly engaged. 2. Locate the reversing light switch on the portion of the transmission that is furthest forward in the vehicle. The switch is mounted in a hole in the transmission housing that faces directly up, and has a two-wire snap-on connector. (This is the location for a '99 911 Carrera 4 with the 6-speed Getrag transmission; your car may be different. Regardless, it shouldn't be hard to find.) 3. Using a medium-sized flat-blade screwdriver, pry the snap retainer of the wiring connector open slightly so that the connector will come off. Note that you will have to pry the connector so the plug can slide out, while at the same time applying pressure to the plug to push it out. The green rubber portion of the connector is to keep water out of the connection area, but it also adds some friction to the connection. You won't have to push too hard, so just make sure you're moving the snap retainer out of the way enough. 4. With the connector removed, drop your 19 mm box-end wrench over the switch from above. There should be plenty of room and it's easy to access. The threads are standard, so lefty-loosey righty-tighty. You should only have to turn the switch with the wrench about 1/12th of a turn at the most to break it loose, it should come the rest of the way out very easily with your fingers. When installing the new switch, be sure the switch body is aligned with the axis of the hole! The switch body material is either aluminum or magnesium, so be careful not to cross-thread the new switch upon installation. The new switch should screw all the way in VERY easily with your fingers. Apply a small amount of torque to the switch with the wrench when bottomed out. DO NOT OVERTIGHTEN the switch, you wouldn't want to strip the threads of the new switch. There is no seal ring between the switch and the transmission housing. When fully seated, the barb/emboss on the white plastic part of the switch (that the snap retainer snaps onto) should be facing the front of the car, approximately. (See photo below.) 5. Reinstall the wiring connector, be sure to push it all the way in so no green rubber boot is visible, and you hear the *click* of the snap retainer. Cheers! You've just saved yourself over $100...1 point

-0001-0001.thumb.png.17f5bb25bf8ec261a17c21e6321c8492.png)